The heart of the heat supply system is the elevator unit

Today we have to find out how the water supply and heating of a residential building work. The object of the study will be the most popular in Soviet-built houses, which make up more than 90% of the housing stock of our vast and vast land, an open heating supply scheme with the selection of hot water for household needs directly from the heating main.

Which boiler is better to choose

The best option for a single-pipe Leningrad system is a gas boiler. Despite the fact that it must be installed by specialized services, it is small in size, equipped with automation, and fuel is one of the cheapest. There are other options:

| Type of equipment | Characteristic |

| Wood-burning | It is large in size and requires a separate room for installation. Fuel must be manually loaded periodically |

| Carbonic | Has the same characteristics as the previous type. In addition, there is the problem of ash disposal. But coal burns for a long time, so you won’t have to load it often |

| Pellet | It has high efficiency (up to 90%), is small in size, and practically does not form soot. The fuel is environmentally friendly, so it is not very cheap. The bunker is loaded every few days |

| Liquid fuel | The device is economical, automatic, but expensive to maintain. This requires additional installation of a fuel tank or pipeline |

| Electric | This type of energy is expensive, but does not require a chimney and is compact. The disadvantage is considered to be a break in work in the absence of power supply |

You also need to pay attention to the direction of movement of the coolant

Heating systems on two wings

And yet, more often they use a system with a dead-end circuit. And all because the return line is longer and it is more difficult to assemble. If your heating circuit is not very large, it is quite possible to adjust the heat transfer on each radiator and with a dead-end connection. If the circuit turns out to be large, and you don’t want to make a Tichelman loop, you can divide one large heating circuit into two smaller wings. There is a condition - for this there must be a technical possibility of such a network construction. In this case, in each circuit after separation it is necessary to install valves that will regulate the intensity of the coolant flow in each of the circuits. Without such valves, balancing the system is either very difficult or impossible.

Different types of coolant circulation are demonstrated in the video; it also provides useful tips on installation and selection of equipment for heating systems.

Terminology

First, to avoid confusion, let's define the terms.

An elevator or heating unit is a place where the control of the heating system and hot water supply of a house or part of it is concentrated.

- The water-jet elevator is the main element of the elevator unit, a mixing chamber in which warmer supply water is mixed with the return water involved in repeated circulation.

- Suction is a pipe connecting the supply and return in the elevator unit. Through it, the colder water of the return pipeline enters the repeated circulation cycle.

- Bottling (bottling) is a horizontal pipe that supplies coolant from the elevator unit to the risers.

- Risers are vertical sections of the heating system that supply water specifically to heating devices.

- Connectors are pipes connecting the riser to the battery.

So, what specific wiring diagrams for heating systems can be used in multi-apartment buildings? What specific elements do they include?

Elevator unit

The minimum gentleman's kit for a simple elevator unit consists of:

- Pairs of input valves - on the supply and return threads.

- Mud on the supply and, less often, on the return.

- Essentially an elevator with a nozzle and suction.

- House valves that shut off the house heating system.

- A pair of resets allowing the system to be completely drained.

- Control valves for temperature and pressure measurement.

Optionally there will be:

- Warm water supply taps (one or two for each thread). In the second case, to ensure constant circulation through the DHW circuit, the flange between the taps on each thread is equipped with a retaining washer.

- Insertions of individual consumers (trade kiosks, shops, etc.). Here the insert itself is washerd on the flange in front of the shut-off valve; the washer limits the water flow through a separate circuit.

Features of connecting single-pipe heating in a two-story house

In two-story houses, natural air circulation, which is the rise of warm air to the 2nd floor and the flow of cooler air to the 1st floor, is especially pronounced and can create noticeable discomfort. To maintain approximately equal temperatures on different floors of the house, you need to carefully consider the order of connecting radiators and the number of sections in them.

You can, of course, solve this issue more simply: block the connection between the floors of the house with a door on the flight of stairs. However, this can ruin the interior of the house, although such a DIY solution to the problem is quite common.

Scheme of one-pipe and two-pipe heating.

There is 2 options for uniform heat distribution throughout a two-story house, called forced ventilation. However, it cannot be taken seriously, because at the first power failure, the discomfort will return, and such a system will be quite expensive to install and operate.

In order for the temperatures on the floors of the house to be equal or at least become closer, on the 2nd floor, instead of heating radiators, you can install a water heated floor system made of metal-plastic pipes with a diameter of 20 mm.

It is almost impossible to solve the issue of equally comfortable heating of 2 floors, especially with your own hands, but a thoughtful layout of the house and installation of an autonomous heating system will allow you to reduce the difference in conditions. Moreover, a single-pipe heating system is best suited for heating a two-story building.

House heating scheme

It was already mentioned above that most modern houses in cities are heated using a centralized heating system. That is, there is a thermal station in which (in most cases using coal) heating boilers heat the water to a very high temperature. Most often it is more than 100 degrees Celsius!

Water is supplied to all buildings connected to the heating main. When connecting a house to a heating plant, inlet valves are installed to control the process of supplying hot water to it. A heating unit is also connected to them, as well as a number of specialized equipment.

Water can be supplied both from top to bottom and from bottom to top (when using a single-pipe system, which will be discussed below), depending on how the heating risers are located, or simultaneously to all apartments (with a two-pipe system).

Hot water, entering the heating radiators, heats them to the required temperature, ensuring its required level in each room. The dimensions of radiators depend both on the size of the room and on its purpose. Of course, the larger the radiators, the warmer it will be where they are installed.

Power calculation

The effective thermal output of the boiler is calculated using the same methods as in all other cases.

By area

The simplest method is the calculation based on the area of the room recommended by SNiP. 1 kW of thermal power should be per 10 m2 of room area. For the southern regions, a coefficient of 0.7 - 0.9 is taken, for the central zone of the country - 1.2 - 1.3, for the Far North - 1.5-2.0.

Like any rough calculation, this method neglects many factors:

- Ceiling height. It is not always the standard 2.5 meters.

- Heat leaks through openings.

- The location of the room is inside the house or near external walls.

All calculation methods give large errors, so thermal power is usually included in the project with some margin.

By volume, taking into account additional factors

Another method of calculation will give a more accurate picture.

- The basis is a thermal power of 40 watts per cubic meter of air volume in the room.

- Regional coefficients apply in this case as well.

- Each standard size window adds 100 watts to our calculations. Each door is 200.

- The location of the room near the external wall will give, depending on its thickness and material, a coefficient of 1.1 - 1.3.

- A private house, which has not warm neighboring apartments below and above, but a street, is calculated with a coefficient of 1.5.

However: this calculation will also be VERY approximate. Suffice it to say that in private houses built using energy-saving technologies, the design includes a heating power of 50-60 watts per SQUARE meter. Too much is determined by heat leakage through walls and ceilings.

Efficiency of a single pipe system

When developing a project for installing a single-pipe heating system, it is necessary to take into account many factors:

- Is there a constant power supply?

- Possibility of allocating a separate room (boiler room) for equipment.

- How many floors are there in the house?

- Design features and level of aesthetics of the future system.

Each individual situation is characterized by its own specific arrangement of equipment and methods of its switching. It is most practical to equip small premises (for example, a country house) with a simple gravity circuit with sequential switching of radiators directly into the main pipe. Using 2-3 batteries, you can do without a significant amount of shut-off valves: in this case, you can simply drain the water from the system if necessary.

If the building has a large area, a complex heating system with a number of branches is required. In such a situation, the best option would be a forced heating scheme of the Leningradka type. It is characterized by the use of diagonal switching of heat-releasing devices and the presence of adjustable bypasses.

Selection of coolant

The coolant can be water or antifreeze. For a gravity system, it is preferable to use water, since antifreeze has a higher density and less heat transfer; more thermal energy is required to heat it - that is, fuel consumption is higher. If a membrane buffer tank is installed in the system, its volume should be larger than that of the coolant-water tank, since antifreeze expands more strongly.

The use of “anti-freeze” makes sense if the house is heated irregularly in winter with long breaks. In this case, the water would have to be constantly drained to prevent the pipes from bursting when frozen.

Operation of the gravity system

The heating scheme for a private house with natural circulation has a number of advantages:

- there is no need to purchase expensive equipment;

- energy independence (the appropriate boiler unit is selected);

- installation is easy to do with your own hands;

- low maintenance requirements.

Circulation in such a system is ensured due to the fact that the density of the liquid decreases as a result of heating (it becomes lighter), and during cooling the density returns to its original one.

In a gravity-flow design there is practically no pressure - calculations show that per 10 meters of water column pressure the pressure is 1 atmosphere. Thus, the hydrostatic pressure in the heating system of a one-story building will be 0.5-0.7 atm. and in the pipeline of a two-story house - it will not exceed 1 atm.

Gravitational circulation occurs due to the expansion and decrease in the density of the heated coolant - it rises along the vertical acceleration section and from the top point moves down through a pipeline mounted with a slope and passing through series-connected heating devices on its way back to the boiler.

An expansion tank is connected to the pipeline with gravity movement of water - a reservoir for “excess” coolant, which is formed due to the thermal expansion of the liquid. A buffer tank (membrane or open) is mounted at the top point of the circuit on the supply pipe.

The gravity heating system can function in combination with:

- With indirect heating water heater. If the boiler is installed in the upper part of the system below the expansion tank, water for domestic hot water will be heated without the use of electrical equipment. If such installation is not possible, the boiler is equipped with a pump and a check valve is installed, which will prevent recirculation of the coolant.

- With heated floor. A circulation pump is installed on the circuit laid in the floor. If there is a temporary power outage, the room will continue to be heated by the wall-mounted radiator.

Open type

The operating principle is the same as that of the closed version. But in this case, excess coolant is forced into an open tank, which is mounted under the ceiling of the room or in the attic.

An open tank is a tank with a leaky lid, which is equipped with an emergency overflow - a pipe led outside the attic to the street or connected to the sewer.

The disadvantages of an open system include the constant supply of oxygen to the coolant, which accelerates the corrosion of the metal from which the circuit elements are made. Airing of the pipeline also occurs - to avoid this, the radiators are mounted at a slight slope and automatic air vents - Mayevsky taps - are installed in the upper part.

In addition, liquid from an open type tank evaporates and it is necessary to regularly add water so that the open system can function normally. Add water to the tank manually from a bucket, or connect a water pipe with a valve.

The advantages of open-type tanks are their affordable cost and the ability to make a tank of the required dimensions with your own hands.

Central heating system

No one will argue that the centralized system of supplying heat to apartment buildings, in the form in which it now exists, is, to put it mildly, morally outdated.

It's no secret that losses during transportation can reach up to 30% and we have to pay for all this. Refusal of central heating in an apartment building is a complex and troublesome procedure, but first, let's figure out how it works.

Heating a multi-storey building is a complex engineering structure. There is a whole set of drains, distributors, flanges that are connected to a central unit, the so-called elevator unit, through which the heating in an apartment building is controlled.

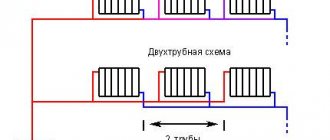

Two-pipe heating circuit.

There is no point in talking in detail about the intricacies of the operation of this system now, since this is done by professionals and the common man simply does not need it, because nothing depends on him. For clarity, it’s better to consider the heat supply diagram to the apartment.

Bottom filling

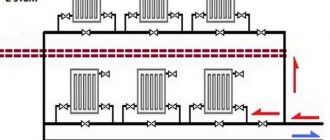

As the name implies, the distribution scheme with bottom filling provides for the supply of coolant from bottom to top. Classic heating of a 5-storey building is installed exactly according to this principle.

As a rule, the supply and return lines are installed around the perimeter of the building and run in the basement. The supply and return risers, in this case, are a jumper between the mains. This is a closed system that rises to the top floor and descends again to the basement.

Two types of bottling in comparison.

Despite the fact that this scheme is considered the simplest, putting it into operation is a troublesome task for mechanics. The fact is that at the top point of each riser, a device for bleeding air, the so-called Mayevsky valve, is installed. Before each start, you need to bleed the air, otherwise the air lock will block the system and the riser will not be heated.

Important: some residents of the upper floors try to move the air release valve to the attic so as not to have to deal with housing and communal services workers every season. Such alterations can be expensive. The attic is a cold room, and if you stop heating for an hour in winter, the pipes in the attic will freeze and burst.

The attic is a cold room, and if you stop heating for an hour in winter, the pipes in the attic will freeze and burst.

A serious disadvantage here is that on one side of the five-story building, where the input passes, the batteries are hot, and on the opposite side they are cool. This is especially felt on the lower floors.

Option for connecting radiators.

Top filling

The heating device in the nine-story building is made according to a completely different principle. The supply line, bypassing the apartments, is immediately carried out to the upper technical floor. An expansion tank, an air release valve and a valve system are also located here, allowing the entire riser to be cut off if necessary.

In this case, the heat is distributed more evenly across all radiators in the apartment, regardless of their location. But here another problem emerges: the heating of the first floor in a nine-story building leaves much to be desired. After all, having passed through all the floors, the coolant reaches downstairs already barely warm; this can only be combated by increasing the number of sections in the radiator.

Important: the problem with freezing water on the technical floor, in this case, is not so acute. After all, the cross-section of the supply line is about 50 mm, plus in the event of an accident, you can completely drain the water from the entire riser in a few seconds, you just need to open the vent in the attic and the valve in the basement

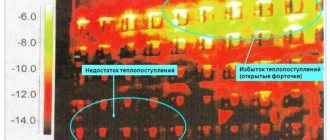

Temperature balance

Of course, everyone knows that central heating in an apartment building has its own clearly regulated standards. So during the heating season, the temperature in the rooms should not fall below +20 ºС, in the bathroom or in the combined toilet +25 ºС.

Modern heating of new buildings.

Due to the fact that the kitchen in old houses is not very large, plus it is naturally heated by periodic operation of the stove, the permissible minimum temperature in it is +18 ºС.

Important: all the above data is valid for apartments located in the central part of the building. For side apartments, where most of the walls are external, the instructions prescribe an increase in temperature above the standard by 2 - 5 ºС

Heating standards by region.

Connection

In double-circuit heating, one of three methods of connecting batteries is used: one-sided, diagonal or bottom. The best method is considered to be a diagonal connection. This way you can achieve maximum heat transfer from heating equipment (up to 98% of the nominal value).

The general diagram of pipe routing and connection of heating devices, boiler and shut-off devices for a one- or two-story house may look like this:

- Despite all the differences between the methods of connecting batteries, they are all used in practice, but with different tasks. In particular, the connection using the bottom method is not very productive, but it is a good option if the pipe needs to be placed under the floors.

- Hidden pipeline installation can also be used in one-sided and diagonal schemes; however, in these cases, large sections of the pipeline will remain visible, which can only be hidden under wall cladding.

- Connecting side-type batteries is practiced when the number of sections is limited to 15 elements - there is almost no heat loss in this case.

Radiator connection options

To know how to properly connect a heating battery, you need to take into account that in addition to the types of pipeline wiring, there are several schemes for connecting batteries to the heating system. These include the following options for connecting heating radiators in a private home:

In this case, the connection of the outlet and supply pipes is made on one side of the radiator. This connection method allows you to achieve uniform heating of each section with minimal costs for equipment and a small volume of coolant. Most often used in multi-storey buildings, with a large number of radiators.

Useful information: If a battery connected to the heating system in a one-way circuit has a large number of sections, the efficiency of its heat transfer will significantly decrease due to weak heating of its remote sections. It is better to ensure that the number of sections does not exceed 12 pieces. or use another connection method.

Used when connecting heating devices with a large number of sections to a system. In this case, the supply pipe, just like in the previous connection option, is located at the top, and the return pipe is at the bottom, but they are located on opposite sides of the radiator. Thus, heating the maximum area of the battery is achieved, which increases heat transfer and improves the efficiency of heating the room.

This connection diagram, otherwise called “Leningrad”, is used in systems with a hidden pipeline laid under the floor. In this case, the connection of the inlet and outlet pipes is made to the lower branch pipes of the sections located at opposite ends of the battery.

The disadvantage of this scheme is heat loss, reaching 12-14%, which can be compensated by installing air valves designed to remove air from the system and increase battery power.

Heat loss depends on the choice of radiator connection method

For quick dismantling and repair of the radiator, its outlet and inlet pipes are equipped with special taps. To regulate power, it is equipped with a temperature control device, which is installed on the supply pipe.

What technical characteristics do aluminum heating radiators have? you can find out in a separate article. In it you will also find a list of popular manufacturing companies.

And about what an expansion tank for closed heating is. read in another article. Volume calculation, installation.

Tips for choosing an instantaneous water heater for your tap can be found here. Device, popular models.

As a rule, installation of the heating system and installation of heating radiators is carried out by invited specialists. However, using the listed methods for connecting heating radiators in a private house, this can be done independently, strictly observing the technological sequence of this process.

If you carry out this work accurately and competently, ensuring the tightness of all connections in the system, there will be no problems with it during operation, and installation costs will be minimal.

The photo shows an example of a diagonal method of installing a radiator in a country house

The procedure will be as follows:

- We dismantle the old radiator (if necessary), after first closing the heating line.

- We mark the installation site. Radiators are fixed to brackets that need to be attached to the walls, taking into account the regulatory requirements described earlier. This must be taken into account when marking.

- We attach the brackets.

- Assembling the battery. To do this, we install adapters on the mounting holes available in it (included with the device).

Attention: Usually two adapters have a left-hand thread, and two - a right-hand thread!

- To plug unused collectors we use Mayevsky taps and stop caps. To seal the connections, we use plumbing flax, winding it counterclockwise around the left thread and clockwise around the right thread.

- We screw the ball valves to the connection points with the pipeline.

- We hang the radiator in place and connect it to the pipeline with mandatory sealing of the connections.

- We carry out pressure testing and test run of water.

Thus, before connecting a heating battery in a private house, you need to decide on the type of wiring in the system and its connection diagram. In this case, installation work can be performed independently, taking into account established standards and process technology.

The video will clearly show you how to install heating radiators in a private home.

Single-pipe heating system with overhead wiring

Types of single-pipe heating with top wiring

In what cases is it important to install a two-pipe vertical heating system with overhead wiring? Most often, a similar scheme is applicable for small houses with an area of up to 100 m². Let's consider an example of organization for the most common system with natural coolant circulation.

Depending on the method of connecting the radiators, the heating scheme with top filling and natural circulation is divided into two types - with parallel and counter movement of the coolant.

Counter scheme

It is characterized by sequential connection of radiators and different directions of water movement in the main and return pipes. In this case, the heating system is single-pipe with overhead wiring, the design of which has a number of features, and is distinguished by the following parameters:

- Inability to adjust the degree of heating in each radiator;

- Dependence of heating of the coolant on the length of the pipeline. The further the radiator is installed from the boiler, the lower the temperature of the water entering it. To normalize the temperature in all rooms, batteries with a different number of sections should be installed;

- Compliance with the angle of inclination of the upper supply line. On average per 1 m.p. the inclination towards the movement of liquid should be 5-7 mm.

An expansion tank must be provided for top filling in the heating system. It is located at the highest point and performs several functions. The main thing is to stabilize the pressure when heating water in the pipes. If an open type tank is installed, coolant can be added through it.

You can increase the water pressure using an accelerating manifold - a vertical pipe installed immediately after the boiler. However, the minimum height of this element must be 3 m, which makes its installation in apartments impossible.

Associated movement of water

Connecting a radiator with bypass piping

In this case, the direction of movement of the hot and frozen coolant is the same. To improve the performance characteristics for the upper and lower heating distribution, experts recommend installing a bypass for each radiator. This is a straight piece of pipe connecting the inlet and outlet pipes of the radiator. The bypass package must include shut-off valves. As an additional control element, you can install a thermostat. In this case, not the entire volume of coolant may reach the battery. Adjustment is carried out using shut-off valves. Such a single-pipe heating scheme with overhead wiring has the following positive qualities:

- Ability to carry out repair work without stopping the system. To do this, the entire water flow is directed through the bypass;

- Installing a thermostat together with a three-way valve forms a system for automatically regulating the degree of heating of the radiator.

However, a heating system with overhead wiring and installed bass is more expensive than an ordinary flow one. This is due to the installation of additional materials and components.

The diameter of the bypass pipe should be 1 size smaller than the main line. In this way, you can avoid a situation where the entire volume of coolant flows through the reserve circuit.

conclusions

- Single-pipe overhead heating distribution is suitable for buildings with an attic space. It does not allow for uniform heating of rooms, but requires lower costs for materials and installation.

- Two-pipe wiring is the choice of owners of cottages intended for permanent residence. Manual and automatic valves guarantee room temperature regulation.

- Bottom routing allows you to disguise pipes in a floor or wall structure.

- The heating network with natural circulation has a limited range of 30 m.

- For multi-story buildings, it is preferable to use a pump. It guarantees the required circulation speed.

- Maximum controllability is typical for the collector system, in which individual radiators can be adjusted and switched off.

The design and installation of heating wiring requires complex engineering calculations, so it is better to entrust the work to specialists. And not for “general profile” builders, but specifically for engineers.

Specialists will select the optimal heating scheme for your home, draw up a project and estimate, and help with installation. The company operates in the Sverdlovsk region.

Installation algorithm

Installation of a two-pipe heating system, regardless of its characteristics, requires the use of the following tools, devices, materials and equipment

:

- tape measure, pencil/marker, building level, plumb line;

- electric drill;

- screwdriver;

- tool for pipeline installation (depending on the selected type of pipe);

- adjustable and gas wrenches;

- pipes (to choose from: metal-plastic, steel, copper, polypropylene);

- heating devices;

- air vents (manual for each battery, automatic for the entire circuit);

- expansion tank;

- boiler piping elements;

- drain valve and check valve for recharging the system, etc.

To simplify installation, an axonometry of the heating system is performed - special drawings are created for the heating circuit on each floor of the house. An axonometric diagram of a heating system implies the location of each element in the drawing along three coordinate axes, none of which is parallel to the picture plane. An axonometric heating diagram allows you to clearly see the relative position of all elements in space. An example of what a heating axonometry looks like can be seen in the figure:

The forced circulation heating system is installed in the following sequence

:

- Installation of the heating unit in a specially equipped place (separate room) with finishing made of non-combustible material.

- Installation of the boiler piping, circulation pump, connection of the distribution manifold, if several heating circuits are provided.

- Installation of heating devices (mounting on brackets to the wall or on stands to the floor). There must be a gap of at least 10 cm between the bottom edge of the radiator and the floor, as well as between the upper edge of the radiator and the window sill for air circulation.

- Laying a pipeline, connecting supply and return pipes to radiators, installing shut-off and control valves, Mayevsky taps and temperature sensors.

- System filling and pressure testing. After checking the circuit for leaks, air is bled from the radiators. Then the system is balanced.

Two-pipe circuit

Design features of a gravity two-pipe circuit:

- Separate pipes are installed for supply and return;

- the supply pipe is connected to each heating device through a separate inlet outlet;

- The return pipe is connected to each heating device separately.

A two-pipe gravity heating system for a private house differs from a single-pipe one in that all radiators are supplied with coolant that has not had time to cool down, due to which:

- heat in the house is distributed evenly;

- there is no need to increase the number of sections in the radiator in order to improve heating;

- it is easier to regulate the temperature in the system;

- installation of the pipeline requires pipes of a smaller diameter than for a single-pipe circuit;

- there are no strict requirements for maintaining the slope when installing system elements - some deviations from the calculated values are not critical.

A two-pipe heating system with upper and lower wiring is easy to install and efficient; it can be used to heat a two-story house.

Single-pipe heating system diagram

Single-pipe heating system: vertical and horizontal distribution.

In a single-pipe heating system, the supply of hot coolant (supply) to the radiator and the removal of cooled coolant (return) are carried out through one pipe. All devices relative to the direction of movement of the coolant are connected to each other in series. Therefore, the temperature of the coolant at the inlet of each subsequent radiator along the riser is significantly reduced after heat is removed from the previous radiator. Accordingly, the heat transfer of radiators decreases with distance from the first device.

Such schemes are used mainly in old central heating systems of multi-storey buildings and in autonomous gravity-type systems (natural coolant circulation) in private residential buildings. The main defining disadvantage of a single-pipe system is the impossibility of independently adjusting the heat transfer of each radiator separately.

To eliminate this drawback, it is possible to use a single-pipe circuit with a bypass (a jumper between the supply and return), but in this circuit, the first radiator on the branch will always be the hottest, and the last the coldest.

Multi-storey buildings use a vertical single-pipe heating system.

In multi-storey buildings, the use of such a scheme allows saving on the length and cost of supply networks. As a rule, the heating system is made in the form of vertical risers passing through all floors of the building. The heat output of radiators is calculated during system design and cannot be adjusted using radiator valves or other control fittings. Given modern requirements for comfortable indoor conditions, this scheme for connecting water heating devices does not satisfy the requirements of residents of apartments located on different floors, but connected to the same heating system riser. Heat consumers are forced to “endure” overheating or underheating of air temperature during the transitional autumn and spring period.

Single-pipe heating in a private house.

In private houses, a single-pipe scheme is used in gravity heating networks, in which hot water circulates due to the differential densities of heated and cooled coolants. Therefore, such systems are called natural. The main advantage of this system is energy independence. When, for example, in the absence of a circulation pump in the system connected to the power supply networks and in the event of power outages, the heating system continues to function.

The main disadvantage of the gravity single-pipe connection scheme is the uneven distribution of coolant temperature across the radiators. The first radiators on the branch will be the hottest, and as you move away from the heat source, the temperature will drop. The metal consumption of gravity systems is always higher than that of forced ones due to the larger diameter of the pipelines.

Video about the installation of a single-pipe heating circuit in an apartment building:

Single-pipe heating system with overhead wiring

In what cases is it important to install a two-pipe vertical heating system with overhead wiring? Most often, a similar scheme is applicable for small houses with an area of up to 100 m². Let's consider an example of organization for the most common system with natural coolant circulation.

Depending on the method of connecting the radiators, the heating scheme with top filling and natural circulation is divided into two types - with parallel and counter movement of the coolant.

Counter scheme

It is characterized by sequential connection of radiators and different directions of water movement in the main and return pipes. In this case, the heating system is single-pipe with overhead wiring, the design of which has a number of features, and is distinguished by the following parameters:

- Inability to adjust the degree of heating in each radiator;

- Dependence of heating of the coolant on the length of the pipeline. The further the radiator is installed from the boiler, the lower the temperature of the water entering it. To normalize the temperature in all rooms, batteries with a different number of sections should be installed;

- Compliance with the angle of inclination of the upper supply line. On average per 1 m.p. the inclination towards the movement of liquid should be 5-7 mm.

An expansion tank must be provided for top filling in the heating system. It is located at the highest point and performs several functions. The main thing is to stabilize the pressure when heating water in the pipes. If an open type tank is installed, coolant can be added through it.

Associated movement of water

In this case, the direction of movement of the hot and frozen coolant is the same. To improve the performance characteristics for the upper and lower heating distribution, experts recommend installing a bypass for each radiator. This is a straight piece of pipe connecting the inlet and outlet pipes of the radiator. The bypass package must include shut-off valves. As an additional control element, you can install a thermostat. In this case, not the entire volume of coolant may reach the battery. Adjustment is carried out using shut-off valves. Such a single-pipe heating scheme with overhead wiring has the following positive qualities:

- Ability to carry out repair work without stopping the system. To do this, the entire water flow is directed through the bypass;

- Installing a thermostat together with a three-way valve forms a system for automatically regulating the degree of heating of the radiator.

However, a heating system with overhead wiring and installed bass is more expensive than an ordinary flow one. This is due to the installation of additional materials and components.

Equipment

So, we are going to install water heating with our own hands. What main elements will our scheme include?

Boiler

Domestic gas heating boilers are the cheapest to operate. In the Moscow region, the cost of heating a 200 m2 house with main gas does not exceed 3,000 rubles per month.

Boilers can be volatile (with electronic ignition) and non-volatile (using piezo ignition and a pilot burner). The former are noticeably more economical - the pilot burner consumes up to 20% of the total amount of gas.

In second place in terms of efficiency are solid fuel boilers. Coal and firewood will be an excellent solution where there is no main gas. However, using solid fuel requires frequent loading: you will have to light the boiler at least twice a day.

There are, however, a number of ways to solve this problem.

- Gas-generating solid fuel boilers split the fuel combustion process into two stages. Initially, it smolders with limited air access, forming flammable pyrolysis gas; then this gas is burned in its own furnace. A gas generator boiler is capable of operating on one load not for 2-5, but for 8-12 hours.

- Top-burning devices use the smoldering of a thin top layer of coal or wood. A coal boiler can operate for up to 5 days without maintenance or cleaning.

- A simple and universal solution is to use a heat accumulator (a thermally insulated container with a volume of 300-2000 liters). Working at full power, the boiler heats the water in the tank after lighting. Over the next few hours, the accumulated thermal energy is gradually released to the heating devices.

Finally, solar and electric boilers differ little in heating costs. They provide the maximum cost per kilowatt-hour of heat. In addition, it is not possible to provide the power required for heating with electricity everywhere.

Estimated heating costs with different heat sources.

Pipes

Their choice is determined by whether we are talking about central or autonomous heating.

The optimal material for central heating is steel pipes of several types.

- Black steel is cheap but susceptible to corrosion. In addition, steel risers and connections require a lot of time and effort for installation. Connections are most often made by welding.

- Galvanized steel is protected from corrosion by a zinc layer; It would be correct to assemble a galvanized liner ONLY on threads. Welding breaks the protective coating, including inside the pipe.

- Finally, a wonderful material is corrugated stainless steel. The pipes are connected using compression fittings with silicone seals and are easy to bend.

Why steel? Because in the central heating system you are not protected from exceeding the design temperature and water hammer. It is better to overpay when installing heating, and not when eliminating the consequences of a dirty boiling water leak.

But autonomous heating means that all parameters are constant and under your control. Hence the choice of materials:

- Metal-plastic with press fittings.

Important: it is better not to use compression fittings with union nuts on heating and hot water. After several heating and cooling cycles, they begin to leak.

- Polypropylene. Preferably reinforced: reinforcement not only increases the tensile strength of the pipe, but also reduces its thermal expansion.

- Cross-linked polyethylene. In addition to strength, these pipes have another advantage: they are flexible and are supplied in coils up to 500 meters long, which is useful for radial distribution with laying pipes in a screed.

This is how cross-linked polyethylene pipes are connected.

Heating devices

And here it is worth separating central and autonomous heating.

In central heating systems, it is better to use steel tubular radiators, steel convectors and bimetallic radiators. Aluminum is not desirable.

And not only from the point of view of strength: the instructions for the use of aluminum radiators specifically stipulate the ability of this metal to accelerate destruction in combination with copper water supply. Metals form a galvanic couple.

Since you can’t know what your neighbors’ eyeliners are made of, it’s better not to take risks.

But for autonomous heating, aluminum radiators are undoubtedly the best choice.

Safety

It is provided by:

- Expansion tank. It accommodates excess coolant during its expansion accompanying heating.

- Safety valve - additional insurance against circuit overflow. The valve is activated and releases excess coolant when its pressure reaches a preset threshold value.

- A pressure gauge or thermomanometer is installed for visual monitoring of parameters.

- An automatic air vent or a manual air vent is mounted at the highest points of the circuits and in air pockets.

Security group installation diagram.