Here you will learn:

- Features of parapet boilers

- Popular models

- Customer Reviews

Choosing a gas boiler for heating a household or apartment is a complex process that takes into account many factors. For example, this is the area of heated premises, the presence of a traditional chimney, the availability of free space and much more. In some situations, when there is not enough space in the home, a parapet gas boiler is purchased here. It is a compact heat source with an unusual design.

What is the device?

This device differs from other products in that it perfectly combines the functions of a convector and is equipped with a sealed combustion chamber. Combustion products are prevented from entering the room. You can use a parapet boiler even if you do not have the technical ability to install a vertical chimney.

The ability to use the device as a convector allows you to avoid installing additional radiators to heat the room in which the device is located. The unit will be able to rationally heat your home. However, the choice of such products is very large. In order not to get confused, it is necessary to consider not only the advantages of the boiler, but also its technical characteristics. In addition, in this article you will learn how to properly install this type of equipment.

Installation

The instructions describe the ignition process in detail. The launch is carried out after installation and strapping. The correct installation must be checked by the gas service. Before lighting the boiler, a number of preparatory and installation work should be performed:

- Avoid proximity to flammable materials.

- Connect cold water, remove the plugs from the pipes. Install a filter and ball valve at the inlet to protect the system from blockages that could cause malfunctions.

- Ball valves are mounted on all pipes involved in the piping.

- Gas pipes are installed by gas workers; they carry out the connection and installation of the meter.

- They lay a power line for volatile models. They make a separate outlet.

- Installation work related to the removal of combustion products is determined by the type of firebox. There are naturally aspirated or turbocharged models.

- After disconnecting the device from the power supply, fill the system with coolant. Check for leaks. Before the first ignition, all components of the system must be carefully checked.

Design and principle of operation of the unit

So, a parapet boiler consists of a combustion chamber, which is sealed and separated from the room. Thanks to this device, combustion products enter the chimney. This device is coaxial. That is, it is made of 2 pipes inserted into each other. Thanks to this design, the required amount of air is supplied to the combustion zone, and the smoke is removed outside.

This device allows you to abandon the forced air supply system. There is also no need to install a direct chimney, which saves space in the room and money for the construction of this structure. Basically, a parapet boiler has a rectangular shape.

The device is ignited using piezo ignition. When gas is supplied, the flame from the igniter spreads to the main burner. Hot gases that pass through the heat exchanger heat not only the liquid, but also the unit itself. Thanks to this, it becomes warmer in the room where it is installed.

The heating temperature is controlled by temperature sensors. Upon reaching the specified parameters, the gas valve closes automatically. Fuel stops supplying to the main burner. The igniter continues to work.

After the coolant temperature drops below the set level, the boiler turns on again. If the igniter goes out or the gas pressure in the central line decreases, the operation of the device is blocked. In this case, the gas supply is shut off. This indicates the safety of using the boiler.

Types of equipment

There are several types of heating installations. Each type of boiler has its own purpose, features and functions. Knowing the features of the installations, you can choose the best option for a particular room.

Types of gas boilers:

- AGV-AOGV. This is the best solution for large houses and premises. The devices do not require connection to the electrical network.

- Condenser. The devices reduce heating costs by 35%. Such boilers use the thermal energy of steam.

- Gas water heaters. The devices are used only for heating water.

- Single-circuit. Standard devices for organizing heating.

- Dual-circuit. Such boilers perform two functions: they provide heat and heat water. Depending on the modification, the unit is equipped with a flow-through heat exchanger or boiler.

Product advantages

The following advantages of the unit can be highlighted:

- Reasonable price.

- High degree of efficiency.

- Quick and simple installation, as well as ease of maintenance and use.

- Small size and compactness, which allows the device to be used even in small spaces.

- Modern design.

- There is no need to clean the chimney and take care of its condition.

- Possibility of connecting the boiler to an individual heating system.

- Installation in any room of the house.

A parapet gas boiler is a profitable investment and saves money, especially since it can be found in almost all stores selling heating equipment.

TOP 5 single-circuit gas boilers

Single-circuit models are used either only for heating, or in conjunction with an external indirect heating boiler. This option allows you to obtain hot water without restrictions on water volumes and without temperature fluctuations. Let's consider several popular models:

Lemax Premium-10 10 kW

Single-circuit gas boiler of domestic production. Designed to heat 100 sq.m. The non-volatile design allows the unit to be operated without being connected to power supplies.

Main parameters of the boiler:

- installation type - floor;

- energy consumption - independent;

- Efficiency - 90%;

- gas consumption - 1.2 m3/hour;

- dimensions - 330x748x499 mm;

- weight - 41 kg.

Advantages:

- energy independence;

- well-organized service and spare parts supply;

- The design was created taking into account Russian climatic conditions.

Disadvantages:

- when heated to 50°, condensation appears in small quantities;

- there is no display, there is no way to obtain information about the state of the boiler components.

Non-volatile models are reliable and simple. They are quite safe, but require a high-quality chimney.

Lemax Premium-20 20 kW

Russian-made gas boiler. The power of the unit is 20 kW, which is suitable for rooms up to 200 sq.m. Equipped with fully mechanical control.

Boiler parameters:

- installation type - floor;

- energy consumption - non-volatile;

- Efficiency - 90%;

- gas consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

Advantages:

- reliability, stability;

- Ease of Management;

- low cost.

Flaws:

- complex ignition;

- you have to adjust the gas pressure so that there is no popping noise when igniting.

Domestic non-volatile boilers are much simpler and cheaper than their European counterparts. This is both a plus and a minus of the units.

Protherm Wolf 16 KSO 16 kW

Slovak gas boiler with a capacity of 16 kW. Optimally suitable for heating a house with an area of 160 sq.m.

Main technical characteristics:

- installation type - floor;

- energy consumption - independent;

- Efficiency - 92.5%;

- gas consumption - 1.9 m3/hour;

- dimensions - 390x745x460 mm;

- weight - 46.5 kg.

Advantages:

- simplicity and reliability;

- no need to connect power supply;

- economical fuel consumption;

- stable operation in automatic mode.

Flaws:

- there is no indication of the state of the main components of the boiler;

- ignition using a piezoelectric element is somewhat difficult.

Gas boilers made by Slovak engineers are highly rated by users, which confirms the high demand.

BAXI ECO-4s 1.24F 24 kW

Gas boiler from a famous Italian manufacturer. The power of the unit is 24 kW, which corresponds to a service area of 240 sq.m.

Options:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92.9%;

- gas consumption - 2.73 m3/hour;

- dimensions - 400x730x299 mm;

- weight - 29 kg.

Advantages:

- compactness, light weight;

- reliability, stability;

- full control over all systems and components using self-diagnosis;

- There is a display showing all the parameters of the unit, both current and permanent.

Flaws:

- when the power supply is turned off, the boiler operation stops;

- high price for the boiler itself and for spare parts.

Italian heating technology is considered elite. It successfully competes with German models in all respects, enjoys well-deserved recognition and high demand among buyers.

Lemax Leader-16 16 kW

Russian single-circuit non-volatile boiler. Its power is 16 kW, which allows you to heat rooms up to 160 sq.m.

Main characteristics:

- installation type - floor;

- energy consumption - independent;

- Efficiency - 90%;

- gas consumption - 1.9 m3/hour;

- dimensions - 431x856x515 mm;

- weight - 95 kg.

Advantages:

- stable, sustainable work;

- low cost of the boiler and repair work;

- independence from power supply.

Flaws:

- minor flaws made during assembly;

- heavy weight.

Floor-standing gas boilers are not limited in the weight and size of units, which allows you to create more powerful and durable units.

The most popular manufacturers

One of the most popular devices is the Aton parapet boiler. This manufacturer has been on the heating equipment market for a long time. It produces various boilers, which, according to consumer reviews, are characterized by high efficiency and performance, long service life, small size and the presence of additional functions.

Units such as Atem are also in demand. This manufacturer has also been on the market for a long time. An important characteristic of the device is its fairly high efficiency - 92% or more. Buyers say that the device is very easy to use with a user-friendly interface. The boiler also pleases its owners with its beautiful design.

You can often find a Danko parapet boiler in stores. According to buyers, its main advantage is energy independence. Thanks to the new heat exchanger design, it is possible to save useful space.

Devices of the “Senior Duval” brand demonstrate high efficiency and manufacturability. This is a relatively new manufacturer, but its products have already proven their quality, as evidenced by the satisfied owners of such devices.

Parapet

In addition to floor models, the manufacturer offers parapet versions for heating chimneyless housing. May vary in shape, size and design of the case. Installation is possible anywhere - on the floor or on the wall. Closed firebox. The burners are installed in different ways: single-level, two-level or modulating.

Heat exchanger materials: cast iron, copper, steel. In Taiga they are made of steel. Gases are removed through a coaxial chimney. Any ignition - piezo or electronic. Sensors and controllers ensure uninterrupted and safe operation. Termotechnik produces 3 parapet series with a power of 7–16 kW:

Types and features of choosing equipment

Parapet boilers, reviews of which are mostly positive, can be classified as follows:

- Single-circuit. They are intended only for heating the room.

- Dual-circuit. They can not only heat the air, but also provide hot water to the house.

When it comes to choosing a device, the following factors should be taken into account when purchasing:

- Power. It all depends on the size of your home. Approximate heat consumption per 10 sq. m. area is 1 kW.

- Economical. Here, take into account the efficiency: the higher this indicator, the more efficiently the device operates.

- Reliable to use. All systems must work correctly, without failures.

- Heat exchanger wall thickness.

- Size and location of outlets for connecting the heating system.

- Coolant used.

- Dependence on the power grid. This parameter should be taken into account if you experience power outages. There are boiler models that cannot operate without electricity, and this can negatively affect the operation of the heating system in extreme cold.

- Device installation location.

- Availability of additional security and control systems.

Which company should you choose?

Parapet boilers were invented in the CIS as an alternative to gas units for those places where there are problems with power supply, stable pressure in gas networks and hard tap water.

The most famous models are produced in Russia and Ukraine:

- ATON (Ukraine) - expensive and functional devices;

- Lemex (Russia) - simple, economical and reliable boilers made of steel with anti-corrosion coating;

- Gefest WPR (Russia) - expensive and high-quality boilers with Italian automation;

- TERMO MAX (Ukraine) - primitive, but comfortable and economical models.

We recommend boilers .

They are suitable for open and closed heating systems, with a pressure not exceeding 1.5 atm, and are equipped with Italian automatic equipment. Parapet devices require regular maintenance, and there are more than 400 service centers of this manufacturer in the former CIS countries.

Installation rules

A parapet boiler, the price of which ranges from 12-65 thousand rubles, is a source of increased danger, so to install it you need to obtain permission from the fire inspection authorities, gas service and others (if necessary). In addition, the installation of the device is carried out in compliance with certain rules:

- The installation can be located in any room, but only near an external wall in which it is possible to make a hole for the chimney. The inside should be treated with special non-flammable materials - steel plates.

- Those objects that can quickly catch fire (furniture, curtains) should be kept at a distance of 30 cm from the boiler. Otherwise, a fire may occur.

- The distance between the device and the facade can vary between 0.3-2.5 m.

- The boiler can only be installed in a room with good ventilation.

- The chimney of the device must be vented only to the street. You cannot install it on closed balconies or porches.

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile design and no impact on the internal atmosphere of residential premises.

If a conventional atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then parapet models are completely separate and do not disturb the air exchange regime.

Another difference is the ability to independently heat air, making a parapet boiler similar to a stove.

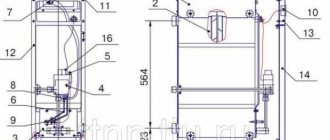

Strapping scheme

What the harness should provide:

- Coolant pressure stability.

- Removing air from the coolant. If an air lock forms, liquid will not pass through it. You need to know how to tie the system correctly. Air vents must be installed.

- Cleaning the coolant from contaminants that impair functioning. The solution is to install filters.

- To compensate for expansion of the coolant due to heating, you need to install an expansion tank.

In the simplest piping scheme - with one circuit - a check valve with a ball valve is installed on the supply side. The pump is installed on return or discharge pipes, since it is necessary to force the liquid to circulate through the system. A strainer is connected in front of the pump. A filter is also needed at the coolant inlet to the boiler. An expansion tank with a membrane is placed nearby to relieve excess pressure resulting from expansion of the coolant.

The latter, circulating, enters the radiators. There is a second piping option, more relevant, when the coolant passes through a manifold that distributes liquid along the circuits. The presence of a safety valve is mandatory: if the coolant boils, the expansion tank may not withstand high pressure. The valve protects against possible risks:

- pipe ruptures and leaks;

- rupture of fittings;

- apparatus explosion.

Installation

The instructions describe the ignition process in detail. The launch is carried out after installation and strapping. The correct installation must be checked by the gas service. Before lighting the boiler, a number of preparatory and installation work should be performed:

- Avoid proximity to flammable materials.

- Connect cold water, remove the plugs from the pipes. Install a filter and ball valve at the inlet to protect the system from blockages that could cause malfunctions.

- Ball valves are mounted on all pipes involved in the piping.

- Gas pipes are installed by gas workers; they carry out the connection and installation of the meter.

- They lay a power line for volatile models. They make a separate outlet.

- Installation work related to the removal of combustion products is determined by the type of firebox. There are naturally aspirated or turbocharged models.

- After disconnecting the device from the power supply, fill the system with coolant. Check for leaks. Before the first ignition, all components of the system must be carefully checked.

Strapping scheme

What the harness should provide:

- Coolant pressure stability.

- Removing air from the coolant. If an air lock forms, liquid will not pass through it. You need to know how to tie the system correctly. Air vents must be installed.

- Cleaning the coolant from contaminants that impair functioning. The solution is to install filters.

- To compensate for expansion of the coolant due to heating, you need to install an expansion tank.

In the simplest piping scheme - with one circuit - a check valve with a ball valve is installed on the supply side. The pump is installed on return or discharge pipes, since it is necessary to force the liquid to circulate through the system. A strainer is connected in front of the pump. A filter is also needed at the coolant inlet to the boiler. An expansion tank with a membrane is placed nearby to relieve excess pressure resulting from expansion of the coolant.

The latter, circulating, enters the radiators. There is a second piping option, more relevant, when the coolant passes through a manifold that distributes liquid along the circuits. The presence of a safety valve is mandatory: if the coolant boils, the expansion tank may not withstand high pressure. The valve protects against possible risks:

- pipe ruptures and leaks;

- rupture of fittings;

- apparatus explosion.

Reviews

Zh7-KS-GS-7.0 S: Roman G., Shakhunya

The main advantages are low cost and compactness. The disadvantage is that it sometimes goes out and does not flare up the first time. After listening to the advice, we bought a Taiga and described the boiler as reliable. In fact, it turned out that there were a lot of problems. The most unpleasant thing is to light it. It happens that you light the wick several times until the burner lights up. The wick goes out on its own. Dissatisfied with the choice.

KS-G-12.5 DS: Victoria E., Bryansk

We have long wanted to replace the old-style boiler with a more manageable and economical one. We chose the floor option. We have a boiler, so we installed a single-circuit boiler. I was attracted by the cost and simplicity of the design. It does not have super functions, like its European counterparts, but it works properly. There were no problems during the season. A powerful device capable of heating our large house in the most severe frosts.

Gas heaters "Taiga" are an advantageous offer in the segment of parapet-type devices. They combine an affordable price with high performance characteristics. This inexpensive and unpretentious device operates smoothly in the harshest climatic conditions. All lines of equipment from Termotechnik are reliable, energy efficient and are in deserved demand among domestic consumers.

The Taiga gas boiler is a product of the Russian company Termotechnik, a worthy alternative to foreign analogues. It features a well-thought-out design and high-quality assembly. Taiga heaters have automatic equipment made in Italy, thanks to which they meet European safety standards.

GC Termotechnik is a Russian company specializing in the production of heating equipment. Year of foundation - 2002. Central office - Pushkino (Moscow region).