The ventilation system is one of the elements that are present in almost every building. Few people even think about this part of the house. If the project is created with high quality, then it will provide comfortable conditions for people to stay inside for a long time. The damper for ventilation is an important part of this particular design. But what is he? This issue is discussed below.

In fact, a gate valve is a type of valve that blocks the flow of air, in full or in part.

operating principle of the gate

The principle of operation is also characterized by maximum simplicity - the same as that of conventional oven dampers. When the process of igniting the fuel begins, the damper is open. The blower is the starting point, then the air goes to the pipe, and the movement is powerful. This part is closed when combustion enters the active phase. This is necessary so that the fuel does not burn out instantly at such a moment. Complete closure of the valve occurs after the end of decay at the last coal. All that remains is a gap with minimal dimensions.

Stove valves become a kind of regulators for draft. They control the speed and intensity with which air flows through the chimney. Ventilation dampers are based on the same operating principle. This device increases or decreases the current of air jets. There are two additional functions:

- The resistance of air flows is equalized.

- Adjusting the transition from the main part to the branches.

Installation of gate dampers is acceptable for air ducts made of any materials; plastic analogues are no exception.

The main classification involves the presence of retractable and rotating products. Any of these types may include rectangular or round dampers. It is better to study the characteristics and features of specific designs in advance in order to understand which solution will be optimal.

Rotary throttle

rotary butterfly valve

Rotary valves are not as widespread as the previous version. The operation is based on a rod, which is located in the center. A metal sheet is installed on it with rotation around its own axis. Due to this, the space is regulated and blocked if necessary.

This is a simple design that can be made on your own without any problems. But the moving part of the mechanism cannot boast of high reliability. Periodic replacement is required, which involves additional costs.

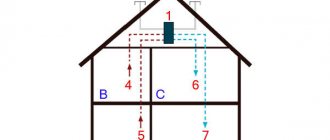

gate diagram

For installation, the socket and flange method is used. The differences lie in the fastening elements, which become relevant in each case.

Installation features

In most cases, the ventilation damper is installed immediately before the fan outlet. If their location coincides, then the design is called a starting gate, then its task is to protect the fan power unit from overheating.

You need to understand that you need to start the fan only when the damper is in the closed position. Otherwise, it will be affected by additional load, which in turn will quickly lead to failure of electrical equipment.

Important!

If you decide to install a damper in a ventilation system with a direct chimney with your own hands, then you need to know that it is quite difficult to carry out maintenance and cleaning of such a design in the future.

Like any other design, a gate valve has its own installation features. There are two main ways to install it:

- pipe-to-pipe method - the mechanism is installed in the chimney due to its design, this principle does not imply the use of additional fasteners;

- the shut-off device is mounted in front of the chimney exit or in the stove, respectively, becoming part of the overall structure; in this case, the maximum height at which the damper can be located cannot exceed one meter.

There is also another method of installing the gate - flange. When using it, you need to pay attention to two factors:

- fasteners that secure the smoke exhaust must be located at a short distance from the gate; they cannot be installed together with the main mechanism;

- all fasteners must be located exclusively on one side of the flange;

- During the installation of a flange type connection, additional sealing must be provided.

Using stove valves allows you to protect yourself from carbon monoxide poisoning. Information about the method of preserving heat in a stove is passed on from generation to generation. Everything is very simple, while the flame is burning - the damper should not be completely closed. Once the fire has gone out, the gate can be closed completely.

The valve, however, like any other mechanism, the creation of which does not necessarily require specialized tools, can be made independently without any problems. To do this, it is enough to have minimal theoretical knowledge and basic work skills.

Required materials and tools

Independent production and installation is impossible without the following devices at hand:

- Markers.

- Compass.

- Roulette.

- Kern.

- Welding with electrodes.

- Vise.

- Pliers.

- Hammers.

- Tap and oil to lubricate the threads.

- Drill.

- Cutting and grinding abrasive wheels.

- Bulgarian.

manufacturing a gate

It is necessary to have a sheet of stainless steel of the domestic brand 12×18n10t. It is acceptable to replace it with an imported analog AISI304. The cost is higher, but the service life is also longer.

The minimum sheet thickness is 1.5-2.5 mm.

Other materials you will need:

- Rod for a metal frame.

- 2 bolts 8 mm.

- 6 mm stainless steel tube.

Types of ventilation dampers

Modern production offers the most diverse range of valves designed for use in ventilation systems. However, the entire existing set of gate types can be grouped into several categories:

| Category | Types of valves |

| Form | Round, rectangular |

| Design | Retractable, rotating |

| Control type | Manual, electric, pneumatic, hydraulic |

| Installation method | Installation in socket, installation using flanges |

| Material | Stainless steel, alloy steel, chrome steel |

We recommend that you familiarize yourself with: Ventilation through hole in the wall

The shape of the dampers is determined by the shape of the ventilation shaft - most often round valves are used, but in some cases rectangular valves are needed:

- There is a need to hide the gate while ensuring the minimum possible use of space.

- When installing ventilation systems that use electric heaters, since they themselves are predominantly rectangular.

Size calculation

Even an extra gap of a few millimeters can be the cause of improper operation of the air vent.

Step-by-step steps to resolve the issue are as follows:

- First, take a tape measure to measure the size of the internal channel.

- 20-30 mm is added to the result. The result is the size of the outer frame.

- An opening for gas release is required for the finished valve.

- The position for the welding holes is also marked as accurately as possible.

Often this design is installed where the fan outlet is located. If you perform a complete installation of the valve and fan, a monolithic structure is formed, which can also be called a starting valve. It serves to prevent the ventilation damper from overheating.

installation of a gate valve

Structural differences

Modern design solutions in ventilation damper models require not only the ability to pull them out/retract, but even install them at a certain angle. The simplest option is a regular retractable gate. It is installed along an axis perpendicular to the movement of the air flow. The use of a damper in this design makes it possible to control the volume of incoming air.

When choosing this type of valve, you should first of all pay attention to the valve itself. For productive and long-term work, it must meet certain criteria:

- Have a perfectly smooth surface.

- Be resistant to sudden temperature changes inside and outside the ventilation system.

- Easy to clean.

The rotary gate is also called a throttle valve. This device is a little more complicated to use, but its capabilities are much wider. This mechanism consists of valves rotating on a central axis, for which a special handle is designed to regulate. It allows you to set a certain angle of inclination of the damper to improve the quality of room ventilation.

The throttle valve is thus a more advanced mechanism that allows you to precisely regulate the flow of air through the ventilation system. However, it also has a certain drawback - the plate tends to break frequently. This classifies this type of ventilation damper as not very practical and, in comparison, expensive.

Whatever the design of the device you purchase, it must be completely safe: meet fire safety requirements and make it impossible to completely stop the flow of air - even accidentally.

Without flange connection

Installation may depend on what form is used for the damper in a particular case. For example, in the case of a round shape, the product is inserted directly into the pipe ends. These are the so-called bells. This installation does not require the presence of additional fixing elements. But the joining seam still requires sealing.

The choice of sealant depends on the temperature that will be maintained inside the installation. To solve the problem, heat-shrinkable cuffs with a hot-melt adhesive layer and sealing butyl rubber tapes are often used.

What is a gate valve

A damper for ventilation is a special valve, the main task of which is to completely or partially block air flows or bulk and liquid materials. Parts of this kind, in addition to ventilation systems, are also widely used in various drainage systems, wastewater channels, etc.

There are two main types of the described mechanism: horizontal and rotary gate. The second is also sometimes referred to as the "throttle valve". Unlike a horizontal type mechanism, it is quite unreliable, so its use is resorted to only in cases where installing a horizontal gate is impossible for technical reasons.

The duct damper is most often used in chimneys made of brick or steel. To ensure complete closure of the channel, it has a perforated shape. These requirements must be met in order to comply with fire safety requirements. It is also worth noting that there are automatic duct dampers with electric drive. The process of closing and opening such a mechanism is carried out remotely by pressing one button.

Description of the concept

The ventilation damper prevents the strong blowing out of air masses.

The ventilation damper serves to limit or completely block the passage of air flow. The device is shaped like a valve. Parts of similar design are used in hoods and water drainage systems. Dampers are used for air ducts made of any material, including polypropylene and plastic in general. Since fire safety regulations require that the chimney be made of fire-resistant material (brick or steel), a metal damper must be used for it.

The mechanism of operation of the part is identical to that of a conventional valve used to control draft in a pipe. When the fuel is ignited, an open damper activates the movement of air flows. While the wood or peat is burning, the part is left only slightly open to prevent smoldering too quickly. When the process is completely completed, the passage can be closed. The damper for ventilation functions in a similar way: it either activates or blocks air flows. The element can control the flows passing from the main node to the outgoing branches.

Principle of operation

When the plate moves inside the device, the channel capacity decreases or increases. The further the damper in the pipe is moved, the sooner the smoke is removed and the combustion of the fuel in the stove accelerates. Completely blocking the hole in the chimney allows the heat to remain in the stove and work to heat the room air throughout the day.

The plate can be completely retracted only in a heated hearth, when substances harmful to human health cease to be released. If the valve is closed too early, there is a risk of suffocation among family members. Sometimes failure to comply with this rule leads to the death of people.

Boiler models are produced with built-in baffles, so installation of a damper is not necessary. Other heating units, furnaces, boilers require the installation of a valve. It is installed in ventilation and exhaust pipes.

Chimney deflector (Photo: Instagram / deflector21)

Classification

What types of gate valves are there for ventilation systems? By what criteria can they be classified?

Duct shape

A typical industrial duct is round in shape. The reason is simple: a circular cross-section has a maximum area with a minimum circumference. As a consequence, with a fixed wall thickness, the price per linear meter of a channel with a certain throughput is minimal.

Rectangular boxes are used a little less often.

What are they needed for?

- In this case, it is much easier to install air heaters that provide heating of the supply air. They mostly have a square or rectangular shape: the production of water heating devices with a round cross-section is simply low-tech.

- A rectangular air duct is easier to hide behind a false ceiling or false wall. With the same cross-section as a round one, it can take up less usable space.

As you might guess, gate valves are produced for both types of air ducts. In the first case, they are mounted on sockets with their subsequent sealing; in the second, flange connections are used.

Rectangular gate for flange mounting.

Angle to duct axis

A typical gate valve closes the air duct, cutting it at an angle of 90 degrees to the longitudinal axis. Even at relatively low air flow rates, a partially closed valve, generating turbulence, becomes a source of loud noise. That is why it is not used to adjust the patency of the canal.

In pneumatic transport systems, however, there is often a need to partially limit the patency of the air duct. In this case, an oblique gate is used, cutting the flow at an angle of 45 degrees.

Its shape allows you to kill two birds with one stone:

The noise level is significantly reduced due to less turbulence on the obstacle.

When throttling with an oblique gate, less turbulence occurs.

More precise adjustment of the channel capacity becomes possible: shifting the valve by a fixed amount means a smaller percentage change in the open cross-section.