Supply and exhaust ventilation works by consuming and processing outside air. In conditions of negative temperatures and long winters, the air flows must be heated, because if you let them in directly, the microclimate inside the building will become unsuitable for humans. The supply air is heated by a heater. The efficiency of the ventilation system directly depends on it. Therefore, the piping of the supply air heater must be carried out in compliance with all norms and rules and only with high-quality materials. The technical part is being developed in the project.

Brief overview of modern models

To get an impression of the brands and models of water heaters, let’s look at several devices from different manufacturers.

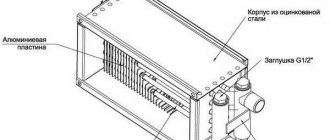

Heaters KSK-3, produced at the company T.S.T.

Specifications:

- coolant temperature at the inlet (outlet) - +150°C (+70°C);

- inlet air temperature – from -20°С;

- working pressure – 1.2 MPa;

- maximum temperature - +190°C;

- service life – 11 years;

- working resource – 13,200 hours.

External parts are made of carbon steel, heating elements are made of aluminum.

The Volcano mini water fan heater is a compact device from the Polish brand Volcano, characterized by practicality and ergonomic design. The air flow direction is adjusted using controlled blinds.

Specifications:

- power within 3-20 kW;

- maximum productivity 2000 m?/h;

- heat exchanger type – double row;

- protection class – IP 44;

- maximum coolant temperature 120°C;

- maximum working pressure 1.6 MPa;

- internal volume of the heat exchanger is 1.12 l;

- guide blinds.

Galletti AREO heater made in Italy. The models are equipped with a fan, a copper-aluminum heat exchanger and a drainage tray.

Specifications:

- power in heating mode – from 8 kW to 130 kW;

- power in cooling mode – from 3 kW to 40 kW;

- water temperature – + 7°C +95°C;

- air temperature – 10°C + 40°C;

- working pressure – 10 bar;

- number of fan speeds – 2/3;

- electrical safety class IP 55;

- motor protection.

In addition to the devices of the listed brands, on the market of heaters and water air heaters you can find models of the following brands: Teplomash, 2VV, Fraccaro, Yahtec, Tecnoclima, Kroll, Pakole, Innovent, Remko, Zilon.

ESBE DRIVES (SWEDEN)

Unique precision and functionality. Possibility of switching to manual mode. Power supply 24V DC/AC current, 50/60 Hz. Control signal 0-10V, 2-10V, 0-20mA, 4-20 mA.

| Name | Specifications |

| ESBE ARA 659 | 24 V, 0-10 V, 6 Nm |

| ESBE 92P | 24 V, 0-10 V, 15 Nm |

| ESBE 95 | 220 V, ON/OFF, 15 Nm |

Types of air heaters

The efficiency and heating rate of air from a steam heater is higher than that of electric and water heaters

Duct heaters are classified according to the type of coolant. The following types are distinguished:

- Electrical. A metal heating element is used as a heating element, which operates from the mains. The device is easy to install and install. The power is designed to serve a room up to 100 sq.m.

- Mermen. These are devices in which water circulates through pipes. Used in ventilation systems in public and industrial premises. It is necessary to install the water heater piping unit.

- Steam. A heater powered by steam has a high efficiency and a high heating rate. The steam is heated to a certain design temperature. Suitable for installation in industrial buildings with a source of water vapor. The piping of a steam air heater for supply ventilation is complex, so it should only be done by specialists.

The choice of the optimal system depends on the type of room, its purpose and capabilities.

Principle of operation

A fan, a heat exchanger and a convector - this is what a water heating device looks like in general terms.

The operating principle of supply ventilation is as follows:

- The air flow enters special air intake grilles that prevent insects, small objects, birds, and animals from entering the ventilation channels.

- Filters clean the air from contaminants, harmful substances, and dust.

- The heater, using heat supplied from the water main, heats it to the desired temperature.

- The recuperator mixes the newly supplied air with the heated one.

- The fan supplies heated air masses into the room, and the diffuser distributes them evenly over the entire area.

- Sound absorbers reduce the sound power of a running installation.

- If the air supply is cut off, valves are activated to prevent cold air from entering the room.

An example of using a VOLCANO air heater in a tire shop (water temperature +90 ºС)

The heater, which does not have its own heater, consists of two main elements:

- A heat exchanger, the design of which is represented by a system of metal tubes - water coming from the general heating system reaches the required temperature here.

- Built-in fan that disperses heated air flow throughout the entire area.

Schemes and types of designs of UTK mixing units

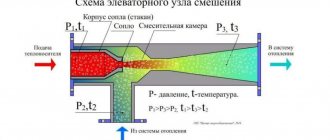

The mixing unit is built according to a three-way control scheme

Ball valves 1 serve to disconnect the unit from the heating network.

There is a filter 2 for hot water on the supply line of the unit. When dirty, the filter element must be cleaned.

A three-way control valve with a servo drive 3 of proportional control is installed on the supply line of the unit. Input B of the valve is connected by a bypass to the return line of the unit. A check valve 5 is installed on the bypass to prevent coolant from flowing from the supply line to the return line, bypassing the air heater. A circulation pump 4 is installed on the supply line of the unit to ensure circulation of the coolant through the “small” circuit.

Basic equipment of heat supply units. Selection and calculation

The heat supply units of air handling units made according to different schemes, as a rule, include identical equipment. Such units differ only in the installation location, the saturation of the reinforcement and the selection method.

When selecting equipment for heat supply units, there are several general rules and recommendations:

- When choosing a particular type of valve, you should carefully check the technical characteristics of both the maximum operating pressure and the maximum temperature.

- It is highly not recommended to purchase ready-made mixing units that are selected based on average conditions without taking into account important parameters such as free pressure drop in the system, type of coolant, flow rate, type of heat source, the need for frequency regulation, and so on.

- The diameter of shut-off valves, as well as check valves and mud traps must be no less than the diameter of the pipelines.

- The diameter of the heating system pipelines is determined as a result of hydraulic calculation based on the calculated (required) coolant flow rate, type of coolant (water or low-freezing liquids) and pipeline material. In no case should the diameter of the heating supply units be selected based on the connecting ports of the heater. It is selected ONLY BY CALCULATION!

Shut-off valves

It is necessary to shut off the water flow in cases of emergency stops of the heating system, for example, to eliminate a leak, to carry out service or inspection work, etc. As shut-off valves, steel or brass ball valves (preferably full bore) or flanged valves are used.

For heat supply units with a pipeline diameter of up to 40 mm inclusive, it is customary to install threaded shut-off valves, and flanged valves over 50 mm.

To facilitate the installation or dismantling of assemblies, threaded fittings should be provided with union nuts, otherwise called “American or socket nuts”.

Check valves

Check valves are used in control units to prevent water from flowing back into the heating system if control valves are opened or closed. Or this is possible when the heating system is not balanced, a large number of units are installed in the system and when the coolant flow changes, pressure may occur on each other. Therefore, check valves are installed on the return pipeline and on the jumper of the heating supply unit.

Control Valves and Actuators

A two-way or three-way control valve is the main actuator, which, by changing the flow rate or by mixing coolants, allows you to regulate the power of the air-handling unit heater depending on the heating demand of the installation. Another important function of the valve is to prevent the coolant from “freezing” when the units operate in winter. When the automation receives a signal about the critical temperatures of the coolant and air after the heater, the drive opens the control valve to the maximum flow.

The valve is selected based on the determination of the throughput coefficient Kv, which means how much coolant flow will pass through the valve in the open state with a loss of 10 meters of water column.

,

The size of the control valve cannot be selected according to the diameter of the pipeline or heater ports. The smaller the Kv or valve diameter, the higher the speed of response to changes in air or heating network parameters will be, that is, the system will not be inertial.

In heat supply systems of air supply units, as a rule, two and three-way valves are used. Two-way valves work only in systems with changes in coolant flow, and three-way valves either act as mixing valves or work to separate heat flows.

Measuring fittings: pressure gauges and thermometers

Pressure gauges and thermometers are necessary tools for visual monitoring of the performance of the heating system. Thermometers are usually installed on the supply and return pipelines directly next to the heater. Pressure gauges are mounted on the pump group to monitor the operation of the pump and visually determine the difference created. Pressure gauges are also installed before and after the sump tank - to determine the degree of its clogging, and on the supply and return pipelines of the heating network in front of the piping unit - to control the free drop necessary for the full operation of the control valve.

Air bleed valves and system drain taps

Automatic air release valve

To bleed air after filling the system and during operation, it is recommended to install automatic air bleed valves in the piping units. They are conveniently mounted on special ports embedded in the heater coils in the upper part of the housing or at the highest point of the control unit pipelines.

Taps for emptying heaters and draining a section of the heating system should be installed at the lowest point of the control unit, or at the bottom of the heater.

Balancing valves

If the heat supply system has several air supply units operating in their own independent mode, then the heat flows in the pipelines will not be constant and may differ significantly from each other. To prevent pressure on each other from the coolant side, balancing valves are provided. Their main and main function is to throttle excess pressure and equalize the distribution of water flow between heaters in accordance with needs. Balancing valves installed on the return pipelines hydraulically link the heaters to each other.

The selection of valves is carried out by analogy with the selection of control valves, taking into account the Kv coefficient. The initial data for determining the valve size is the excess pressure drop that the balancing valve must absorb and the calculated flow rate in the network section.

Circulation pump

The circulation pump of the internal circuit of the piping unit is designed to ensure constant circulation of water in the heater. This will minimize the risk of the heater “defrosting” at low outdoor temperatures. But the main purpose of the pumps is to overcome hydraulic resistance in the regulated area, that is, on all functional elements of the mixing unit, unloaded from the pressure of the heating network.

Automated air heating in supply ventilation

Options for constructing round and rectangular ventilation shafts - the system is automated

- The operation of the equipment is controlled using a control panel (CP). The user presets the mode for regulating the supply air flow and temperature.

- Using a timer, the heated ventilation system automatically turns on and off.

- Equipment that provides heating can be connected to an exhaust fan.

- Heaters are equipped with a thermostat that prevents fire.

- A pressure gauge is installed in the ventilation system to monitor pressure differences.

- A shut-off valve is installed on the supply ventilation pipe; it is designed to block the entry of incoming wind masses.

(no votes yet)

Design Features

Essential elements

- Air intake grille. It has both a decorative purpose and serves as a barrier to dust and other particles contained in wind masses.

- Valve. When ventilation is turned off, the valve blocks the passage for fresh air, creating an insurmountable barrier. In winter, it can block a lot of air flow. You can automate its operation using an electric drive.

- Filters clean wind masses. They need to be changed every six months.

- Water, electric heater, which performs the function of heating the air.

- For small buildings it is advisable to use an electric heater. In large rooms it is better to use a water heater.

Installation and connection features

Assembly and connection work must be carried out by professional workers from a specialized company. Before starting equipment installation work, it is necessary to check the condition of all elements and components of the mixing unit, the integrity of the insulation of the electrical wires of the drive and circulation pump.

Requirements for installation of electrical equipment

- The pump must be connected to the electrical network using a three-wire cable.

- It is necessary to install a junction box on the pump casing, where the phase, neutral and ground connections are connected. The terminals must be accessed by unscrewing the screw element in the middle of the protective cover of the box.

- The electrical cable must be removed from the junction box through an insulating ring.

- It is prohibited to supply current to the electrical cable until installation work is completed.

- Maintenance work must only be carried out with the mixing unit switched off.

To prevent emergency situations during the operation of mixing hydraulic units of ventilation systems, it is necessary to accurately calculate and select the standard sizes of valves, additional elements, pump power, etc. that meet the requirements.

Adjusting the heating process

There are 2 types of heating adjustment:

- quantitative – temperature adjustment occurs due to changes in heat resource consumption;

- high-quality - this option uses a change in the parameters of the heat carrier while maintaining constant consumption of heat resources.

Installation recommendations

Floor installation of a water heater

It is not difficult to master the technique of installing supply air heaters. You will need to carefully study the assembly instructions and then strictly follow their instructions. Before starting work, it is taken into account that household models, even of relatively light weight, are hung on a base, the strength of which is checked in advance. Strong concrete or brick walls are suitable for this; Moreover, wooden and plasterboard partitions are immediately discarded. Next, the need to use a freeze protection thermostat for the supply ventilation channels is determined. If in this place the temperature can drop below normal, the installation of a thermal stabilizer is considered mandatory.

The procedure for carrying out installation work:

- A metal frame in the form of a bracket with holes for attaching the housing (mounting console) is installed at the selected location.

- The heater body is suspended, to which pipes with a set of shut-off valves are then connected in the sequence specified in the instructions.

- The mixing unit is also installed here if it was not installed before the installation work began.

They mount heaters on concrete walls under decorative panels.

There are two ways to cut into the heating system. In the first case, connecting fittings or couplings with gaskets are used, and in the second approach, welding is used. The latter option is more reliable, but its use is unacceptable in the presence of flexible connections.

One of the weak points of the mounted structure is the heat exchange pipes, which are subject to constant deformation. Replacing rigid steel tubes with flexible hoses will help increase the reliability of the system in the area where they are located. This technique will lead to a reduction in the load on the pipes, which at the joints are additionally sealed using a sealed compound.

If the heater body is fixed to a fixed and durable base, connection via rigid pipes is allowed. If during operation the device is expected to be moved or moved from the workplace, it is necessary to use a flexible connection. At the final stage of installation, the device is checked for functionality.

Immediately before testing, you will need to remove exhaust air from the exhaust channels, as well as check the condition of the valves and blind guides.

Heater thermal power reserve

9. Determine the thermal performance reserve of the adopted heater(s). ((q - Q) / Q) • 100 q - actual thermal power of the selected air heaters, W; Q is the calculated thermal power for heating the required volume of air, W. The actual thermal performance of the adopted steam-air heater must be greater than the calculated one. The range of the permissible percentage ratio of actual and calculated power, according to various sources, can be from 96 to 120 (from - 4 to 20)%. In any case, you need to strive for the closest possible equality of power (actual performance = 100 - 110% of the calculated one). If, during the calculation, the difference is greater than the above figures, a recalculation should be made.

An example of calculation and selection of a KPSk heater. Step-9

Select a suitable KPSk heater for heating 6500 m³/hour from a temperature of -28°C to +29°C. The coolant is dry saturated steam with a pressure of 0.1 MPa. 9. We calculate the discrepancy between the actual and calculated thermal power of the selected heat exchangers ((104653 - 133426) / 133426) • 100 = -21.6% - for the KPSk 2-10 air heater ((150642 - 133426) / 133426) • 100 = 12.9% - for heater KPSk 3-10 ((188874 - 133426) / 133426) • 100 = 41.6% - for heater KPSk 4-10 104653, 150642, 188874 - actual thermal power of the selected steam heat exchangers, W; 133426 — calculated thermal power for heating a given volume of air, W. -21.6, 12.9, 41.6 — thermal performance reserve of the selected air heaters. Of the considered models of heaters KPSk number 10, only the three-row air heater KPSk 3-10 corresponds under given conditions to the recommended ratio of actual and calculated power.

Strapping methods

The piping is a frame made of reinforcement, with the help of which the flow of hot water is regulated. The piping unit helps to monitor the performance of the supply ventilation heater, control it and maintain a given temperature regime in the building. The location of the piping units is determined by the installation location, air exchange diagram, and technical parameters of the equipment. There are 2 installation options:

- Recirculated air masses are mixed with supply air.

- Only indoor air is recirculated according to a closed principle.

Taking this into account, there are 2 methods of strapping:

- 2-way valves - with uncontrolled reverse water flow;

- 3-way valves - when controlling water flow in a boiler room or boiler room.

Some produce piping units of various modifications, which are entire sets consisting of valves (balancing and check valves, two and three-way), pumps, bypasses, ball valves, pressure gauges, and cleaning filters.

Scheme of piping heater units for supply ventilation. (Ball valves installed at the inlet and outlet allow you to shut off the water, and a thermomanometer allows you to control temperature and pressure)

If natural ventilation is well established, then there are much more opportunities for successful operation of the equipment. The correct choice of piping in such cases is effective both for heating large areas in production and for private houses and cottages.

The heater used for ventilation is usually connected to the heating system directly at the air intake point. If forced ventilation is in effect, then the air heater can be installed anywhere. Air heaters for forced ventilation allow you to create a comfortable temperature regime in both industrial and residential premises

It is only important to correctly decide on the choice of coolant, which will be the most effective (with minimal costs and maximum performance) under certain conditions. An automated system - such as a supply ventilation control panel with a water heater - will make the use of heating devices for supply ventilation convenient and safe

Connection diagrams

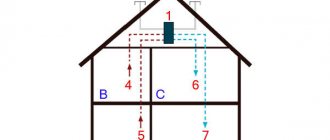

Scheme with two ventilation circuits

To effectively heat the incoming air using a heater, it is necessary to make the correct connection. There are several installation schemes, which include:

- One ventilation circuit and one heater. This is the simplest scheme in which one heating device is located at the inlet or any other section of the channel. This connection is used for seasonal heating and does not have a backup heat source.

- Two ventilation circuits and several heaters. This is a more complex scheme, suitable for installation in complexly shaped rooms. Suitable for year-round use. There are several tying knots. The first circuit is used for heating in autumn-winter, and the second for summer. Due to the large number of devices, the system can operate continuously even in the event of an accident at one of the piping units.

Ventilation diagram with heater

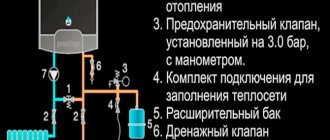

The classic harness includes the following elements:

- Circulation pump. It is used in water systems and disperses liquid through pipes.

- Compressor-condensing unit. It is used as an external unit in the cooling system piping.

- Temperature and pressure control devices.

- Locking mechanisms.

- Bypass.

- Filter.

- Two-way or three-way automatic valve.

- Tubes, connectors and other parts to connect the mixing unit for ventilation.

Temperature regulation

Temperature control is the most important task of the system. There are two ways to adjust:

- Quantitative. This is an outdated method in which the temperature directly depends on the volume of coolant.

- Qualitative. A more efficient method in which the coolant is consumed linearly. This is done using a three-way valve and pump. There is no possibility of leakage.

Experts use the second method. It is compatible with any heater connection scheme.

Ventilation system

Trim with two-way valve

The choice of the optimal ventilation scheme is influenced by the required temperature, heating intensity, coolant source, and pressure difference. There are several systems:

- Piping of the ventilation unit using a two-way valve. It is placed at the entry point without an additional heat exchanger. As a result, the valve acts as an intermediate buffer and dampens the pressure of the water flow. The disadvantages of the scheme include the risk of freezing at subzero temperatures. Pump installation required.

- Using a three-way valve. The result is two strapping systems. In the first case, the water flows are separated, and in the second, they are mixed. The scheme is used in autonomous heating networks.

Advantages and disadvantages

Despite all their convenience, air heaters consume a large amount of electricity

Water and steam heaters designed for heating industrial premises are extremely profitable because they do not require additional investments. Financial resources are spent only on the purchase of the device. Their advantages:

- quickly achieving the desired air temperature;

- simple installation;

- safety;

- reliability;

- possibility of adjusting the heating level.

Disadvantages include:

- use in rooms with positive air temperatures;

- impossibility of using for heating apartments;

- equipment is required to provide air traction;

- If the coolant supply stops, the system stops working.

The last point is also true for electric heaters, but only concerns power outages.

Pros and cons of using

If the enterprise has its own heat supply system, the use of air heaters for supply ventilation of production premises is as cost-effective as possible.

A set of water fan heaters for servicing a warehouse. Air heaters with an air flow rate of 5200 m³/h and a coolant temperature of + 130 ºС heat the air and maintain the set temperature

Advantages of devices connected to a centralized system:

- simple installation, no different in complexity from installing heating pipes;

- rapid heating of a large room;

- safety of operation of all components;

- possibility of adjusting the flow of heated air;

- strict industrial design.

But the main advantage is the absence of regular financial investments - payment occurs only when purchasing new equipment.

Current prices for KSK bimetallic water heaters produced by Novosibirsk, which manufactures heating equipment. The final price depends on the basic configuration and technical characteristics

The main disadvantage is considered to be the impossibility of using water models in everyday life, especially in urban housing. An alternative is to use electrical appliances.

Another nuance concerns negative temperatures: the equipment must be installed in rooms where the minimum threshold does not fall below 0 °C.

There are practically no wearing parts in the design of the water heater. They rarely fail and require serious repairs, which should also be included in the “treasury” of equipment advantages

Types and characteristics

In a water heater, water performs the functions of a coolant

The devices in question operate on ordinary water and other types of energy carriers. According to the type of energy source used, the following types of heating units are distinguished:

- water;

- steam;

- electric.

A water air heater is a common type of device, characterized by safety, efficiency and ease of maintenance. The function of the coolant in it is performed by hot water coming from the local hot water supply network or from the boiler. Water heaters for fresh air ventilation are a very profitable option, characterized by minimal maintenance and operating costs. The only problem with a water heater is the difficulty of installation associated with the installation of centralized or local heating pipes. This connection does not allow you to quickly move the device to a new location.

An air-steam heater is a complete analogue of water models, differing from them only in the type of coolant used. The structural difference is manifested in the greater wall thickness of copper tubes (2 mm versus 1.5 mm for water samples). This is explained by significant pressure in the system, forcing the structure of the outlet channels to be strengthened.

Technical characteristics of water heaters

An electric heater installation does not require a coolant, since the energy source in it is a mains voltage of 220 Volts with a frequency of 50 Hertz. Easy connection of electrical units ensures mobility and ease of use. Their disadvantage is significant energy consumption, which limits the use of devices. They are in demand in situations where local heating is required during one-time work (as emergency or temporary heat sources).

The main characteristics of air heaters include:

- water temperature at the inlet and outlet of the device;

- the speed of movement of the carrier along the heating channels;

- air temperature at the outlet of the unit;

- operating pressure in the system.

When describing devices, the maximum operating temperature of the liquid circulating in the nozzles and the service life of the product are also indicated.

CONTROL VALVES

Control valves ESBE (Sweden) VRG 131 series:

Valve material: DZR brass.

Maximum operating temperature +110°С (short-term up to +130°С)

Maximum operating pressure 10 Bar.

Transmittance 0.02%.

| Valve model | Valve Kvs | Attach. size |

| VRG 131 15-1.6 | 1,6 | G 1/2″ |

| VRG 131 15-2.5 | 2,5 | G 1/2″ |

| VRG 131 20-4.0 | 4 | G 3/4″ |

| VRG 131 25-6.3 | 6,3 | G 1″ |

| VRG 131 25-10 | 10 | G 1″ |

| VRG 131 32-16 | 16 | G 1 1/4″ |

| VRG 131 40-25 | 25 | G 1 1/2″ |

| VRG 131 50-40 | 40 | G 2″ |

| 3F50 | 60 | F 2″ |

| 3F65 | 90 | F 2 1/2″ |

| 3F80 | 150 | F 3" |

Quality of work: air handling unit heater piping unit

There are 2 methods of installing the device, which are determined by the heat exchange diagram. If we talk about natural ventilation, the heater should be located in the basement near the water intake point. With a forced ventilation system, the device will begin to function correctly only with the correct installation of the heater module piping unit.

These devices allow you to regulate the temperature level of the heat exchanger:

- Bypass;

- Eyeliner;

- Cleaning filter;

- Pump;

- Ball Valves;

- Thermometers and pressure gauges;

- Electric valve.

If we are talking about installing a piping unit with a rigid liner, communications will be carried out using steel pipes. Sometimes flexible connections with corrugated hoses in the system are also used for installations. The location of the node is determined in advance. Tying a knot does not involve any serious expenses.

Variants of typical solutions for piping steam equipment

Today, various equipment is used to install steam heaters. Depending on what it will be, completely different patterns and piping knots are used.

Special heater steam piping system for condensate removal:

Typical steam equipment piping.

- 3 shut-off valves, which are installed at the inlet, outlet and in the middle;

- thermodynamic diverter, which has a valve and a built-in filter to protect the system;

- sight glass for periodic inspection;

- check valve;

- special drain pipe for condensate;

- condensate drain;

- condensate line

The minimum length of the common condensate drainage unit for a steam heater is 1 m.

Collector piping.

If it is necessary to connect several points, then the use of a steam manifold with drainage is required. The diagram includes the following nodes:

- 3 shut-off valves (at the beginning, end and middle for adjustment);

- pressure gauge for pressure control;

- viewing window for system monitoring;

- float drain for condensate, which has a built-in filter and valve to protect the system from contamination;

- check valve

Steam reduction unit with pilot control.

Such a unit is necessary for generating steam; it includes:

Steam reduction unit.

- shut-off valves;

- several pressure gauges to control pressure in different areas;

- filters that are designed to work for 3-9 hours;

- pressure reducing valves designed to control the system;

- check valve;

- viewing window for monitoring the system and its condition;

- blast safety valve;

- special drain pan for collecting condensate;

- conclusion;

- drain pipe.

The length for such a system unit cannot be less than 10 diameters of the steam line; in some cases, a built-in impulse tube is provided.

Supply ventilation with water-heated air

The air is heated to the required temperature by a water heater. It is presented in the form of a radiator with tubes containing coolant. The pipeline has fins that increase the area of contact with the circulated air.

The principle of operation of the system is as follows: the coolant heats the tubes to the desired temperature, they transfer heat to the fins, which in turn heats the air. Thus, heat exchange takes place.

Supply ventilation with water heated air is much more profitable than heating using electricity. On the other hand, there is water inside the water heater, so there is a risk of it freezing with minimal radiator operation.

The power of such a device is adjusted using electrical and plumbing components.

- Area with controller and temperature sensors. Servomotor that controls the valve.

- The mixer is responsible for heating the water in the heating equipment to the required temperature.

The electrical component will control the plumbing unit. It is enough to set the required air heating temperature, and the system will execute this program.

DIY mixing unit

When assembling yourself, you need to consider the following features:

The actuator on the control valve must not be turned down; The axis of the circulation pump should not be directed downward, like the electrical box; The sump of the coarse filter should be directed downwards.

Following the above rules, the process of assembling the mixing unit begins with connecting the components. When connecting, you need to focus on the diagram and, depending on the purpose, follow the connection sequence. The joints are sealed using waterproofing agents: fum tape, tow, or thread

It is important not to overtighten the connection to avoid cracks and chips. A fully assembled unit requires a test connection

If water leaks, the leak must be eliminated by reassembly. A properly assembled unit will last a long time.

Classification of power control options for installations

The supply ventilation heat supply system can operate in several fundamentally different control modes:

- If during the operation of ventilation systems there is a smooth or stepwise change in water temperature at a constant flow rate, then it is customary to say that high-quality regulation is used at this unit. It is used in boiler houses or in individual heating points, that is, changes in coolant parameters will occur directly throughout the entire heat supply system. The hot water temperature is adjusted according to a special schedule of the heat supply organization depending on changes in the outside air temperature.

- If a change in the heat load occurs when the amount of coolant entering the installation changes, that is, at a constant temperature, the flow of hot water changes smoothly. Here we are dealing with quantitative regulation.

- With the qualitative-quantitative control method, temperature adjustments occur in the heating system (or from a heat source) and coolant flow changes zonally at each installation in its own mode. A rather complex control method, but most widely used in ventilation heat supply systems. It can only be implemented when installing an automation system.

Heat energy consumption systems: air supply unit control unit

There may be several systems that are combined with a heater. This includes a ventilation system, radiator heating, and also floor heating and a thermal curtain. We can look at each in general terms.

Systems combined with a heater:

- Ventilation system - the maximum temperature of the heat exchanger is influenced by the technical parameters of the equipment; the heater must be protected from freezing. That is, in winter, when subzero air is “supplied,” you cannot reduce energy consumption or coolant temperature lower than determined by the system.

- Radiator heating - there is a strict limitation on the temperature of the coolant. But it can decrease as much as desired, even until the operation stops, and this is the main difference between this item and the ventilation unit.

- Underfloor heating differs from radiator heating in that the maximum coolant temperature is limited. Usually it does not exceed 50 degrees.

- Thermal curtain – its working time does not exceed a couple of minutes. The installation location is always located away from the heating source. Usually this is a sub-ceiling location.

As for efficiency, the device of the fan heater should be given first place. In this case, less energy is consumed. But the final choice is yours.

Basics of operating water units

The IP degree in rooms with high humidity must be at least 66

In order for the ventilation heater to serve for a long time and perform its functions properly, you must adhere to the following rules:

- monitor the quality composition of the air in the room being served - the requirements for this indicator can be found in GOST 12.1.005-88;

- installation of the system should be carried out in strict accordance with the attached instructions and taking into account the manufacturer’s recommendations;

- do not increase the coolant temperature above the limit value (+ 190 °C);

- during operation, do not exceed permissible pressure standards (about 1.2 MPa);

- after prolonged cooling of the serviced room, warm it up gradually (by about 30 °C per hour);

- Make sure that the ambient temperature does not fall below 0°C, which can lead to rupture of the heat exchanger tubes.

If the heater is intended to be used in a room with a high level of humidity, the degree of dust and moisture protection of the device should not be less than IP66.

It is not recommended to repair the device yourself if it breaks down. You need to contact a service center and entrust the restoration of an expensive device to professionals.

Before purchasing, it is advisable to determine the power consumed from the network.

Power calculation

Before you start choosing a heater, you should calculate the main indicators, such as the power and temperature of the air flows at the outlet of the installation. In addition, it is necessary to take into account a number of characteristics depending on the use of different types of power and the number of phases. So, when connecting an electric heater with a power of 5 kW, it is necessary to arrange a three-phase connection.

In addition to electrical calculations, it is necessary to find out the temperature of the supply flows when using a heater of a particular power. The formula used for calculation is T=2.98xP/L, where L means the system performance, and P is the power of the electrical element. Standard indicators for the power of air heaters for apartments and private houses are considered to be values from 1 to 5 kW, despite the fact that the power of devices installed in the ventilation systems of large industrial enterprises is 5-50 kW.

Options for adjusting temperature during heating process

Diagram of a heater piping unit with a three-way valve

The heating control process is of two types: qualitative and quantitative.

The use of quantitative heating control is not always advisable, since the amount of coolant constantly changes during operation.

High-quality heating regulation implies operation of the heater using the same volume of coolant.

There are several advantages of the high-quality heating principle:

- stable linearity of the process is ensured in any position of the control valve;

- freezing of the unit can be prevented or reduced by ensuring a constant flow of water;

- if there is a special pump and a three-way valve, then in this case the qualitative principle of heating control is used.

Protection of heaters from defrosting. Coolants in ventilation systems

The number and purpose of air heaters in supply ventilation installations may vary depending on the composition of the installation and the purpose of its operation. The heaters can be of first heating, second heating, with preheating in front of plate recuperators, separate for operation at different times of the year, or used for heating on separate branches of air ducts if the temperature conditions of the served premises are different.

Therefore, it is customary to say that preheating or 1st stage heaters always operate on “hot” air. That is, air with a very low temperature enters the heaters. In a continental climate, the danger of heaters defrosting is very high when starting up installations in winter or during new construction, when there are frequent interruptions in the power supply and interruptions in the supply of hot water.

There can be a huge number of reasons for water freezing in heaters in winter: from accidental closing of the valve at the inlet to a failure in the power supply and automation systems. Also, the most common cause of defrosting is the incorrect choice of circuit, low pressure drop in the heating system, incorrect selection of the control valve and a drive with a long response time.

Defrosted heater of the supply ventilation system

You should also know that the ideal choice for controlling control valves is an actuator with analog control using a 0-10V signal. An equally rare cause of system defrosting is uncoordinated operation of the supply and exhaust ventilation systems. For example, it is a common case that during non-working hours the air supply units are switched off, but the exhaust units continue to operate for some reason, and a vacuum of air is created in the building. To replenish the air balance, air begins to be sucked in through all available leaks, including through a leaky air damper. Thus, when the system’s automation and insensitive sensors are turned off, the signal about low temperatures does not issue a command for the automation to turn on the heating of the heating system and the water in the heat exchanger freezes.

Video on defrosting the heater of the supply ventilation system:

Of course, heater piping units must also be equipped with the required number of sensors and protective thermostats complete with control cabinets, but in the event of power surges or lack of power supply, the automation system will not be able to protect the heaters. The only option to protect the system from defrosting with a 100% guarantee is to fill it with low-freezing coolants.

The main advantages of antifreeze include a low crystallization temperature and the absence of thermal expansion in a frozen state, which does not lead to rupture of the walls of air heaters. Low-freezing liquids include sets of additives that protect the pipeline system from corrosion, minimize cavitation and prevent sediment from forming when the system heats up or cools down.

The use of low-temperature coolants in some heat supply systems is limited by a maximum maximum temperature of 95-100°C, above which the chemical composition will decompose. Therefore, in an individual heating point, a temperature regulator or valve should be installed on the media separation heat exchanger (water-NZT), which will protect the heating system circuit from increasing the temperature above the critical one.

In heat supply systems, as a rule, ethylene glycol or propylene-glycol mixtures are used, which differ in both price and scope. Ethylene glycol is the cheapest coolant, therefore it is most widely used in engineering systems. Propylene-glycol mixtures are used in safe industries, where in the event of system depressurization, a toxic coolant can pose a potential threat to life or disrupt the technological cycle. Such requirements are found mainly in the food industry or in medical institutions.

A low-freezing coolant with a crystallization temperature of -30°C contains 40% ethylene glycol mixed with distilled water. The main feature of all ethylene glycol-based coolants is the formation of a plastic gel at low temperatures, which does not cause rupture of heater tubes or the formation of cracks in welded joints.

It is not recommended to use a low-freezing coolant with a crystallization temperature of _65 degrees in heat supply systems, but it should be diluted with water to the required concentration.

After filling the networks with ethylene glycol solutions, the system should be carefully pressurized, since it is most likely that small coolant leaks or leaks may occur at the threaded connections. This is due to the low surface tension of all coolants and the ability to penetrate into all cracks and leaks in the system.

When carrying out a hydraulic calculation of a heating system that will be filled with an ethylene glycol solution, it should be taken into account that the coolant flow rate will be 8% higher than the water flow rate, and the pressure of the pumping equipment should be increased on average by 54%. When selecting the diameters of pipeline sections, it is necessary to take into account the increased viscosity of coolants and introduce a correction for an increase in diameter, where necessary.

Water heater and supply ventilation system

Many words like “mixing device”, “cooler device” and “connection of air heaters” confuse the inexperienced user. He has only heard about the structure of the freon circuit, and he understands quite roughly what the piping units are. To learn more about heat appliance systems, you can “learn” from disassembling such a unit as a water heater.

If we talk about the quantitative option, then a changing heat consumption is inevitable. This is not the best option, of course, which is why today the so-called good regulation principle is used. It ensures linearity of the process, no matter what position the control valve occupies. This principle also implies excellent resistance to possible freezing of the heating device.

A good control principle uses elements such as a centrifugal pump and a three-way rod valve. They allow you to increase the efficiency of the heater and piping. They also guarantee that there can be no leaks on the floor from the steam appliance.

How is the heating of the heater regulated?

In order to control the heating procedure occurring in the device piping unit, you can use one of two possible methods:

- quantitative;

- quality.

If you choose quantitative control of the system’s operation, then you will face an inevitable and constantly “jumping” coolant consumption. Such a method can hardly be called rational, and this is one of the reasons that in recent years people have more often resorted to another principle of control - qualitative. Thanks to it, it became possible to regulate the operation of the heater, but the amount of coolant does not change at all.

In addition, if you regulate the system using the quality principle, then the control is guaranteed to remain linear, regardless of what position the control valve is in.

Important! Quality control has one more advantage - this way the heater will be maximally protected from possible freezing, since water will constantly flow into it. All this became possible only thanks to the fact that a water pump is installed in the heater circuit

There is a flow of water in the circuit, which will not depend on any external influences. In addition, quality control involves the use of a three-stroke rod valve and a specialized pump. All these parts built into the device’s piping have significant advantages that increase the efficiency of the heater and the entire system as a whole:

All this became possible only due to the fact that a water pump is installed in the heater circuit. There is a flow of water in the circuit, which will not depend on any external influences. In addition, quality control involves the use of a three-stroke rod valve and a specialized pump. All these parts built into the device’s piping have significant advantages that increase the efficiency of the heater and the entire system as a whole:

- The regulation valve is located in the place where the coolant enters the heater. If you compare this to a two-stroke device, it controls the entire mixing procedure. If the circuit is in a closed state, then internal circulation occurs; if it is open, then the coolant does not recirculate. If such a design is installed with a rod, this will not only increase the service life of the valve itself (which, as is known, very quickly becomes unusable in products that do not have rods), but will also increase heat transfer.

- The motor of a centrifugal circulation pump is “wet”; in other words, it operates while completely immersed in water. Consequently, the bearings of the device, as well as other elements, are constantly lubricated with water, so there is no need to use any kind of seals. If the heater piping is equipped with such a pump, then leakage is completely eliminated even in cases where the pump is broken or has completely exhausted its service life.

What it is?

The heater for supply ventilation is made in the form of a heat exchanger, in which the air masses coming from the street are heated to the desired temperature. The device is a separate device that is either installed into the system independently or is already built into the ventilation unit. This depends on the design features of the ventilation unit, and is determined by the technical capabilities of installation and the personal preferences of the consumer.

In prefabricated modular systems, all elements are purchased separately and then connected into a single ventilation network, while in monoblock installations the elements are already installed and adjusted. In addition to heaters, the ventilation unit includes a filtration and humidification system, which allows you to obtain air at the entrance to the room that meets strict sanitary and hygienic standards. Some modern systems are additionally equipped with devices for disinfection and ionization of air flows.

Coolant flow

To calculate the coolant flow rate, you first need to find the frontal cross-section of the device.

It is determined by the formula F = (L x P)/ V, in which:

- F – frontal section of the heat exchanger;

- L – air mass flow;

- P – table value of air density;

- V – air flow speed (3-5 kg/m²s).

After this, you can calculate the coolant flow using the formula G = (3.6 x Qt)/(Cin x (tin - tout)), in which:

- G – water requirement for the heater (kg/h);

- 3.6 – correction factor for converting the unit of measurement from Watt to kJ/h, so that the flow rate is in kg/h;

- Qt – heater power in W, which was found earlier;

- Cw – indicator of the specific thermal capacity of water;

- (tin - tout) is the difference in temperature of the coolant in the return and forward lines.