Removing air from the heating system of a private house

In private homes, the design of heating systems varies, depending on the layout of the buildings.

For different types of systems, appropriate expansion tanks are used - open or closed. Therefore, individual homeowners often have to think about whether it is more expedient to bleed air from the heating radiator or through the expansion tank. In an open type system, air bubbles have a free exit through an expansion tank installed in the attic. If the heating is working normally, there is no need to bleed air from the system, since it comes out on its own. But the liquid gradually evaporates, and the water level in the open expansion tank can drop so low that an air lock appears in the upper part of the supply pipe. In this case, the circulation of the coolant will slow down or stop completely, and in this situation we should already be talking about how to bleed air from the heating system.

To expel the air lock, you can add water to the expansion tank from above, but it is better to replenish the volume of liquid in the system through the lower tap connected to the water supply. The water coming from below will fill the void in the pipe and push the air out through the opening of the expansion tank.

During the heating season, it is necessary to ensure that the expansion tank is constantly filled with water to approximately 2/3 of its volume, and add water when the level decreases.

In closed systems, membrane expansion tanks are used. Sometimes a membrane rupture occurs in them, and then the system

air gets in. If it can be determined that the cause of airing is a faulty expansion tank, it will have to be replaced. But before starting repairs, before draining water from the heating system, you need to prepare everything you need so as not to leave the house without heat for a long time

The influence of air on the heating system

The functioning of the heating system is based on the circulation of heated water with the release of part of the heat into the radiators to heat the room. If air enters the internal part of the system (the process is called airing), a disruption in the circulation of the coolant occurs. The system responds to airing as follows:

- When the coolant circulates, noises are clearly audible, which not only creates discomfort for residents, but is also a symptom of pipeline vibration, as well as backlash in connections. In some cases, vibrations result in the destruction of welded joints with obvious unpleasant consequences.

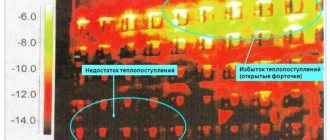

- Air pockets form in the circuits. This happens especially often in non-residential premises where there is no regular temperature control. The result of traffic jams is defrosting the system.

- Deterioration of circulation or its complete cessation. Under conditions of slow circulation, the efficiency of the system decreases and fuel consumption increases.

- The development of corrosion processes as a consequence of air penetration into internal metal parts. The result of corrosion is a reduction in the operating life of equipment.

What signs indicate the need to install an air valve?

In order to prevent air accumulation, heating engineers suggest using an air valve for heating from the very beginning of operation of the circuit, so heating specialists, in the drawn up heating diagram, give recommendations as to which air vent is suitable for a particular heating system.

However, in some cases, trying to save money on the purchase of this type of control valves, owners refuse to install the devices and thereby provoke a number of problems. To solve them, they have to install an air valve for the heating system after the circuit has been connected and connected to the boiler.

The following signs indicate the presence of air pockets and indicate the need to integrate an air vent into the heating circuit:

- uneven heating of batteries;

- the appearance of “cold spots” on the pipeline;

- poor circulation in the heating system;

- noise in heating devices;

- poor-quality heating of the house.

Selection criteria

In order to decide on the type of device, you need to understand what problems the installed ventilation system has, whether it is necessary to increase the flow of fresh air or help the exhaust part of the system. Next, choose whether you need an autonomous or electric type of valve. Aesthetics also plays an important role in choosing the right device. And also calculate your financial capabilities. Wall valves are more powerful than window valves, but they also have a corresponding price. But installing window valves is much easier than installing wall valves.

The most effective type of supply system is considered to be a design with a forced element for the influx of air masses. The components of such a device are the following:

- electric fan;

- filters for air flow purification;

- heating elements.

Such devices have the following advantages:

- ability to work independently of the general ventilation system;

- additional air purification;

- moisture level control.

Design and operating principle

The automatic air valve for heating systems has a simple and reliable design. The hollow metal body is equipped with a connecting pipe, which is located at the bottom or side, depending on the version of the product. In the inner chamber of the device there is a float made of polymer resin. The float is connected by a lever rod to a needle valve that closes the hole in the upper part of the air vent cover.

When removing the plug using a manual valve, you need to control the process in order to shut off the device in time - the air will be completely released when a trickle of coolant flows through the vent. Installing an automatic air vent eliminates the hassle of servicing the heating system.

The operating principle of the device is based on the use of gravity - a hollow float is lighter than water, but heavier than air. In the normal state, the air extractor is filled with coolant, due to which the float is in the upper position, pressing the needle valve. Over time, the coolant is displaced from the internal chamber of the device by accumulating gas.

As a result, the float falls down under the influence of gravity, opening the valve slightly. The accumulated air under the pressure of the liquid in the heating system comes out through the hole in the drain body, and the chamber is again filled with coolant, which raises the float, automatically closing the valve.

Float ventilators serve to remove air pockets and also help speed up the draining of coolant from the system during maintenance or repair work. Due to a decrease in the coolant level in the circuit, the valves automatically open, and the air entering through them causes the liquid to drain faster.

Reasons for airing the system

Air in the heating circuit negatively affects the function and durability of the system. Oxygen reacts with steel and causes corrosion. Air locks interfere with the normal movement of the coolant, blocking the heating of the upper part of the radiators or entire heating devices. The presence of air bubbles in the coolant leads to premature wear of the moving parts of circulation pumps.

Air-filled heating system

There are several reasons for the formation of air jams

:

- Using water from a water supply system as a coolant that has not undergone special treatment to remove dissolved air. When heated, gases leave the liquid medium and accumulate at the upper points of the pipeline and batteries.

- Excessively fast filling of the system with coolant or its supply is not from the lowest point. In such a situation, the liquid does not have time to displace air from all corners of the installed system.

- Loss of system tightness due to installation errors or damage to elements.

- The use of polymer pipes that do not have a barrier coating, which prevents the penetration of oxygen molecules into the coolant.

- Errors when developing a project or arranging a system (incorrectly chosen angle of inclination of pipes, etc.).

- Air entering the system during repairs that require dismantling circuit elements.

Ventilation of the sewer riser

However, I will have to start with a small lyrical digression. To understand why a sewer vacuum valve is needed, you need to have a good understanding of the processes occurring inside the sewer riser.

Full-time job

All risers are brought out by the builders beyond the flat or pitched roof. As with any other vertical pipe, a constant draft occurs in the riser. Foul-smelling sewage fumes are drawn outside the home and dispersed into the atmosphere;

During a volley discharge of water (flushing a toilet tank), a flow rushes down the riser, completely or partially blocking its entire cross-section. The flow forces the air filling the riser into the sewer through an outlet or into the basement through one of the open tees. A vacuum is formed in the upper part of the riser, which is compensated by air suction through the fan pipe - a ventilation outlet on the roof.

Features of operation

Problems with air valve operation occur when the stem or diaphragm becomes stuck in one position. And if this position is “open”, a sewer smell will appear in the apartment or house, and if it is “closed”, the risk of water seal failure increases.

To avoid this situation, the valve must be regularly inspected for malfunctions, and it is important to ensure that the membranes and stems fit tightly and do not become a place for debris to accumulate. The design of aerators is simple, so you can always carry out easy repairs yourself

If a new element has appeared in the sewer system (for example, a washing machine that drains water under pressure), an additional valve must be installed on it. The speed of water flow from the washing machine dramatically changes the pressure in the pipeline, and the old air valve, even if it has worked without failure for several years, may not be able to cope.

When is the only solution to install a vacuum valve?

As a rule, pipes are used to connect the toilet to the central sewerage system, inside of which there are always gases. In any case, a large amount of both cold and hot water is flushed into the sewer, and according to the law of physics, hot steam rises.

To quickly solve this problem, you need to immediately tighten the plug at the end of the riser. To eliminate unpleasant odors, you need to install special water seals. If there is no ventilation on the riser, then due to the powerful flow of water in the pipe, a vacuum is created when the toilet is flushed. As a result of this phenomenon, the contents of the nearby water seal are withdrawn. After some time, an unpleasant smell from the sewer may be felt in the room. To prevent such a nuisance, many experts recommend installing a vacuum valve at the highest point of the riser.

You can decide to install this element by paying attention to the following tips:

- Using a vacuum valve, you can effectively solve the problem associated with ventilation of the sewer riser in a low-rise building. If several toilets are flushed at the same time, the device is unlikely to cope with its intended purpose;

- You cannot independently cut off the vent riser leading to the attic in a house with several floors in order to install a vacuum valve. In such situations, apartments located on the upper floors are unlikely to suffer from unpleasant odors, but on the lower floors the smell of sewage will be clearly felt. One way or another, specialists will identify the cause of the problem, which will have to be fixed at their own expense.

Advantages and disadvantages of the sewer element

The advantages of a vacuum valve include:

- no need to make a special hole in the roof to remove the riser pipe. The roof covering remains intact, while the installation process of the sewage system is greatly simplified;

- the sewer riser ends inside the building, so the appearance of the house will not be spoiled by installing numerous pipes to create ventilation, which are not cheap;

- there is no need to perform periodic maintenance and repair of the device.

The disadvantages include:

- danger of failure due to heavy load on the sewer system;

- The vacuum valve is quite expensive, this is explained by the fact that the device is made by hand.

How does a vacuum valve work and how is it designed?

If normal pressure is observed in the sewer pipeline, this device will be closed. As a result of this phenomenon, protection is provided against the penetration of unpleasant odors and harmful fumes into the room. When a pressure release occurs, for example when a toilet is flushed, the vacuum valve opens automatically, allowing air into the system. During this process, pressure equalization occurs.

Such a sewerage element can be used to create local aeration. To do this, the valve is installed on the pipes of plumbing fixtures, the use of which requires a large flow of water.

In order for such a solution to be as effective as possible, you must follow the installation rules:

- the valve must be installed on the sewer riser above the point of connection of the plumbing fixture;

- installation should be carried out in a well-ventilated room, this could be an attic, a toilet or a bathroom. In addition, access to the device must be provided for periodic technical inspection;

- The vacuum valve should only be installed on the vertical area of the pipe.

This sewer device is a simple shaped part, so it can be attached using a sealant.

The item is supplied with the following parts:

- a plastic body with a side hole;

- a rod that, if necessary, can open a side hole;

- to prevent the rod from moving upward, a special rubber gasket is installed;

- The rod assembly is securely closed with a protective cover connected to the body.

Vacuum valves with diameters of 50 and 110 mm are available for sale. The first option can be installed in houses equipped with no more than two plumbing fixtures or in cases where low water consumption is provided.

Types of automatic air vents

Depending on the manufacturing option, the automatic float air vent can be straight, angular or radiator. Models differ in appearance and installation location, but the principle of air bleed is the same.

Devices with straight connection

A straight air vent is the most popular version of the device, since it is suitable for installation on the upper ends of vertical risers, on underfloor heating manifolds, as part of a safety group, on circulation pumps. Using a tee, it can be cut into a problem section of the pipeline if a small slope angle provokes the occurrence of air pockets.

Design of a direct automatic air vent with a pipe

Radiator and corner models

The corner air vent is designed for installation in hard-to-reach places. For example, due to the pipe located on the side of the housing, the device can be connected to the threaded end of a horizontal pipeline of a dead-end branch of the heating system. If necessary, corner automatic air vents in the heating system can be used instead of straight ones.

Instead of a Mayevsky manual tap, standard corner automatic drain valves can be installed on radiators to remove frequently occurring air pockets from radiators. However, a more rational approach is to use special radiator automatic air vents. This model also has an angular design, but differs from the standard one in its threaded design - it is suitable for connecting the device directly to the radiator, without using an adapter.

Technical specifications

Air vents for heating systems operating in automatic mode have different connecting diameters. Russian heating systems use devices with 1/2” and 3/4” threaded connections. The most common thread is 1/2”, which is also known as DN15 (connecting size is 15 mm).

The following characteristics are also taken into account when choosing:

:

- operating pressure (standard 10 atm, there are models with an indicator of 16 atm);

- operating temperature of the environment (standard up to 110-120°C);

- type of threaded connection - external or internal thread.

Pay attention to the case material. Reliable devices are made from high-quality plumbing brass

Silumin products are characterized by increased fragility.

Technical data of automatic air vent

Any heating system air vent with the required thread type is suitable for a home with an autonomous heating supply.

It is more difficult to select a device for radiators connected to the central heating network - it is important to check with the housing department or other organization responsible for the house the operating parameters of the system

When to install valves on metal-plastic windows

We recommend using window air intake devices only as a last resort, when other methods of organizing air supply are not available. Causes:

- Due to the small size of the flow hole, the ventilation valve for plastic windows does not allow enough air to pass through. Manufacturers claim a throughput of 10...30 m³/h (depending on the type of device), but the figures indicated do not correspond to reality.

- Installing a ventilator valve involves violating the design of the PVC window - removing part of the standard rubber seal or milling a through slot in the frame profile.

- The operation of such an “inflow” is highly dependent on the efficiency of natural exhaust. If the exhaust shaft in the apartment does not work well, the flow of fresh street air will be scanty.

- Through the open channel, insects can climb inside the frame profile and settle there (for example, wasps). You definitely need to come up with some kind of net or cover for the summer.

- The valves often do not have an air filter, and dust will begin to accumulate in the window. Cleaning out this dirt is quite problematic.

Diagram of air movement in a private house with natural ventilation.

Devices for supplying outside air can be window and wall valves, breathers, recuperators. The air flow through the slot valve is easy to calculate. In order for 30 m³/h of air to penetrate into the room at a speed of 1 m/s (this is the maximum for natural ventilation), the flow area of the channel must be F = 30 / 3600 x 1 = 0.0083 m². We use the formula presented in the article on air exchange calculations for a private house.

Now let's compare this figure with the manufacturer's data. For the Aereco E-EMM² window ventilation valve with an increased flow rate of up to 35 m³/h, 2 technological holes measuring 172 x 16 mm are made, the total cross-section of the gap is 2 x 0.172 x 0.016 = 0.0055 m². Then at a speed of 1 m/s we get only 20 cubic meters of air in 1 hour. The performance of valves from other companies (Air-box, VENTS, etc.) is even less.

Conclusion. For natural fresh ventilation, it is better to install a wall valve in each room, located near the window opening or under the window sill. In apartments with poor ventilation, you can use climate control units with forced air injection by a fan - breathers, recuperators.

What problems can an air vent solve?

When moving along the circuit, the coolant chooses the path of least resistance, and since the airy areas are a serious obstacle to the passage of heated water from the boiler, the batteries with accumulations of air mass remain cold or only partially warm up. In addition to the fact that this phenomenon worsens the quality of heating, it also has a detrimental effect on the performance of all elements connected to the circuit.

If the heating system does not use a valve on the heating radiator to bleed air, then the owner can expect the following troubles:

- failure of the boiler as a result of overheating of the heat exchanger;

- corrosion of heating devices;

- low radiator temperature when the boiler is operating at peak performance;

- the risk of defrosting an individual radiator or an entire circuit in severe frosts;

- sudden pressure surges in the circuit, leading to leaks and damage to the integrity of heating devices.

It is worth understanding that air in the circuit is a serious nuisance. You can find out how to get rid of air in the circuit in our article “How to properly bleed air from a heating radiator?” It has different physical properties from water - when heated, it expands more and faster. This leads to serious emergency situations.

Knowing how to properly ventilate the heating system, the owner will protect himself from unnecessary hassle and costs, and will take the level of reliability of the heating circuit to a new level.

How to get rid of an air lock

Unfortunately, the air lock is not always in an easily accessible place. If there are design or installation errors, air can accumulate in the pipes. It is very difficult to get him out of there. First we determine the location of the plug. In the area of the plug, the pipes are cold and a babbling sound can be heard. If there are no obvious signs, they check the pipes by sound - tapping on the pipes. In a place where air accumulates, the sound will be louder and louder.

Any air lock found must be removed. If we are talking about the heating system of a private house, this is done by raising the temperature and/or pressure. Let's start with pressure. Open the nearest drain valve (in the direction of flow of the coolant) and the make-up tap. Water begins to flow into the system, increasing the pressure. It forces the traffic jam to move forward. When air gets to the bleeder, it comes out. Stop feeding after all the air has escaped - the drain valve stops hissing.

This is a security group. An automatic air vent is installed at the middle outlet

Not all air locks give up so easily. For particularly stubborn ones, it is necessary to simultaneously raise the temperature and pressure. These parameters are brought to values close to maximum. You cannot exceed them - it is too dangerous. If the plug does not go away after this, you can try to open the drain valve (to drain the system) and the make-up valve at the same time. Maybe this way it will be possible to move the air lock or get rid of it altogether.

If a similar problem occurs constantly in one place, there is an error in the design or wiring. In order not to suffer every heating season, a valve is installed in the problem area to remove air. You can cut a tee into the main line and install an air vent at the free entrance. In this case, the problem will be solved simply.

Types of air vents

To remove air pockets in the central heating system, drain valves are installed on the outer radiators in each branch. Valve taps make it possible to bleed air displaced to the extreme point of the branch when the system is filled with coolant.

Autonomous heating systems, as well as new radiators connected to the central heating network, are equipped with special air bleed valves. There are two types of devices - an automatic air release valve and a manual valve (Mayevsky valve).

The devices are selected taking into account the principle of operation and ease of use, they are mounted in those places of the heating circuit where the risk of air pockets is greatest - on the upper collector of each radiator, at the highest point of the heating system.

Automatic air vent

The automatic air valve consists of a hollow cylinder with a plastic float inside. The device is installed vertically, its internal chamber is normally filled with coolant, which enters under pressure through an opening in the lower part of the chamber. The air vent is equipped with a needle release valve - it is to this that the float is attached to the lever.

Operating principle of automatic air vent

When an air plug forms in the pipeline, it tends to the highest point of the radiator or the heating circuit as a whole. If an air valve operating in automatic mode is installed in this place, the coolant from its internal chamber is displaced by gases. When the liquid is displaced, the float moves down and opens the valve, as a result of which gases are released from the heating pipeline, and the chamber is again filled with coolant.

Note! The valve for automatically releasing air from the heating system becomes silted over time and becomes overgrown with scale. This leads to jamming of the mechanism, loss of tightness of the valve - moisture begins to leak through it

Such a device requires replacement - automatic air vents cannot be repaired.

The number of automatic air vents depends on the characteristics of the heating system.

Device required for installation

:

- as part of the safety group of the boiler unit at the outlet pipe of the water jacket, where the coolant is heated to the maximum temperature;

- at the highest point of vertical risers - this is where gaseous substances rise and accumulate;

- on the distribution manifolds of underfloor heating so that air can be vented from the circuits;

- on U-shaped loops made of polymer pipes, which are installed to compensate for the thermal expansion of the pipeline.

Manual air vent

A manually operated drain valve is commonly known as a Mayevsky valve. This device has no moving elements, therefore it is more durable and reliable than an automatic one.

The cylindrical body of the air vent is equipped with an external thread. The longitudinal through hole in the housing is closed with a screw with a cone-shaped end. A circular channel extends from the central hole.

The principle of operation of the Mayevsky valve is extremely simple: unscrewing the screw frees the passage into the side channel, thanks to which the accumulated gases escape out through the hole in the body. After removing the air plug, the screw is screwed into place.

Type of manual angle air vent with shut-off cone

Manual air vents in the standard version are designed for installation on the pipeline. But the greatest demand is for Mayevsky radiator taps, which are mounted on sectional and panel-type heating devices.

Review of manufacturers

Automatic air vents for gas release are:

- brass with a polyethylene float that is not subject to oxidation;

- cast iron with epoxy coating;

- brass with nickel coating and polyethylene float;

- made of stainless steel.

Among the companies producing automatic air vents for heating systems, the following brands have gained a good reputation.

- Flamco company from the Netherlands. It produces Flexvent domestic air vent valves. The body of the parts is made of brass; the products are mounted in circuits with a small amount of air masses. Mainly intended for batteries.

- The Portuguese company Adca specializes in valves for the industrial segment and heating circuits. The products are made exclusively from stainless steel and are installed in heating circuits with a maximum coolant temperature of no more than 300 degrees.

- Mankenberg produces high quality air vents. The main difference between air vents from this manufacturer is the ability to be installed in heating systems with various types of coolants, even aggressive ones. Air vents are made of stainless steel.

- produces air bleed valves mounted on water supply, heating and sewage systems. Russian-made devices are currently manufactured for heat supply systems - the KAT12 series, water and sewer circuits - the KAT50 series.

- Armstrong is considered the most sought-after manufacturer of high-end automatic air vents throughout the world.

Installation instructions

The first step is to turn off the water supply riser in the apartment or house. Then select the area where the valve will be located and cut it out with a grinder. Clean the end surfaces of the pipe from nicks.

To ensure a tight seal, a rubber gasket must be placed in the socket (if the installation is threaded, instead of the gasket, use plumbing film). After this, install the aerator and firmly fix it into the riser.

For one apartment, at least 3 valves are required for internal sewerage - one for each consumer.

Aerators must be accessible so that they can be easily inspected and cleaned. And cleaning is needed once a year.

https://youtube.com/watch?v=Nd3e2wF8Ggw

Radiator air vent

Radiator air vent

An automatic radiator air vent is mounted on radiators instead of Mayevsky taps. It is slightly different from the traditional model in size and more expensive. Insertion of the element is necessary in aluminum and bimetallic batteries, where air pockets are constantly formed during the chemical reaction of the metal alloy with the carrier.

Features of installing an air vent in a private house

You will need a wrench for installation.

An air vent designed for heating communications in a private home must be installed strictly in a vertical position. For installation work you will need a threaded tee, FUM tape, and an open-end wrench.

The installation process is carried out in stages:

- Tee fastening. You will need a piece of pipe onto which a tee is fixed by soldering, glue or simple shrinkage.

- Preliminary check of the location of the vent at the highest point of the equipment. The device connection must have an upward direction.

- Installing the shut-off valve on the hexagon of the device using an open-end wrench.

- Connect the automatic air vent so that the protective cap with nipple faces upward.

- Screw the cap tightly to prevent debris from accumulating.

- Checking the tilt of the device (for radiator models). The battery section with the drain rises slightly.

After installation, the devices do not need to be adjusted - they will bleed air automatically.

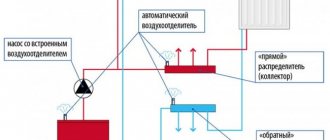

Features of a multi-stage scheme

The multi-stage deaeration scheme provides for the installation of automatic devices along the entire line. Connecting the vents in this way allows you to locally and simultaneously remove air pockets. The automatic device is placed in the zone of rotation, formation of a loop. To extend the service life of the valve, an additional filter is installed. Once assembled, the system operates with the radiator hot at the bottom but cold at the top.

In two-story houses, installation of diverter devices must be carried out on the top floor.

A corner, straight or radiator vent is suitable for the heating main of an apartment building or private building. The automatic device is simple, reliable and maintainable. After installing it, the owner does not have to waste time monitoring the system and manually bleeding air.

Rules for installing liquid shut-off valves

The instructions for installing such fittings often do not cause difficulties even for amateurs.

It consists of 5 main actions:

Personal toilet valve.

- The device cuts into the point of connection of 2 sectors of the pipe or at the point where the sewer pipeline is connected to the plumbing, for example, to the toilet;

- If the fittings are mounted horizontally, then they must be set clearly in level, without distortions;

- The same devices that cut into vertical and inclined systems can be installed at any angle;

Operating principle of a vertical membrane structure.

- When assembling a sewer pipeline, the connecting sockets must be directed towards the movement of the liquid. You need to pull out the pipe sector and insert the valve neck into the socket in its place, then cut off the excess from the pipe you removed and insert it into the valve on the other side;

- At the last stage, the check valve or pipes on both sides directly next to the lock must be firmly secured with clamps to the floor or nearest wall. This should not be neglected, since the operation of such equipment causes slight vibration, which means that sooner or later the connection may depressurize.

As you can see, the instructions for installing a check valve with your own hands are not complicated, but there are a lot of little things that need to be taken into account.

Horizontal valve with two plugs.

- On each check valve, regardless of the model, there is an arrow indicating the direction of fluid movement, so before installing the device, find this arrow;

- It would be a good idea to check the device for leaks before installation. To do this, take the device, pour water into it, like into a glass, from the side through which it should not pass and leave. Typically, leaks are caused by trapped debris or an old gasket;

- The pipe stop must be installed with the same cross-section as the pipe itself. Any adapter greatly increases the risk of blockage, plus these are additional connections, and the fewer of these connections, the more reliable the system;

- And finally, such equipment is installed to prevent emergency situations, which means it must be provided with unobstructed, convenient access in case of cleaning or inspection.

Plastic check valve 110 mm.

The most difficult thing is to install such equipment in multi-story buildings. The ideal option is to install shut-off valves at the entrance to the central riser pipe.

But the thing is that the dimensions of the bathrooms in most of our houses are, to put it mildly, modest, and the valve for a pipe with a cross-section of 110 mm is a voluminous thing. So the owners have to install several personal valves for each drain instead of one capital common valve.

In the literature, I came across a proposal to install a similar lock on the access riser, just below the first floor drain. But this can be justified only if blockages regularly occur not in the riser itself, but in the central sewer well or main line, which, believe me, happens extremely rarely.

Check valve with 90º rotation.

The fact is that installing the valve just below the first floor is virtually useless. Think for yourself, the water does not come from below, the pipe is filled by draining wastewater from the upper floors. If there is a blockage in the basement on the riser, then the system will fill up to the valve, it will close and the system will continue to fill further, which means it will flood the first floor.

Insertion of the shutter into the central drain.

In private houses, as a rule, there is enough space, but there is no point in installing such a valve in a residential area. Flooding can only come from the side of a septic tank or a common central sewer line.

Accordingly, it is better to install the device either in the basement or in a separate insulated well, equipped specifically for installing a shut-off valve.

Design with manual flow blocking.

When installed on drainage system outlets, all outlet pipes must be equipped with locks. In this case, there is enough space in the well and almost any model can be mounted, but here it is better to install valves with floats.

Floats are the same petal system, only a float is connected to the rotating rod of the membrane. When the tank is filled, the float floats up and the valve closes. This process is clearly shown in the video in this article.

Options for metal shut-off valves.

What is an air valve

The air valve for heating is a sealed cone-shaped or cylindrical body made of brass. Inside it is a hollow float made of Teflon or polypropylene. This float is connected by a lever to the drain valve, which is equipped with a locking plug. This plug prevents coolant leakage if the device breaks down.

Air vents for heating systems come in three types:

- Direct devices of traditional type. They are mounted only vertically.

- Corner type devices that are installed at right angles. They are mounted on radiators instead of Mayevsky taps or in the event that a direct type of air vent cannot be installed.

- Special models for installation on radiators.

According to the principle of operation, the air vent can be manual (Maevsky tap) or automatic. The last variety is the float-type devices described above.

Operating principle of manual valve

Let's figure out how a manual air bleeder for a heating system works. To understand the structure of this type, you need to look at the drawing of the Mayevsky crane. At the end of the brass body with external thread there is a hole with a diameter of 2 mm. It is covered by a screw with a cone tip. On the side of the same body there is a hole of a smaller diameter, which is used to bleed air.

The operating principle of a manual air vent is as follows:

- In operating mode of the heating circuit, the shut-off screw is tightly tightened. The outlet is hermetically sealed with a cone.

- To release the air lock, the screw is unscrewed a couple of turns. As a result of coolant pressure, air begins to escape through a small hole, then enters the outlet channel and is discharged outside.

- Moreover, at first only air comes out of the hole, then an admixture of water appears. The tap must be closed when only a stream of water flows from the hole.

Because there are no moving parts to clog, rust, or wear out, a manual air vent is a reliable, trouble-free device. This valve is installed only on radiators.

Manual type valves are divided into the following types according to the method of unscrewing:

- a metal or plastic handle is used for opening;

- More often you can find a slot for a screwdriver with a flat working blade;

- To unscrew it with a special key, there is a screw with a tetrahedral tip.

Operating principle of automatic valve

The automatic air collector for the heating system works without human intervention. It is essentially a vertical brass cylinder with threads and a plastic float inside. The float is connected by means of a lever to the air release valve pressed by a spring. This valve is built into the lid.

The operating principle of an automatic air vent in a heating system is as follows:

- When the heating system is operating, the internal chamber of the device is filled with water, which presses the float up. As a result, the air valve is pressed by a spring and tightly closed.

- When air accumulates in the upper part of the chamber, the level of the coolant decreases, which causes the float to lower.

- When the liquid level drops to a critical value under the weight of the float, the spring compresses and opens the valve. As a result, the air begins to bleed out.

- Due to the increased coolant pressure in the system, all air is displaced from the chamber of the device. The liquid takes the place of the displaced air and causes the float to rise, which pushes the valve up and tightly closes the hole.

While the network is being filled with coolant, air pockets are constantly being bled off, since the float lies at the bottom of the container. When water fills the chamber, a spring mechanism raises the valve. As a result, the bleeding process stops. However, some oxygen remains in the housing under the cover, but this in no way affects the operation of the heating circuit.

Automatic devices come with angular and direct connection. The latter type discharges vertically, and the first - to the side. The corner version is valued for its reliability, but collects air bubbles worse.

Valve or drain pipe

Now let's decide whether a vacuum valve can completely replace a drain pipe.

We will also break this question into two: Is it possible to equip the sewerage system in a private house with a valve instead of ventilation? Is it possible to dismantle the sewer riser on the top floor of an apartment building above the cross or tee with your own hands and install a vent valve instead?

A private house

Installing a valve instead of ventilation is possible, but not advisable. Why?

- There is no escape from the draft created in the risers. The slightest violation of the tightness of the sewer - and the smells of sewage will begin to saturate the kitchen and bathroom. When ventilation is running, any gap between the plumbing fittings and the pipe socket will, on the contrary, draw air out of the corresponding rooms;

- When connected to a central sewer, the drain pipe facilitates ventilation of the manhole through the outlet. In particular, the methane content drops under the lid. The argument is not far-fetched: every year several people die from suffocation in a well;

- If you use a septic tank, its ventilation through the septic pipe will promote the activation of aerobic bacteria and, therefore, better processing of wastewater with a reduction in solid sediment and odors.

Apartment house

I strongly do not recommend disassembling the riser outlet onto the roof. Even with replacing the drain pipe with a vacuum valve. You see, the benefit from such a solution will only be the opportunity to make the cabinet above the toilet a little more spacious; but the righteous anger of the neighbors below, the housing organization and representatives of the municipality will fall on your head.

Why?

The mechanism in brief is:

- After dismantling the drain pipe and installing the valve, the ventilation of the riser will stop, but the draft in it will not go away. Meanwhile, the connections between washbasins and combs in most apartments are leaky. The sudden appearance of amber will arouse the interest of residents on the floors below you and a bunch of complaints to the housing office or management company;

- When a mechanic comes to a call, the first thing he does is inspect the outlet of the vent pipe to the roof. After making sure that it is missing or cut off at the attic level, he will pay a visit to the top floor - to you;

- Based on the results of the inspection of the riser, an act will be drawn up on the unauthorized reconstruction of utilities, affecting the interests of other residents;

- The consequence will be an order to restore the original configuration of the riser with the possible imposition of an administrative penalty.

How the device works

An air valve (or several) is installed in the heating system, in places where air bubbles are most likely to accumulate. This prevents the formation of a large traffic jam and the heating operates uninterruptedly.

Mayevsky crane

Such devices are named after the name of their developer. The Mayevsky tap has a thread and dimensions for a pipe with a diameter of 15 mm or 20 mm. It's structured simply:

- There are 2 through holes made in the body of the valve body, which in the open position of the Mayevsky tap communicate with the heating system.

- These holes are closed by a threaded screw with a conical tip.

- Air is released through a small (2 mm) hole directed upward.

In order to bleed air from the system, unscrew the screw 1.5-2 turns. The air escapes with a whistle as the communications are under pressure. The end of the air plug exit is characterized by a drop in pressure and the appearance of water.

On the market you can find several varieties of the Mayevsky tap, which are identical in design, but differ in the way they regulate the shut-off screw. There are:

- with a convenient handle for unscrewing by hand;

- with a regular head for a flat screwdriver;

- with a square head for a special key.

For an adult, the principle of unscrewing the locking screw does not matter. However, in a house where there are children, it is safer to use devices that should be unscrewed with a special tool. By unscrewing a regular tap with a comfortable handle, a child can be scalded by boiling water.

Automatic crane

The automatic air release valve is designed on the principle of a float chamber, the design includes:

- vertical housing with a diameter of 15 mm;

- float inside the housing;

- a spring valve with a cover, which is connected and adjusted by a float.

The automatic air valve for the heating system operates without human intervention. In normal condition, when there is no air in the system, the float is pressed by the pressure of the liquid filler to the valve cover. The lid is tightly closed.

As air accumulates in the valve body, the float moves down. As soon as it drops to a critical level, the spring valve opens and bleeds air out. Under the pressure of the carrier in the system, the space is again filled with liquid. The float rises, closing the spring valve cover.

When there is no coolant in the communications, the float lies at the bottom of the valve. As the system fills, air comes out of the tap in a continuous stream until the coolant reaches the float.

The following configurations of automatic air valves for heating are distinguished:

- with vertical air discharge;

- with side air discharge (through a special jet);

- with bottom connection;

- with corner connection.

For an amateur, the design features of an automatic crane do not matter. However, for a professional there is a difference in choosing between devices.

It is believed that:

- a device with a jet and a side hole is more reliable in operation than an automatic valve with vertical air discharge;

- a bottom-mounted valve traps air bubbles more effectively than a side-mounted valve.

If the design of the Mayevsky crane has not undergone changes for many years, the design of automatic valves is constantly being improved and supplemented.

Manufacturers offer automatic valves with additional devices:

- with a membrane to protect against water hammer;

- with a shut-off valve for easy dismantling of the device during the heating season;

- mini valves.

Automatic heating air valves require frequent inspection and cleaning. The undoubted advantages of these devices include the ability to install them in hard-to-reach places.

Types of locking mechanism

All existing heating air valves, sewerage or water supply can be divided according to the design of the locking mechanism. The following types are distinguished:

- Rotary. The models are fixed to the pipeline thanks to an insert. A spool or lever is used to control the air flow. When there is a strong influx of air, the spool turns and air passes through. This type is considered safe and reliable.

- Ball. Such valves are convenient for use on small diameter pipes. The mechanism consists of a ball and a spring, they control the flow of water and air. It is appropriate to use the devices on the system in front of the washbasin or shower.

- Lifting. If the apartment has a vertical riser with a wide pipe diameter, then a lifting type of locking mechanism will come in handy. The essence of the work is to change the position of the membrane made of polyvinyl chloride. The flow lifts the device from below, but reliable fasteners prevent it from rising back.

- Wafer. A small wafer-type air valve is mounted using a thread and can be used on plastic or metal water pipes. The flexible membrane is the working part of the mechanism; its position changes under the influence of water flow.

An example of installing a device under a sink.

A large selection of air valves can be found in plumbing supply stores. The buyer must decide in advance what type of product is needed for installation in the water supply, sewerage or heating system.

Design features of air vents

Operating principle of the air vent

The air vent from the heating system is made as a cylindrical or cone-shaped brass body. It contains a hollow polypropylene or Teflon float. The element is connected to the release valve with a special lever.

The drain valve is made with a plastic plug (cap) that prevents water leakage in case of malfunction. During operation, the cap is open, but the user unscrews it.

On the side of the outlet there is a nozzle connected to the body with an O-ring. A holder with a spool is used to lock the nozzle passage channel.

When connecting, an adapter from a check shut-off valve is used in the form of a spring-loaded locking mechanism and an associated flag. At the moment of screwing in, the device presses on the flag, which moves down, and water flows onto the air vent body.

Operating principle

The automatic air vent for the heating system has a very simple operating principle:

- The chamber in working condition is filled with water. The float is on top, the valve with the spring is closed.

- When air accumulates at the top of the chamber, the amount of coolant decreases. The float gradually lowers.

- At the moment the coolant falls to the critical point, the float overcomes the rigidity of the spring mechanism. After this action, the air is vented out.

- Due to excess pressure, water removes air from the container, enters its place and pushes out the float.

- The valve goes into the closed state.

Characteristics of descenders

Manufacturers produce devices that are equipped with multi-apartment buildings or a private house

When selecting a dumper, you should pay attention to the following characteristics:

- Thread diameter - available in ½, ¾ and 3/8 inch versions. Domestic marking of the first is Du-15, the second is Du-20.

- Mounting method - straight and side devices with a top or side outlet valve are used.

- Type of thread - external and internal.

- Operating pressure - air vents for the home can operate at a maximum value of up to 10-12 bar. It is better to choose a 6 bar option for an apartment.

- Coolant temperature limit - for centralized systems, models up to +90 degrees are suitable; in private households it is better to install a product up to +150 degrees.

Reasons for heating heating

There are several reasons for the appearance of air in the heating system:

- the content of dissolved oxygen in water heating pipes, which, when heated, is released in the form of microbubbles, which subsequently form an air plug;

- supply of media too quickly when filling the system, as a result, the air does not have time to bleed;

- air entering the pipes as a result of media leakage (for example, loose connections);

- use of pipes with oxygen-permeable walls in heating;

- the appearance of air jams as a result of improper installation of the heating system and after repairs.

What to do if the heating system is affected by one of the listed troubles? Of course, bleed the air. To do this, an air vent is cut into the system. Let us further understand what an automatic type device is.

Automatic air vent

There are mainly Italian and German models of automatic air vents on the market. These are Caleffi, Pettinaroli, Valtec, Watts, Oventrop and Flamco. The most commonly used air valves are the so-called float valve type.

Design

There is a float in a brass or stainless steel body. A simple hinge mechanism called a “rocker arm” is attached to it at one of the edges. A needle (rod) is attached to the other edge of the mechanism. When the body is filled with water, the needle is in a calm state and the valve remains closed. But as soon as air accumulates in the air vent body, the water level, and with it the float, drops. The needle together with the “yoke” begins to move. When the needle enters the spring-loaded spool, it presses on the rod, which, moving, opens the holes for air release. This is how an automatic air vent works.

In addition to the air valve, which is part of the boiler safety group, an automatic air vent should be installed at the highest point of the circuit. Installation can be done on both vertical and horizontal pipelines. To do this, the manufacturer makes the coolant supply to the air vent both lower end and lower radial. The operating position of the automatic air vent is always vertical.

To be able to remove the automatic air vent without emptying the entire system, its threaded part (G1/2″, G1/4″) is connected to the heating pipe through a shut-off valve.

This simple device consists of a boss with a plastic flap. When the air vent is screwed in, the damper automatically opens, and when unscrewed, it closes.

When installing the air vent, a regular open-end wrench is used; the lower part of the vent body is made in the shape of a hexagon. The air nipple cap must be closed during installation.

Valve malfunctions and solutions

Due to the high salt content of the coolant, the needle may become overgrown with scale and the air vent begins to leak. To clean the vent from scale and rust, unscrew it after first insulating and draining the water from part of the pipeline. If there is a cut-off valve on the fitting, the water is not drained. The valve is disassembled, washed, and the needle is carefully cleaned. During the assembly process, the body parts are sealed together.

To prevent the automatic air vent from becoming clogged, it makes sense to place a mechanical filter directly in front of it.

Very often the air vent is made collapsible. The connection between the body and the lid occurs through a special ring. If it breaks, it causes a leak. It is unlikely that you can buy such a ring at retail. It’s easier to use fum tape or silicone sealant.

If the air vent is mounted deviating from the vertical, it will leak. There is only one salvation - dismantle, plug the fitting and install it strictly vertically in a new place.

The cause of the leak may be a skewed float. It is easy to fix it yourself when disassembling it.

Basic installation rules

You will need a compensating pipe, a clamp, couplings, and a tool for cutting pipes. If the valve is installed in a new sewer, then no tools are needed - everything is done manually.

- shut off the water supply to the system;

- make a cut on the selected section of the pipe;

- remove a section of pipeline that is identical in size to the valve;

- install the air valve and secure it with clamps;

- fill all joints with sealant;

- check the system: open the heating valves and fill the pipes with liquid, checking them for leaks.

Example of device installation

When installing the device in a sewer, it is necessary to connect the water supply and drain the tank several times. The valve is adjusted manually, and if the device is equipped with an electric shutter, the process occurs automatically.

When installing things on their own, many apartment owners make mistakes. For example, they do not clean the joints with the pipe before installation, which leads to accumulations of waste. One of the omissions is the presence of a chamfer, which must be removed before assembling the socket joints. Do not forget that the air valve must be mounted at the highest point of the system.

Source

Features of choosing air vents

Not everyone knows where to start choosing an automatic air vent. In order for the product to serve for a long time and without failure, it is recommended to buy products of European or domestic production, but not cheap Chinese counterfeits. Buying a cheap automatic graduate can cause the following adverse consequences:

- Passing not only air, but also coolant through the valve. In this case, a puddle of water will be detected under the radiators or in the places where the air vents are installed.

- The product is jammed, so it will not work.

- Rapid deterioration.

Although automatic type safety valves have a shorter service life than manual ones, they must serve without fail for at least 10 years. Manual products have a service life of over 15 years, so instead of buying a cheap machine, it is better to give preference to a manual device. This will allow you to win not only in terms of savings, but there will also be no problems with air bleeding.

To choose good quality Mayevsky uranium, you need to pay attention to the following criteria:

- The presence of a handle allows you to conveniently open the valve for bleeding air. The disadvantage of faucets with handles is that they can be accessed by children, who are quite capable of opening them. Installation of such outlets with handles is appropriate only in hard-to-reach places; in other cases, it is recommended to install conventional products with a key or a screwdriver.

- To avoid losing the special bleeder key, it should be placed on the wall next to the radiator. This will prevent you from losing the key, and will also allow you to quickly bleed the air.

- Buy products with anodized coating. This spraying allows you to protect the metal from the occurrence of oxidative processes.

- If your budget allows, you can purchase a product that can trap air bubbles. However, such manual air vents do not differ much in cost from automatic air vents.

In order not to make a mistake with your choice, you need to pay attention to the manufacturer. Depending on the brand of plumbing and heating equipment, not only the quality, but also the cost will differ

In addition, if a closed heating system is used, then you need to pay attention to the technical parameters of the devices, in particular, operating pressure.

How to disassemble

It often happens when using automatic air vents that they begin to leak. In this case, plaque and mechanical deposits appear on the needle-type valve. In this case, the tap closes completely, the coolant flows out, that is, the tap is leaking. It is necessary to dismantle the device, disassemble it, clean the needle itself, the seat and other disassembled parts with a soft tool. With good cleaning, you may not notice such problems until the next time precipitation occurs. To assemble the air vent, it is recommended to use FUM tape as a thread seal, and the body is screwed in by hand.

Installation location and technology

In open systems, air escapes through the expansion tank.

Forced circulation heating circuits require the following measures to remove gas accumulations:

- When laying a pipe with hot coolant from the main riser to remote areas, it is necessary to use a certain lift. An important condition is the coincidence of the movement of the released gas and liquid.

- The highest point of the circuit is equipped with air collectors. The stimulus for the release of dissolved oxygen from water is a change in the direction of flow and a decrease in its speed.

- Installation of air vents for heating should be carried out in areas where gas is most likely to accumulate (risers, separators, combs, etc.). It is also advisable to equip each heating device in a similar way: aluminum batteries especially need this, because aluminum stimulates the process of water decomposition well.