To organize a wood heating system in a private house, it is necessary to install radiators, pipes and stove boilers. In this case, experts pay attention to the following points:

- What area does the house have?

- Boiler power indicators - when choosing, it is necessary to take into account the climate zone, heat loss, windows, doors, etc.;

- Length of pipes and number of batteries used.

To create a boiler room, you need to determine a specific location that will meet all safety requirements. You will also need a dry, closed space in the house for firewood.

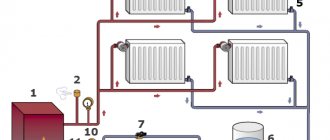

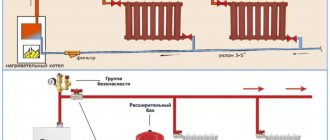

Two-pipe scheme

Two-pipe heating system

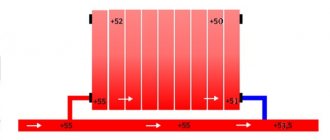

Of all modern heating schemes, the two-pipe one is considered the most efficient. It is based on a closed loop where all the components of the structure are connected. Its operating principle is quite simple: the coolant gradually reaches the desired temperature and begins to spread throughout the battery. Here the process of energy exchange between the liquid inside and the manufacturing material is already taking place. Thus, the coolant completely releases thermal energy and returns to the main boiler. Then the process is repeated. The two-pipe design was created in order to avoid the disadvantages of the single-pipe design. In this case, the equipment includes the work of two main parts:

- A heat supply pipe through which water circulates into the battery;

- To remove heat through which the liquid returns to the boiler.

Due to this scheme, it is possible to achieve maximum efficiency.

Types of two-pipe system

Features of coal combustion

Let's look at how to properly heat a solid fuel boiler with coal. For kindling, wood chips approximately 5 cm thick are used, which must be laid out on paper. You need to put 3-4 logs with a diameter of 10-15 cm on top of the wood chips. After this, you need to set fire to the paper and close the firebox door, as well as cover the ash pan. In this case, the draft must be sufficient to ignite the firewood. If the boiler is equipped with a slide valve, then it is only slightly opened when lighting. If there is a thermostat, then it should be set to a temperature of 70-80 °C.

Coal can be added after 15-20 minutes of intense burning of the logs, when the chimney and the boiler itself are already sufficiently warm. In this case, you need to reduce the temperature set on the thermostat and fully open the gate valve. Before throwing coal, be sure to close the ash pit. The first layer of coal is laid with a thickness of 5-6 cm. After it burns out, a second layer with a thickness of about 15-20 cm is laid. Further layings also have this thickness.

It is also important what kind of coal to heat a solid fuel boiler. When using fine-grained fuel (up to 5 cm), it should be moistened by adding about a liter of water to a bucket of coal. The optimal fuel is large anthracite of a fraction of 6 cm. It does not require wetting. Water is added only if it is necessary to prevent overheating of the boiler.

Making a wood-burning boiler yourself

Making a wood boiler

If you want to make such a boiler yourself, then you need to understand the basic principles of its design. It is based on two containers - one is placed in the other. The internal part is used for the firebox, and the external component transfers heat to the room. The advantages of such a structure are that it works not only on wood, but also on other types of fuel. However, the efficiency here is much lower than in similar types. You need to be prepared for the fact that the consumption of firewood will be significant.

If we consider the structure of pyrolysis boilers, then there are two chambers:

- To load fuel

- For pyrolysis gas.

When installing a water boiler, first of all you need to take care of a strong seal. The firebox, which is placed in a barrel, is a water jacket. If a horizontal pipeline is installed in the system, then the cold pipe is installed lower than the hot one. In another option, the pipes must be placed vertically (a slight deviation is allowed).

When installing a heating system yourself, it is better to place the pipes in a checkerboard pattern. This way you can achieve high efficiency for the entire heating system. In order for the boiler to have a high thermal conductivity, it is necessary to make the equipment from heat-resistant steel.

Difficulty of maintenance

The boiler is designed to distribute heat using a water heating system consisting of pipes and radiators.

The use of a liquid working medium entails the following difficulties:

- danger of leaks, freezing and boiling;

- reduction in the service life of the unit due to corrosion and scale fouling of the boiler tank;

- purchase of expensive components: valves, hydraulic accumulator, valves, air vent, pump, pressure gauge.

The stove heating method, based on the use of a convector, is cheaper and easier to implement. Hot air is distributed through a system of plywood channels with dampers, available for self-production.

Chimneys to which solid fuel boilers are connected must be cleaned of soot annually, otherwise it may ignite. This reduces the service life of the pipe and creates a risk of fire. It is also recommended to clean the inside of the heater from soot, since it plays the role of a heat insulator.

Firewood must be dried to a moisture content of 20%. Raw fuel produces less heat (increases consumption) and covers surfaces abundantly with soot. For natural drying, freshly sawn wood should be stored under a canopy for 2 years.

Heating installation in a private house with a wood-burning boiler

Before starting installation work, you need to know that the heating boiler is directly connected to the finished heating system (this can be natural or forced circulation). There are several important points to consider during installation:

Natural circulation system

Forced circulation

- The installation process must comply with the requirements of SNiP and PPB;

- Compliance with recommendations for the placement of fuel storage. This is due to the fact that in one such season the boiler will burn about 15 cubic meters of firewood, which must be stored under the right conditions

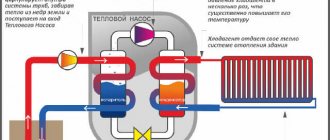

Types of heating systems and units

Which heating system for a country house to choose, which energy carriers will work in the circuit, how to install and use heating, depends on an extensive list of factors. These include existing utilities (gas, electricity, water supply), and the layout of the premises in the house, and the building materials from which the house is built, and the number of residents, and the frequency of visits to the house in winter. Even the type of foundation affects the effective heating of a summer house in winter.

There are several options for heating systems that are offered to the consumer depending on the energy resources that can be used in the house:

- Heating is on gas;

- Heating by electric appliances with or without water heating connection;

- Conventional wood (coal) stove, fireplace;

- Liquid fuel or solid fuel heating units at the dacha in winter;

- Universal heating boilers.

Country heating in a 3-D project

Where can a wood boiler be installed?

A wood-burning boiler with a water circuit can be installed in a place that fully complies with fire and technical safety conditions. However, there are a number of rules that it is advisable to follow when choosing a location:

- Any technical room with a height of at least 2.2 m and an area of more than 8 m2 is suitable. There should also be good lighting and ventilation.

- A basement is suitable as a room if it has heating and there is no humidity. These conditions will help increase the service life of the entire system and its parts.

- Be sure to ensure a solid base for installing the boiler. If the device is made of cast iron, then an additional concrete foundation will have to be poured. The wooden base is additionally covered with a metal sheet, which helps protect the room from fire.

- For convenience, it is better to organize firewood storage in an adjacent room.

- A person must have access to all filtration elements and components if equipment repair is necessary.

When installing a wood-burning boiler, you will also need an electrical connection, so this point needs to be thought through in advance. For safety, you can additionally connect an uninterruptible power supply and a stabilizer. It is recommended to make the connection itself directly through the shield. The chimney must also be installed according to safety requirements, and all heating elements must be insulated.

Wood boiler in a separate room

How to choose the right model

When purchasing, you should be guided by all the information about the features of the models that will be important during operation. From the ability to install in a prepared room to the quality of the wood burned. The choice of a specific model is determined by the following economic and technical characteristics:

- Price. The cheapest are classic designs. They are 2-4 times cheaper than pyrolysis analogues.

- Boiler weight. Steel construction is lighter than cast iron. The heaviest models are some types of pyrolysis boilers. Weight can reach 500 kg. This factor should be taken into account when purchasing. The floor in the boiler room must be sufficiently reinforced.

- Power. It is generally accepted that 1 kilowatt is needed per 10 m2 of area with average energy efficiency of housing. In regions with harsh climates, a correction factor is used. Sometimes it can be up to 2 units. A high level of thermal protection, on the contrary, will reduce the average value. For a “smart home” you can apply a coefficient of 0.5-0.7.

- Material of manufacture. Steel boilers are noticeably cheaper. The metal burns out faster, and the service life of such a device is about 20 years. Cast iron is more resistant to high temperatures and will withstand 35 years of regular use, and it is also more inertial. It warms up slower, but cools down longer, which in some cases is very beneficial.

Domestic wood boilers Source criptopia.ru

Heating schemes for a private house with a wood-burning boiler

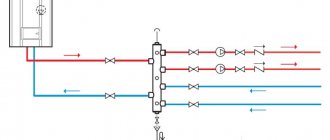

At the moment, there are several ways to install a wooden boiler. First of all, you need to pay attention to the structure and details of the boiler, as well as the features of the room - then you can choose the layout. All schemes can be divided into the following large categories:

- Forced circulation - in this case, the system structure uses a circulation pump, which is the main source of pressure. But here the system is completely dependent on electricity.

- Natural circulation - works due to the expansion of the liquid during the heating process. In this case, the coolant moves independently throughout the structure. However, during installation it is necessary to strictly follow the instructions, which stipulate the dimensions of the slopes and angles. In this case, it is better to turn to professionals.

- Single-pipe system - each battery is connected one after the other. Each radiator receives a water circuit, and then the liquid goes back to the boiler. But what

- The farther the boiler is located, the less heat transfer will be.

- Two-pipe system - the return and supply water supply are connected to one radiator at the same time. As a result, heat is supplied evenly.

When installing a liquid system, it is necessary to draw up a detailed plan, and also comply with all requirements and standards during the work. If we are talking about a two-story house, then you need to approach the wiring with all responsibility and be sure to install a security group.

Heating schemes for a private house with a wood-burning boiler

Heating with solar panels

Absorbing the sun's energy is a popular idea that has lived in people's minds for decades. Modern technologies have made solar panels more accessible; today solar panels are appearing on cottage houses throughout the country. The heating device with solar panels is simple:

- Solar energy is absorbed by the panels, turning into thermal energy.

- Thermal energy is used in room heating systems.

Solar panels are an environmentally friendly way to obtain additional free heat to heat your home or to obtain hot water (which is what they are most often used for). It is worth remembering that the method is applicable when there are a large number of panels involved, depending on weather conditions and the geographical location of the building. Not suitable for residents of northern regions with little daylight. The method, again, is very expensive,

Calorific value of firewood: comparison table of different species

Calorific value of firewood

The combustion process itself is a chemical reaction that involves the interaction of wood and oxygen, resulting in the release of byproducts. The chemical composition and characteristics of each type of wood determines the amount of heat given off.

Wood is based on compounds such as cellulose and lignin. Together they form containers in the form of cells where air and water accumulate. In addition, wood contains various resins, tannins and proteins. A comparative table of the calorific value of various types of wood is presented below.

What is wood moisture content and what does it affect?

Wood moisture content is an indicator that reflects the moisture content in the material. If we look at a specific example, then 100 kg of firewood, where the humidity is 25, contains 75 kg of wood and 25 liters of water. This indicator directly affects the heat generated: the less moisture inside the tree, the more heat it releases during combustion. Thus, several categories of wood can be distinguished by composition:

- Driftwood that contains more than 80% moisture. Usually it stays in water for a long time or is fused - due to this it gains such an amount of moisture.

- Freshly cut wood (moisture content from 45% to 80%) - it usually still contains natural moisture, since the cut occurred recently.

- The air-dry type contains from 20% to 45% - it is pre-dried in an open area.

- Room-dry type of wood (from 7 to 20%) - this type of material is kept in a dry and ventilated place for a long time, so almost all the moisture evaporates (sometimes a drying chamber can be used for this).

- Absolutely dry variety (0%) - in this case the material is thermally treated.

If you need to dry wood at home, then even with the most ideal indicators you will be able to achieve no more than 15-20% moisture. It is possible, of course, to improve this indicator, but the costs will not be recouped. That is why it is not recommended to spend money on special conditions for storing wood.

Build process

The process of creating a boiler includes several stages. When manufacturing each element, it is worth taking into account the special operating conditions of the product being manufactured.

Air supply device

We cut a section from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the firebox. We weld a bolt to the bottom. From a steel sheet we cut out a circle with the same diameter as the pipe or larger. We drill a hole in the circle large enough to pass the bolt welded to the pipe. We connect the circle and the air duct pipe by tightening the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed by a freely moving metal circle. During operation, this will allow you to regulate the intensity of firewood combustion and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical slits approximately 10 mm thick in the pipe. Through them, air will flow into the combustion chamber.

Housing (firebox)

The body will require a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a thick-walled steel cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which the exhaust gases will be removed.

The length of the pipe is selected depending on design considerations.

Connecting the housing and the air supply device

We cut a hole in the bottom of the housing with a diameter equal to the diameter of the air supply pipe. We insert the pipe inside the body so that the air vent extends beyond the bottom.

The air supply pipe should end a few centimeters before the start of the chimney.

Heat Dissipation Disc

We cut out a circle from a metal sheet 10 mm thick, the size of which is slightly smaller than the diameter of the body. We weld a handle made of reinforcement or steel wire to it.

This will greatly simplify the subsequent operation of the boiler.

Convection hood

We make a cylinder from sheet steel or cut a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the firebox (body). You can use a pipe with a diameter of 500 mm. We connect the convection casing and firebox together.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the firebox, if the gap is large enough. With a smaller gap, you can weld the casing to the firebox around the entire perimeter.

From a steel sheet we cut out a circle with the same diameter as the firebox or a little larger. We weld the handles to it using electrodes, wire or other available means.

Considering that the handles can become very hot during operation of the boiler, it is worth providing special protection made of material with low thermal conductivity.

To ensure long burning, we weld the legs to the bottom. Their height should be sufficient to raise the wood-burning boiler at least 25 cm above the floor level. To do this, you can use various rolled products (channels, angles).

Congratulations, you have made your own wood-burning boiler. You can start heating your home. To do this, just load the wood and light it by opening the lid and heat dissipation disk.