Only automatic releases cut directly into the pipeline, but not manual ones. Mayevsky's tap is not capable of capturing air bubbles, since it does not have a corresponding chamber, so they are designed for installation on heat exchangers.

Knowing where to place automatic air releases, you can check the correct location of these products. If your system has a Mayevsky valve installed on the pipeline, then this placement is incorrect. If the size of the automatic device spoils the design appearance of the radiator and the room as a whole, then you can replace them with special mini-graduates.

Features of choosing air vents

Not everyone knows where to start choosing an automatic air vent. In order for the product to serve for a long time and without failure, it is recommended to buy products of European or domestic production, but not cheap Chinese counterfeits. Buying a cheap automatic graduate can cause the following adverse consequences:

- Passing not only air, but also coolant through the valve. In this case, a puddle of water will be detected under the radiators or in the places where the air vents are installed.

- Rapid deterioration.

The product is jammed, so it will not work.

Although automatic type safety valves have a shorter service life than manual ones, they must serve without fail for at least 10 years. Manual products have a service life of over 15 years, so instead of buying a cheap machine, it is better to give preference to a manual device. This will allow you to win not only in terms of savings, but there will also be no problems with air bleeding.

To choose good quality Mayevsky uranium, you need to pay attention to the following criteria:

- The presence of a handle allows you to conveniently open the valve for bleeding air. The disadvantage of faucets with handles is that they can be accessed by children, who are quite capable of opening them. Installation of such outlets with handles is appropriate only in hard-to-reach places; in other cases, it is recommended to install conventional products with a key or a screwdriver.

- To avoid losing the special bleeder key, it should be placed on the wall next to the radiator. This will prevent you from losing the key, and will also allow you to quickly bleed the air.

- Buy products with anodized coating. This spraying allows you to protect the metal from the occurrence of oxidative processes.

- If your budget allows, you can purchase a product that can trap air bubbles. However, such manual air vents do not differ much in cost from automatic air vents.

In order not to make a mistake with your choice, you need to pay attention to the manufacturer. Depending on the brand of plumbing and heating equipment, not only the quality, but also the cost will differ. In addition, if a closed heating system is used, then you need to pay attention to the technical parameters of the devices, in particular, operating pressure.

In addition to the familiar Mayevsky taps, modern heating systems commonly use a device such as an automatic air vent. Its task is to remove air from a certain section of the heating network without human intervention. How this important device works, the principle of its operation and its installation location - all these nuances will be discussed in this article.

What types of air vents are there?

Air vents are divided into two types:

- manual;

- automatic.

Manual products are designed to deflate air through human intervention. To do this, utility workers either independently go around all the apartments to carry out such manipulations, or inform the residents of the house. Automatic air vents for heating systems do not require human intervention, so they release oxygen on their own. The cost of such devices is several times higher than manual ones, so utility services are not able to provide all high-rise apartments with automatic air vents.

Automatic air vents are installed in places where there is a high probability of air lock formation. The locations for such devices are heating radiators.

Types of Automatic Air Valves

Based on their design, devices can be divided into 3 types:

Note. Despite external differences and different areas of application, the principle of operation of the air vent remains unchanged.

The most common are traditional devices with a direct connection pipe. The scope of their application is very wide. Automatic air separators are primarily designed to release air through the highest points of the pipeline network. To do this, they are placed at the very top of vertical risers, where, according to the laws of physics, all air accumulations that appear in the pipes tend to fall. If it were not for the automatic air vents in the heating system, it would have been very difficult to manually release air from the highest points.

Closed heating systems under pressure are equipped with boiler safety groups, which are located on the supply pipeline leaving the heat generator. Along with the safety valve and pressure gauge, this group also includes an automatic air valve. Its task is to bleed air when the boiler tank is filled with water. If the piping of the unit is done prudently, then, if necessary, it can always be cut off from the rest of the system and emptied using an air vent, and refilled after servicing.

Note. Safety groups for heating must be installed on boilers that burn solid fuel.

Air vent devices are also used in some models of circulation pumps. The goal is to ensure uninterrupted operation of the pumping unit. The fact is that the pump can only move an incompressible medium - water or other liquid. The entry of air into the area of the unit's impeller threatens to completely stop the circulation of the coolant, which is what the air vent of the circulation pump is designed to prevent. Any air or steam from the boiler that enters this area will be immediately released and the pump will continue to operate.

What it is

The device that controls the removal of air from the heating circuit is a metal sealed plug. At the bottom of the structure there is a threaded pipe with which a “smart” device for the radiator is connected to a specific component of the heating system.

To understand how an automatic air vent works, pay attention to the design features:

- Has a cast brass body.

- Sealing ring.

- Locking mechanism and cover.

- The needle mechanism is connected through a flag to a float made of polymer resin.

- Jet.

Operating principle of air vents

Inside the metal body there is a float made of a light polymer alloy. In a normal, fully functioning state, there is hot water inside the cast structure. It raises the plastic core to the maximum height of the smart device’s camera. At this moment, the needle valve closes - the automatic air vent is at rest.

- If air appears in the system, the water pushes it to the surface, and it enters the chamber - the receiving area of the metal housing.

- The float, connected by a rod to the needle valve, goes down or falls due to the settled water level, and the “needle” is pulled by the flag.

- In the “open needle” position, a small hole opens in the device, and the accumulated air safely leaves the system.

- Water fills the vacated space, raising the level of the float. He pushes the needle valve up, the hole closes tightly.

An automatic air vent for the radiator removes a slight accumulation of air masses from each circuit, and the radiators fully heat the entire screen area.

In a private house

Shut-off structures are installed in individual heating lines, which are adjusted manually. Typically, a control check of the system is carried out at the beginning of the heating season. Next, as cool areas are detected on the radiator screen, the valves are unscrewed and air is released.

In an apartment building

Multi-storey buildings have closed heating systems. The coolant is under pressure, which is controlled at the outlet of the heat generator. The air vent removes air masses during the stage of filling the boiler with water. A shut-off valve allows you to isolate a section of the system or a heating unit to release air masses.

If the apartment building still has cast iron radiators connected to a common closed heating system, they are equipped with a manually operated Mayevsky tap and drain pipe.

Advantages in automation

It is almost impossible to monitor the accumulation of air in each circuit in real time. And the airiness of the system requires increased operation of the boiler and pump. To ensure that the equipment does not run idle and there is no excessive consumption of energy resources or heat loss, it is necessary to install an automatic air vent.

When it's needed

Sometimes, after the end of the heating season, the water is completely removed or changed. Due to rust removal, automatic air vents in the heating system open when the water level drops - the emptying process occurs faster. While the operation of the device on the radiator and pipes can be controlled, the underfloor heating system cannot. In this case, you cannot do without automation. The need to install automation is due to the following cases:

- Installation in radiators due to the complex circuit design, in the upper part of which convenient cavities are created for air accumulation.

- The heated towel rail is equipped with a “smart” device, since the manual control option is located high.

- For the normal functioning of the boiler piping system, it is impossible to do without automation, which will control the presence of air in the system and ensure safe operation.

- If there is a section on the route with an upward protrusion (bypass), in this case all loops or U-shaped bends are a convenient place for accumulating and automatically discharging the air mass.

- At the production stage, the collectors present in the design of the heated floor are equipped with two air vents for the return and direct coolant supply lines.

Corner and radiator air vents

In different heating systems, many situations may arise when it is necessary to remove air pockets in the most inaccessible or remote places. It is impossible to list them all, as there are too many options. Where it is not possible to install a simple valve because the threaded pipe at the end is in a horizontal position, an angled air vent will do. Its pipe, coming out from the bottom, turns at an angle of 90º and can be connected to a horizontal section.

It should be noted that an angular air vent with an external threaded connection is no different from a conventional straight valve except for a rotated pipe and can be used instead of it if necessary.

Often, to automatically bleed air from batteries, instead of the traditional Mayevsky tap, some users install an angle valve. This can be relevant in an unpleasant set of circumstances, when gases are constantly formed in the network and this happens precisely in radiators. The reason is a chemical reaction of substances sometimes present in water with the aluminum alloy of batteries at elevated temperatures. There is no point in installing a valve with an angle pipe, because there is a special automatic air vent for radiators, shown in the photo:

These devices are designed for batteries only and have a suitable threaded connection. Instead of manual taps, it is preferable to place them on heaters made of aluminum or partially bimetallic, where there is also contact between the alloy and water. In other situations, the radiator air vent is mounted at will, but there is no doubt that it will bring ease of use.

Note. It is still better to equip traditional cast-iron batteries included in the centralized heating network with a Mayevsky manual tap and drain pipe.

For ease of maintenance and cleaning, complete devices are available for sale - automatic air vents with a valve. The latter is a small threaded adapter with a spring-loaded petal valve inside. The adapter is screwed onto the thread directly in front of the air vent and serves so that when the system is in operation, it can be removed and cleaned or replaced. Air vents from DANFOSS, VALTEK and many other well-known brands are equipped with similar adapters.

Features of the functioning of manual descenders

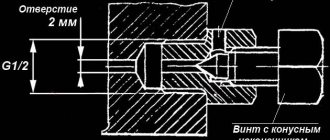

The design of the simplest manual air vent is shown in the diagram below.

This air vent is called the Mayevsky crane, the operating principle of which is very simple. The device has two holes that are covered by a threaded element. When unscrewing the threaded element, air is released, which is pushed through the 2 mm hole in the diagram above, and exits the system through the second hole.

To bleed air from the system, it is enough to make 2-4 turns of the screw, after which, under the pressure of the coolant, the air will tend to escape through the holes. You can know that all the air has been drained from the system by the appearance of water flowing out of the hole. As soon as a dense stream of water flows from the hole, you need to screw the screw in until it stops. Modern Mayevsky cranes are presented in various types: turnkey, with handles and even with a screwdriver. The photo below shows a list of such types.

A manual air valve in a heating system is an ideal device that functions flawlessly over a long period of time. The reliability of this device is due to the absence of moving parts, which over time are subject to clogging, corrosion and failure. This is typical for automatic air exhaust products.

Often, instead of Mayevsky’s manual taps, apartment owners install drainage taps. They can be installed temporarily, but not permanently, since they are not intended for installation on radiators. If such products fail, it will be very difficult to replace them during the heating season.

Air in the heating system - why is it bad?

It would seem that the heating system is closed, completely filled with coolant, where does the air come from? There are several ways for it to appear inside, among them there are several main ones:

While filling with coolant

While you fill the heating system with water or other coolant, it mixes with air. It is almost impossible to avoid this, so you have to take it for granted.

Through poor connections

Poor installation of the heating system, installation and connection of a solid fuel boiler or other heating device, poor quality, defective or broken shut-off valves or other elements - all this leads to air penetration inside.

Chemical reactions

In addition to air, other gases can accumulate inside. For example, if you use a coolant with high acidity and aluminum radiators, hydrogen will be released as a result of a chemical reaction.

Photo 1: Automatic air vent for heating systems

As you can see, there are many reasons for this phenomenon. But why is this so bad? The first thing this leads to is cavitation. It significantly accelerates the wear of equipment and leads to noise during its operation. The second reason is corrosion. It destroys the elements of the heating system and carries their particles with the coolant flow to other devices, clogging and interfering with their normal functioning. Thirdly, the presence of air reduces the actual heat transfer of heating devices and leads to disruption of the pumps. It can even cause a rupture of the boiler casing.

To eliminate all these problems, an automatic air vent is used. Let's figure out how it works in the heating system and what components it consists of.

Return to contents

Where are air vents installed?

In a closed system, when installing a device for effective gas removal, certain rules must be observed:

- The pipes are laid so that the vectors of movement of water and air coincide, and the hot liquid is directed from the main riser to distant ones.

- The air collector must be mounted at the highest point, for example, when going around a doorway from above, since air is released from the liquid at low water speed.

- Devices for removing air should be placed in areas where gas accumulation is guaranteed: at turns of risers, in places where pipes change to another cross-sectional size, on all batteries, separators, and combs.

It is mandatory that air vents are mounted on aluminum radiators, which release hydrogen upon contact with the coolant. For partially bimetallic batteries, the problem is not so urgent, but they do contain aluminum, which means that gas will have to be removed, although not so often. There is no aluminum in 100% bimetallic models, but manufacturers strongly recommend using them together with devices for bleeding air.

Design and principle of operation of an automatic air vent

The design of this small device is very simple. Inside the brass body there is a polypropylene float which is connected via a rocker arm to the spool. As the body fills with air, the float moves down and opens the exhaust valve. The freed space is filled with water and the rising float closes the spool. To prevent various debris, dust and dirt, from getting inside the spool, its outlet hole is closed with a plastic cap.

Photo 2: Design of an automatic float-type air vent

There are models with a slightly different implementation of this process, but in general it is always the same: when the float is down, the valve is open and releases air; if it is raised, the spool closes and the device accumulates gas again. This cycle is repeated again and again automatically.

Return to contents

Types and markings, popular models

There are several types of automatic air vents. All of them are divided into two large types: automatic and manual air vents for radiators or Mayevsky taps.

Depending on the diameter of the threaded connection, they are of two types: 1/2 and 3/4 inches. The first is better known by Russian markings as an automatic air vent valve Du 15, the second - Du 20.

According to the method of fastening, they are divided into classic straight and lateral. For air vents of the second type, the threaded connection is rotated 90 degrees. The air release valve may also be located on the top or side. Various modifications are produced by the manufacturer to facilitate installation in difficult places in the heating system or for mounting on the side of radiators.

Photo 3: Automatic air vent DN15 “Valtec” VT 502 with shut-off valve

In the domestic market, the two most famous are Danfoss. supplies the Russian market with an automatic air vent VT.502 with a mounting diameter of 1/2 (DN15). The model has proven itself well and is very popular among installers of autonomous heating systems in private homes. It has a brass body coated with a layer of nickel, which is designed for a maximum pressure of 10 bar and a temperature of 110 °C. The average price at which you can currently buy this model is 280 rubles.

Photo 4: Automatic air vents 1/2 "Danfoss" series "Eagle" and "Wind"

Takes second place. It produces automatic air vents in two series: “Eagle” and “Wind”. Despite the general technical characteristics, they differ only slightly in appearance. The models are made in brass cases and are designed for a maximum pressure of 10 bar and a temperature of 120 °C. In addition to the standard mounting thread DN15 (1/2), Danfoss also produces automatic air vents with fastening 3/8 (DN10). Prices for these devices are also within 300 rubles.

Return to contents