A modern type of fuel that is used for combustion in pellet boilers

Pellets are currently an excellent alternative to gas and other fuels, but many do not know what it is. Heating with pellets is 3-4 times cheaper than gas, but so far the technology for manufacturing such a material does not make it possible to completely replace gas with it. But many people consider pellets as an alternative.

Pellets are considered an environmentally friendly fuel

Crushed wood used to make pellets

One of the characteristics of fuel pellets is the amount of thermal energy released, which affects the cost of raw materials

Wood pellets in a vessel near the boiler create some decor in a modern interior

Pellets: what is it?

Externally, fuel pellets look like cylindrical granules. Wood and agricultural waste is pressed into them. Their standard sizes are:

- Diameter – 6-8 mm.

- Length – from 5 to 70 mm.

- Humidity – 7-10%.

“Loose” granules are convenient when using feeding devices in boiler rooms

Due to this indicator, they are successfully used in pyrolysis boilers. If we compare it with firewood, the efficiency of boilers using this fuel is 1.5 times greater.

But the size of one pellet depends on the material used for production, the type of raw materials and the scope of use.

Note! This type of fuel is actively used abroad, especially for automated boiler houses. Pellets are widely used in both domestic and industrial use. In terms of their thermal conductivity, pellets are compared to coal. In addition, this fuel is environmentally friendly.

Well-dried pellets work more efficiently

Production and sale of pellets in the Moscow region, Russia and Belarus on the map

You can find on the map the manufacturer (supplier) of pellets closest to you or with more favorable delivery conditions. All deliveries occur directly, without our participation and material benefit. Use health information. Pellets from the manufacturer without intermediaries ultimately significantly save heating costs.

Repair of pellet boilers

Repair service for pellet boiler manufacturers: Metal-Fach, BIODOM, FACI, Kostrzewa, Roteks, etc.

Call a specialist: +7(495) 646-04-91

Environmental factor

Buying pellets means maintaining a stable environmental background. They are the result of waste recycling, which means they will not harm the atmosphere or people. It is believed that pellets are part of the CO₂ cycle in the environment, that is, they release exactly as much as the tree absorbed during growth.

In the process of burning pellets, the same amount of carbon dioxide is released as formed during the natural decomposition of wood

Note! Waste is used in production, which means that every ton of such fuel keeps trees in the forest safe and sound. And the environment is not polluted by wood processing waste.

What is very important is that emissions into the atmosphere from the combustion of such fuel are not as harmful as if coal and diesel fuel were burned.

The chemical characteristics of pellets depend on the raw materials from which they are made

Sales on the domestic market

What is typical for our country now is the appearance on sale of inexpensive household boilers that use fuel pellets. In this regard, at first glance it may seem that there will be no problems with the sale of these products. It should be noted that there are certain difficulties in this issue. The fact is that now there are many wholesale warehouses that specialize in the sale of granular fuel. Moreover, many manufacturers have already managed to establish direct delivery directly to the consumer.

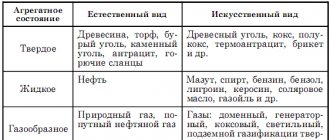

Pellet classification

The price of pellets largely depends on the raw materials used in the manufacturing process. There is such a classification:

Variety of pellets based on raw materials

- White pellets – this variety is also called “premium”. They are made from waste wood without bark. The calorific value of such pellets reaches 17.2 MJ/kg. The ash content is almost zero. Such pellets make up about 95% of all that are on the market today. They are suitable for all types of boilers.

The advantage of white pellets is their low ash content. Cleaning the boiler after such raw materials is necessary no more than once a month

- Industrial - they contain lower quality wood. In addition to wood waste, they may contain bark and non-combustible particles. In terms of calorific value, they are almost the same as the first type, but the ash content is slightly higher. When using them, the boiler will have to be cleaned more often.

Additional elements in industrial pellets make their color a little darker

- Agropellets - they are made from agricultural waste. Their calorific value is lower - up to 15 MJ/kg, ash content is more than 4%. This means that the boiler will have to be cleaned frequently. Among the advantages of such fuel is their affordable price. They are used primarily to produce heat in large thermal power plants. They are also convenient if boilers have automatic ash removal. They cannot be used in all boilers, but only in those designed for such fuel.

An economical option for standard quality fuel, which can only be used in special boilers

Advantages and disadvantages of pellet fuel

- High energy efficiency. Pellets are superior in specific energy intensity to many other types of dry fuel;

- Profitable price. The cost of 1 kW of pellet fuel is lower than the cost of other solid fuel.

- Low ash content. Due to the low ash content of the fuel, there is no need to clean the boiler every day;

- Possibility of automatic feeding. Pellet boilers are equipped with a special storage hopper with automatic pellet supply;

- Ergonomic storage. Packaged pellets take up much less space than firewood. A small room is enough to create a fuel supply for the season.

The disadvantages of fuel pellets include the high cost of pellet boilers. However, every year their prices are gradually decreasing.

Production process

Pellet production is a multi-stage process that requires both material and time costs. But first of all, raw materials are delivered to the plant. Raw materials can be:

- Bark, sawdust, wood chips, and other logging waste.

- Agricultural waste: corn, straw, sunflower husks and others.

Pellets for heating boilers from sunflower husks

The production process consists of the following stages:

- Coarse crushing.

- Drying.

- Fine crushing.

- Mixing and water treatment.

- Pressing.

- Cooling, drying.

- Packaging.

Waste wood chips are used to make wood pellets

Primary crushing

It is also called coarse crushing. During the process, grinding occurs to dimensions of 25 x 25 x 2 mm. This process ensures rapid drying of raw materials to the required moisture content. Since such material is stored on a concrete floor to prevent mixing with sand and stones, it is fed into the grinder using a scraper device.

Shredding wood waste is the first stage in the production of pellets

Drying

Now the raw material has a moisture content of 15%, which is not suitable for the next stages, since it will not be pressed well. And pellets that contain so much moisture are not suitable for boilers. The optimal humidity range is from 8% to 12%, but the correct pellets have 10%. In order to dry the primary crushed raw materials, drum belt dryers are used. The choice of one or another drying method depends on the type of raw material, its quality and other factors.

Raw materials for the production of pellets with inappropriate humidity require additional moistening or drying

Note! This process is energy-intensive, because in order to dry 1 ton of raw materials, at this stage you need to burn 1 m³ of firewood. In order to reduce the cost of this process, bark or sawdust is burned into the dryer firebox.

Secondary (fine) crushing

In order for the press to work, the particle size should not be larger than 4 mm, so repeated grinding is used. For this purpose, hammer mills are used, which are excellent for crushing fibrous shavings and sawdust.

Sawdust prepared for re-crushing

Water adjustment, pressing

Since the raw material was dried in the previous stages and currently has only 8% moisture, it will be difficult to glue it together. To do this, the material is moistened with water or steam. The latter is necessary when pressing hard wood waste. If the raw material is soft wood, then additional moisture is quite enough.

As for pressing, equipment for pellets has different matrix shapes - flat and cylindrical. The diameter of the matrix itself is about 1 meter, and the power is measured at 500 kW.

Presses from some manufacturers do not require additional steam due to their design features

Cooling, packaging

In order to obtain high-quality pellets, they must be well cooled. This process helps dry the granules. After the press they have a temperature of +70-90 ⁰С. After this process is completed, they are sifted and packaged.

Since pellets are loose raw materials, they are often stored in bulk, but this can negatively affect the quality of the material, as it will gain moisture. Therefore, manufacturers package and recommend storing fuel in large big bags. The highest quality pellets that you can buy are packaged from the factory in 20 kg bags.

The packaging of granules depends on the storage system that the consumer has: in bulk, in big bags or in small packages

What are they made from?

Any raw material containing lignin is suitable for making pellets. The most common raw material in Russia is wood, and coniferous species are used more often, despite the fact that deciduous species produce higher quality fuel. The popularity of coniferous species is explained by the fact that the processing of hardwood requires more complex and expensive equipment: almost all hardwoods do not press very well, therefore more powerful equipment is required; it is often necessary to experimentally select the processing/moistening/pressing mode, which takes time and money . Moreover, the cost of pellets when sold on the domestic market depends only slightly on the material.

The raw materials for the production of pellets are any combustible waste

What is the difference between birch pellets and coniferous ones? Birch pellets have a slightly higher heat release during combustion than coniferous pellets, but the difference is small. But when burning birch, there are no resins, which, with prolonged use of pine, settle in the chimney, which requires cleaning it.

Agropellets are often made from straw. Although the heat transfer of such pellets is less than that of wood pellets, they are much cheaper. Among agropellets, granules made from rapeseed straw have greater heat transfer. husk pellets are excellent competitors to brown coal granules. They have many advantages: husk granules are cheaper, their ash content is many times lower, and they emit more heat, and husk ash is environmentally friendly, which is an excellent fertilizer for agricultural crops.

| Specific heat of combustion, kcal/kg | Specific heat of combustion, kW/kg | Cost of 1 ton, $ | |

| Wood pellets | 4100 | 4.7 | 80-125 |

| Straw pellets | 3465 | 4.0 | 75-80 |

| Sunflower husk pellets | 4320 | 5.0 | 75-115 |

Peat granules are a waste-free, economic and environmental type of fuel. But they are used mainly in industry due to their high ash content. The use of peat granules to enhance the effect of mineral fertilizers is also widespread.

Pellets from waste paper are produced using a different technology. Instead of drying, they are moistened and then placed in a pellet press. Due to the nature of the raw material, paper granulation requires more costs.