Here you will learn:

- General principles of thermal insulation

- In what cases and why is insulation from below correct?

- Features of work on insulating floors with ecowool

- Advantages and disadvantages of ecowool floor insulation

- Calculation of the amount of insulation and the density of its layer

- Ecowool floor insulation technology

Insulating the floor with ecowool in a wooden house can be done manually or mechanically. To insulate with ecowool, you will need to prepare the floors and make cells from boards, and the ecowool needs to be fluffed before backfilling.

What is ecowool?

Before making a choice in favor of ecowool, you should understand what kind of material it is and what it consists of. It is made from waste paper. The consistency is loose, the material is light in weight, and is produced with the addition of substances that prevent combustion and decomposition. Only through their inclusion and impregnation do the fibers acquire durability and avoid rapid destruction. Durability and fire safety are achieved by adding borax and boric acid. Borax affects the fire hazard and increases the safety class to G2, thus the material is used for insulating roof structures, facades, interfloor ceilings and floors of buildings. But its use for insulating air ducts of gas boilers and passages from solid fuel combustion chambers is prohibited. Boric acid prevents the penetration of rodents, rot and fungi. Unlike mineral wool and basalt slabs, in this material there are rarer cases of their penetration and development.

Technical characteristics of ecowool.

The structure of the material is a single mass of long fibers that can ensure the creation of a single and seamless layer of insulation, without the formation of cold bridges. Its application into the interfloor flooring ensures reliable and dense filling of the space and protection of the more vulnerable part of residential premises - the floors.

Thanks to its high technical properties (thermal conductivity reaches 0.040 W/mK) and adjustable density (from 25 to 95 kg/m³), ecowool is not very different from other good thermal insulation materials - mineral or basalt wool, extruded insulation. But there are several parameters that still make it stand out against the general background.

What to look for when choosing ecowool for the floor

Insulating the floor with ecowool may not bring the desired result if you purchased products of unknown origin. Pay attention to the properties of the material. It must meet the following characteristics:

- High-quality insulation is similar in appearance to down;

- When touching ecowool, you should not feel damp;

- There are no large pieces of newspaper in the mass;

- When set on fire, the material smolders without igniting and goes out;

- Ecowool color is grey. The yellowish tint of the insulation indicates the use of low quality raw materials;

- Ecowool with high-quality fibers does not shed mineral salts.

We recommend choosing a trusted manufacturer with many years of experience in the market of thermal insulation materials. GreenWool produces high-quality and reliable cellulose-based insulation, whose plant is located in Kanash, Chuvash Republic. The material is produced on equipment with automated dosing of components, which ensures stable quality of ecowool.

This is important: familiarize yourself with the composition of the insulation. Apart from cellulose, borax (sodium tetraborate) and boric acid, it should not contain any other components. The presence of ammonium sulfate should alert you: such insulation emits an unpleasant odor for a long time, and the floor insulated with it will quickly lose its heat-protective properties.

Advantages and disadvantages of ecowool floor insulation

The material has numerous advantages, thanks to which it is very popular among users:

- The product is multifunctional. A layer of substance on the ceiling of a multi-story building not only insulates it, but also soundproofs it.

- The fibrous structure adheres well to any surface. It forms an elastic mass that, when installed correctly, does not sag.

- The material is impregnated with antiseptics that are destructive to fungus and mold. Mice do not live in the insulating layer.

- It retains its qualities even at 20 percent humidity, and no vapor barrier is required when laying on the floor.

- Cold bridges never remain in cotton wool. The mixture is supplied in a hose under pressure and fills all voids.

- Working with the substance does not require personal protective equipment.

- Installation of the product is carried out in the shortest possible time.

- Insulation requires a small amount of wool - 28-65 kg/m3.

- After insulation there is no need to wait for the raw materials to dry. Finishing can be done immediately after applying the substance. In addition, it is allowed to work at any temperature and humidity.

- The use of special devices allows you to quickly cover large areas.

Thermal insulation of ceilings with cellulose has a number of disadvantages that the home owner should be aware of:

- Before insulating floors with ecowool, the installation site must be carefully prepared. Preliminary work takes a lot of time.

- The substance is made from waste paper, but the technology is quite complex, so its final cost is much higher than products for a similar purpose. In addition, the insulation process requires special expensive equipment.

- Despite the presence of antipyrine in the substance, under the influence of an open fire, cotton wool begins to smolder. To avoid trouble, it is not recommended to use it in fire hazardous areas. Places near the stove should be protected with asbestos or basalt mats.

- Over time, the cotton wool shrinks, so it is filled with a reserve.

Preparing the base

Insulating the floor in a private country house is not a difficult task at all if you follow some rules. The optimal thickness of the insulating layer should be at least 20 cm. This is enough to minimize heat loss. However, in regions with cold winters, insulation up to 30 cm thick is installed in the floors.

Typically, in private houses, logs are assembled from boards measuring 20x5 cm. The distance between the logs is 60 or 40 cm, depending on the floor covering and expected loads.

OSB sheets or boards treated with an antiseptic are attached to the bottom of the joists to prevent ecowool from shedding. Then, using a stapler, a layer of windproof film is mounted with the rough side up to the heat-protective material. The membrane is laid in rows with a 15 cm overlap.

When insulating an old floor with ecowool, preliminary preparation is also required. Under the structure it is necessary to provide protection against crumbling. To do this, boards or OSB sheets are attached to beams or joists. Insulating material is blown through the holes in the subfloor covering. The size of the holes must be no less than the diameter of the blower hose.

Dry technique

If it is necessary to insulate a frame house, underground space, ceiling, etc., then the heat insulator is applied using a dry method. For this method of laying ecowool, it is necessary either to have a closed cavity or to place the insulated surface horizontally.

Base waterproofing

A typical example of the implementation of the dry method is floor insulation with ecowool.

The work is carried out according to the following scheme:

- Cut-off waterproofing is laid on the base - bitumen mastic, roofing felt, membrane or thick polyethylene.

- A floor frame is mounted on top of the waterproofing - a system of joists supported by adjustable posts or cranial bars.

Blowing material

- Cellulose fiber is blown into the gaps between the joists using a special compressor. In this case, the volume of material is calculated so that the upper boundary of the insulation layer is slightly higher than the upper edge of the joist. This will avoid excessive compaction of ecowool when laying the covering.

It’s not worth saving - slight shrinkage is still typical for the material, so there is a risk that over time large voids will form under the floor.

Covering of boards over a layer of insulation

- A subfloor made of boards or plywood is laid on top of the insulated joists. Laying a vapor barrier membrane is not required.

The method of thermal insulation of walls differs from floor insulation in a slightly greater complexity:

- First, the frame is sheathed, with continuous vertical cavities remaining between the posts, not separated by horizontal partitions.

- To access the insulated cavity, either a special hole is made or a small fragment of the sheathing is not installed.

Blowing through holes in plasterboard sheathing

- As an alternative to sheathing, membranes (Tyvek and analogues) can be mounted on the frame, forming closed cavities and preventing the insulation from crumbling.

- The injection device hose is inserted into the hole in the upper part of the cavity. Ecowool is fed through it, which fills all the free space layer by layer.

Do-it-yourself home insulation

Loosening can be done with a drill

For frame houses, ecowool is an ideal insulation material: there is no need to bring a ton of material at once, tie the installation to the pitch of the sheathing, and it is easy to maintain the microclimate in the room, since insulation can be done to a depth of up to 500 mm. The logs of a wooden house are insulated on both sides

An important advantage is that a film that locks moisture from the inside is not needed - the environmentally friendly material allows it to pass freely. The room, as they say, “breathes”

The surface of ecowool is covered evenly

A block house made of aerated concrete, foam concrete, gas silicate can also be insulated with ecowool. It is usually applied externally. At the preparatory stage, a vertical sheathing is installed (steps up to 1 m). The insulating material is applied using the wet-adhesive method. The house breathes and therefore does not need a vapor barrier. When insulating block structures, it is necessary to identify the location of the dew point in the layer cake so that it does not end up in the insulation. It is resistant to moisture, but it also has its limits. Such facades are usually covered with siding.

The manual method differs from mechanized insulation in the duration of installation and material consumption. The main advantage of doing the work yourself is saving resources. The floors, ceilings (starting from the second floor), and walls are insulated manually. The surface is sheathed using self-tapping screws with building material (for walls - from bottom to top). The algorithm for insulating ecowool is simple:

- Insulating material (kraft paper, vapor barrier) is applied to the prepared wall.

- The material is removed from the packaging by pouring the cotton wool into a container of the appropriate size.

- To loosen a dense workpiece and give the desired volume, you can use a drill with a paint remover attachment.

- The fluffy insulation is manually (using a spatula or spatula) filled into the space between the roof rafters or floor joists.

- It takes 2-3 days for the insulation to dry and compact.

- At the final stage, the finishing coating is laid.

It is better to insulate a house while wearing a protective mask, since dry ecowool can generate a lot of dust. The floor is insulated by filling the joists up to a small slide. After laying the finishing material, the insulating layer will be compacted. When insulating walls, the material is additionally compacted. As a result, the volume of insulation is reduced by 2-3 times. It is convenient to insulate small surface areas manually.

Insulating a house manually

Mechanized application

If you invite a team of professional builders, the insulation time will be reduced from two weeks to two days. Installing ecowool using special equipment allows you to use insulation more economically and minimize the likelihood of problems due to the human factor. To isolate space in interfloor ceilings and non-demountable structures, horizontal or inclined surfaces, the dry method is also used. The technology involves several stages:

- A hole is made at the top point of the structure.

- The hose from the compressor is placed in it.

- Ecowool is blown under pressure into the prepared niche.

- After filling evenly, the hole is closed with a decorative plug.

In any case, ecowool is laid after the vapor barrier layer and kraft paper. Density standards – 44 kg/cu.m. m.

Insulating a house using a compressor

Insulating a house using the wet method

The method is suitable for insulating an open surface. The advantage of wet material is that it sticks reliably to the insulated surface. High adhesive properties of ecowool are ensured by lignin (when moistened, its adhesion is maximum). Wet insulation algorithm:

- A frame is constructed from a metal profile or timber.

- The cells are filled with insulation using a pneumatic installation.

- The hole from which the cotton wool is supplied is moistened with water.

- The insulation is laid in a dense layer that cannot be deformed

- Excess protruding parts are cut off for reuse.

The material is left to dry for 2-3 days until a stable crust forms.

Insulating a house using the wet-glue method

The difference between this technique and the previous one is that glue is additionally added to ecowool to enhance adhesion. This technique is indispensable for insulating ceilings and suspended complex structures with thin walls

It is important to consider that shrinkage can also be avoided when laying vertically if you spray ecowool as chaotically as possible

If you can insulate a room (horizontal floors) using the dry method yourself, then for other options you need to invite specialists. It is better to insulate walls using wet methods - the likelihood of shrinkage is lower.

Roof insulation with ecowool

Ecowool floor insulation technology

As a rule, the floor design with some non-fundamental differences looks like this:

- The base of the floor is filled with concrete mortar or remains earthen;

- Next, the subfloor is made up of wooden logs;

- The bottom side is lined with a vapor barrier film (this option is required if the floor is earthen);

- The underside of the subfloor can be additionally covered with a layer of moisture-resistant plasterboard;

- Ecowool is manually poured on top without tamping (see below for the mechanical method of blowing);

- A finishing layer of floorboards, OSB, DSP or laminate is laid on top of the wooden logs and insulation;

- When mechanically blowing ecowool, special technological holes are used in the floor, which has already been laid with the top finishing layer. After the insulation is blown into the cavity between the joists, the technological holes are closed.

This technology allows for seamless insulation of the floor of a country house. Ecowool fills the entire space, covering all communications and electrical cables laid along the base of the floor. After insulation, there are no gaps left between the communication elements and the floor.

Ecowool belongs to the G-2 flammability class and, if wiring in the floor catches fire, it prevents the spread of fire, since it does not burn, but smolders.

Cellulose insulation is not suitable for insects and rodents due to their intolerance to the natural component - borax. This gives the home additional comfort and sanitary safety.

Selection of equipment for installation of ecowool

Before laying, the raw materials must be fluffed to a uniform consistency. Only in this state does it have the necessary insulating characteristics. Mechanization of the process involves the use of special devices that automatically loosen the material and supply it along with air through the pipe to the ceiling.

A typical blow molding device design looks like this:

- Platform on which the engine, gearbox, blower and other components are mounted.

- Electric motor with gearbox - can be two or three stages. This scheme allows the buyer to choose products based on performance and power. Typically, the power plant operates on a low current, which ensures the machine is silent and durable.

- Gateway - designed to capture cotton wool and fluff it up. From it the working mass is fed into the hose.

- Funnel - for loading material into the device.

- Damper - allows you to regulate its flow into the gateway.

- Baking powder - fluffs the compressed substance.

- Remote control - to control the installation. In many products, you can change the speed of movement of biomass and its supply remotely.

- Emergency switch - for quickly stopping the machine.

Preparation for insulation using the blowing method

Insulation of walls and ceilings using the blow-in method begins with preparation for this process. If you plan to do the thermal insulation work yourself, then you need to purchase all the necessary equipment, calculate the material and prepare the working surface. Knowing the consumption of the substance per cubic meter and the thickness of the walls, you can determine what the consumption of ecowool is per 1 square meter. m.

Calculating the amount of cellulose wool required for insulation is an important procedure. Mistakes at this stage will lead to unnecessary costs for raw materials.

The consumption of ecowool per square meter of walls and ceilings varies, which must be taken into account when calculating the amount of ecowool required for work. Ecowool is transported in bags. One bag contains 0.14 cubic meters or, in terms of weight, 15 kg of thermal insulation composition. For a house with a base area of 60 m2, with an ecowool consumption of 50 kg per m2, you will need about a hundred of these bags. The amount of insulation depends on the thickness of the walls or floor slabs.

Advantages of mechanized insulation

Professional equipment is used to insulate the floor with ecowool. The operator smoothly moves the sleeve, ensuring uniform application of ecowool.

Mechanized installation has a number of advantages compared to manual installation:

- Manual labor for carrying material to insulated structures is eliminated;

- The blowing machine fills all hard-to-reach areas and crevices with material;

- A layer of insulation without seams, differences in thickness, with uniform density;

- Thermal insulation does not shrink due to the high density of the layers.

This is interesting: the process of insulating an ecowool area of 100 m², 20 cm thick, manually takes approximately two days. Continuous installation using blow molding equipment lasts 2.5 hours.

To make floor insulation with ecowool as effective as possible, use a professional that not only produces GreenWool insulating material, but also carries out installation using specialized equipment.

The insulation process is not limited to simply applying material to the surface. This also includes a set of related works:

- Assessment of the condition of the object;

- Recommendations to the customer on choosing the method of installing ecowool, the optimal layer thickness, taking into account the specifics of the design;

- Selection of insulating materials to provide protection against moisture penetration into the insulation: steam and waterproofing membranes.

The installation of ecowool on site is carried out by a team of two operators. Our specialists have been trained to work with blow molding machines and have at least 20 years of experience in this field.

Insulation of floors with ecowool is carried out using imported equipment with a productivity of up to 1270 kg per hour, depending on the volume of work. For effective and high-quality thermal insulation, the machines are equipped with additional accessories: hose attachments, adapters, nozzles. This allows you to insulate complex structures and hard-to-reach places.

Professional installation using specialized equipment will guarantee high energy efficiency of a home, industrial facility, administrative building, or other facility.

Laying features

There are the following main methods of insulating buildings with ecowool:

- wet;

- wet-adhesive;

- dry.

Spraying cotton wool with a special installation allows you to improve the quality and uniformity of the coating and at the same time reduce material consumption.

Wet

The method is used for walls and other vertical surfaces.

In this case, compositions such as PVA or lignin of natural origin are used as glue. The wetted fibers adhere well to the walls. In this case, a monolithic insulating layer with a density of 50 to 65 kg/m3 is formed.

Cotton wool moistened with water without glue is also well applied and distributed over the wall, but there remains a risk of it settling during long-term use.

Application by wet-glue method

Excess cotton wool can be cut off with a construction knife, crushed and reused.

Dry method

Fluffed cotton wool is poured into the sinuses until it begins to spring back when pressed with your hand. It is better to fluff the cotton wool in a large tank or construction basin. To estimate the mass of the required material, it is enough to calculate the volume of the cavity to be filled and multiply it by the standard filling density.

Dry blowing

For vertical surfaces, the recommended density is 65 kg/m3; for horizontal surfaces, 45 kg/m3 is sufficient.

Industrial method

The method requires the use of a special fan that delivers the fibers to the application site through a sleeve under slight pressure. Ensures uniform fiber distribution. Allows fibers to be wetted with adhesive or water when using a wet or wet-adhesive application method.

Scheme of operation of an industrial unit

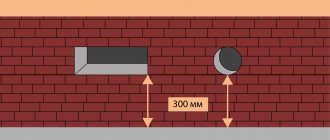

For blowing, technological holes or openings with a width of at least 10 cm are left. Upon completion of application, they are sealed.

With your own hands

Household-grade installations cost from 20 thousand rubles. But you can do it yourself by manually pouring the material. In this case, it will be necessary to strictly adhere to the technology, first of all, the quantity and density of application.

The fibers, pre-fluffed in a spacious container, are simply poured onto horizontal surfaces and leveled. To loosen, you can use a construction mixer at minimum speed.

Backfilling by hand

To insulate vertical surfaces, cotton wool is poured into prepared cavities between two walls until the material begins to spring back when pressed by hand.

The method is good for small volumes of insulation or repair work, insulation of a change house or shed. To insulate an entire house, it will be easier to buy or rent an installation.

General principles of thermal insulation

The correct technology for thermal insulation of floors consists of five main stages:

- dismantling old floors;

- installation of rough (technical) floor;

- laying insulation and securing it;

- laying a hydro-vapor barrier over the insulation;

- installation and securing of the finished floor.

Each specified stage must be carried out with the utmost care. If errors are made during the installation process, correcting them may require large amounts of time and money. Therefore, it is not recommended to carry out work without prior preparation, in a hurry and without due care.

A little history about Ecowool

The properties of cellulose have been known for a long time

Research into the possibilities of paper material at the end of the 19th century interested manufacturers and led to the creation of ecowool production technology. At the beginning of the twentieth century - 1928, the first production facility producing cellulose insulation was opened. The championship belongs to Germany.

Since then, cellulose insulation has only victoriously gained popularity: in the USA, Canada, Europe, Japan and other eastern regions, it is recognized as the most environmentally friendly and inexpensive. In Russia, domestic cellulose thermal insulation material has appeared since 1993. The technology, equipment, and even the Russian name for this insulation came to us from Finland. In Finland, the share of ecowool (where it is called “Ecovilla”) among insulation materials for low-rise construction reaches 70%.

The production of ecowool and its use is only gaining momentum in the post-Soviet space: In Kazakhstan, the material has been produced since 1999, in Estonia - since 1990, in Lithuania - since 1994, and in Ukraine and Belarus - since 2007, and since 2012 production of “Ekovata-Nevskaya” was launched near St. Petersburg.

Calculation of the amount of insulation and the density of its layer

When insulating the floor of interfloor ceilings, it is necessary to remember that the thickness of the layer of material should be 10-20 centimeters, and for the lower and upper floors - 20-30 centimeters. Density with manual open filling is 30-35 kg/m3, with mechanical blowing into a closed cavity - 40-45 kg/m3, and with mechanical open application the density is 35-40 kg/m3.

The mechanical method of blowing ecowool (between the joists) makes it possible to guarantee that the entire internal space of the floor is filled without leaving seams in it. This method allows you to achieve the optimal density of the ecowool layer and give it maximum thermal insulation characteristics.

How is insulation carried out?

This video talks in detail about wet and dry insulation. I think after watching you will have no questions left about how to insulate a house with ecowool. It is better to do it with the hands of masters. I initially wanted to insulate my house with ecowool with my own hands using a garden vacuum cleaner, but the deeper I delved into the topic, the more I realized that it’s not worth insulating the walls using the dry method - it will settle. But it’s impossible to do it with wet hands.

So at the same time I ordered ecowool from a specialist using both the dry and wet methods, why spend money on a vacuum cleaner that costs 5-10 thousand and waste months of time manually blowing it into the floor.

Necessary equipment for installation of ecowool

The main disadvantage of ecowool is the use of expensive equipment, which not everyone can purchase for domestic use.

In the process of laying the material you will need:

- attachment for a drill or mixer to loosen the material;

- container in which loosening will take place;

- personal protective equipment and gloves to protect hands and respiratory organs from small particles of material.

Having weighed all the advantages (low cost of the material, waste-free and easy installation), we can conclude that ecowool is an excellent way to insulate a residential building.

A few words about the design features of the structure

Hello again, dear subscribers. Now we are in the underground. This is a basement room. The house consists of two separate parts - the first is small, it is something like a warehouse or boiler room. The second part of the structure in question is the space under the floor covering with a height of approximately 700-800 millimeters (by eye), where our guys have already begun dismantling work - they remove the lower elements and remove the vapor barrier film. Everything here was covered in garden cellophane. It covered logs, floors, beams, and other structural parts. Using cheap film is a homeowner's mistake. This material is not intended to solve such problems, because it promotes the accumulation of condensation.

Garden film and PPS boards

What was here after the film matter? I'm showing you! The owner laid PPS slabs here. For those who don’t know, this is ordinary polystyrene foam in square or rectangular blocks. Pay attention to how they are laid (see video) or the image below in the text. There are holes and cracks ranging from one to twenty millimeters in size everywhere. For obvious, objective reasons, this material does not bring any benefit. It just hangs there, taking up space. Next there is a rough board about five centimeters. In my hands you see a slab 2.5 centimeters thick - a value that is extremely insufficient for thermal insulation work. We will not break the lower, rough part, but we will move it to the side by 3-5 centimeters.

Glassine as a vapor barrier

The space between the lower and upper parts is occupied by some kind of roofing material - the so-called glassine. It functions as a vapor insulator and also provides support for slag, basalt, and stone wool. Glassine is a flammable material. It is strictly not recommended to use it in insulating residential buildings. In the West, by the way, as far as I know, it is officially prohibited for use. Correct me (the author) if I'm wrong. We take a knife and open the canvas to see what else the insulating pie of this house consists of. See for yourself. There is URSA glass wool here. As soon as I touched it, I was already itching. What do you think, boys and girls, what density of insulator is here? Two, maximum three centimeters, pay attention to the picture below.

Glass wool as the main insulation

The generally accepted standard for floor insulation in a wooden cottage is two hundred millimeters. As you understand, this is the norm. We are short of it, according to the most conservative estimates, from one hundred seventy to one hundred eighty millimeters. Horror! For obvious reasons, remove the glass wool, collect it in bags and throw it away. Upon completion of the work, the guys will take the garbage and solid waste to a nearby landfill, but let’s not be distracted from the main topic. Next, we again have garden film - a material that is categorically unacceptable for use. Why? Because in this case the house turns into some kind of glass jar. We put it on the ground, wait thirty minutes and get a great amount of condensate in milliliters.

Lack of ventilation and risk of moisture formation

Moisture is an insidious and very strong enemy of wood. It destroys the structure, forming condensation, causing the appearance of fungal deposits and moldy areas. In the example of this house, film building materials practically eliminate the free movement of air. If there were no vents here, we would have faced additional difficulties in preparing the structure for blowing in ecowool. I would like to note that there is a forced ventilation system for the room - a small one, but still a plus. It is advisable to replace garden fabric (film) with a vapor barrier membrane. I'll talk about this a little later. Do not switch the video clip, watch further. Don't forget to like it by clicking on your thumb, and also subscribe to the YouTube channel "Ekovata-MSK".

Ecowool and other heat insulators

When choosing what is best to use for insulating a house, it is important to evaluate the features of the most popular thermal insulation materials. And here we will have to make a decision about what will be used - ecowool or basalt insulation, fiberglass or polystyrene foam.

Comparative energy efficiency is very high

Unlike polystyrene (pictured), ecowool is not damaged by rodents

To compare materials, you can use the table:

| Parameter | Glass wool | Plates based on basalt wool | Expanded polystyrene | Ecowool |

| Thermal conductivity, W/(m*0С) | 0,043 | 0,047 | 0,05 | 0,04 |

| Density, kg/m3 | 15 | 37 | 25 | 35 |

| Vapor permeability | High | High | Low | High |

| Biological resistance | Does not rot, is not damaged by rodents | Does not rot, may be slightly damaged by rodents | Does not rot, severely damaged by rodents | Does not rot, is not damaged by rodents |

| Fire safety | The fiber itself does not burn, but the binder may melt, releasing toxic smoke. | Does not burn; when heated strongly, it can release decomposition products of the binder | Actively melts with the release of large amounts of toxic smoke | Does not ignite, dies out quickly, and when exposed to an open flame it smolders, emitting relatively harmless smoke. |

The special structure of the fibers ensures the preservation of heat-saving qualities when moistened

As you can see, it is not possible to make a clear choice as to which is preferable – ecowool or mineral wool. The material we are considering may well compete with insulation based on mineral fiber, surpassing them in some parameters, and inferior in others.

Heat resistance comparison

From this comparison we can draw a fairly simple conclusion: the decision to use ecowool or other material is best made after a comprehensive analysis of the conditions. This insulation is quite effective, so the main factors of choice will be its availability in the region and the cost of thermal insulation work.

Popular ecowool manufacturers

Responsible companies monitor the composition and quality of cellulose wool produced. These features, as well as the brand’s reputation, affect the cost of insulation. Well-known companies producing ecological wool include:

- Termex. Insulation of Finnish origin. Ecowool of this brand is popular in Scandinavian countries. The material contains magnesium sulfate, boric acid and pure natural clay, which acts as a fire retardant.

- Isofloc. The product from a German manufacturer is intended for the blow molding method. Suitable for insulating any surfaces, especially in houses located in the northern regions. The products have FSC, Natureplus and Swiss-Label quality certificates.

GreenFiber. Manufacturer of thermal insulation - USA. The company is considered a leader in the production of heat-insulating materials, but its products are rarely found on the Russian market due to their high prices. Ecowool from GreenFiber is considered one of the best.

GreenWool. Russian cellulose wool, which is produced at the Finnish plant Makron. High quality products comply with the national standard ISO 9001-2015. Insulation is used in the construction of residential, commercial and industrial facilities.

Climacell. Popular brand from Germany. A distinctive feature of production is the use of clean newsprint that does not contain printing ink or has safe natural dyes. Climacell is one of the most popular European brands.

In addition to the named manufacturers, other companies are also involved in the production of ecowool: Equator, Nanovata, Kirov Ecoplus, EcoVilla, ECOCELL, IGLOO Cellulose. Choosing high-quality insulation and following installation technology helps solve the problem of heat loss in rooms. Ecowool insulation today is considered one of the effective methods of thermal insulation.

Technology for laying ecowool in floor construction

- Ecowool is laid in the floor structure between the joists. There is no need to use rubber protective gloves for work; cotton gloves are sufficient.

- Ecowool is poured between the joists onto a pre-laid roll vapor barrier or hemming sheet material.

- The poured ecowool is slammed down with a stiff brush or compacted in any other available way. The volume of ecowool should be 10% greater than the filled volume.

- After drying, the ecowool is covered with glassine and further planning of the floor is carried out.

Dry method

The dry method is also applicable for insulating ecowool walls on the indoor and outdoor sides. As a rule, it is used when necessary to fill the voids in the walls of frame houses. Insulating the roof with ecowool using a dry method is also possible, but only if there is a frame to fill it with heat-insulating material. Ecowool consumption with this method is 10-15% more economical than when applying insulation using the wet method.

Before you start applying insulation, you need to prepare it. The raw materials arrive in pressed form, so it will be impossible to apply ecowool in a commercial form. Modern equipment has the function of fluffing raw materials with a built-in mixer, but if this is not available, then the composition will need to be fluffed manually. Subsequently, under the influence of high air pressure in the hose, the composition will reach the required state. The degree of “fluffiness” of the raw material affects the penetration of insulation into all corners of the cavity, providing maximum coverage.

Thermal insulation with sawdust

Sawdust insulation is one of the most budget-friendly options for thermal insulation of wooden floors. The environmentally friendly material is quite light, so it can be used to insulate interfloor ceilings. The thickness of the heat insulation layer can be easily varied due to its flowability. Thus, it is possible to regulate the level of heat loss in the room.

When finishing the base with sawdust, you can use the following types of wood-based coatings:

- Blocks of pressed sawdust. The material is produced from copper sulfate, sawdust and dry cement. As a rule, it is laid between the joists when insulating the first floor. Lightweight blocks of small thickness - up to 15 mm, can be used for wall cladding;

- Pellets with sawdust. Granular bulk material is made from sawdust treated with an antiseptic and glue. Hard-to-burn sawdust can be used to insulate interfloor floors, since they do not create a large static load due to their low weight;

- Arbolit. In this case, the base material is mixed with synthetic and organic additives, and then molded into blocks. The non-flammable thermal insulator has high bending strength, while it is hygroscopic. Therefore, during its installation it is necessary to use waterproofing layers;

- Sawdust concrete. Externally, blocks with sawdust resemble cinder blocks. They are made from a mixture of wood chip granules, cement and sand. Suitable only for thermal insulation of the first floor of a house.

Insulating the floor along joists with sawdust in any case involves the use of a waterproofing layer. Hygroscopic material is a good environment for the development of mold and pathogenic flora, so during the operation of the coating it is necessary to exclude the possibility of moisture ingress.

Characteristics and properties

Characteristics and properties

Thermal insulation materials have various characteristics that determine their properties and consumer qualities.

Ecowool is quite light due to its low density: 32-67 kg/m3.

Cellulose fibers have low thermal conductivity λ = 0.0312-0.043 W/m*C, which guarantees high thermal insulation properties of the material.

The insulating coating is completely fireproof and has a flammability group of G2 (moderately flammable) in accordance with GOST requirements. In addition, ecowool belongs to the category of non-flammable materials with low smoke generation.

The material is slightly breathable, which makes it possible to retain heat inside the room as efficiently as possible, thanks to minimal air movement through the insulation layer.

Ecowool is vapor-tight and has low wetting ability and sorption moistening.

It is also important that ecowool is a very passive medium for corrosion processes and does not cause oxidation of metals directly in contact with it.

In addition to thermal insulation properties, ecowool has sound insulation properties due to the good absorption capacity of the cellulose fibers of the material.

This thermal insulation material meets all the basic requirements for a modern insulation product.

Ecowool insulation composition

The main raw material for the production of ecowool is waste paper of certain types. More and more attention is being paid to the collection of waste paper, the number of waste paper collection points is constantly growing, and as a result, the cost of building materials from recycled materials, including ecowool, is decreasing. True, cellulose adds some specific properties.

At the reception points, waste paper is sorted, how this is done can be seen on the website https://priem-makulatury-13.ru/ waste paper acceptance in Saransk. The sorted paper goes into production. The following types of waste paper are suitable for the production of ecowool:

- Waste from paper and cardboard production;

- Waste paper and newspaper type.

In the production of ecowool, paper products are separated into components without soaking, using the dry method. At the output, ecowool is obtained in the form of a dry, powdery substance. To reduce the flammability of paper, special impurities are added to the cotton wool.

Compound:

- 80% recycled cellulose;

- 12% boric acid, as an antiseptic,

- The rest is a fire retardant, usually sodium tetraborate, to reduce the flammability of ecowool.

Features of insulation by logs

How to properly insulate a rough foundation along the joists? During the installation of the thermal insulator, the following scheme must be observed:

- The rough base is lined with boards that must be attached to the joists;

- To prevent moisture from getting under the coating, lay a layer of vapor barrier;

- Then the base is insulated with polystyrene foam, mineral wool or other materials.

If you need to make high-quality thermal insulation of a room above a non-residential and unheated room, then it is better to use mineral wool with a thickness of more than 40 mm as insulation. In this case, the “pie” made from a vapor barrier and mineral wool will retain heat in the room, preventing heat exchange between the cold basement and the first floor.

How to insulate with ecowool?

Ecowool can be used for insulation in three ways.

1. Dry filling. As a rule, horizontal surfaces are insulated using this method. For example, in the photo they insulate the floor by placing ecowool between the joists:

If there were ceiling beams instead of floor joists, it would look exactly the same.

This is how the roof is insulated:

Apparently, there is a residential attic under the roof.

2. The second way to insulate ecowool is by mixing it with a special paste. After which the wet mass is applied to the insulated wall:

In the photo, ecowool is sprayed onto the wall with a special “vacuum cleaner”.

In the same way, having obtained a viscous wet mass, you can insulate the wall along the frame:

Here we do without expensive equipment, but simply throw on the wet mass, like any other plaster solution, and level it, using the frame slats as beacons. Decorative trim is then attached to the same slats.

This solution has a higher density than dry ecowool, so the thermal conductivity is greater. But it is more convenient to insulate vertical structures this way and you can be sure that such “plaster” will not “sag” later, which means that cold bridges will not appear.

3). The third method is to insulate the walls, again using the frame, but without paste. We are talking about simply filling ecowool inside the wall pie. How to do this, what the risks are and how to avoid mistakes, read on.

So, even without considering myself too much of an expert, I did not find that there are any disadvantages of ecowool in terms of ease of use for insulation.

Nuances of insulation of various building elements

Stan

Walls can be insulated using all available methods. For example, insulation is poured into a frame house manually or blown mechanically into closed wall cavities. The brickwork “well” is also insulated in the same way. The wet method is not suitable here.

When insulating the facade, the wet-adhesive method is used. The technology for applying insulation includes:

- fastening to the wall a sheathing made of timber with an edge of 10-20 cm and a cell size of 60x100 cm;

- preparing the insulation mass for application;

- applying insulation under pressure;

- drying the applied layer;

- cutting off the excess, after which the outer layer of thermal insulation is covered with OSB boards.

Walls from the inside can be insulated manually, dry or wet.

For manual and mechanized blowing of cotton wool, a frame is made of timber or metal profiles. The pitch between vertical posts is 600-1000 mm. The thickness of the insulating layer is 20 cm (the width of the timber or metal profile is 200 mm). If the room height is more than 3 m, horizontal partitions are attached in the middle of the wall, which should take up half the weight of the insulation.

Otherwise, after a few years, under the weight of the column of cotton wool, the bottom will sag, opening a large bridge of cold at the top of the room. A vapor-permeable film or kraft paper (wrapping paper) is attached to the sheathing to create an enclosed space. A hole is made at the top of each niche to supply cotton wool. After filling each cavity, the hole is sealed, after which the operation is repeated with the next cell of the frame.

Important: in some materials you can find a recommendation to use parchment on the walls, which does not allow them to breathe. Oiled paper can only be used when insulating the roof, but, again, not in the attic.

After insulating the entire wall, the sheathing is covered with sheets of OSB, plywood or plasterboard. The disadvantage of this method is a significant reduction in the volume of the room.

Wet wool is applied using the same technology as on the facade of the building, which can be seen above.

Roofs

At the stage of preparation for insulation, the roofing material is waterproofed. The rafter system is reinforced with metal profiles or well-dried coniferous timber. The attic space is cleared of all unnecessary things.

There is no need to prepare the sheathing, since the rafters serve as a ready-made frame. All that remains is to use parchment or vapor barrier film to create a niche for blowing in the cotton fibers. Here, unlike the wall, the roof slope can be closed from the bottom up in stages, one meter in height, if the work is done manually. When using specialized equipment, it is more convenient to attach film or paper over the entire surface of the roof and fill the cavities through the hole at the top of the film.

Note that the wet method is not used for thermal insulation of roofs, although there are no obstacles to this.

Paula

Dry cotton wool is used for the floor. Insulation can be done manually or using equipment. In the first case, cotton wool is manually poured between the joists, leveled, and then covered with a finished wooden floor. If the finishing floor covering is laminate, linoleum, parquet or ceramic tiles, OSB or plywood sheets are laid over the joists.

When using the equipment, the finished floor or protective boards should already lie on the joists, creating a closed niche for the insulation.

Advantages of the material

Undoubtedly, each material has a number of advantages over others. What are the advantages of ecowool?

Elastic and elastic cellulose fibers in ecowool (unlike mineral fibers used for the production of other insulation materials) do not shrink the material over time.

Ecowool Extra

The thermal insulation layer, made according to all the rules using ecowool, is more durable. Among other things, the thermal insulation properties do not deteriorate over time, which cannot be said about some other materials.

This coating is completely hygienic, hypoallergenic and non-toxic, and is also safe for humans and animals throughout the entire life of the building. Due to special processing, the components that make up ecowool remain non-toxic even with significant heating, without emitting harmful volatile gases.

Structure of mineral wool and ecowool

In the event of a fire, ecowool will not only not ignite, but will also actively localize the fire, preventing its further spread. Belonging to the category of substances that are difficult to ignite, the material does not melt or burn even at high temperatures. The decay of cellulose fibers is safe for humans and nature, and when the source of fire is eliminated, the process stops immediately.

Ecowool is fireproof

Ecowool is hygienically resistant and not susceptible to rotting, mold, various fungi and bacteria. The biostability of the insulation also extends to the materials in contact with it; their physical, chemical and consumer qualities are preserved.

It is known that concrete and brick without special treatment over time under the influence of microorganisms can be subject to destruction processes at the cellular level, which in turn can negatively affect the condition of walls, interpanel seams or window openings, causing freezing or icing of certain areas. The use of ecowool can significantly minimize this risk.

Insects and rodents do not grow in the heat-insulating layer of ecowool. Cellulose fiber and an admixture of boron are an unacceptable environment for their habitat, due to the property of boron to block the respiratory tract, causing swelling of the mucous membranes and, as a result, the death of the rodent. For certain regions, this is perhaps the only way to protect your home from rats and mice.

The fine-fiber structure is capable of filling all the voids and recesses of the room being treated, regardless of the building material, which makes it possible to build a soundproofing wall and allows you to at least double the sound insulation in comparison with mineral wool slabs, reducing to zero the transmission of sound waves through gaps and cracks in walls, floors or ceilings . No other material can provide this.

Ecowool for home

High moisture-resistant properties and low vapor permeability make it possible to accumulate and remove moisture from the hollow capillaries of the material fibers without the latter losing its qualities. Ecowool is hygroscopic, which means it does not accumulate micro-condensation, regardless of weather and climatic conditions, which prevents rotting of internal wooden floors.

The ability of the material to “breathe” makes it possible to install ecowool without using an additional vapor barrier layer, without worsening the microclimate of the building.

Ecowool allows you to obtain an even, seamless contour of thermal insulation, in which the insulation fills all hard-to-reach places and irregularities without the formation of temperature bridges.

Ecowool quality

Installation of the material is waste-free, which certainly reduces the cost of work.

Laying the insulation layer can be done at any time of the year, regardless of temperature conditions. The installation process itself is easy and technologically advantageous - there will be no waste of material. In addition, this heat-insulating composition is distinguished by high speed of installation work.

Thermal insulation ecowool

Ecowool allows for “additional insulation” during major repairs without dismantling the existing insulation layer.

In addition, ecowool can be reused without any processing.

The use of ecowool allows you to reduce heating costs in winter by 2-3 times. And keep your home cool by 30-40% in the summer.

This material is universal and can be used on any surface - vertical, horizontal or inclined.