House with insulated masonry

Brick is the most common material for constructing load-bearing walls. It is successfully used both in multi-storey industrial construction and in private low-rise buildings. The only drawback of brick is its low thermal insulation qualities. To solve this problem, additional insulation of the walls is carried out. Brickwork with insulation inside makes it possible to build a warm house with minimal investment of time and money.

When are multi-layer walls needed?

Traditional single-layer walls came under great attention from heating specialists around the world with the beginning of the energy crisis in the 70s of the twentieth century. In the USSR, and then in the CIS, this process shifted by 10–15 years. But the most serious shifts in this direction took place in the 2000s. In Russia, standards for thermal efficiency of buildings have become more stringent.

Traditional single-layer walls came under great attention from heating specialists around the world with the beginning of the energy crisis in the 70s of the twentieth century. In the USSR, and then in the CIS, this process shifted by 10–15 years. But the most serious shifts in this direction took place in the 2000s. In Russia, standards for thermal efficiency of buildings have become more stringent.

According to the new standards, to achieve the required thermal insulation characteristics, a single-layer wall must be of the following thickness:

- from ceramic brick (thermal conductivity coefficient - 0.8 W/(m °C)) - from 1.1 to 4.5 m;

- from silicate (0.87) - from 1.2 to 4.8 m;

- from ceramic hollow (0.5) - from 0.7 to 2.9 m;

- foam blocks, with a density of 800 kg/cu.m. m. (0.37) – from 0.5 to 2 m, with a density of 400 (0.15) – from 0.2 to 0.8 m;

- expanded clay 1,800 (0.9) – from 1.25 to 5 m;

- the same at a density of 500 (0.23) - from 0.3 to 1.2 m;

- reinforced concrete (1.8 - 2.1) - from 2.2 to 11.5 m.

It turns out that only from foam concrete with a density of less than 500 kg / cubic meter. m. you can get a “digestible” wall thickness.

If the thermal engineering calculation of the wall shows that a wall made of aerated concrete should be more than 0.4 m, and for hollow ceramics with micropores - more than 0.45 m, then it is cheaper to build houses with two-layer walls.

In addition, single-layer walls have the following disadvantages:

- high humidity of the material, i.e. the thermal resistance of the wall is lower than the design value, and the house is colder;

- irrational consumption of materials, because the thickness of the wall is much greater than that required for its strength.

Therefore, to meet the thermal technical requirements of the walls, you need to use two, three or more layers, one of which will give the wall strength, the second will protect the house from the cold, the third will ensure quick drying of the wall after construction, the fourth will protect from bad weather, UV radiation, or simply make the wall beautiful.

Multi-layer walls are not needed:

- in areas with a mild climate and not frosty winters;

- when materials make it possible to build a heat-saving wall of the required strength and acceptable thickness.

In this case, the following can be used:

- poromaterials: porobrick, aerated concrete, gas silicate, expanded clay blocks, foam blocks, etc.;

- hollow: hollow brick, ceramic, sand concrete, slag concrete and expanded clay hollow blocks, etc.;

- large-format blocks: a) concrete foam blocks; b) composite blocks: wood concrete, sawdust concrete, polystyrene foam concrete, etc.

Exterior decoration of the house - choice of facing bricks

It is difficult to dispute the merits of a brick house. After all, finishing bricks have higher performance characteristics than panels for cladding the outside of a house. It reliably protects the surface of the main wall of the house and the foundation of the building, effectively retaining moisture. Insulation is installed in the gap between the wall and the masonry. Also, the brick easily lays on the cement mortar, giving the building an attractive appearance.

Until now, brick remains one of the most popular facing materials.

When choosing a brick for finishing a private house, pay attention to the following characteristics of the building material:

- correct product geometry and size compliance. For finishing buildings, standard brick with dimensions of 25x12x6.5 cm is used. This is a universal material from which the main wall is made, and the facade is also decorated;

- absence of through cracks in products. You should not buy material with chips and deep cracks. Due to the heterogeneity of the structure, the strength properties of the material sharply decrease;

- clarity of corners and straightness of edges. Products manufactured under production conditions are molded with strict adherence to geometry. This material has a marketable appearance and is easy to install;

- brick color, its compliance with technical requirements. For example, a pale pink tint indicates a violation of the manufacturing process, in particular a violation of the annealing technology. This material is more hygroscopic, fragile and produces a dull sound when struck;

- uniform color range and absence of foreign inclusions. The uneven color of the brick and salt stains on its surface indicate the presence of lime in the brick mixture and an increased concentration of salt. Such a structure not only worsens the appearance of the lined buildings, but also reduces strength;

- water absorption rate. Depending on the type of finishing brick used, the ability of the material to absorb moisture changes. The maximum level of water absorption varies from 8% - for silicate products to 14% - for ceramic bricks;

- degree of frost resistance. The resistance of bricks to negative temperatures is indicated by the Latin letter F and a digital designation in the range 35-100. As the digital value increases, frost resistance increases;

- strength properties. Different types of products differ in strength. The brittle brick of the M25 grade breaks apart after several blows with a hammer. Products marked M50 are characterized by increased strength. High-strength products of the M300 brand are capable of withstanding significant shock loads.

If you cover an old house with bricks, the dilapidated building will turn into a modern and stylish one.

The next serious indicator that you need to pay attention to when purchasing building materials is the thermal conductivity coefficient. It is determined by the design features of the product. Thermal characteristics are also influenced by the properties of the components from which the brick is made. With an increase in the number of internal cavities, the thermal characteristics of the material increase. Solid brick has reduced thermal efficiency.

Finishing work is carried out using various types of bricks:

- silicate This is a common finishing material made from fine sand, quartz, lime, cement and water. After molding, the brick is subjected to autoclave treatment, which determines its characteristics. Silicate material is a budget solution for finishing private houses. The brick is distinguished by its correct geometry, increased density, increased sound insulation properties, as well as a long service life. Buildings finished with sand-lime brick have maintained an attractive appearance for more than half a century. However, the products are characterized by increased weight, increased hygroscopicity and low frost resistance;

- ceramic. It has superior performance characteristics to silicate material and is made from clay by high-temperature firing. It has a characteristic color corresponding to the shades of fired clay. The manufacturing technology involves the addition of coloring pigments that determine the color range of the product. The material is characterized by increased fire resistance. Brick is able to withstand temperature changes and provide effective thermal insulation protection. In addition, ceramic bricks retain their original appearance over a long period of use. The disadvantage is the increased moisture absorption of the material, which requires additional protection;

- clinker It is made from clay by firing at elevated temperatures. The finishing material is distinguished by its density and high strength properties. Clinker bricks are resistant to moisture. The material easily tolerates sudden temperature fluctuations while maintaining its original structure. The outer surface of clinker bricks is not susceptible to the formation of fungal plaque. The advantage of using this finishing material is that there is no need for additional maintenance of the facade of the lined building. The disadvantages include the high price of building materials, as well as the relatively large mass;

Advantages and disadvantages of multi-layer walls

In double-layer walls, the thermal insulation layer is usually installed on the cold side, on the outside.

Most often, according to the recommendations of the Ministry of Construction, new brick walls should be three-layer.

In three-layer structures, a layer of thermal insulation is installed between two layers of load-bearing material of equal thickness. That is, the wall is divided in half and a layer of thermal insulation is placed between the halves. The halves of the walls are “tied” together repeating in 5–8 rows:

- one or two rows of solid brickwork;

- galvanized steel reinforcement ties or meshes;

- continuous reinforced concrete belts – vertical and horizontal.

But more often the outer layer is made of 0.5 bricks from a special facing brick.

There are also other methods, but they are used less frequently.

Advantages of multilayer walls:

- the wall is lighter, because strength is provided by a relatively small amount of material, and thermal insulation, by definition, weighs little;

- highly efficient insulation provides thermal parameters with a reserve, and the facing (outer layer) provides appearance;

- fire resistance;

- simple materials;

- You can build all year round and in winter too, etc.

Disadvantages of multi-layer walls:

- heterogeneity of the average density of the wall material (cold bridges from connections, concrete diaphragms, etc.), which gives different thermal efficiency of the wall in different places;

- highly qualified performers are required;

- ceilings facing the outer surface of the wall provide up to 20% heat loss;*

- load from temperature changes - the concrete of the floors is always warm, and the facing masonry is in the freezing/thawing zone; **

- minor repairs are almost impossible;

- accidental unintentional damage to thin layers is possible;

- the volume of hidden work is large and defects are possible: incorrect or incomplete installation of insulation, incorrect installation of vapor barrier, and many others. etc;

- high labor intensity;

- the cost of a house is more than with two-layer walls, and even more so with single-layer ones.

* When interfloor floor slabs on any type of wall face the outer wall, their steel reinforcement conducts heat much better than dense concrete, although concrete also has high thermal conductivity. Internal voids with a diameter of 130 to 250 mm, filled with air, also participate in this process.

To reduce heat losses:

- the ends of the slabs are covered with standard (design) thermal insulation and external cladding;

- the cavities of the slabs are filled with thermal insulation or foam-aerated concrete liners (at least 0.5 - 1 m). Precast concrete factories can do this on request during the production of slabs.

** When temperature changes occur, the floor concrete, protected from them by thermal insulation, has slight changes in size, while the entire facing masonry is under the influence of these changes. In the zone of their contact, crumbling of materials and gradual destruction are possible.

Required tools and materials

Tools for construction

Before you start laying brick walls with insulation, you need to prepare a drawing that indicates the relative position of the elements, the main dimensions and distances. You also need to stock up on enough insulation. You can use the table of thermal conductivities of basic materials. The higher the value of this parameter, the thicker the insulation layer should be.

You will also need the following tools to carry out the work:

- reinforcing mesh;

- container for mixture;

- waterproofing from rolled bitumen materials;

- construction anchor bolts;

- level;

- putty tool;

- trowel;

- plumb line

It is necessary to stock up on bricks for the construction of the wall structures themselves. With three-layer masonry, the façade part is made of special facing grades.

Choice of insulation

A wide range of insulation materials that meet the recommendations of SNiP can be used as a heat-insulating material.

Firstly, the thermal conductivity of the material must be such as to ensure protection of interior spaces at the maximum minus values typical for a given region.

You can familiarize yourself with the thermal insulation properties of insulation in the manufacturer’s instructions on its packaging or in the technical specifications tables of SNiP. By comparing these indicators with winter minimum temperatures, you can calculate the required thickness of the insulation layer.

Secondly, the insulation must have sufficient vapor permeability. Otherwise, moisture will accumulate inside it, which will lead to its loss of thermal insulation qualities.

And thirdly, the internal insulation must be fire resistant. Due to its non-flammability, it will not only not support combustion, but will also create a fire-retardant layer inside the masonry.

Mineral wool

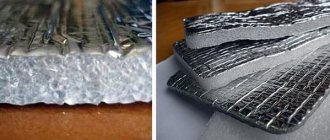

Mineral board

A large family of insulation materials based on mineral fibers have excellent heat-saving characteristics. They are made by churning molten minerals in a centrifuge: glass, basalt, slag, etc. The low level of heat transfer in this case is achieved due to the high porosity of the material - air layers do not allow cold to penetrate through the mineral wool.

Mineral insulation is absolutely not flammable, but is very susceptible to dampness. When wet, it almost completely loses its heat-saving properties, so when laying it, care must be taken to ensure effective waterproofing.

Thermal insulation layer in masonry

In principle, any insulation can be used as a heat insulator, but experts recommend giving preference to basalt wool. Thanks to its high resistance to moisture and low thermal conductivity, there will always be a comfortable microclimate in the house. The optimal density is 140 kg/m3.

Expanded polystyrene and mineral wool are also used in three-layer masonry, but it must be taken into account that the first material has low resistance to fire, and the second - to moisture. These factors predetermine the safety of the structure in non-standard situations during operation. Polystyrene also does not allow vapor to pass through well, that is, it interferes with normal air circulation, which, if there is insufficient ventilation, provokes the development of mold and mildew in the home. Eliminating shortcomings takes a lot of nerves and money; it’s easier to think through everything at the stage of building walls.

According to the installation rules, the heat-insulating layer is installed as closely as possible to the load-bearing wall. This will prevent the formation of so-called open zones.

Requirements for insulation for interior work

When choosing a heat-insulating material, you need to take into account not only its heat-saving ability. The following qualities are important:

- ease of installation;

- environmental cleanliness;

- non-flammability;

- no harmful emissions when the temperature rises.

With a small area of the insulated room, slab material 50 mm thick plus a ventilation gap will lead to a smaller room. In this case, it is permissible to use penofol, which combines the functions of insulation and vapor barrier.

Important! the foil surface of penofol works to reflect thermal radiation only if there is a gap between the insulation and the finish.

Sequence of wall cutting work

To make an opening for a door in the wall at home, you will need a grinder as a tool. To carry out larger-scale work, such as remodeling doors, windows, partitions and the entire home, you cannot do without a stone-cutting machine.

In addition to the grinder, we prepare for work:

Grinder device for cutting bricks.

- a hammer drill equipped with a crown cutter of any size;

- chalk;

- ruler;

- cutting wheels;

- roulette

We begin work by marking the future opening with chalk. It should look like the letter T, that is, the crossbar should protrude onto its frame. A beam is inserted into it, which will support the upper masonry. For partitions, a strip of wood is used, semi-load-bearing walls are reinforced with 50 mm thick boards, and beams made of reinforced concrete or metal are used in the load-bearing brick wall.

If a window or door frame is to be inserted into the hole, it must be larger in size than the units being inserted. After securing the latter, the gaps should be filled with foam. It will act as both insulation and fixative.

Let's look at how a wall cut is made along a brick wall with varying degrees of complexity. Let's start with a partition that is 1/2 or 1/4 brick deep. We equip the grinder with a disc with a diameter of at least 250 mm and coated with diamond coating.

Covering window and door openings.

Using a grinder, an incision is made according to the markings. To make it easier to knock out bricks, several holes are cut with a hammer drill. As soon as the first elements of the brickwork pop out, things will go faster by taking a chisel, hammer and hammer drill to help. Only it will need to be re-equipped: instead of a crown, a chisel is inserted, switching the operating mode, eliminating rotation.

If you do not have a core cutter, then a thick drill bit can replace it. It can be used to drill out masonry units, drilling them in several places and along their seams. Using the same drill, we then help to pull out the filling of the opening.

In order to avoid jamming the door or the appearance of cracks in a thin wall or partition, you need to take a timber beam with a thickness of at least 50 mm for the crossbar. Fix it in the opening and treat it with cement mortar very tightly, eliminating the possibility of backlash.

A load-bearing wall will require more complex processing, but the feature of obtaining a hole is the same as for thin partitions. For the crossbar, a channel is used - an I-beam. The opening must be reinforced with vertical posts; for them it is recommended to take 50 x 50 mm profile corners; instead, a 40 x 20 mm profile rectangular pipe will do. A metal strip is selected for the screed.

Marking an opening in a brick wall.

The difficulty of working with a load-bearing wall is explained by the fact that it has complex masonry - bricks and filler. But you need to start work in the same way, by marking the future opening and marking it with a grinder. As soon as we have removed part of the interior in the upper part, we wedge an I-beam there and place vertical supports from corners or pipes, rigidly fixing the beam. This is a very important moment. Any defect will cause subsidence of the ceiling and the possibility of endangering the lives of workers working on the site.

Only after the channel is securely fixed can you continue to knock out the hole. First, the sealant is removed, and then the bricks. If you can access the back side of the wall, then the task will be easier. Using a long drill, horizontal through holes are first made. Markings are made along them on the reverse side, the outline is cut and the material is removed. At the same time, it is necessary to tighten two vertical supports forming the letter P with a metal strip.

Thus, using the rules, you can make a cut into the wall.

//www.youtube.com/watch?v=HTHQ4YIjE6s

I-beams and flat angles are more expensive, but they will ensure the reliability of the hole.

Technology of insulation and wall cladding

In order to insulate the walls outside a building, it is not at all necessary to be a professional builder, the main thing is to strictly follow the recommendations.

Preparation of tools and materials

The choice of materials for home insulation is dictated by the local climate. Having decided on the insulation, you can choose tools - it could be a square, a building level, a trowel, a toothed trowel, etc.

Preparing the wall

Before starting work, it is necessary to prepare the facade for installation. To do this, the masonry is cleaned of dust and dirt, it is also necessary to seal the cracks and, if necessary, level the surface of the masonry. After this, we treat the facade with a primer.

Pre-cleaning of the facade

It is necessary to take care of the leveling of the walls because after installing the insulation, the resulting voids in place of the cracks can become a place for deformation of the insulation - a small mechanical impact is enough for this. Also, it will not be possible to tightly glue the insulation onto the pits and tubercles.

Wall insulation

The technology of three-layer masonry with insulation and facing bricks contains the following steps:

- We lay out the inner wall - there is nothing complicated about it, since the masonry technology is the same as the masonry of any load-bearing wall. For it, either aerated concrete blocks or solid brick are selected. The thickness to the straight line depends on the minimum winter temperatures in the area and can be either 1 or 1.5 bricks.

- The next stage is laying out the outer wall with cladding. It is performed in such a way that a gap is formed between the walls - heat-insulating material is inserted into it. If granules are used, wells are formed for them. For strength, the walls are connected to each other with connections made of reinforcement and die-cuts. Alternatively, you can make a brick dressing at certain intervals.

- Waterproofing is an important step that will protect the insulation from moisture, which inevitably penetrates the brick layer. A thick film or roofing felt can be used as an insulator against moisture.

- Backfill thermal insulation material is poured into a niche as soon as the height of the wall reaches 1 m. If roll or sheet facing insulation is used, it is attached to the inner wall - for this, “mushrooms” with a large-diameter plastic cap are used. Having secured the insulation, we cover it with external facing masonry.

- For normal gas exchange, it is necessary to leave ventilation vents every 0.5-1 m - this is the name for the vertical seams between bricks, which are deliberately not filled with mortar.

As practice shows, three-layer masonry allows you to achieve several results at once and significantly improves the operation of the building in winter.

You can do it yourself, but it is better to turn to professionals, since errors in the technical process will negate all the advantages of this option for facade insulation.

Disadvantages of masonry without insulation

More recently, the issue of thermal insulation of brick buildings was solved in a simple way - by increasing the thickness of the wall. Thus, for the middle zone, the usual wall thickness was 3 - 3.5 bricks, and in the northern regions it could reach 1 - 1.5 m. This is due to the high thermal conductivity coefficient of the brick, which causes large heat losses.

Comparative analysis of materials

Laying walls of such thickness was a necessary measure in the absence of effective and inexpensive thermal insulation materials. Another factor promoting the use of “thick wall” technology in Soviet times was the relative cheapness of bricks. This made it possible to simplify masonry technology by eliminating the use of thermal insulation materials.

However, recently this approach has become too wasteful from a financial point of view: in addition to the cost of bricks, the costs of arranging reinforced foundations are increasing.

Another problem that you may encounter when installing brickwork without thermal insulation is a shift in the dew point indoors.

In construction, the dew point is the point inside or outside the outside walls of a building where the cooled vapor contained in the air begins to condense. The transformation of steam into dew occurs when warm air comes into contact with cold surfaces.

The location of the dew point for different wall designs.

The most preferable option is to locate the dew point outside the building, in which case the condensing moisture will simply evaporate under the influence of wind and sun. It is much worse if the dew point is shifted indoors. Dampness that forms on the inner surfaces of walls negatively affects the microclimate in the house, becoming a source of increased humidity and the cause of the appearance of fungus and mold.

During winter frosts, walls that are not insulated are cooled to their entire thickness, as a result of which steam condensation occurs on their internal surfaces.

In areas where sub-zero temperatures are established in the cold season, the technology of laying bricks with insulation is the only acceptable one.

Brick insulation options

The insulation of a brick house is attached in two versions: on the outside and on the inside. Although it is worth noting that internal insulation is less effective than external insulation and is used less frequently. But there are options when only this will do. If your exterior decoration is made of facing material, this can also include clinker tiles, then internal insulation is mainly chosen.

Attention: For any insulation, the brick must be properly waterproofed. Otherwise, all the work will be done in vain and you will not achieve the desired result.

Let's look at when each type is used:

External insulation

This option solves the main problem, which is saving heat to the fullest. In this case, you avoid the appearance of dampness in the room and the formation of fungus. When choosing this option, all work consists of the following steps:

- Application of adhesive material;

- Application of thermal insulation;

- Application of a reinforcing layer;

- Application of facing material.

Now let's look at what we achieve by using it:

Positive aspects Negative aspects

|

|

Internal insulation

Insulation for brick walls in this option is most often installed. This especially applies to multi-storey buildings. In this case, the work will be much cheaper. But there are also negative sides.

Thermal insulation protection

Some insulation materials require protection from getting wet, blowing or, for example, direct sunlight. Some of these tasks may be assigned to the finishing layer, but the main protection is provided by special membrane materials.

One of the most commonly used insulation materials in Canadian frames, stone wool, has the ability to sharply reduce the resistance to heat transfer when wet. The source of moisture can be precipitation or condensation of water vapor. In the first case, special synthetic burlap is used that allows air and water vapor to pass through, but retains water droplets.

The penetration of steam from the inside cannot be completely limited, because the building must carry out natural gas exchange with the environment. However, it is possible to limit the amount of water vapor to such a level that it is not enough to raise the relative humidity in the cooled indoor air to 85–90%. Typically, such a calculation is carried out for the point of separation of the rows of a frame or supporting system with external insulation. However, the same method can also be used to calculate layer-by-layer the dew point displacement throughout the year inside homogeneous walls.

Products

In the case of a system with an air gap 2-5 cm wide, for its ventilation, vents (holes) are installed in the lower and upper parts of the wall, through which vaporous moisture is removed outside. The size of such holes is taken at the rate of 75 cm2 per 20 m2 of wall surface.

The upper ventilation ducts are located at the eaves, the lower ones at the plinths. In this case, the lower holes are intended not only for ventilation, but also for water drainage.

- Air gap 2 cm

- Bottom of the building

- Top of the building

To carry out ventilation of the layer, a slotted brick is installed in the lower part of the walls, laid on its edge, or in the lower part of the walls, bricks are laid not close to each other, but not at some distance from each other, and the resulting gap is not filled with masonry mortar.

What construction forums discuss on this topic, and what reviews and recommendations they give

Having looked through various construction forums, it cannot be said that there is a consensus on the question - is it possible to cover a house made of timber with bricks without consequences? Many forum users are convinced that a brick-lined house made of timber will not lose its properties and longevity. Main:

The only bewilderment among people is the very fact of covering the timber with bricks.

- Construction stores offer a large assortment of facade materials that are less expensive and do not require much effort or skill. But the timber wall itself looks complete. You don't have to do any cladding. Exception: ordinary timber. Profiled and glued have a beautiful texture and refined appearance. Why then build a wooden house and then line it with brick? You can immediately build a house from brick or other available material other than wood.

- It is necessary to take into account the fact of shrinkage of the wooden structure and inter-seasonal fluctuations of the walls. Will a lined house be able to cope with the process without cracks in the brick wall. The foundation and brick wall must follow the movements of the log house.

- Cladding a house made of timber is only required if the house is old, there are cracks, and the wood looks unsightly. It is not possible to correct shortcomings with less expense. Then you can use brick.

- Calculate the costs needed to cover the timber with brick. Are they worth the result? To complete all the work on lining a house on one floor, you will need at least 300,000 rubles, maybe more. It depends on where you live and the square meters of the house. There are alternative methods for less money.

It is better to try to restore a house made of timber to its previous appearance using sanding, caulking of walls, and paints and varnishes for wood. Brick is good, but if the initial choice was made in favor of wood, is there any point in covering it up? Decision is on you. Situations are different and require an individual approach.

Making connections

The inner and outer parts of a three-layer brick wall are connected to each other by special embedded parts - ties. They are made of fiberglass, basalt plastic or steel reinforcement with a diameter of 4.5–6 mm. It is preferable to use connections made of fiberglass or basalt plastic due to the greater thermal conductivity of steel connections.

These connections also perform the function of fastening the insulation boards (the insulation is simply pinned onto them). They are installed during laying into a load-bearing wall to a depth of 6-9 cm in increments of 60 cm horizontally and 50 cm vertically at an average rate of 4 pins per 1 m2.

To ensure a uniform ventilated gap over the entire area of the insulation, locking washers are attached to the rods.

Often, instead of special connections, bent reinforcing bars are used. In addition to ties, the outer and inner walls of the masonry can be connected with steel reinforcing mesh laid at 60 cm vertical intervals. In this case, additional mechanical fastening of the plates is used to create an air gap.

The insulation boards are installed with the seams bandaged close to each other so that there are no cracks or gaps between the individual boards. At the corners of the building, gearing of the slabs is created to avoid the formation of cold bridges.

Mistakes to Avoid

Unscrupulous builders can take advantage of the fact that the owner does not understand anything about construction, so they violate masonry technology. This leads to cracks appearing on the walls, the finishing falls off, and mold and mildew form inside the insulation, spreading to the inner and outer walls. An inexperienced owner who does everything with his own hands can make the same mistakes.

Here are some of them:

- The elements are laid crookedly, unevenly, with a large deviation in the seams, with a small amount of mortar, not level, or in places where the roof goes obliquely - instead of trimming the bricks, simply lay the bricks along an inclined line.

- Laying out the basement or corners with hollow bricks. As a result, moisture will instantly enter the building through the holes. Plus, such a brick simply will not withstand the load and will crumble in the near future, and with it the house.

- Using low-quality bricks. A material that contains a lot of lime will lose some of itself over time, i.e. pieces of brick will fly off from it in wet weather, and water will begin to get into the voids.

- Lack of clearance for ventilation, as a result of which condensation accumulates in the wall, the walls freeze and become damp.

- Poor filling of seams. Using a mortar that is too thin or too thick will prevent the brick from being securely fixed in place. Because of this, the strength of the wall decreases. And if the mason turned out to be dirty, the terribly sealed seams will ruin the entire appearance of the wall and it will have to be plastered (even if this was not planned).

Masonry technology with insulation

- Laying the facing layer up to the tie level

- Installation of the heat-insulating layer so that its top is 5-10 cm higher than the facing layer

- Laying the load-bearing layer to the next level of connections

- Installing connections by piercing them through the insulation

if the horizontal seams of the load-bearing and facing layers of the wall in which the ties are placed do not coincide by more than 2 cm in the load-bearing layer of the brickwork, the ties are placed in a vertical seam

- Laying one row of bricks in the load-bearing part of the wall and the facing layer

Characteristic features of brick walls

In its properties, brick differs from other building materials. It is worth noting the following:

- Bricks can be either full or hollow - the choice of material directly depends on operational factors: the average temperature in the region, the load on the foundation, the chosen thermal insulation option.

- The format of the brickwork is also taken into account. The most common option is solid masonry, this method is the simplest. A more complex option is well masonry - in this case, so-called air pockets are made of bricks, and it is in them that the insulating material is placed.

- Alternatively, thermal insulation material can be installed between two layers of building material. This multi-layer structure consists of a load-bearing wall made of foam blocks, a layer of thermal insulation and a facing layer - the air space between the thermal insulation and the facing layer ensures the necessary air circulation.

- Since brick has good sound insulation properties, additional sound insulation for a brick facade is not needed.

Material options

Seal the cracks and prepare the sheathing

If the wall is severely damaged, it is repaired. Before insulating a brick house from the outside, it is important to inspect the walls. If cracks are found, it is important to seal them so that cold bridges do not form. This is done with stone sealant, cement or other natural materials.

When the option with a ventilated facade has been chosen for insulation, the sheathing should be prepared. It is attached to the wall at a distance of the width of the insulation so that the slabs can be laid evenly in the created space. Using a building level and a plumb line, the sheathing is aligned around the perimeter.

Preparatory activities

Before installing insulation between the block and the brick, preparation must be carried out. After purchasing and calculating the material, it is important to collect the following tools and consumables:

- brick;

- masonry mixture;

- mesh for reinforcement;

- material for thermal insulation (concrete, crushed stone);

- insulation (foam plastic, penoplex);

- plaster for brick cladding;

- trowel;

- putty knife;

- plumb line;

- building level;

- solution container;

- anchor.

Main stages of installation

Do-it-yourself insulation of a private brick house from the inside begins with installing sheathing to match the size of the slab material. When insulating EPS or EPS, you can use wooden blocks or guides for drywall, installing them at a distance corresponding to the width of the insulation boards. For mineral wool, the distance between the sheathing elements is calculated by subtracting 1-2 cm from the width of the material for a more dense installation of the insulation. If PPS or EPS is chosen as thermal insulation, after installing them it is necessary to foam the cracks, if any. After installing the expanded polystyrene, you need to secure a layer of vapor barrier along the sheathing, gluing the seams with special tape.

Important! Ordinary tape, even double-sided tape, is not a substitute for vapor barrier tape .

When working with extruded polystyrene foam, a vapor barrier is not required. Mineral wool insulation also requires a layer of vapor barrier. The final finishing can be lining or imitation timber. Before installing the wooden planks, it is necessary to secure the counter-lattice for the ventilation gap. When finishing with plasterboard, a ventilation gap is not required.

Note! Penofol can be used as a vapor barrier.

Methods of external insulation

- Insulation with polystyrene foam and expanded polystyrene can be done in two ways: laying tile insulation in the cells of the frame or gluing the slabs directly to the wall. A detailed algorithm for insulating a house with EPS is described in the article “Step-by-step instructions for thermal insulation of a log house with polystyrene foam.” Thermal insulation with foam plastic is carried out in a similar way.

- Thermal insulation with polyurethane foam (PPU) is carried out by spraying using professional equipment.

- Installation of thermal panels is quite simple. Each element is provided with a “groove and tenon” type fastening. First, a starting profile is installed on which the elements are laid, joining them to each other. After final installation, the space between the wall and the panels is filled with foam.

- When laying mineral wool, installation of lathing is mandatory. The material strongly absorbs and accumulates moisture, which causes a decrease in its thermal insulation characteristics. The frame installation method allows you to make a ventilation hole between the wall and the insulation, as well as install a hydro- and vapor barrier layer on both sides of the insulation. Detailed instructions for installing mineral wool can be found in the article “Features of external insulation of a house with mineral wool.”

What is written in SNIP about this

The regulatory document regulating the construction of the reinforcing layer, namely SNiP 3.03.01-87 “Load-bearing and enclosing structures”, has the following points:

- When reinforcing masonry of external walls and columns, the thickness of the seam should be no more than 1.6 cm, and exceed the sum of the diameters of the reinforcement at the intersection by at least 4 mm. When laying transversely in walls and piers, the mesh must consist of at least two rods in width. And it should protrude beyond the outer edge of the wall by 2-3 mm.

- Partitions may not be reinforced if they are not secured with temporary fastenings, and have a height of 1.5 m and a thickness of 9 cm. With a thickness of 12 cm, the height should not exceed 1.8 m.

- With longitudinal steel reinforcement bars are connected by welding. If it is not used, then the rods end with hooks and are tied with wire. The rods overlap and each end should not be shorter than the sum of 20 diameters.

Calculations of the thickness, diameter and size of mesh cells are determined from the standards given in SNiP II-22-81 “Stone and reinforced masonry structures”.

Standard length, width and thickness of bricks

Since bricks have their own standard dimensions (6.5 x 12 x 25), the thickness of the brick wall will have several standard dimensions, taking into account the thickness of the seam between adjacent bricks.

There are other sizes, but they mainly differ in height, and the height of the brick does not affect the thickness of the wall.

Standard dimensions of a brick wall

| Number of bricks, pcs | Wall thickness, cm |

| 0,5 | 12 |

| 1 | 25 |

| 1,5 | 38 |

| 2 | 51 |

| 2,5 | 64 |

In addition to the thickness of 65 mm, there are brick thicknesses of 88 mm - one-and-a-half bricks and 138 mm - double bricks. Those. sizes 8.8x12x25 and 13.8x12x25. In general, the thickness (height) of the brick does not in any way affect the thickness of the brickwork.

The main criterion when choosing the thickness of a brick wall is the purpose and location of the wall itself.

Types of reinforcement

Reinforcement on brickwork can have different locations:

- longitudinal;

- transverse;

- vertical.

Reinforcement mesh is purchased in a store or made independently at a construction site before laying.

Longitudinal reinforcement of brickwork

To strengthen the building under lateral loads and bending, longitudinal reinforcement is used. In this case, the mesh is installed quite rarely; mainly steel rods, corners, strips, and wire are installed. The reinforcement is placed in a longitudinal position when laying enclosing structures and partitions. Elements of the reinforcing layer can be located on the inside or outside of the wall.

Preparation for finishing

After installing and protecting the insulation, it is time to equip a load-bearing subsystem for ventilated cladding or a surface for finishing with a wet facade. In the latter case, wind and water protection of the insulation can be provided by a layer of plaster finishing and/or paint.

Installation in both cases follows different schemes. To ensure the necessary strength of the sheathing for the installation of panel materials, the installation step of the frame racks is chosen in advance quite often. After temporarily securing the waterproof membrane with staples to the frame ribs, it is lined with spacer slats about 25–30 mm thick. In this case, space is provided for drainage of water that gets inside and ventilation. If desired, the junction of the slats can be sealed with fresh oil paint or mastic.

Frame house wall pie: 1 - internal OSB cladding; 2 - vapor barrier; 3 - insulation; 4 - wooden frame; 5 - superdiffusion membrane; 6 — counter-lattice; 7 - facade finishing (siding, lining, block house)

When constructing a continuous sheathing for plastering work, sheet materials are used that serve as an excellent vapor barrier. A high concentration of moisture can provoke condensation of droplets, to remove which ventilation is provided between the waterproofing and the sheets. The sheets, in turn, prevent the insulation from blowing through.

Plastering the walls of a frame house: 1 - internal OSB cladding; 2 - vapor barrier; 3 - wooden frame; 4 - insulation; 5 - superdiffusion membrane; 6 — counter-lattice; 7 — external OSB cladding; 8 - basic plaster; 9 — plaster mesh; 10 - decorative plaster

In some cases, the external cladding system is mounted on top of sheet materials. This decision may be made due to the high dew point offset range. The possible formation of condensation in the ventilated layer does not pose any particular problems when using moisture-resistant sheets. However, in this case, the connection to the base and cornice has a more complex structure.

Brick is one of the strongest and most durable building materials today. And this despite the fact that the construction market is replenished every year with the latest technologies that could not have been dreamed of before. Brick walls will most likely never go out of fashion, thanks precisely to their strength and durability, proven over many decades. What should be the optimal thickness of a brick wall at home? We'll talk about this further.

Advice from professionals

Professionals know the secrets of their craft and are ready to share them with those who insulate the house themselves:

- When choosing insulation, its thickness and installation method, calculate the energy efficiency of the wall pie in accordance with the climate zone.

- When installing the sheathing, control the work with a building level. A leveled sheathing will make it easier to install the finishing touches.

- Use dry lumber.

- Having purchased compressed mineral wool, unpack it a day before installation.

- Follow the manufacturer's recommended vapor barrier overlap.

- Tape the foam joints with aluminum tape.

- Follow the material manufacturer's recommendations.

Internal insulation of the walls of a brick house using vapor barrier materials prevents the removal of moisture from the room. Take a carbon dioxide level measurement. Exceeding the standard indicates low efficiency of the ventilation system.

Main types of insulation and their brief description

Organic heat insulators on the market are represented by a wide range

They are based on materials of natural origin:

- Arbolite insulation is considered the newest material, which is based on sawdust, shavings, uncut straw and reeds. Also, the insulation is made of cement and organic additives. These are CaCl2, H2SO4, as well as the product obtained after processing ordinary clay, kaolin or nepheline, and Na2O.

- Foam-polyvinyl chloride insulation. It consists of polyvinyl chloride resin, which, after exposure to light or electromagnetic vibrations, acquires a characteristic foam structure. At the same time, it is considered a universal heat insulator.

- Chipboard insulation. Components - shavings, resin obtained as a result of controlled chemical processes, antiseptics, fire retardant.

- Insulation with a fiberboard base. It resembles chipboard in its own way. The base is wood waste, or trimmed corn and straw stalks. The material may well also consist of compressed old paper.

- Polyurethane foam is based on polyester, it includes H2O, an emulsifier and isocyanates. When catalysts begin to act, all elements interact as a result of a chemical reaction, in which a new type of insulation appears.

Minvata

This concept includes the following varieties:

glass wool, as well as stone wool;

slag wool

All these materials are characterized by corresponding fibers, which are based on glass, rocks, and slag.

Averages:

- thermal conductivity – 0.041-0.044 W/(mK);

- impermeability – 20-200 kg/m3.

IMPORTANT! Before deciding whether to insulate a brick facade with this material, you must take into account that it is prone to excessive moisture absorption. Therefore, it is additionally treated with special chemical materials.

Mineral wool

Styrofoam

An oversized material, which, due to its characteristics and affordable price, has become the most popular material for thermal insulation. In the construction market you can always find a copy whose average indicators are:

- thermal conductivity – 0.033-0.037 W/(mK);

- impermeability – 11-35 kg/m3.

Foam plastic is practically free from moisture, plus it is vapor-proof. In addition, the material is quite fragile, easily flammable, and during smoldering it releases many dangerous chemical elements. This material has many disadvantages, but it is ideal as an economical option.

Styrofoam

Extruded polystyrene foam

In terms of its characteristics, the material resembles the foam plastic described above, only there is one difference - exclusively the latest developments are used in its production.

Averages:

- thermal conductivity – 0.028-0.032 W/(mK);

- impermeability – 25-38 kg/m3.

It is often used for external insulation; it is quite strong and retains heat well. Naturally, its cost is several times higher than that of the two options discussed above.

Warm plaster

It is distinguished by sound insulation and vapor permeability.

Characteristics:

- thermal conductivity – 0.065 W/(mK);

- impermeability – 200-340 kg/m3.

This is an ideal insulation material for cladding the external wall of a brick house, but requires special conditions due to its characteristics:

- layer of plaster no more than 50 mm;

- the foundation must be further strengthened.

Plaster

Inorganic heat insulators

Mineral wool comes in two types: slag and stone. To produce the first, companies use slag. Stone wool is distinguished by: CaCO3, rocks that are used for paving streets, minerals containing calcium and magnesia, volcanic rocks and others.

Which three-layer wall design to choose

For regions with cold winters, in the case of using vapor-transparent insulation mineral wool or aerated concrete 100 kg/m3, the presence of a ventilation gap in the wall is mandatory to ensure its normal condition.

In this case, the ventilation gap remains open under the roof, and in the lower part of the wall for air supply, the vertical joints between the bricks are left unfilled; slotted bricks are used, so that the area of the holes is at least 75 cm2. for 20 square meters. masonry

Mineral wool with a density of up to 80 kg/sq.m. must be covered with a windproof superdiffusion membrane, which prevents air from blowing through its layer. The membrane and layers of wool are secured with 10 pcs disc-shaped dowels. per sq. m. into a load-bearing wall.

EPS, aerated concrete, erected using glue, in accordance with the recommendations above. Additional fixation is usually 3 - 5 plastic dowels per square meter.

In a three-layer wall, it is recommended to use a masonry mesh that binds all layers (and brick cladding). In this case, the vertical installation step of the mesh is 500 - 600 mm, according to the size of the insulation board (smaller possible). If fiberglass connections are used, their number should not be less than 4 pieces. per square meter, and the horizontal installation step is no more than 500 mm., near openings, at corners, the installation spacing of connections is reduced to 8 pcs. per sq. m.

The brick cladding is reinforced with masonry mesh with a vertical pitch of no more than 1.2 meters, with the mesh inserted into the load-bearing wall.

Doors and windows are located along the depth of the wall opposite the insulation-load-bearing wall boundary. In this case, better heat savings are achieved at the openings, and the risk of glass fogging is also reduced.

Recommendations for cladding

Brick lining of aerated concrete blocks is a complex job consisting of three stages, which are worth considering in more detail:

- Pouring the foundation.

- Selection of bricks.

- Formation of brickwork.

Laying the foundation

This is the main point that needs to be thought through initially, i.e. even before construction starts. Here it is necessary to take into account three nuances: the width of the gas block, insulation and brick for cladding. A prerequisite is that the cladding should not hang over the edges, i.e. the width of the foundation should be the sum of the three above components.

Brick selection

The aerated block must be lined with brick, mounted to its width, in other words, to half a brick. The manufacturing material can be hollow, clinker, solid and silicate. Most often in practice, clinker or hollow bricks are used. The first method is much more expensive, but it also has many positive qualities:

- high compressive strength;

- Clinker frost resistance is much better than ordinary facing brick;

- attractive appearance;

- low water absorption (5%) compared to conventional bricks (about 13%).

Brick laying

The final stage of cladding, which includes several stages with many important points. To reliably protect the foundation from condensation, you should lay it on a layer of rolled waterproofing. The remaining rows are placed on a pre-prepared mortar so that the seams in the previous row are densely filled. For masonry you will need a metal rod with a diameter of 0.8-1 cm. Place it outside. A similar rod is used to create a vertical seam.

The mortar is laid out on the formed row and the next brick is laid. When moving the row, do not forget to move the rod along it.

Remember that reinforcement is required for several rows. For shaping, a synthetic mesh is suitable, which can be cut into strips 8 cm wide. As the solution hardens, it may be necessary to undo the seams. First, they are filled with a solution, and after its formation, jointing is done using a special tool.

conclusions

Nowadays, low-density autoclaved aerated concrete is replacing mineral wool, due to the fact that it is more environmentally friendly and durable.

The use of aerated concrete insulating panels in a three-layer wall lined with brick and a load-bearing wall made of heavy materials seems optimal. But with this insulation it is advisable to create a ventilation gap, since the material itself is susceptible to moisture.

The use of heavy materials for load-bearing walls eliminates problems with moisture accumulation in the thickness of the wall. A load-bearing wall made of high-density aerated concrete must be protected from the inside with a vapor barrier for any two- or three-layer wall design.

It is better to use mineral wool boards of high density, from 80 kg/m3, without a windproof membrane, which is also a “weak link” in the structure, given its inseparability.

You can reduce construction costs and reduce wall thickness if you use expanded polystyrene for insulation without ventilation. gap They also have a lower thermal conductivity coefficient, they can be used in a thinner layer, which will ultimately result in a thickness savings of up to 5 - 8 cm. Additional savings are laying facade bricks on the edge, with a layer thickness of 6 cm. But this requires an increase in the number of connections.

The use of low-density polystyrene foam and mineral wool in a three-layer wall seems to be an unjustified saving.

Mineral insulation - low-density cellular concrete

Recently, another type of insulation has been gaining popularity - products made from low-density cellular concrete. These are heat-insulating boards based on materials already known and used in construction - autoclaved aerated concrete, gas silicate.

Thermal insulation slabs made of cellular concrete have a density of 100 - 200 kg/m3 and a dry thermal conductivity coefficient of 0.045 - 0.06 W/mOK. Mineral wool and polystyrene foam insulation have approximately the same thermal conductivity. Slabs with a thickness of 60 - 200 mm are produced. Compressive strength class B1.0 (compressive strength not less than 10 kg/m3.) Vapor permeability coefficient 0.28 mg/(m*year*Pa).

Thermal insulation slabs made of cellular concrete are a good alternative to insulation made from mineral wool and expanded polystyrene.

Well-known brands of thermal insulation slabs made of cellular concrete in the construction market: “Multipor”, “AEROC Energy”, “Betol”.

Advantages of thermal insulation slabs made of cellular concrete:

Products for construction and repair

⇆

The most important thing is higher durability. The material does not contain any organic matter - it is an artificial stone. It has a fairly high vapor permeability, but less than mineral wool insulation.

The structure of the material contains a large number of open pores. The moisture that condenses in the insulation in winter dries quickly in the warm season. There is no moisture accumulation.

Thermal insulation does not burn and does not emit harmful gases when exposed to fire. The insulation does not cake. Insulation boards are harder and mechanically stronger.

The cost of insulating a facade with cellular concrete slabs, in any case, does not exceed the cost of thermal insulation with mineral wool insulation or expanded polystyrene.

When installing heat-insulating slabs made of aerated concrete, the following rules are followed:

Thermal insulating slabs made of aerated concrete up to 100 mm thick are attached to the facade using glue and dowels, 1-2 dowels per slab.

A wall made of slabs more than 100 mm thick is laid close to the insulated wall. The masonry is laid using glue with a seam thickness of 2-3 mm. The masonry of insulation boards is connected to the load-bearing wall with anchors - flexible ties at the rate of five ties per 1 m2 of wall. A technological gap of 2-15 mm can be left between the load-bearing wall and the insulation.

It is better to connect all layers of the wall and brick cladding with a masonry mesh. This will increase the mechanical strength of the wall.

Insulation of a brick house: 4 suitable materials

By insulating a brick building, you change the appearance of your home. Such a brick building, like a house, has the ability to retain heat, but without insulating the roof walls and so on, there is no way to save on heating. And if you are the owner of your own home, then you are faced with the task of making your home a cozy environment and giving it comfort. This applies to houses built of brick. It is very difficult to choose a material for insulation, since there is a huge range of insulation materials on the market. We will figure out how to insulate a house, what material to use, and how to achieve minimal heat losses.

Production nuances

The main task in the production of clinker panels is the reliable joining of the outer ceramic layer with the insulation.

If polyurethane insulation is used, the production process includes the following steps:

- foaming of polyurethane foam occurs;

- clinker tiles are laid in aluminum molds;

- the tiles are covered with sandy quartz or marble chips (to protect the insulation from the sun in the joints);

- some manufacturers provide metal or polymer fasteners for installation;

- freshly foamed insulation composition is poured.

After hardening and cooling, the panel is released from the mold and sent to the finishing shop to be shaped to the required size in accordance with the standard.

Sometimes manufacturers use oriented strand boards to create the structure of the thermal panel pie and impart rigidity to the panel on the insulation side. Then such panels will be three-layer.

When the insulation is extruded polystyrene foam, the clinker panel production technology is somewhat different.

In production, ready-made polystyrene foam boards are used, which go through complex stages of high-precision cutting to the shape required for installation. Using powerful adhesives, polystyrene foam is glued to clinker.

IMPORTANT! When producing boards with expanded polystyrene, a technique is used to ensure closed perforation, which ensures the necessary vapor exchange.

This technology is only available to large manufacturers who can afford expensive equipment.

Stages of work

First of all, before insulating the walls of a house internally, it is important to know that the dew point will change - the place where moist air turns into condensation. Consequently, if you choose the wrong material or its thickness, then such insulation can worsen the condition of the walls: mold, mildew, or destruction of the partition will appear

Consequently, if you choose the wrong material or its thickness, then such insulation can worsen the condition of the walls: mold, mildew, or destruction of the partition will appear.

Before starting work on wall insulation, certain rules must be followed:

- Remove old coatings to the base of the surface, clean, remove possible formations of mold or mildew.

- Treat the wall with an antiseptic and primer solution. At the same time, give each coating a chance to dry.

- When using polystyrene foam, plaster the surfaces with the placement of beacons, which will allow for a more even plane. Allow to dry for at least two days.

- Laying the material.

- Finishing the wall.