Quite often in articles about thermal insulation of various structures, the abbreviation EPPS is found; what it is and how it stands for is not clear to everyone. As well as what are the advantages of the material over other insulation materials, what are its weaknesses, what criteria should be used to select the material and how to work with it. For those who are going to build a house, lay communications, make a blind area or dig a well, information about it will certainly be useful, since this universal heat insulator can be used almost anywhere.

EPPS is an excellent insulation for plinths and blind areas Source oboiman.ru

Description of material

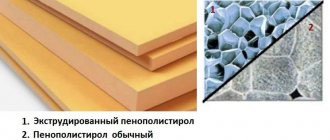

EPPS is extruded (or extruded) polystyrene foam. To put it simply - polystyrene foam, but not the usual pressed one, which easily disintegrates into small white balls, but more dense and durable. The composition of these materials is the same, but EPS has improved characteristics due to a special production method in which the prepared mass is extruded through the profiled holes of extruders. The cross-section of these holes gives the products a given shape.

Extruded polystyrene foam is used to produce slabs, substrates, shells for thermal insulation of pipes, and other products used in construction for insulation and insulation of various structures. As well as decorative elements.

Thermal insulation for sewer pipes Source fis.ru

The most popular and widespread product is slabs. They come in different thicknesses, smooth and corrugated, with smooth and stepped end faces. The latter ensure installation without through joints, which is very important for continuous insulation, as it eliminates cold bridges.

Each manufacturer sets its own sizes of slabs, but most often their width is 600 or 580 mm, and their length is 1000, 1200 or 2400 mm. The number of slabs in a package depends on their thickness.

For reference! In the catalogs of large online construction stores, this material is often listed under the name XPS. This abbreviation is accepted in European countries. Why it is used here is not entirely clear, because almost all products made from extruded polystyrene foam in our stores are represented by domestic brands.

Production technology

Most people not involved in the construction industry think of EPS as being the same foam plastic, but denser. In fact, there are many differences between pressed and extruded polystyrene foam, and they are associated with different production methods.

The raw material for the production of both materials is polystyrene Source dormakomplekt.ru

Before melting, crushed granulated polystyrene is mixed with chemicals that improve the characteristics of the finished product, making it more durable, less flammable, etc. Carbon dioxide or another foam-forming agent is introduced into the molten hot mass, which expands when the pressure and temperature are reduced. The foamed substance is fed into the extruder and squeezed out of it through a hole with the specified parameters.

In the case of slab production, it is rectangular and determines the thickness and width of the finished product. Solid EPS strips are sawed to length after cooling.

Line for the production of extruded plates Source masterplex.rf

Differences from polystyrene foam

EPS granules are much finer than those of polystyrene foam, since the material is exposed to very high temperatures and is formed under high pressure. Their size is tenths of a millimeter, while the diameter of the foam balls is several millimeters.

The dense, finely porous structure makes the material much more durable and resistant to stress. It is not so easy to break and almost impossible to crumble, since the adhesion between the granules is very strong. At the same time, the thermal conductivity and vapor permeability of extruded slabs is even lower than that of foam plastic.

Due to its porous structure, polystyrene foam is highly brittle and brittle Source ppu-prof.ru

Thanks to special fire retardant additives, they resist direct fire longer, and their dense structure does not particularly attract rodents and insects.

Advantages and disadvantages

Polystyrene is a polymer material, plastic, which is given special properties and structure through special processing. Therefore, speaking about extruded polystyrene, what it is and what characteristics it has, it is quite possible to say that it is plastic, but very light and friable. Accordingly, it has all the advantages of synthetic polymer materials. And there are many more advantages associated with the structural features. Let's list everything.

- Absolute moisture resistance - the material is not afraid of exposure to water, upon contact with it it does not collapse, does not rot, or becomes infected with mold.

- Low thermal conductivity, which is provided by sealed cells filled with air.

4 cm thick EPS can replace 85 cm of brickwork Source dy.spb.ru

- Extremely low water absorption: water does not penetrate into the EPS structure and therefore does not affect its thermal insulation properties.

- Durability is also associated with virtually zero water absorption, the absence of moisture in the material, which freezes and expands at sub-zero temperatures and causes internal destruction.

For reference! Water can penetrate inside only to a small depth, through damaged cells located on the surface. But this does not affect the properties of the insulation.

- Low vapor permeability makes EPS the most convenient heat insulator, without requiring additional protection from water vapor in the form of special films.

- Resistance to compressive loads, which increases in proportion to the density of the slabs.

- Low degree of thermal expansion due to changes in ambient temperature.

- Light weight - insulation, more than 90% consisting of air, practically does not increase the load on foundations and other foundations.

- Easy and all-season installation - EPS is easy to cut and attach, you can work with it at any temperature and humidity.

You can insulate buildings with polystyrene foam in any weather Source kraski-net.ru

See also: Catalog of companies that specialize in insulating houses

It is impossible not to mention the affordable price of this material, because of which it is often preferred to other insulation materials, ignoring the disadvantages. And EPPS also has them. Moreover, one and the same property is an undeniable advantage in one situation, and a disadvantage in another.

For example, low vapor permeability makes it practically unsuitable for insulating wooden houses, since polystyrene locks moisture in the wood and prevents condensation from evaporating. Which leads to wooden structures getting wet, rotting and gradual destruction.

The second important disadvantage is the release of substances harmful and dangerous to life and health from the material when it is heated above 70 degrees. By itself, it is considered low-flammable, since when exposed to fire it is difficult to ignite and almost does not burn. But it melts with the formation of toxic smoke, and it is this, and not fire, that is the more common cause of death in fires.

Fire safety certificate EPPS Source tutteplo.ru

Being resistant to stress, extruded polystyrene foam is easily destroyed by certain chemicals of inorganic origin, which include:

- bitumen mastics;

- acetone;

- toluene;

- paints and adhesives containing inorganic solvents;

- petroleum oils;

- impregnation for wood.

Therefore, when waterproofing, painting and other work, you need to carefully monitor the composition of the materials used if they come into contact with the insulation.

What is XPS Extruded Polystyrene Foam

Another name for extruded polystyrene foam XPS (eXtruded PoliStyrene) is extrusion. A similar term is applied to materials that are produced by extrusion - by forcing a viscous melt through a molding hole. First, polystyrene granules are mixed with foaming agents (freons or carbon dioxide-based compounds), then mixed under high pressure, and only then squeezed out of the extruder.

Extruded polystyrene foam has a fine-cell structure

At its core, expanded polystyrene is a plastic with evenly distributed closed cells measuring 0.1-0.2 mm. Externally, the material looks like a smooth plate - transparent or colored. The fine-mesh structure can be easily seen directly on the cut. The edges of the slabs can be straight or in the form of an L-shaped edge, which provides more reliable adhesion of the products during installation. You can explore different types of extruded polystyrene foam by going to the product catalog.

Where is EPS used?

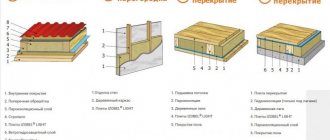

The material described is used in a variety of fields, but we are interested in what EPS is in construction. This is a universal thermal insulation material that is used to insulate almost all parts of buildings:

- walls;

- foundations and plinths;

- floors and ceilings;

- basements and undergrounds;

- roofs;

- blind areas.

It is recommended to insulate EPS walls from the outside or use it as an intermediate layer when laying walls made of bricks and blocks.

Insulated brickwork Source bitrix24.ru

For external wall insulation, both ordinary EPS boards are used, which are then covered with plaster or a curtain wall, as well as decorative sandwich panels that do not require finishing.

It is important! If the house is insulated from the inside with polystyrene foam boards, it is necessary to take into account their low vapor permeability and consider a competent ventilation system. Otherwise, the indoor air will be humid, which will lead to mold.

In addition to insulating the main structural elements of buildings, slabs and other products made from EPS are used for thermal insulation of above-ground and underground pipelines, wells, septic tanks, caissons, cellars, and heated greenhouses. This material is laid on a rough base when installing a heated water floor, and is used as permanent formwork in the construction of foundations and walls.

Thermal insulation substrate for heated floors made of polystyrene foam Source fis.ru

Conclusions and useful video on the topic

You can learn about the criteria by which extruded polystyrene foam should be selected from the following video:

Considering that almost no one pays attention to the weak sound insulation of insulation, sensitivity to ultraviolet radiation is treated by the fact that the material is always protected by a layer of finishing, and low vapor permeability as a minus is eliminated by the presence of good ventilation, of the total number of shortcomings, only “not environmentally friendly” and the “expensiveness” of the material, but these shortcomings are also easy to refute.

The very concept of “not environmentally friendly” suggests that the material is extremely durable, since over time, especially with proper use, it does not break down into its components. Isn’t this a criterion for considering the “non-environmental friendliness” of a building material as a plus? Well, regarding the high cost of EPS, there is an excellent proverb: “The miser pays twice.” With all the ensuing morals and consequences .

Have you thought about using EPS as insulation and want to clarify a couple of nuances of its use after reading our material? Ask any remaining questions to our experts below this post - we will try to help you.

If you are a professional installer of XPS and want to give useful advice to beginners or supplement the material presented above with valuable comments, write your comments in the block below.

How to choose EPS insulation

The main parameters by which the material is selected are the density, size and configuration of the slabs.

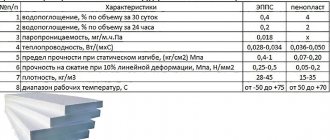

Technical specifications

The density of polystyrene foam is an important criterion for selection. The larger it is, the stronger the slab and the greater the load it can withstand without deforming. Products with the highest density are even used in the construction of roads and runways.

The bulk of such products for universal use have a density from 25 to 45 kg/m3; in the marking it is indicated by the corresponding numbers. But there are products of both higher and lower brands. The higher the expected load on the insulated base, the greater this indicator should be.

For example, for insulation of plinths and foundations it is better to choose material of grade 35-40 and higher, but for roofs 25 is sufficient.

Video description

Since not all manufacturers indicate this parameter, you need to be able to determine it yourself.

How to do this is shown in the video: The quality of products also varies and depends on the manufacturer’s compliance with manufacturing technology. Some introduce harmful additives into raw materials or do not use recommended components. Sometimes ordinary polystyrene foam is sold under the guise of EPS. To be sure of quality, you should buy certified products manufactured not according to the manufacturer’s technical specifications, but according to GOST.

Advice! You can verify good quality by performing a simple test. You need to break off a piece of material and inspect the fracture site - small regular polyhedra should be visible on it, not balls.

Depending on the place of application, choose slabs with a stepped edge or a corrugated surface, which facilitates the application of a plaster layer on it.

Significant disadvantages of insulation

Despite the fact that the material has much fewer disadvantages than advantages, in some cases they become the key reason for refusing to use it.

As it turns out, plastic not only has advantages, and all the disadvantages of EPS are also related to the fact that it is of “polyethylene nature.”

When insulating frame and wooden houses, it is best to choose special extruded polystyrene foam impregnated with fire-resistant agents. The photo clearly shows that it will be very difficult, if not impossible, to set such material on fire.

The main disadvantages of extruded polystyrene foam are:

- Poor sound insulation . The material is able to slightly muffle sound waves, but it is not able to absorb them completely, nor can it reflect them.

- Sensitivity to ultraviolet radiation . Under direct sunlight, without specially hiding materials, for example, plaster and other finishes that, among other things, serve as protection, the EPS is destroyed.

- Low vapor permeability . In some cases this can be a plus. But not in all of them. Therefore, homes insulated with extruded polystyrene foam require impeccably installed and effective ventilation. Otherwise, condensation will accumulate in the walls, which will contribute to their destruction.

- Low environmental friendliness of the material. No matter how manufacturers of polystyrene foam protect their product, plastic always remains plastic. Even if it is porous, it will still decompose much longer than any non-synthetic substances.

- The high cost of this type of insulation also makes some people think. Moreover, the harder and denser its variety, the more expensive it is.

Separately, I would like to point out that, for obvious reasons, this material is very susceptible to attacks from rodents.

If rodents have access to polystyrene foam, they can travel along the walls in it, gnawing holes in it. Animals use small granular particles to decorate their nests.

If there is open access to the EPS insulation layer, mice and rats make whole labyrinths of passages in it and even make their nests in them.

Therefore, it is advisable to carefully seal the layers of insulation with such finishing materials that rodents will not be able to get through to the coveted layer of polystyrene foam.

But the main disadvantage of this type of material is the low degree of fire resistance. As soon as the edge of the stove catches fire, the flame instantly eats it completely. Moreover, combustion is accompanied by the release of highly toxic substances into the atmosphere - phenols, which can cause no less dangerous harm to the lungs than the high temperature itself.

Ordinary extruded polystyrene foam can catch fire, depending on prevailing third-party factors, at temperatures from 250 to 450 degrees Celsius, which is why it should be used for insulation of wooden buildings and structures with the greatest caution.

In such cases, experts advise purchasing EPS, flavored with special fire-resistant additives during the production process.

Installation features

Knowing why extruded foam is needed, what it is and what positive characteristics it has is completely insufficient if you decide to install it yourself. The method of fastening depends on the type of insulated surface.

On the floor and blind area

When insulating horizontal surfaces, polystyrene boards do not require fastening. They are laid on a leveled surface - a floor slab or a sand cushion. When installing an insulated blind area or concrete screed, it is recommended to reinforce the concrete layer on top of the insulation with steel mesh.

If the insulation of a wooden floor is carried out followed by the laying of laminate, linoleum and other finishing coatings, then a wooden frame made of bars is first installed on the base, and EPS boards are laid between them. Sheets of plywood or OSB are fixed to the frame.

All joints and seams are filled with foam Source tetrapilon.ru

On the walls

EPS can be attached to vertical surfaces in different ways.

- Gluing.

The slabs can be glued to mineral substrates - to smooth walls made of brick, concrete, building blocks using special adhesives. Many manufacturers of extruded polystyrene foam also produce glue for their installation. In particular, TechnoNIKOL and Penoplex have them. But in construction stores you can find adhesive mixtures of other brands.

Manufacturers and lines of EPS

The specific technical characteristics of a particular type of extruded polystyrene foam depend on the manufacturer of this material. I am familiar with several companies offering this material on the Russian building materials market, which I will tell you about

Ursa

This company produces extruded polystyrene foam under the URSA XPS brand. Due to its very low thermal conductivity coefficient and high strength, this material is ideal for use in private and large commercial construction. They can be used to insulate both country cottage structures and railway embankments or highways.

Ursa is a well-known manufacturer of insulation materials.

This material is especially valued when used in extreme conditions - where the insulating layer is installed in conditions of high humidity, may experience heavy loads or is in direct contact with the soil.

Briefly about the features of URSA XPS:

- Efficiency. The material has a unique combination in the construction industry of high compressive strength and low thermal conductivity. Therefore, it is used in cases where a thermal insulation material that can withstand increased load is needed.

- Rigidity. The deformation characteristics of URSA insulation boards make it possible to perceive and further distribute an external load equal to 50 tons per square meter. In addition, the material has increased bending strength, so it can be laid directly on a sand bed to create insulated floors on the ground.

- Environmental friendliness. Natural carbon dioxide is used as a foaming agent in the manufacture of slabs, rather than freons. Therefore, the company's products fully comply with the requirements of the Kyoto Protocol on environmental protection.

- Frost resistance. According to studies, URSA brand EPS is capable of withstanding more than 500 cycles of sequential freezing and thawing without any consequences for its own technical characteristics. Experts recommend using this material for insulating structures subject to frequent changes in temperature conditions.

- Flammability. When producing EPS boards, fire retardants are added to the raw polystyrene mass, which reduce the flammability of the material by limiting the access of oxygen in direct contact with the flame.

The product line of this manufacturer consists of several types of insulation, which I will now describe in detail:

- URSA XPS N-III . Extruded polystyrene foam of high rigidity, which has perhaps the lowest thermal conductivity coefficient among similar materials. Can be used to insulate surfaces that are in direct contact with liquid, soil or plants. The edge of the slabs is designed in the form of a step, which ensures a tighter fit of the material parts to each other.

Extruded polystyrene foam TM URSA.

The exact technical characteristics of EPS are presented in the table:

| Characteristic | Meaning |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,25 |

| Fire Safety Group | G3 |

| Water absorption coefficient, % of volume | 0,3 |

| Vapor permeability, mg/(m*h*Pa) | 0,004 |

| Permissible operating temperature, degrees Celsius | from – 50 to +75 |

This material is ideal for thermal insulation of flat and pitched roofs, layered masonry (with insulation between blocks), walls with subsequent plastering, basements inside and outside, pitched roofs, balconies and underfloor heating.

- URSA XPS N-III . Rigid slabs of extruded polystyrene foam, which are specifically designed for use in private construction. Unlike the previous one, this material has a wide variety of sizes.

All types of URSA slabs in this category are shown in the illustration below:

Assortment of URSA extruded polystyrene foam boards.

The main areas of application of this material are insulation of basements and ground floors, balconies, walls with plaster facades, garden paths, pitched roofs. It is not very suitable for thermal insulation of flat roofs and installation inside laminated masonry walls.

- URSA XPS NV. Material for professional use, which has increased strength characteristics. Due to its ability to absorb and distribute loads exceeding 50 tons per square meter, this XPS is used in the construction of roads and railways, airfields, and so on.

In the photo - URSA XPS NV - material for professional use.

The exact technical characteristics of EPS are presented in the table:

| Characteristic | Meaning |

| Thermal conductivity, W/(m*K) | 0,033 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,5 |

| Fire Safety Group | G4 |

| Water absorption coefficient, % of volume | 0,3 |

| Vapor permeability, mg/(m*h*Pa) | 0,004 |

| Permissible operating temperature, degrees Celsius | from – 50 to +75 |

Ursa is not the only manufacturer of extruded polystyrene foam that is used by domestic builders. Another brand is discussed below.

Styrofoam

According to some studies, insulation of this brand ranks first in popularity for use in civil, industrial and commercial construction in Russia.

Styrofoam is the oldest manufacturer of EPS in the world.

Thermal insulation boards of this brand are painted in a characteristic blue color and are used for insulation of various building structures. I will tell you about specific types of products and how to use them in private construction.

- Styrofoam 250A. Extruded polystyrene foam with a smooth surface, which is suitable for insulating pitched roofs, structures buried in the soil, attics, wells and multi-layer walls.

The insulation has an L-shaped edge, making it easier to join the plates to each other.

The exact characteristics of this type of material are given in the table.

| Characteristic | Meaning |

| Density, kg/m3 | 32 |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,25 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,2 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G1 |

| Surface texture | smooth |

| Edge design method | tongue and groove |

| Dimensions, cm | 250 to 60 |

| Thickness, mm | from 40 to 120 |

- Styrofoam 300 A. Insulation used to protect flat roofs, external surfaces of foundations and basements, underground and basement structures from heat loss. Extruded polystyrene foam boards of this category are used for thermal insulation of walls inside and outside, followed by protection with thin-layer cement plaster.

Using EPS for insulating a reinforced concrete residential building.

A special feature of 300A slabs is the stepped edge shape, thanks to which the parts are connected to each other “in a quarter”. This installation method not only makes work easier, but also prevents condensation. Glue or cement mortar can be used to secure the EPS to the surface. Insulation can be used as part of permanent formwork during reinforced concrete work.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 32 |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,3 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,2 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G1 |

| Surface texture | smooth |

| Edge design method | stepped |

| Dimensions, cm | 125 by 60 |

| Thickness, mm | from 30 to 120 |

- Styrofoam 500 A. Extruded polystyrene foam boards that are suitable for increasing the thermal resistance of building envelopes of buildings of any type and purpose. The material of this brand is able to withstand very large external mechanical loads. Does not contain organic components, is anti-allergenic and protected from biocorrosion.

Styrofoam 500 A is an ideal material for insulating roofs in use.

The main areas of application are thermal insulation and sound insulation of pitched and flat roofs, basements of strip foundations, walls, highways, railway embankments, hangars, industrial utilities. To achieve greater efficiency, laying the material in several layers is allowed.

Polyurethane adhesives and bitumen mastics are used to secure the slabs to the surface. In the latter case, the mastic forms an additional waterproof layer that prevents the buried structures from getting wet. If there is no need for protection from water, the slabs can be secured with umbrella dowels. To increase the adhesion of the EPS surface when plastering it, you need to treat the insulation with coarse sandpaper.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 38 |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,5 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,2 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G1 |

| Surface texture | smooth |

| Edge design method | stepped |

| Dimensions, cm | 125 by 60 |

| Thickness, mm | from 50 to 120 |

- Styrofoam IB 250 A. Extruded polystyrene foam of a characteristic blue color with a fine-grained porous structure. It is produced in the form of separate slabs with rough surfaces and smooth joints, which ensures improved adhesion and reliable adhesion to mortars.

Insulation of walls using the “wet facade” method using EPS Styrofoam.

This material is specifically intended by the manufacturer for use in the construction of multilayer insulated walls and partitions, including monolithic and panel reinforced concrete structures. With its help, you can insulate the façade of a building and isolate places where cold bridges may form.

The insulation of this brand is excellent for arranging facades and then covering them with cement plaster reinforced with fiberglass mesh. Can be used indoors and outdoors.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 32 |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,25 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,5 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G1 |

| Surface texture | rough |

| Edge design method | flat |

| Dimensions, cm | 125 by 60 |

| Thickness, mm | from 30 to 120 |

- Styrofoam IBF 250 A. Extruded polystyrene foam with specific properties, used for insulation of structures buried in the ground and surfaces that will experience increased mechanical load during operation. It differs from the previous type in the increased length of the sheets, which speeds up installation on a large surface area and reduces the number of joints.

Insulation of the foundation and basement of the building using EPS Styrofoam IBF 250 A.

The manufacturer recommends using this type of EPS for installation on the external surfaces of building walls, for insulating underground tunnels and truck bodies. This extruded polystyrene foam is also used in multi-layer wall panels made from profiled sheets. Suitable for insulation of sports facilities and road surfaces.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 32 |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,25 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,5 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G1 |

| Surface texture | rough |

| Edge design method | flat |

| Dimensions, cm | 250(300) at 60 |

| Thickness, mm | from 30 to 120 |

- Styrofoam GEO 350 A. Insulation with good thermal insulation properties and sufficient strength, which allows the material not to collapse under significant loads during operation.

Styrofoam GEO 350 A – insulation of unused flat roofs.

This material has been introduced into the company's product line as an alternative to more expensive and dense extruded polystyrene foam. Its use is recommended in cases where the design load on the insulated surface will not exceed 400 kPa.

Thermal insulation material is ideally suited for insulating the foundations of shallow buildings, flat unused roofs, interfloor slabs, underground parts of buildings, industrial refrigeration units, and road surfaces.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 34 |

| Thermal conductivity, W/(m*K) | 0,032 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,35 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,5 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G4 |

| Surface texture | smooth |

| Edge design method | flat or stepped |

| Dimensions, cm | 300 to 60 |

| Thickness, mm | from 30 to 50 |

- Styrofoam GEO 500 A. High-strength universal insulation, which is used to solve a huge range of problems arising during civil and commercial construction.

Styrofoam GEO 500 A – insulation of structures that can be subject to significant loads.

The material has high resistance to mechanical loads and retains its performance properties regardless of the temperature and humidity of the surrounding air.

Recommended for insulating structures that experience significant external mechanical stress. It is used to insulate sports rentals, industrial concrete floors, road surfaces, storage facilities and warehouses, tunnels, hydraulic structures, and subways.

Extruded polystyrene foam of this brand can be used in direct contact with groundwater, and also withstands the loads of heavy engineering equipment used for backfilling pits.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 38 |

| Thermal conductivity, W/(m*K) | 0,033 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,5 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,5 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G4 |

| Surface texture | smooth |

| Edge design method | flat or stepped |

| Dimensions, cm | 300 to 60 |

| Thickness, mm | from 30 to 50 |

- Styrofoam GEO 700 A. A very durable thermal insulation material that contains additives that increase its water-repellent and fire-fighting properties. The cost of this material is quite high, so it is used only in industrial construction.

Styrofoam GEO 700 A – insulation of large industrial facilities.

The main areas of application are the prevention of freezing of building envelopes experiencing constant dynamic loads. These include buried foundations, heavily trafficked floors, cold storage and warehouses, heavily trafficked industrial roofs, runways, and so on.

The exact characteristics of this material are shown in the table:

| Characteristic | Meaning |

| Density, kg/m3 | 45 |

| Thermal conductivity, W/(m*K) | 0,034 |

| Compressive strength when the surface is deformed by 10%, MPa | 0,7 |

| Vapor permeability, mg/(m*h*Pa) | 0,006 |

| Water absorption coefficient for 4 weeks, % of volume | 0,2 |

| Permissible operating temperature, degrees Celsius | — 160 to + 75 |

| Fire Safety Group | G4 |

| Surface texture | smooth |

| Edge design method | flat or stepped |

| Dimensions, cm | 300 to 60 |

| Thickness, mm | from 40 to 50 |

The list of manufacturers, of course, does not end there. For example, in this article I did not describe such a popular insulation as Penoplex. But I once dedicated a separate article to him, so those interested can read it on this blog.

Video description

This video shows how to properly attach insulation to Ceresit CT 83 adhesive:

- Fastening with dowels.

This method is more economical and is used on uneven substrates, as well as on wooden surfaces. Plastic dowels with a large head hold light insulation well, a few pieces per slab are enough. Typically, fasteners are installed in the corners and in the center.

- Combined method.

If the walls are leveled with cement plaster, EPS boards can be glued onto a still fresh mortar and additionally secured with dowels.

- Frame method.

It is used for insulating walls under a suspended ventilated façade. The slabs are placed between the wooden frame guides in the same way as is done when insulating the floor. If the frame is metal, they are mounted on hangers fixed to the wall, and only then the profiles are installed.

Insulation of EPPS facade for finishing with siding Source 918747.ru

Insulation of walls from the inside

A situation often arises when it is impossible to insulate a building from the outside. For example, if the facade decoration is replete with decorative elements, especially if the object is of high cultural and historical significance. In this case, the only way to improve the temperature and humidity conditions of the internal space is to insulate the walls with polystyrene foam from the inside.

Installation

For interior work, extruded polystyrene foam of a smaller thickness is used - from 10–20 to 30–40 mm, in one layer. Before installing the insulation, the walls are cleaned and dried if necessary.

The material is laid directly on the inner surface of the wall using glue. It is not necessary to supplement the fixation of insulation sheets with other fasteners.

Ventilation gap

In the absence of external insulation of facades, a small ventilation gap is left between the insulation layer and the inner surface of the wall. This is necessary to prevent the appearance of condensation on the walls from inside the room, which can lead to premature destruction of the surface from dampness and rotting. Ventilation allows the wall to dry out and be freed from excess moisture.

Sometimes a ventilation gap is left between the finishing material and the insulation when insulating the inside of a building. But this leads to a noticeable reduction in the internal space of the building. After all, the thickness of the walls increases significantly as a result.

Finishing

A wooden sheathing is installed on top of the slabs, onto which finishing materials are subsequently attached. Sheets of plasterboard are often used as finishing, which can be painted, wallpapered, decorative plaster or other finishing coatings applied.

Video description

Watch a video about roof insulation over solid flooring:

On the formwork

To make permanent formwork from extruded polystyrene foam slabs, you will need special plastic ties with which the opposite walls of the formwork are fastened to each other and fixed at a certain distance.

The design of the ties allows you to change this distance and has special sockets for fixing the reinforcement cage bars.

Mounted formwork with a steel frame Source homemasters.ru

How to cut EPS

When carrying out thermal insulation work, EPS boards often have to be cut, cutting out pieces of the desired shape and size. Since the material is quite soft, this can be done with a knife, the main thing is that its blade is very sharp, durable and thin, otherwise the material will crumble.

Advice! To get rid of the strong squeaking noise that accompanies cutting, the knife blade can be periodically moistened with machine oil.

Another suitable tool for cutting is an angle grinder (simply an angle grinder) with a metal disc. The thinner it is, the less debris and dust will be generated, and the cleaner the cut will be.

There are also special tools for cutting foam plastic that work on the principle of thermal cutting - special machines and “hot knives”.

Thermal cutter for polystyrene foam Source allegroimg.com

It makes no sense to buy such equipment for one-time use, especially since a cutting machine can be made with your own hands from nichrome wire stretched between two driven nails. To make the wire glow, the nails are connected to a transformer and voltage is applied to them.

It is important! The thermal method of cutting polystyrene foam can only be used in the fresh air or when using personal protective equipment such as a respirator or gas mask, since when it is heated, toxic substances are released that can be harmful to health.

Homemade machine option Source pochini.guru

Where is XPS expanded polystyrene used?

Due to low vapor permeability, XPS is not recommended for use in the interior of residential and public buildings. Otherwise, the microclimate inside the facility will not be very favorable.

The use of XPS for interior work is permitted only in buildings that are equipped with a reliable forced-air supply and exhaust ventilation and air conditioning system. This is especially true for multi-storey buildings, where it is impossible to insulate the outside of the building and have to do it from the inside.

In other cases, XPS polystyrene foam is very widespread, especially in Russia, where there are a lot of wet and swampy soils. The unique properties of the material allow it to be used for insulation:

- foundations,

- roofs,

- floors,

- facades.

Work on building insulation with extruded polystyrene foam

Extruded polystyrene foam can be used to insulate various engineering structures, private and industrial construction sites, namely the floors of the first floors, basement and semi-basement basements. In the case of facades, such insulation can be used both in the “wet” method (plaster) and when installing a ventilated frame structure under siding. The scope of application of XPS expanded polystyrene also includes insulation:

- tunnels;

- highways on permafrost and heaving soils;

- airports;

- parking;

- garages;

- runways.

The use of extruded polystyrene foam for insulation under siding

Briefly about the main thing

We can say about the EPS board that it is a universal thermal insulation material for all structural elements of buildings. It retains heat perfectly, insulates noise, is not afraid of water and weighs almost nothing. But its scope of application is limited by two factors: toxicity when heated and very low vapor permeability, due to which expanded polystyrene is not recommended for insulating wooden houses. The quality of the material depends on strict adherence to the production technology regulated by GOST. And its installation is quite simple and accessible even for beginners in construction.

Insulation of hollow walls

Recently, the construction of buildings with hollow walls has become popular, which can significantly save money on building materials. In this case, the insulation of the walls is carried out directly in their thickness, i.e., the heat-insulating material is laid in the cavities of the load-bearing structures.

This results in a three-layer system. The internal wall has the function of distributing the weight of the building onto the foundation and counteracting lateral loads. The outer part of the wall protects from climatic conditions. The intermediate layer is needed for thermal insulation and sound absorption.

This significantly increases the performance characteristics of any building - interior and exterior finishing is done directly on the wall surface, the heat-insulating material lasts even longer, since there is no contact with the environment and its aggressive factors.

With this design, after the building is built, there will be no access to the insulating layer. Therefore, increased requirements are placed on the material for thermal protection. It should be durable, hold heat well, and not be afraid of moisture. Extruded polystyrene foam is excellent for these purposes.

The supporting structure itself is created from sufficiently strong materials that can withstand any load, i.e. the presence of cavities does not in any way affect the quality of the entire building, on the contrary, it improves its characteristics many times over.