Cold floors in a wooden house are a common occurrence. This is all due to cold air currents rising from the ground cover. They penetrate through cracks and make the floor surface temperature uncomfortable. Insulating the floor in a wooden house from below will help .

This is what floor insulation looks like during construction

It is necessary to carry out work on insulation from below technologically correctly. This provides a number of undeniable advantages:

- the height of the floor of the room does not change;

- there is no need to select the rigidity of the insulation, which can withstand the weight of furniture and equipment;

- the line of condensate settling outside the structure is reduced, which prevents the process of rotting of the house.

Placing insulation is an effective measure of protection from the cold

Floor insulation options

When starting work, you need to choose the material and method of laying the insulation. The determining factor will be the design features of the building , as well as the wishes and financial reserves of the owner. It is important to take into account the key details of the installation and subsequent operation of the wooden structures from which the house itself is made.

Foundation options:

- foundation on piles;

- strip foundation;

- frame type;

- screw piles.

There are also generally specific points that are important to consider:

- Use of waterproofing. A radically important measure. Prevents the appearance of swollen boards. It is best to use single-sided fiber.

- Two-layer insulation method. The best way to keep your home warm. To prevent the effects of temperature fluctuations and humidity, the wooden parts of the building are pre-treated with special protective equipment.

- Stability of thermal insulation material when adjacent to wood. The selected thermal insulator must be inert with respect to the elements of the floor and foundation.

1-joists, 2-cranial block, 3 – subfloor, 4 – lutrasil (glassine), 5 – shavings (sawdust), 6 – lime mixture, 7 – finishing floor

Calculation of insulation thickness

The thickness of the insulation layer plays an important role. It is calculated individually for each home, taking into account design features, climate and type of insulation. The formula is given in SNiP 02/23/2003:

- R – thermal resistance. It is determined from the tables in the SNiP appendix.

- A is the thermal conductivity coefficient. Each type of insulation has its own. The value is indicated by the manufacturer or can be found in the SNiP tables.

If you need to lay a thin layer of insulation, it is better to use extruded polystyrene foam and other materials in mats or rolls. Mats increase strength and elasticity.

How to insulate a wooden floor with penoplex - step-by-step instructions

Penoplex is the latest generation material. This is a foamed polymer produced by extrusion. It has low thermal conductivity due to its durable structure with a large number of cells.

Penoplex is produced in slabs, the thickness of the slab is from two to 10 centimeters . Outwardly, it strongly resembles polystyrene foam. Does not increase the weight of the structure.

Does not absorb moisture . Foamed polystyrene is not affected by fungi and rotting processes.

It should be noted that the thermal conductivity of penoplex is 25 times lower than the thermal conductivity of expanded clay concrete. This factor significantly increases the insulating characteristics.

Penoplex density is 22 t/m

Therefore, the material is mechanically strong and does not require a frame to work with it.

If necessary, this thermal insulation material can be used to install “warm floors” (electric and water type). Penoplex is fire resistant .

The cost of penoplex is slightly higher than the cost of other insulation materials, but it easily pays for itself in the cold season.

Let's figure out how to act correctly when carrying out insulation work.

The most convenient way to place expanded polystyrene foam is to alternate with logs and lay the floor covering on top of them.

Find out how to make a water heated floor in our specialized article.

Prices for thermal insulation materials Penoplex

Thermal insulation materials Penoplex

Video - Error in insulating the floor in the house

Step 1. Prepare the base for laying the material.

We install the logs on the completed foundation elements. It is important to maintain a distance from joist to joist of 1-1.2 meters . Next, we mount thickened plywood (possibly chipboard sheets) and use self-tapping screws.

Blank for a new floor

Step 2. Lay the penoplex.

The insulation has already been laid, all that remains is to cover the floor with a finishing board

The height of the insulation layer varies. However, it is worth remembering that it should not be higher than the level of laying the logs. We must not forget about the layer of waterproofing material. They need to cover the subfloor itself and the joists and the insulation layer itself before laying the floor covering. It is also advisable to use wood treatment with solutions of antiseptics and antifungal mixtures.

Step 3. Seal the joints.

We glue the waterproofing joints with metallized tape to maintain tightness. Such measures will prevent the absorption of condensate by wooden beams and the growth of mold and fungi.

Penoplex slabs

Experts recommend sealing the joints of insulation boards using polyurethane foam .

Step 4. Work on the finished floor.

We fix the finishing boards on top of the waterproofing layer.

Find out how to lay laminate flooring on a wooden floor, and also read the step-by-step instructions in a special article on our portal.

Key points of installation work

All materials used for floor insulation have their own methods of fastening. However, there are the main points of the thermal protection device. They are recommended to be observed when installing any material.

The order of arrangement of the main layers when installing floor insulation in a wooden house with your own hands:

- waterproofing layer;

- thermal insulation layer;

- vapor barrier material;

- direct structural elements of the floor;

- flooring.

When choosing insulation, it is worth calculating the height of all layers

Experts say that this arrangement of the main layers will allow for optimal thermal conditions inside the room. This technology maintains the necessary circulation of moisture in the house.

Helpful advice! When insulating the basement floor in a wooden house, you can choose beams with a cross-section from 50 to 100 mm. They are fixed from below, and a layer of insulation is laid between them. Additionally, the resulting “pie” should be covered with boards.

Waterproofing

When insulating the floor in a private house, you cannot do without waterproofing. Due to the ability of cold air to condense on a warm surface, the wooden floor is exposed to moisture. Its constant presence in the room leads to the active development of fungus, mold and causes rotting of the structure itself. Especially if no special means were used during the construction of the house.

Layout of waterproofing for floor insulation

When laying thermal insulation without a waterproofing layer, exposure to moisture negatively affects the thermal conductivity properties of the material. The result is an increase in indoor humidity and a decrease in temperature. Waterproofing helps to avoid these unpleasant moments.

A waterproofing layer is laid on the side exposed to cold air currents.

Vapor barrier laying

Human heat and equipment operating in the home release warm air. It passes through the ceilings and condenses when it encounters cold air. The problem with this phenomenon is that moisture settles inside the structure. As a result, the tree swells and begins to rot from the inside. It will not be possible to prevent this process by treating with special means. Therefore, when insulating the floor in a wooden house from below with penoplex or other material, the presence of a vapor barrier is mandatory.

Scheme of laying a vapor barrier during insulation of a wooden floor

When carrying out installation work from below, the vapor barrier layer is laid first. The simplest and most affordable material for this is polyethylene film. It is excellent for both vapor and waterproofing.

The presence of such layers in the floor covering must be designed in advance. If this was not done on time, then it is necessary to lay the film immediately after putting the house into operation.

Helpful advice! Moisture-windproof membranes are an excellent material for hydro- and vapor barrier. This material allows air to circulate and retains moisture from it. It can be used when insulating the floor with penofol or other insulation.

Thermal insulation materials for floors

1. Mineral wool.

A commonly used heat retaining medium. Non-flammable lightweight material with good sound insulation properties .

There is slag, stone, and glass wool.

Mineral wool in a roll is convenient for work

2. Expanded clay.

Expanded clay is a natural material

Prices for expanded clay

Expanded clay

It is made from clay or slate. Expanded clay is fired at elevated temperatures.

Table 1. Properties of expanded clay.

| Advantages | Flaws |

| Excellent sound insulation | The density of the insulation mass increases under the influence of its own weight |

| Can be used in sub-zero temperatures | May cause subsidence of the structure |

| Eco-friendly, safe for the home microclimate and human health | Absorbs moisture |

3. Sawdust.

Small wood shavings, waste from the wood processing industry.

They are quite cheap, but they provide a good insulating effect and can create sound insulation. They require special treatment to prevent rodents and insects from appearing in the sawdust. Next, it is mixed with cement and water and applied as insulation. It also makes sense to use clay. This will increase the thermal insulation properties of sawdust.

Sawdust is cheap and practical for do-it-yourself home insulation

When working with sawdust, it is extremely important to carefully lay the material, obtaining a dense and fairly even insulating layer. If the technology is not followed, the effectiveness of thermal insulation is greatly reduced.

4. Foam plastic.

Aka polystyrene foam. Resistant to moisture, fire, chemical factors. Good thermal insulator . Easy to install and remains in good condition for a long time.

Modern foam looks like this

5. Ecowool.

80% consists of cellulose fibers . For production, waste paper, waste and waste from paper production are used. It also contains sodium tetraborate, which makes it resistant to fire. Boric acid in ecowool provides protection against bacteria and fungi.

Ecowool applied dry

It is advisable to use ecowool for insulating houses with high humidity , as this prevents the appearance of abundant condensation in the walls and other internal environments of the structure.

There are three ways to apply ecowool. These are dry, wet and glue methods.

- dry application mainly works for country houses;

Cellulose wool is supplied using specialized equipment. During the work, dust is created, which is why it is better to use masks, respirators and goggles for safe installation of insulation.

- the wet application method is used when there is a need for further wall covering;

Water is added to the raw material.

When the resulting mixture hardens, it forms a dense mass.

- The adhesive method is used to insulate reinforced concrete or metal structures.

Installation of different types of thermal insulation

Options for thermal insulation are offered that differ in the technological process (spraying and laying insulation).

Spraying of polyurethane foam

Before starting work, it is necessary to dismantle the floor covering. The rough foundation and logs should remain.

Step 1. It takes specialists about an hour to prepare the equipment for work. The future foam (polyol) and hardener (isocyanate) are mixed under high pressure (150 atmospheres). To insulate the floor, a closed-cell material is used that is not afraid of moisture (open-cell polyurethane foam is more suitable for insulating interior partitions).

The future foam is mixed with a hardener

Step 2. It is better to cover surfaces that are valuable (to a height of about 0.5 meters from the floor along the entire perimeter), since during work the finely dispersed mass can stain objects and cladding.

Sockets are covered with film

Step 3. The flooring begins. Work must be carried out in protective suits and masks (only half an hour after application the foam becomes completely harmless).

Floor pouring begins

It is necessary to ensure that no open cavities are left. The result is a monolithic base made of foam insulation.

Monolithic PPU coating

Step 4. The room must be ventilated. What needs to be done after the foam has hardened? Clean it off the beams. After this, the finishing coating can be laid. If excess polyurethane foam has formed, it can be removed with a regular stationery knife.

Laying mineral wool insulation

Such work is completely within the capabilities of every home owner. This is the floor that needs to be insulated (there is no finishing coating, but if it is present, it will have to be dismantled).

This floor needs to be insulated

Step 1. All joists and rough boards must be treated with an antiseptic.

Step 2. A vapor barrier is laid on the surface of the rough base. The canvases should be placed overlapping (if there is no moisture penetration from below, you can skip this step). If you attach the material with double-sided tape, this will ensure the tightness of the coating.

Laying vapor barrier material

Step 3. Insulation will be made of mineral wool 5 cm thick, laid in three layers. The first layer is made of rolled material to minimize the number of joints. It needs to be cut using a construction knife so that it fits tightly between the lags (it is recommended when cutting to ensure that the width of the thermal insulation is about a centimeter greater than the distance between the lags). Having straightened out, it will fill the entire space.

Mineral wool is laid between the joists

Step 4. Next, the slab material, cut to width, is laid.

Mineral wool in slabs

During installation, the offset of the slabs of adjacent rows must be observed. This must be done so that the seams are located at a distance from each other. Thus, the thermal insulation characteristics of the coating will be higher.

Thermal insulation boards laid

Of course, it is easier to work with slabs, they are denser, and easier to lay.

Step 5. A vapor-waterproofing membrane is also overlapped on top (smooth side down). A construction stapler is perfect for securing. The coating should extend slightly onto the walls of the building.

The membrane should extend slightly onto the walls

It is recommended to secure the edges of the membrane to the walls with double-sided tape (the protective film is then removed).

The edges of the membrane are fixed with double-sided tape

The floor is ready for finishing.

You can start finishing

Wooden houses are always associated with comfort. However, for your home to be truly comfortable, you need to take care of its insulation. Thermal insulation of the floor is the most important step, which is usually performed immediately after the construction of the structure.

Insulation of a wooden floor with mineral wool

You can find various modifications of insulation on the market. There is mineral wool in ready-made rolls and slabs.

Capable of absorbing moisture, which means good vapor barrier is extremely important. At the same time, it is able to protect the wood of surrounding structures from excessive moisture and decay .

Experts recommend taking precautions when working with mineral wool: using protective clothing

The required attributes also include gloves, a mask and goggles. The small fibers of the material may cause severe itching, redness of the skin or irritation of the respiratory tract.

Ecowool

Ecowool is made mainly from waste paper: more than 75% of the composition of ecowool is recycled paper. The rest is natural ingredients of organic origin.

Already from the name of the material it is clear that it is environmentally friendly, therefore, unlike mineral wool or extruded polystyrene foam, it is safer for humans. Ecowool retains heat well and does not ignite. It loses its thermal insulation qualities after being saturated with moisture, but as a result of drying it quickly restores them.

There are two ways to insulate the floor in a wooden house using ecowool. It can be placed between the joists manually. You can also use injection molding machines to fill the gaps between the joists. The second method is quite fast, but it is more often used for applying ecowool to walls (using the so-called wet method).

Floor insulation with penofol

Penofol looks like a layer cake. Foamed polyethylene is covered with pure aluminum foil. Available for sale in large rolls. The penofol sheet has a thickness of three to ten millimeters. It retains heat perfectly, provides high-quality sound insulation, and is safe for the environment of the home.

Foil penofol is an easy-to-work material

The effectiveness of penofol is based on the reflection of thermal radiation . This is how heat is retained indoors. This is due to high quality aluminum foil. Here its properties are close to those of precious metals.

I distinguish between penofol with two and with one layer of foil. In addition, there is self-adhesive penofol.

Penofol is susceptible to moisture. However, it is not capable of absorbing moisture on its own.

Penofol does not support combustion

The disadvantages of the material include low rigidity, which can create additional difficulties when working with it.

Attaching penofol may also require additional effort. Punch-out fasteners cannot be used, because this will lead to deterioration of properties. All that remains is special glue, which will also have to be purchased.

To work with vertical and inclined surfaces, it is advisable to take self-adhesive penofol .

Recommended for use as additional insulation. Serves no more than 5 years .

Ventilation device

The first stage of insulation is the installation of a ventilation system in the underground, which will ensure air circulation inside the room and prevent the formation of condensation on surfaces.

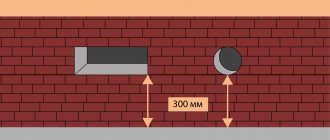

Underfloor ventilation consists of installing two pipes on different sides of the room. The optimal location of pipes is on the south and north sides of the house. The installation of pipes is carried out in accordance with the laws of physics, cold air tends downward, and after warming up it rises.

The supply pipe is located at a height of 20-30 centimeters from the basement floor, and the inlet pipe - 40 cm from the ground. The outer opening of the pipe is covered with a fine mesh - protection against rodents entering the basement.

The outlet pipe is placed 30 centimeters below the basement ceiling. And its upper end is brought out onto the roof of the house. The top of the pipe is covered with a protective cap. This arrangement of pipes will ensure optimal air movement in the underground and protect the room from mold.