One of the most common problems in functioning heating systems is airing, which leads to uneven heating of radiators or underfloor heating pipes. To combat this negative phenomenon, air vents for heating systems operating in different modes are widely used.

Using an air vent installed at the inlet of the heat exchange devices, air is released from the heating circuits. There are various types of air vents on the market, in order to understand the wide range of models and choose the right device for an individual heating system, you should know the operating principle, existing types and design features of manufactured air vents.

Rice. 1 Air vents

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises up and impedes the movement of the coolant.

If there is a large volume of air, a plug may form, leading to a complete stop of coolant circulation in the pipeline - the line becomes air-filled.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

Rice. 2 Air vent for venting air from the heating system - design

Air vents for heating systems - operating principle

To bleed air from the circuit, you can use a regular valve by draining a certain amount of liquid. If in communal houses a decrease in the volume of water in the circuit does not cause negative consequences and it is replenished by utility services, then in individual houses the drained coolant will have to be replenished independently.

For a closed system, adding coolant is quite a big problem - you will have to connect a manual or electric pump, and if there is toxic ethylene glycol antifreeze in the line, carrying out the work while taking the necessary safety measures will take a lot of time.

The main difference between special air vent devices and conventional valve locks is the small diameter of the outlet hole, its location at an angle of 90 degrees and the ability to smoothly adjust the cross-section of the outlet channel with a threaded screw.

As can be seen from Fig. 2, the screw has a cone-shaped shape and a similar seat, thanks to which, when closed, it reliably and hermetically covers the inlet hole. To bleed air, the screw head is turned one or two turns, opening a small-diameter outlet drain hole, and the air-filled coolant along with bubbles will begin to flow out of the tap in small quantities while the air plug will be released more intensively.

The advantage of using an air vent is that when you turn the screw, first of all, with a characteristic hissing sound, the air flow comes out, and then the aired coolant flows out, a small amount of which does not need to be added to the system.

Fig.3 Operating principle of an automatic air vent

Link to video to text

A completely simple but important device - the air vent valve in the heating system performs an important function. The reliable circulation of the heating medium and the efficient operation of the heating network installation as a whole depend on its presence in the circuit. Moreover, the device is part of the so-called safety group, since it helps to automatically release air. The installation locations for vents are indicated by the heating network design. The same document establishes the standard size and modification of the protective device. Many types of heating equipment, including boilers running on gas fuel, are equipped with air vents already at the factory, during the assembly of devices and units.

How do air vents for heating systems work?

The cold coolant poured into the heating line tends to release air when heated; to bleed it, automatic air release from the heating system is used.

The operating principle of all automatic devices is to open the bleed hole when air appears in the internal area of the air vent housing. The element that reacts to the presence of air is a float immersed in the inlet pipe of the device, which is connected to a valve that closes the air outlet hole. The automatic device works according to the following principle (Fig. 3):

- When the heating is functioning normally, the float located in the space of the cylindrical working chamber is in the upper position and the cone-shaped rod connected to it closes the outlet channel.

- If air accumulates in the upper part of the tank, the float goes down along with the locking rod and the air valve opens, air is released from the device.

Rice. 4 Automatic air release valve from the heating system

Device

There are various designs of automatic air bleed valves on the market; let’s look at the design and operation of one of the most common types.

This model (Fig. 4.) has a composite body made of brass, including the main part 1, which is screwed into the pipeline, and its cover 2 with a locking mechanism, connected to the base through an o-ring 10.

Installation principles

The automatic air release device is installed vertically - for both straight and corner models, the cap covering the outlet is directed upward. A ball valve or shut-off valve must be installed in the pipeline before the drain valve.

Attention! An exception is the air vent in the boiler safety group - there should be no shut-off valves between this unit and the boiler pipe.

A shut-off check valve allows you to clean the air vent or replace a faulty device without draining all the coolant from the circuit. The automatic air vent with a check valve is easy to use.

When installing an automatic Mayevsky crane, use a wrench rather than an adjustable wrench to control the tightening force of the fasteners. In this case, you should not hold the device by the body, so as not to break it. Hold the air vent by the hexagon under the cylindrical chamber.

Types of air vents and their design features

There are air vent valves of automatic and manual operating principles, the former are mainly installed at the top points of collectors and pipelines, manual modifications (Mayevsky valves) are placed on radiator heat exchangers.

Automatic devices are distinguished by a wide variety of designs for locking mechanisms; their cost is in the range of 3 - 6 USD; the market offers a wide range of models from domestic and foreign manufacturers. The cost of standard Mayevsky taps is about 1 USD; there are products at a higher price, designed to function in non-standard radiator heaters.

Rice. 6 Air vents for heating systems with a rocker mechanism

Automatic

Automatic tappers have different designs depending on the manufacturer; the main differences between the devices are:

- The presence of a reflective plate inside the body. It is placed at the entrance to the working chamber, protecting internal parts from hydraulic shocks.

- Many modifications are supplied complete with a spring shut-off valve into which the air vent is screwed; when it is removed, the spring is compressed and the O-ring closes the outlet channel.

- Some models of automatic diverters are designed for operation in conjunction with radiator heat exchangers; instead of straight ones, they have side threaded pipes of the appropriate size for screwing into the radiator inlet. If necessary, corner automatic air vents of any type can be used, for example, at the connection points of heated floor circuits, hydraulic arrows, if their threaded diameters of the inlet and outlet fittings match.

- There are analogues of air vents on the market - microbubble separators; they are mounted sequentially in the pipeline on two inlet pipes corresponding to the diameter of the pipes. When liquid passes through the body tube with a soldered copper mesh, a vortex water flow is created, which inhibits the dissolved air - this promotes the rise of tiny air bubbles, which are released through the automatic air release valve of the chamber.

- Another common design (an example of the first was given above) is a model with a rocker mechanism. In the chamber of the device there is a float made of plastic; it is connected to a nipple locking needle (like a car one). When the float is lowered in an airy environment, the nipple needle opens the drain hole and air is released; when the water rises and the float rises, the needle closes the outlet.

Rice. 7 Operating principle of separator-type air vents for bleeding microbubbles

Manual

Manual devices for removing air from the system are called Mayevsky valves; due to the simplicity of their design, mechanical air vents are universally installed on radiators. On the market you can find manual taps in a traditional design for installation in various places, and some modifications of shut-off valves are equipped with Mayevsky taps.

The Mayevsky cranes produced do not differ in a wide variety due to their simple design, consisting of a body with an air duct bent at 90 degrees and a cone-shaped locking screw.

A mechanical vent for removing air from a heating system works as follows:

- In operating mode, the conical screw is tightened and reliably seals the outlet hole of the housing.

- When it is necessary to remove excess air from the battery, make one or two turns of the screw - as a result, the air flow under coolant pressure will come out of the side hole.

- After the air is released, the water begins to bleed out; as soon as the water stream becomes intact, the screw is screwed in again and the de-airing operation is considered complete.

What equipment can replace it?

An automatic device has advantages, but such air vents are not installed on old cast-iron radiators. The most popular replacement option will be a manually operated Mayevsky crane. The reliability of the design lies in the fact that there are no moving parts inside the body that become clogged or rust. A manually operated mechanical valve is still a popular device along with automatic air vents.

Where should air vents for heating systems be installed correctly?

When installing a heating system, installing air vents is a mandatory procedure; to determine the required quantity, you need to know where to place these devices. Air vents are recommended to be located in the following places:

- The highest points of the system. If during installation the pipeline rises upward, bypassing any obstacle, and then descends down to the heat exchangers, an automatic air vent for the heating system should be installed on top. This will prevent airing due to the fact that light air always rises and accumulates in the pipeline on the upper floor.

Rice. 9 Types of automatic air vents

- Heating radiators. Radiator heat exchangers have a complex shape, including a large number of sections - this creates convenient cavities for air accumulation. Therefore, Mayevsky outlet valves are always used in radiators; in an individual heating circuit, they are installed on each radiator, regardless of the connection diagram (one-pipe, two-pipe, bottom, side, diagonal). Radiator manual models of exhaust valves, unlike automatic ones, are small in size, less expensive, fit aesthetically into the radiator contour, and therefore are installed on batteries in the vast majority of cases by the manufacturer and, if necessary, by home owners.

- Heated towel rails. Industrially produced heated towel rails of the complex “ladder” shape, popular in everyday life, are always equipped with an air vent with a straight pipe located in its upper part. It is more convenient if the heated towel rail is equipped with an automatic air vent for the following reasons: the screw located at the top of the manual model is inconvenient to tighten, in residential buildings there may be periodic lack of water and manual adjustment becomes troublesome, in addition, the duct protruding from the side spoils the aesthetic appearance of the heater.

- U-shaped bends and bypasses. Any section of a pipeline with an upward-facing loop collects air; if a shut-off valve is used to turn off the loop, it is installed at the highest point, using a model with a built-in automatic Mayevsky valve (naturally, the air vent at the top can be installed separately from the valve).

- Boiler piping system. It is also recommended to equip the boiler piping with a valve to ensure safe operation of the heating equipment in the event of airing in the main line.

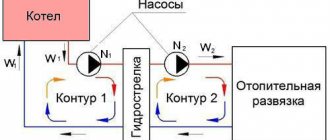

- Hydroshooters. It is not so often that in household heating systems they use hydraulic arrows, to which circulation pumps, radiator and heated floor collectors are connected - if the device is located vertically, an automatic air bleeder is screwed into its upper part.

- Collectors. When installing multi-circuit heated floors, manifolds with combs are used, to which the pipeline of various circuits is connected. The collectors are located above the level of the water floors and are always equipped with automatic air vents, which are installed in their housing by the manufacturer; the system includes two devices for the supply and return lines.

Rice. 10 Manual and automatic air vents for heating systems - location diagram

Operating instructions

- Modern models of devices are equipped with elastic gaskets so that the connection to the radiator and pipeline is elastic and reliable.

- If the presence of a gasket is not enough, plumbing thread is wound at the joint or linen tow and putty are used.

- Installation is available without inviting a plumber. To connect to the system, just use an adjustable wrench.

- Experienced plumbers recommend installing an automatic air vent, the operating principle of which involves effective bleeding of air, not from the blind radiator plug, but on the inlet pipe - between the radiator and the tap.

Video: installation of an air vent

Set it and forget it: is that true?

The Smart Home system implies the presence of various devices that create comfortable living in the house. The monitoring device periodically requires attention, despite its autonomous operation. Over time, the air vent begins to bleed not only air, but also water. The needle valve stops opening and closing independently due to the jamming of the polymer resin float. The light weight and soft texture of the core make it vulnerable to the slightest ingress of debris and hard abrasive particles.

If left unattended, this may cause flooding.