In many private homes, heating with wood and stoves remains a priority. Some people have a metal stove, others a brick one, but they have one thing in common - this type of heating is not the most convenient. Too much attention and not enough comfort. The solution is stove heating with a water circuit.

Stove heating with a water circuit is an opportunity to combine tradition and comfort

First, let's understand the terminology. When people say “stove,” they most often mean a heating device made of brick that is heated with wood. But often this is also the name given to a metal stove burning wood or coal. The operating principles of brick and metal units are the same, but the method of heat transfer changes. Metal ones have a greater convective component (most of the heat is transferred by air), while brick ones have a predominant thermal radiation - from the walls of the furnace and the heated walls of the house. Our article is mainly about brick stoves, but most of the information can also be applied to metal wood-burning (coal) units. Stove heating with a water circuit can be made using any type of stove.

The correct procedure for installing stove heating with water circuits

The dimensions of furnaces and their location are usually reflected in the design stages.

In this case, the location of interior partitions and furniture must be taken into account. Large ovens require a strong concrete base that can support the weight. There should be a gap between the base of the stove and the floor material to reduce the likelihood of fires. Masonry is done using high-quality mortar and bricks. If you have no experience, it is better to purchase the mixture from construction organizations. A waterproofing layer must be laid on the base. The bricks are soaked in water and only after that are used for laying out according to the pattern. Once the dimensions are known, the order can be easily found on the Internet.

A register-coil is installed into the structure being built, which is then used to connect the coolant input and output pipes. According to one of them, the hot coolant is sent through the expansion tank into the system, and according to the other, it returns back to the register. Water circulation occurs due to the presence of gravitational forces.

Seams should not exceed four millimeters. The presence of sharp corners in the firebox and smoke exhaust ducts is not allowed. Rounded corners will not reduce smooth smoke removal, and there will be less soot in the firebox.

Important rules for constructing furnaces

Regulatory requirements for the construction and operation of the furnaces in question are as follows:

- It is mandatory to have a gap between the stove and the adjacent walls and a metal sheet in front of the firebox, which serves to protect the floor and wall structures.

- Ensuring maximum strength by reinforcing every four rows of masonry with metal pins.

- Using clay mortar of medium plasticity. A small ball rolled out of it does not give large cracks and does not crumble when it hits the floor.

- The chimney, at least five meters high, ends with a cap, that is, an element that protects the pipes from rain and debris getting inside. It enhances traction and decorates the building.

It’s not that difficult to build a stove yourself, although it may be possible to use a ready-made metal structure. However, you should not forget that a brick stove has a more aesthetic appearance, decorating the interior of homes.

It is necessary to choose a suitable brick, the best option of which is red ceramic, pre-fired. It has a uniform color. When tapped, a metallic sound is heard.

Burnt and unburned material cannot be used, since it will not guarantee the required quality and compliance with safe operation standards. For fireboxes where the highest temperatures are observed, the best option would be to use refractory refractory bricks, which will eliminate problems during the operation of this equipment.

Water circuit installation

A water heating system works efficiently by installing a register, which is a heat exchanger or boiler. Its popular name is serpentine. This product is placed in the firebox.

The design of such a system includes combustion chambers, ash pans, hermetic doors, cleaning hatches, heating surfaces, injectors, dampers, grate bars and convective pipes.

When making containers yourself, the parts are connected only by welding. Couplings, fittings, etc. are used to connect pipes. This design guarantees savings on the boiler, since the materials for it are cheaper than what is needed to purchase a finished unit. The best option is to use a regular metal pipe with holes for the inlets and outlets of the pipelines.

The construction of a heat exchanger for a home requires a certain thickness of structural walls. If you plan to use a wood-burning stove, the walls may be thinner, while those operating on coal briquettes may be thicker. Ignoring this requirement leads to rapid burnout of boilers and their rapid replacement, ahead of the established operational dates. In practice, this means that you will have to actually reassemble the stove after such a replacement, investing additional funds.

How to install a heat exchanger in a finished oven

If the furnace is already ready, then there may be several options for installing a heat exchanger.

Option 1

Installing the device in the firebox. It can be carried out either with or without dismantling the structure (if the device is a heating and cooking device, and the stove is installed in such a way that it can be removed without dismantling the masonry). With the second method, no difficulties will arise, but during disassembly they may arise. Although if you draw the location of each brick in the rows that are planned to be dismantled for the purpose of further restoration of the masonry, then you will be able to cope with everything on your own.

Note! If at the same time some bricks were destroyed, then replace them with products of the same type and quality.

Option 2

As already noted, many experts are confident that the register should be located outside the firebox. Ideally, it should be placed in a bell-shaped chimney, and then one end of the device should be welded to the supply of hot coolant to the system, and the other to the “return”.

Location of the register in the hood

Features of water circuit pipe routing

The pipe system is connected to a heat exchanger installed in the furnace through sockets that are inserted through one of the walls. The water circuit in such a system is often arranged in the form of a two-pipe system. The wiring can be either lower or upper.

Register for the stove from an old battery

Naturally, the heating circuit must be fully equipped. The expansion tank is installed at the highest point of the line, safety and air valves are installed, and a safety unit with a pressure gauge is also included in the system; valves are connected at the inlet and outlet of the radiators.

The water circuit can be connected to a circulation pump; it significantly increases efficiency and allows for a more flexible approach to solving the issue of pipe routing. But there is a problem with this approach. If the pump stops working due to a power outage, the water will not circulate and will begin to boil in the coil.

In the cold winter, when the boiler is working at full capacity, one minute can be enough for the consequences to be disastrous. The stove, unlike a gas boiler, cannot be turned off quickly. For these reasons, it is recommended to use a combined wiring method.

Exiting pipes for heating

In the supply pipe, after it leaves the furnace, an acceleration manifold is installed, raising the pipe vertically by 1-1.5 m, and then lowering it to the level of the radiators. Sections of the highway are located at a slope of 3-5°. In case of emergency mode, coolant circulation will be natural.

It is better to install the circulation pump in the return circuit as close as possible to the expansion tank using a bypass, and the pump axis should be located strictly horizontally.

Basic requirements for the register and installation process

- The internal size of the heat exchanger must be at least 3 centimeters, otherwise the circulation will be weak and the water may boil. In the case of forced circulation, the size may be smaller.

- The thickness of the register walls should be at least 4-5 mm. If the walls are thinner, they will soon burn out and the entire device will need to be replaced.

- There should be a small gap (about 1.5 cm) between the heat exchanger and the firebox to compensate for thermal expansion when heated. If the heat exchanger is made of steel sheets, then the gap should be 0.5-1 cm.

- Sometimes the heat exchanger is installed in the hood of the structure. Experienced stove-makers say that this option is preferable, since there are conditions for complete combustion of wood. A diagram of such an arrangement is shown below.

Option for using a radiator as a coil

Prices for cast iron radiator MS-140 as a coil

cast iron radiator MS-140

A more complex water heating system using wood

It is a pyrolysis boiler. which consists of two sections. In the lower section, firewood is burned, and in its upper part, the gas generated during combustion circulates. Due to the fact that in this design, gases do not immediately enter the chimney, its efficiency is higher, and such a boiler consumes less firewood.

It is tied with thick-walled pipes through which water circulates, heated by the boiler.

It is necessary to take into account that for the normal functioning of such a boiler, it is necessary to use only dry firewood. If the farm has a pyrolysis boiler, then there should also be a supply of well-dried firewood.

There are systems that use hot air rather than water for heating. It passes along the circuit and is supplied to the living quarters. Cooled air, according to the physical law of convection, falls down, enters special air intakes and again enters the boiler.

Is it possible to install a heating register in an existing furnace?

It would be more correct, of course, to build the furnace around the manufactured register. But, if the stove is already standing, you can still build a water circuit into it. True, you will have to try hard - they are of considerable size and must somehow hold on. So the task is not an easy one. In addition, do not forget that you will have to make two more conclusions - to connect the supply and return pipelines.

The best option is to make a water jacket under the shape of the stove (this one is for a metal stove with burners)

Finding a place to locate the register is also not very easy. Its direct contact with fire is very undesirable, but it should be in an environment of hot gases. In this case, you can hope that the heat exchanger will last a long time.

System Features

A conventional brick stove consists of components such as a combustion chamber, an ash pan, grates and chimneys. These components of a simple Russian stove are probably familiar to any village resident. Visually, modern types of stoves are practically no different from traditional village designs.

Main characteristics of water-heated furnaces

Traditional ovens have the following characteristics:

- A simple village stove can produce more than 6500 Kcal of heat in one hour. This amount of heat is quite enough to heat a house with a small area. Such a heating system would be an ideal solution for a small country house. A water-heated furnace, in which the main component is a water boiler, will be approximately 2.5 times more efficient. Using such a heating system, you can heat a house with a much larger area. In order to heat a house, the same amount of fuel will be required, which means that such a system will be more economical.

- A heating system that combines a stove and a boiler will also be effective. If both systems work simultaneously, their productivity increases many times over. A tandem of two such heating systems can release more than 21,000 Kcal of heat in one hour of operation. This amount of heat is enough to heat a house with an area of up to 300 square meters. meters.

Stove connected to water heating

- Most often, such a heating system uses fuel such as coal or wood. The price of such fuel is not high, and its transportation should not cause any particular difficulties. Firewood can be combined with coal at the same time.

- There is no need to constantly heat water-heated stoves. Fuel can be added to the stove several times a day. You can create comfortable conditions indoors, no matter what the weather or temperature is outside.

- If we compare the efficiency of traditional stove heating with a combined system, this figure will increase from 50% to 85%. For heating with wood, this figure can be called ideal.

- The materials that are necessary to organize such a heating system are quite affordable and are not included in the expensive price category.

Disadvantages of water-heated stoves

Stove heating also has its disadvantages, and it would be unfair not to list them.

A brick stove with water heating can be installed not only in a rural or country house, but also in luxury cottages. Typically, owners of luxury homes strive to ensure that such a water heating stove, in addition to its usual functions, also plays a decorative role. During operation of such a combined system, it is necessary to follow some safety and system care rules:

A stove for water heating at home must be under human control at all times.

This applies not only to the issue of loading fuel, but also to cleaning the ash chamber. Smoke ducts also require attention. Before starting a fire in the lever, you must make sure that the smoke channel valves are in the open position. Such systems can only be used in the cold season.

During the warm season, using such a heating stove with a water circuit for cooking will be impractical. If you need to cook food, it is better to use another alternative heat source for this purpose.

If you want to make custom-made stoves for water heating at home, it is better to turn to professionals for help. If your stove is manufactured by an unqualified person, there is no guarantee that the stove will function properly or be completely safe. Overheating of the oven can cause some problems that will eventually lead to complete breakdown of the oven.

A conventional stove is usually designed to heat a small room

Since the flame has high temperatures, it will eventually damage the integrity of the boiler walls. This means that the time will come when the heat exchanger will need to be replaced. This is not so easy to do, since you need to remove a good part of the masonry.

conclusions

Considering the question of how to make water heating from a stove, we started talking about the use of various heating systems. At the same time, as practice shows, stove heating is the most popular in our country. The prevalence is explained by the use of available fuels.

The proposed modern gas or electric units operate on rather expensive sources. Water-heated stoves are more economical systems that can be easily equipped with your own hands, which also guarantees lower costs.

This heating is based on the combination of traditional stoves, known to us for centuries, and modern technologies. The result is the desired warmth in residential buildings, which people have always strived for and strive for.

A heater of this type means long service life without dependence on centralized sources. With proper care of heating units and furnaces, you can not worry about the temperature microclimate for many decades.

How the system works

The simplest water circuit is with natural circulation of water flow. Its basis is a simple physical phenomenon: the expansion of liquids when they are heated. The unit that creates pressure is an expansion tank (a container for collecting water), installed in the attic or attic.

The water circuit is a closed system. The boiler heats the water in it and, expanding, it is directed through a pipe into a storage tank. The movement is carried out under pressure created by the cooled water constantly entering the boiler and passing through the entire system. Boiling water from the expansion tank is directed by gravity down through the pipes leading to the batteries. Having given off the heat, it returns to the tank and heats up again.

Installing a pump will help to significantly increase the pressure in the system and speed up the circulation of the coolant. At average outdoor temperatures, it can be turned off and the circuit will function on the natural movement of water. This will save you on your energy bills. Water enters the pump with the check valve closed. By turning it off (leaving it open), the entire volume of coolant is directed to bypass the pump.

Such a stove can be loaded not only with wood or coal. When using alternative fuels, it is possible to complicate the structure of the system by adding:

- granule storage tank;

- a mechanism that feeds pallets into the firebox (pneumatic or auger).

You can make the operation of the furnace easier by installing an automatic system for regulating its operation and forced ventilation.

Types of systems

There are two options for heating a house using a stove. In the first case, it will be a system with a natural type of coolant circulation, and in the second - forced circulation.

Steam heating from a natural circulation stove does not require an electrical connection, since water circulates through the heating circuit due to the laws of physics. However, in this case, the heating pipeline must be of a large diameter, which leads to an increase in the volume and inertia of the system. Such a stove will take quite a long time to heat up when lit. At the same time, when the wood burns out completely, the coolant in the circuit will remain warm longer.

Among the disadvantages of natural circulation in steam heating from a stove in a private house, it is also worth mentioning the fact that the supply pipes must be placed either under the ceiling or at the level of the radiators. If the house is two-story, a pipe comes out from the top of the stove, through which the coolant disperses through the radiators of the second floor, and only then falls to the first floor and heats the rooms on it.

Do-it-yourself stove heating with a natural circulation type is not highly efficient, since the water in the circuit moves slowly and does not supply enough heat to the premises.

In the second case, a water-heated brick oven is equipped with a circulation pump, which ensures constant movement of the coolant inside the circuit at a certain speed. By changing the speed parameters, you can regulate the degree of heating of the rooms. Thus, this type of system is more efficient. However, it requires electricity to operate. If there is a power failure, the pump will turn off and the coolant inside the operating furnace will boil. To avoid such troubles, in case of sudden power outages, the circulation pump should be connected to an uninterruptible power supply with a battery. If there are regular power outages, you will also need a power generator, and this is quite expensive.

Conditions for optimal system performance

The system will be operational provided there is constant circulation of coolant in the pipes. This is ensured by a mandatory slope, as well as the desirable installation of a circulation pump, which guarantees the necessary movement and prevents water from boiling.

Small in size, but with sufficient power, the pumps guarantee good circulation. They are necessary especially if the heating system is long. Installation of such a pump is carried out on the return line, that is, on the coolant return pipe.

You should not rely only on the pump and install pipelines without a slope, since interruptions in the supply of electricity may lead to boiling and failure of both the pump and the system itself. In such cases, it is better to resort to installing expansion tanks that compensate for the expansion of water.

Design work is completed by familiarizing specialists with the diagrams. They will help eliminate errors leading to unstable operation of water heating from the stove. This is also an opportunity to avoid security violations.

Examples of industrial furnaces with a water circuit

Purchasing finished products in some cases is more profitable than do-it-yourself stove heating with a water circuit in a wooden house.

The reasons are as follows:

- The finished product will cost less than building it on your own or with the help of specialists.

- The structures were created on the basis of prototypes, the technology has been proven and the owner will no longer be able to disturb the equipment, which means the risk of breakdown and fire is reduced.

- Ready-made systems are made from heat-resistant cast iron and steel, which cannot be purchased to form your own furnace and heating system.

- The industrial enterprise has great capabilities for the manufacture of structures that meet regulatory requirements.

Such stoves have a long warranty period, they are easier to install on site, and the kit already includes ready-made standard designs that you can use as a guide when creating a new heating system or integrating it into an old structure.

Fireplace insert with water circuit Aquarius

These are products of the Termofor company. The firebox can be supplemented with a water circuit to form a heating system in the house. The product is available in two versions - with and without a water heat exchanger. As for the characteristics of the samples, they are in the technical documentation.

Design Features:

- heat-resistant glass allows you to observe the intensity of combustion without the risk of burns;

- the firebox is produced in large volumes, which reduces the regularity of adding raw materials;

- fireclay stone protection increases the service life of the product;

- products are available in different sizes, so you can choose a firebox to match the parameters of the fireplace;

- a firebox with a heat exchanger works only in open-type systems.

Through a water heat exchanger system, the system transmits up to 6 kW of energy, which is enough for rooms with an area of 55-65 m2 with a ceiling height of up to 2.7 m. To warm up the room where the fireplace is installed, it is necessary to provide convection flows on top of the firebox so that the warm air is evenly distributed distributed throughout the room.

Using the product as a heating system in a house will be more practical if a circulation pump with a bypass is installed on the return line. In this case, water can be transported both naturally and by force.

Solid fuel heating boiler Armada 20

Also a product from a Russian manufacturer, which is a furnace with water coolant. The characteristics of the Armada 20 are given in the technical documentation and depend on the dimensions of the structure.

Peculiarities:

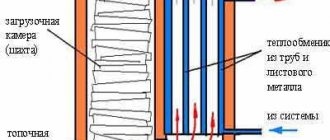

- The heat exchanger is equipped with a large number of pipes, so the total heat removal area is much larger than the volume of coolant. This feature provides significant heat transfer.

- The door is supplemented with heat-resistant glass.

- The surface of the boiler is equipped with a hob, so this stove heating boiler for a private home can serve as a stove.

- The upper part of the firebox is removable, which facilitates the process of cleaning the structure and chimney from soot.

- The outer parts of the heat exchanger act as an air convector.

- The boiler is designed for burning solid fuels.

- It is impossible to put the equipment into operation without water.

- The design is built into an open or closed heating system with operating pressures not exceeding 3 MPa.

The Armada 20 water circuit stove can be used as a heating system for a large house, used for heating water and cooking.

Bottom line

To provide heating for a home, several options are usually considered. Popular gas or electric equipment runs on expensive energy resources. The most economical type is heating and cooking furnaces with a water circuit. They are easy to build yourself, which results in noticeable financial savings. This type of heating involves a combination of traditional brick construction and modern technology. As a result, the home receives the necessary warmth and comfort. In addition to brick ones, they often make metal stoves with a water circuit with their own hands. By ensuring proper maintenance of your heating system, you can guarantee a suitable microclimate in your home for many years.

Heating registers

Before installing stove heating, it is worth deciding on the type of heating water circuit, also called a register, heat exchanger, coil or water jacket. Most often it is a rectangular flat container or several tubes connected together.

But before connecting the heating to the stove, two pipes must be welded to the register. The first serves to draw hot coolant from the furnace, and the second supplies cooled water back to the heat exchanger.

The size of the heat exchanger can be determined by the level of heat loss in a particular house. So, if 10 kW of thermal energy is required, the heat exchanger area should be 1 m2. It is worth considering that the oven does not work all day, but for about 1.5-3 hours, depending on the outside temperature. This time should be enough to warm up the water in the heat accumulator. Consequently, to calculate the register area, the daily consumption of thermal energy in the house is determined.

So, with heat loss at home of 12 kW/hour, daily consumption will be 288 kW of energy. Let's assume that the oven operates 3 hours a day. It turns out that every hour 288÷3=96 kW of energy should be released. Then the area of the heating register will be 96÷10=9.6 m2. The shape of the heat exchanger in this case is not important, the main thing is that the surface area is no less than the obtained data.

When using antifreeze as a coolant, you can further increase the volume of the heat accumulator, since water and antifreeze have different heat capacities.

If the buffer tank is additionally insulated, the heat will be retained in it further, and the efficiency of stove heating will increase.

Advantages of fireplace stoves

Fireplace stoves combine the positive qualities of these heating devices, while they are devoid of their inherent disadvantages. What are the main differences between a traditional stove and a fireplace?

- The furnace takes a long time to heat up , but is capable of accumulating heat and radiating radiant energy from the walls of the furnace into the surrounding space for a long time. The heat from the fireplace immediately spreads throughout the room in which it is installed, but after the fire stops, it quickly cools down and the temperature in the house decreases.

- The heating furnace is usually fired with a small blind door, this reduces the likelihood of smoke and helps improve draft. The firebox is open and occupies about half the area of its façade. If the chimney is not installed correctly or bad weather conditions, reverse draft and smoke may enter the room, which leads to an unpleasant odor, deposition of soot and soot on household items.

- The stove's smoke exhaust system has a complex design : the smoke in them passes through numerous channels, giving off most of the heat to the body of the stove. It comes out of the pipe almost cooled down. The chimney in the fireplace is almost straight , the smoke is retained only under the arch, so its outlet temperature is much higher, and the heat removal is worse.

- The efficiency of heating stoves is on average 60-80%, for fireplaces - no more than 50% .

- The stove is not very decorative , and it can only be given an aesthetic appearance with the help of finishing. The fireplace itself is an interior decoration , and the flames decorate it even more.

Industrial production models take into account all the features of these heating devices, eliminate the most significant disadvantages and emphasize the advantages. As a result, modern fireplace stoves have a number of advantages:

- high efficiency - up to 80%, and when connecting a heating water circuit - up to 92%;

- a sealed firebox with a large glass that allows you to observe the flames, but does not allow smoke to enter the room;

- smoke channels with smoke circulation and heat exchanger, which improves heat removal and transfer to the room;

- aesthetic appearance, there are models decorated with ceramic panels or metal forging;

- light weight - they can be installed even on wooden floors laid on joists, without constructing a foundation;

- small dimensions with high power - fireplace stoves do not take up space, which is very important for small houses;

- the ability to connect a water circuit allows you to heat all rooms of the house and retain heat for a long time, as well as avoid daily temperature fluctuations;

- low price compared to the cost of materials and work for the construction of brick stoves or fireplaces;

- Simple and quick installation that you can do yourself.

In addition, modern fireplace stoves may have a number of other useful functions:

- hob;

- a glass cleaning system that prevents it from darkening, as well as a long-burning mode that is very popular among consumers.

Feedback from the owners of such stoves is clear: the stoves can heat a residential building for a long time and efficiently, without causing problems or hassle for the owners.

Recommendations for carrying out construction activities

When constructing a stove with a hob and a water circuit, the following standards must be adhered to:

- The stove and nearby surfaces must be separated by a safe distance. For these purposes, a metal sheet is additionally installed in front of the firebox to protect the floor and partitions.

- To make the masonry as strong as possible, every 4th row of bricks is reinforced with metal pins.

- A clay mortar of medium plasticity is used as a mounting mixture. A small ball rolled from it should not crack or crumble when it hits the floor.

- The chimney must have a height of at least 5 m: the presence of a head is a prerequisite. This element is designed to protect the chimney from climatic precipitation and blockages. In addition, it helps to increase traction and decorate the building.

Building a home stove with a boiler with your own hands usually does not cause any particular difficulties. Quite often you can find metal structures that are not inferior to brick ones in terms of external aesthetics. Such a product can greatly decorate a home interior. For the construction of brick kilns, a special building material is selected. The best option is fired ceramic red bricks. They are distinguished by their uniform color and metallic sound when tapped.

DIY construction

First, a project is prepared, after which a heat exchanger is made according to the drawings, which should subsequently be installed in the stove. Actually, the stove is built according to its dimensions.

When designing, you need to think about how the device will be located in the room. The place must be user-friendly and accessible to the public.

After the foundation is installed, the brick is prepared for laying. It must be fireproof, without any chips, damage or cracks. It is also necessary to provide in the project the location of the blower and combustion chamber, smoke exhaust, and hob. The latter may not be installed, it all depends on the preferences of the home owners.

Construction occurs in a certain order:

- First, a solution is prepared. It consists of water, clay and sand. This mixture can be purchased ready-made in specialized stores, but experienced craftsmen make it themselves.

- The foundation is insulated with a layer of film or roofing felt.

- A uniform layer of mortar is laid on top and the first rows of bricks are laid.

- A firebox and ash pan are being installed. The accuracy of the masonry must be checked using a building level.

- Next, the door is fixed and the vault is made. A chimney is also installed. For the walls of the chimney you need to use semicircular bricks.

- At the final stage, the water circuit is installed. Pipes and batteries are connected, as well as a heat exchange tank. After this, the liquid is poured. You can use plain water or prepared solutions.

You can also decorate the stove if desired. You can make an economical stove device yourself. Such a device is durable, has a high efficiency, so the house will receive an installation independent of centralized heating.

Building materials and stove fittings

To make a Russian mini-oven with your own hands, you need to buy components and materials:

- solid ceramic bricks – 670 pieces (the chimney is counted separately);

- fireclay bricks for the firebox – 25 pcs. (brand ША-8);

- fireclay block brand ШБ-94 or similar in size – 1 pc.;

- door of the main chamber mouth 25 x 28 cm, possible with fireproof glass;

- loading door 21 x 25 cm;

- ash pan door 14 x 25 cm;

- two grates measuring 300 x 250 and 220 x 325 mm;

- wooden template - circle - radius 460 mm, length - 65 cm;

- cast iron hob with 2 burners 71 x 41 cm;

- 3 valves: 13 x 25 cm - 2 pcs., 260 x 240 x 455 mm - 1 pc. (brand ZV-5);

- equal angle corner 40 x 4 mm – 3 meters;

- steel sheet 1 mm thick for a shelf in a stove;

- galvanized mesh for reinforcement, cell 3 x 3 cm - 2.1 lm;

- kaolin wool, corrugated cardboard.

Red brick laying is done using sand-clay mortar. When constructing a chimney, it is allowed to add M400 cement. Fireproof stones are placed on another solution - fireclay clay, mortar and the like.

Laying progress - step-by-step instructions

A reinforced concrete or rubble concrete foundation is cast under the furnace, the dimensions of which are 10 cm greater than the dimensions of the structure. Start construction when the concrete reaches 75% strength; under normal conditions, the hardening process will take about 2 weeks. This assumes an average daily air temperature of +20 °C and proper care of the monolith.

Having installed waterproofing from 2 layers of roofing material, make the first row continuous (40 bricks will be needed). How to fold the stove according to the order, read on:

An ash chamber is formed on 2-3 tiers, a cleaning door is installed, and columns are built to support the bottom of the furnace. The 4th row continues the main walls of the stove; the ash chamber is covered with cut stones. Rows 5-6 form the main smoke channel and the bottom of the firebox made of refractory bricks. The grate is installed without mortar; a row of fireclay stones placed on edge is placed on top.

On the 7th tier a loading door and a vertical summer shutter are installed. Rows 7-9 are laid according to the pattern, at the end the fireclay brick is covered with kaolin wool (marked in green)

Please note: on the seventh tier the walls are reinforced with steel mesh.

Rows 10 and 11 partially cover the flues and the lower heating chamber; a grate for the furnace and a hob are installed. The 12th tier begins to form the main firebox, and on the 13th tier the door is attached to the mouth of the furnace.

Rows 14-17 are laid according to the diagram, corners are mounted to cover the cooking opening

On the 18th tier, steel profiles are covered, and an arched vault with a radius of 46 cm is built from wedge-shaped stones. Tiers 19, 20 are made according to the scheme, the cavity between the vault and the walls is filled with sand or filled with thick masonry mortar. When the filler dries, 21 rows are laid - the roof.

From 22 to 32 tiers the front part of the heater is built. On the 24th row, both smoke valves are placed, on the 25th - an iron shelf measuring 42 x 32 cm. Having laid the 29th tier, cover the stove with the same sheet.

To understand the construction down to the smallest detail, we suggest watching a video with a detailed demonstration of the masonry of each row and explanations from the master:

Furnace heat exchangers

To install this type of heating, a register is installed in the combustion chamber and the latter is connected to the circuit. There are many designs of registers, but all of them must ensure maximum heating of the working fluid and its good circulation.

You may be interested in information about the Leningrad heating scheme

Coils made of sheet steel are easier to manufacture (thickness is from 3 to 5 mm), and it is much easier to clean them from soot. But their heating area, when compared with pipe products, is smaller.

Often, heat exchangers are made by craftsmen specializing in heating systems. But if you have welding skills, you can handle this on your own. As an option, you can prepare the required parts and entrust the welding work to an experienced welder.

Register made of pipes

Pipe register diagram

A diagram of one of the most effective heat exchanger options for a furnace is shown below. Its use is advisable in designs with cooking surfaces, since it allows you to place a stove above you for cooking.

To simplify the manufacturing process, you can slightly change the design: instead of U-shaped pipes ø5 cm, use a 6x4 cm profile pipe. In this case, cutting holes for vertical pipes will be much easier, as well as carrying out welding work. You can leave the vertical pipes themselves round, or you can use rectangular ones instead - 3x3 cm or 4x4 cm. You can read what a convector is in our article.

If the register will be installed in a stove without a hob, then several more horizontal tubes ø3-4 cm can be welded to the upper U-shaped pipe in order to increase the efficiency of the register. There is another option - install a convector heater - or make a structure from L-shaped pipes, shown in the image below.

Here, water from the heating system will be supplied to the lower part of the device (pipe diameter is 4-5 cm, wall thickness is about 4 mm), heated and gradually rises through vertical pipes of the same cross-section into the upper collector pipe, from which, accordingly, back to highway.

Register made of pipes

Water jacket made of steel sheets

This design is used in heating furnaces. To make it you will need:

- sheet steel 3-5 mm thick;

- pipe sections ø4-5 cm (to supply/discharge working fluid);

- a pipe made of a rectangular profile measuring 4x5 cm.

Note! You can change the length of the device if the dimensions of the firebox require it.

Steel register

Visually, this is a solid U-shaped structure of their sheet metal. The heat transfer surfaces in it are all the internal walls.

There is another option for making a register from steel sheets - make it without a top shelf, leaving only the side ones, connected at the top and bottom by rectangular pipes 4x6 cm or round pipes ø5 cm (this option is called a “book”). Although smaller pipes can be used in the front part of the product to improve circulation.

Steel register

We also note that, if desired, a water jacket can even be installed in a Russian oven. The result will always be the same - increased efficiency and uniform distribution of generated heat.

Option "book"