Properly selected and installed insulation allows you to improve the microclimate in the room, because... It helps keep you warm in winter and cool in summer. The formation of additional thermal insulation is economically beneficial, because Helps reduce heating and cooling costs.

Thermal insulation materials on the market differ not only in characteristics, but also in areas of application.

Insulation materials are an extremely popular product on the market of thermal insulation materials. Regardless of what field of construction you work in, insulation materials can be used in both civil, private, and industrial construction. We offer an extensive line of Isoroc insulation. The material is based on mineral wool. Environmentally friendly raw materials, processed using modern equipment, fully comply with GOST standards. This means: you get European quality at an affordable price. The truth of these words is confirmed by the experience of leading developers: Isoroc thermal insulation was used in the construction of the largest construction projects in Russia.

We offer an extensive line of Isoroc insulation. The material is based on mineral wool. Environmentally friendly raw materials, processed using modern equipment, fully comply with GOST standards. This means: you get European quality at an affordable price. The truth of these words is confirmed by the experience of leading developers: Isoroc thermal insulation was used in the construction of the largest construction projects in Russia:

More recently, another interesting fact was revealed. It turns out that the integrity of superthin basalt fibers is not damaged by the radiation environment. Therefore, Isorok mini-plates began to be used as thermal insulation for nuclear industry buildings.

ISOVENT-N

Isoroc Isovent-N is a mineral wool insulation based on stone fiber. The material is made from natural components of igneous rocks of the basalt group.

Non-flammable hydrophobized mineral wool slabs based on stone. Intended for use in civil and industrial construction as unloaded heat and sound insulation of horizontal, vertical and inclined building envelopes of all types of buildings, including low-rise and cottage-type individual buildings; middle layer in three-layer lightweight masonry (layered, well); inner layer for two-layer insulation in curtain wall systems with an air gap; heat and sound insulation of technological equipment with a temperature of the insulated surface from minus 60 to +400°C.

Universal heat insulator ISOFLOOR

This material from the manufacturer Izorok contains non-flammable stone wool, which also has a high level of moisture resistance. The form of the material is presented in the form of plates. Thanks to this heat-insulating product, it is possible to reduce the amount of heat loss from various types of foundations (concrete or reinforced concrete structures, self-leveling, electric, water floors and similar structures).

The cost of this insulation product is 130 rubles per square meter.

ISOFLOOR

ISOROC's assortment includes various thermal insulation building materials. Including Isoflor. This building material can be used to solve a wide range of problems. From us you can purchase Isoflor both wholesale and retail. We are a product manufacturer. Therefore, our price for Isoflor does not contain any unreasonable markups. It is significantly lower than most resellers. In this section you will learn useful information about the properties of building materials and the terms of cooperation with us.

Mineral wool Izorok – reviews

Still, it is important to know what people who have already dealt with it think about the material. Here are some reviews found on the forums:

Fedor, Voronezh : “We used Isovent for the facade - excellent, elastic slabs, although the size was a little unusual. There were no problems during installation - everything was quick and easy. I liked that there is no dust from such slabs and the edges do not even crumble after cutting. For me, this is an indicator that everything will fit perfectly in the sheathing, and the insulation will not be blown out through the gap.”

Alexander, Moscow : “I am an inexperienced builder, so I spent a lot of time studying reviews about different materials. As for the insulation, I couldn’t choose a brand for a long time, so I decided to look at everything in the store and immediately feel it. I liked Izolight-L from the inexpensive series, especially since it didn’t give off “fluff” like Rocklight.”

Peter, Kaluga : “I have used Isorok more than once, but only this year I had the opportunity to work with the Ultralight variety. It seems to me that this is the worst decision of the company, since there is stratification. When laid, the mats broke up into bundles of fibers. We had to correct everything during the installation process - we threw the slabs onto a film backing and, as if on a stretcher, delivered them to the attic one by one. In principle, it turned out well - I compacted it between the lags, and then carefully pulled out the film.”

ISORUF V

The use of rigid Izoruf V slabs as an insulating material (alone or together with Izoruf N slabs for the bottom layer) seems to be the most rational option for thermal insulation of a load-bearing roof. Before the advent of this material, a layer of rigid insulation had to be first placed on the roof structure, followed by a cement screed, and only after that could waterproofing be installed. This inevitably led to a heavier structure and forced the construction of more powerful supporting structural elements. The total cost of construction increased.

Do-it-yourself installation of ISOROC insulation

Installation diagram of Izorok mineral wool on the facade

The general principles of working with the material consist of several simple recommendations:

— slabs of material are laid in several layers with overlapping joints, excluding cold bridges;

- protected on the warm side by a vapor barrier, and on the cold side by a waterproofing film;

— the material must be additionally secured to vertical walls to prevent slipping;

— it is necessary to provide access to remove moisture from the surface of the film by creating a ventilation gap.

ISORUF-NL

Thermal insulation is the most important stage in the construction of a facility for any purpose, and today many types of materials are offered for this work, each of which has certain characteristics and properties. The Isoroc company, which has been working in the field of manufacturing heat and sound insulating materials for a long period, offers Isoruf slabs for the installation of a reliable and effective thermal insulation structure. Izoruf can be classified as a unique energy-saving material that is made using the latest technology.

Products ISOLIGHT

Scope of application of Izolight products

Izolight products (Izorok Ultralight) are slabs made from basalt wool, which has a high level of moisture resistance. A total of 3 varieties are sold, which have different densities. This product is used for residential, non-residential and industrial premises. Used for thermal insulation and sound insulation. It is a universal material, as it can be used in various fields. Thermal insulation is carried out for external and internal walls, partitions, roofing, basement and so on. Suitable for completely different types of surfaces.

Costs per square meter are 100 rubles. This is an excellent price, since it is less than similar products from Rockwool, TechnoNIKOL and others.

PP-60/-80

PP-60/-80 are non-flammable mineral wool slabs based on stones with water-repellent and dust-removing additives. Designed for use as unloaded thermal and sound insulation of pitched roofs, floors, ceilings, internal partitions, light frame structures, three-layer lightweight walls of low-rise buildings made of brick, aerated concrete and other blocks, for thermal insulation of equipment and pipelines with an insulated surface temperature of - 60 C to + 400 C.

Specifications

Technical characteristics of insulation

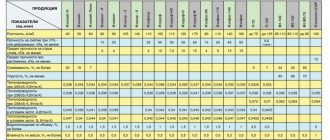

Let's consider the technical characteristics of insulation from the manufacturer Isorok. Pay attention to the table. Here are presented materials from Izorok, which have different densities.

| Products | Isolite - L | Isolite | Isolite Lux | Isovent - L | Isovent | Izokor - C | Izokor - K | Isoflor |

| Options | ||||||||

| Density, kg/m3 | 40 | 50 | 60 | 80 | 90 | 105 | 140 | 110 |

| Compressive strength at 10% deformation, not less | 10kPa | 20kPa | 25kPa | |||||

| Ultimate peel strength of layers, not less | 3kPa | 4kPa | 4kPa | |||||

| Compressibility, no more | 30% | 15% | 7% | |||||

| Elasticity, %, not less | ||||||||

| Thermal conductivity at (283±5) K | 0,036 | 0,034 | 0,034 | 0,034 | 0,034 | 0,037 | 0,038 | 0,034 |

| Thermal conductivity at (298±5) K | 0,038 | 0,036 | 0,036 | 0,036 | 0,036 | 0,038 | ||

| Water absorption, no more | 1,5% | 1,5% | 1,5% | 1,5% | 1,5% | 1,5% | 1,5% | 1,5% |

| Humidity by weight, no more | 0,5% | 0,5% | 0,5% | 0,5% | 0,5% | 0,5% | 0,5% | 0,5% |

| Organic substances by weight, no more | 2,5% | 2,5% | 2,5% | 3,5% | 4% | 4% | 4% | 4% |

| Fire hazard class | Non-flammable | Non-flammable | Non-flammable | Non-flammable | Non-flammable | Non-flammable | Non-flammable | Non-flammable |

*

P-125

P-125 are non-flammable mineral wool slabs based on stones with water-repellent and dust-removing additives. Designed for use as unloaded heat and sound insulation of horizontal, vertical and inclined building envelopes of all types of buildings, including: in three-layer lightweight masonry (layered, well); frame walls and partitions; attics and interfloor ceilings, for thermal insulation of equipment with a temperature of the insulated surface from -60 °C to + 400 °C.

Scope of application of ISOROK thermal insulation

Due to their performance properties, ISOROC insulation materials can be used for thermal insulation of structures of various types .

Low thermal conductivity and good moisture resistance determine the use of ISOROC mineral wool materials for insulation of external walls (facades of various types) and roofs . Technical thermal insulation provides fire protection for ventilation ducts and other utilities.

Good vapor permeability and effective noise absorption make basalt mineral wool a good option for insulating internal walls and interfloor ceilings . At the same time, it not only reduces heat loss, but also creates a favorable indoor microclimate.

ISOVENT-SL

Isoroc ISOVENT-SL is a non-flammable hydrophobized mineral wool slab based on stone. Designed for use as heat and sound insulation of horizontal, vertical and inclined building envelopes, including: in three-layer lightweight masonry (layered, well); suspended facades with an air gap (ventilated facades) with single-layer insulation and as an outer layer with a two-layer insulation scheme, for thermal insulation of equipment with a temperature of the insulated surface from -60 to +400 ° C.

Insulation materials

0 votes

+

Vote for!

—

Vote against!

High energy efficiency of buildings against the backdrop of rising prices and obvious savings in energy resources is the need of our time. There are many methods for these purposes, and one of them is insulation. The choice of quality material plays an important role here. New production lines have made it possible to produce high-quality materials intended for insulation of enclosing and building structures. The article will focus on Izorok insulation.

All products manufactured under the Isorok brand meet all international quality requirements and are one of the leaders in thermal insulation materials. The excellent performance properties of insulation, combined with an affordable price, ensure its widespread use in the construction of new and renovation of old premises, increasing their energy efficiency.

Isorok characteristics

The entire line of Izorok insulation, which includes many types of material, is characterized by the following properties.

- Low thermal conductivity. The presence of a large number of air pores in minislabs allows one to accumulate and retain heat in the walls of buildings and reduce energy costs.

- High level of sound insulation. Mineral wool insulation, due to its structure consisting of small fibers, has excellent soundproofing properties. Fibers of different lengths can effectively absorb the energy of any sound waves. By using minislabs, you can successfully solve the problems of soundproofing rooms.

- Excellent tensile strength. The high resistance of the slabs to mechanical stress helps to increase the properties characteristic of insulation - sound and heat insulation.

- Excellent resistance to deformation. Isorok insulation materials have excellent strength properties that ensure strength and durability.

- Excellent water-repellent properties. This characteristic was made possible thanks to special hydrophobic additives that prevent the penetration of moisture into the material, increasing the thermal insulation properties of the minislabs.

- High fire-resistant properties. Natural non-flammable elements that are included in the composition enable the fibers to retain their original properties over the widest temperature range.

- Environmental friendliness of the product. All Isorok products are made from pure natural raw materials, which ensures high environmental performance of the finished material. The use of mineral wool insulation of this brand is a guarantee of providing favorable living conditions in any insulated room.

- High resistance of the entire line of insulation to the destructive influence of aggressive environments.

- The water resistance of mineral wool boards makes it possible to insulate them using aqueous solutions.

- The high strength of the material, which is achieved during the production process, ensures the absence of shrinkage, breakage, and deformation of insulation sheets, and, accordingly, the high quality of the work performed.

- Resistance to fungi and microorganisms is explained by the inorganic nature of the material.

All types of insulation of the Isorok brand are durable and stably maintain their performance characteristics even after the warranty period has expired, which is the best recommendation for both large developers and individuals who want to insulate their homes efficiently and reliably.

Application of Izorok insulation

All Isorok products are varied and include slabs for heat and sound insulation, vapor and waterproofing membranes, pierced mineral wool mats. Isorok brand insulation has a wide range of purposes and is used in the construction of various structures, buildings and structures of industrial and residential stock, for their reconstruction and repair. This list may include both temporary structures and buildings intended for long-term use.

Depending on the density of Isoroc, it is used for:

- internal thermal insulation of walls;

- floor insulation;

- insulation of attic structures and roofs of various buildings;

- in multi-apartment buildings for soundproofing individual rooms;

- thermal insulation of various types of communications;

- increasing the anti-seismic characteristics of any structures.

Industrial products are mainly used for:

- thermal insulation of pipelines above ground and in basements;

- insulation of pipes handling liquids with positive and negative temperatures.

For each type of work, there are different brands of insulation, with their properties and characteristics best suited for them. In order to make a choice, you need to know the brand and its purpose. This will make it easier to choose the appropriate one, which will guarantee the quality of the work.

Brands and purpose of Izorok insulation

Insulation for interior work:

- Isolite . Minslabs are designed for insulation and sound insulation of various building structures. These structures include vertical, inclined and horizontal surfaces. Izolyte can be used for insulating wall frame structures, including for creating partitions, as insulation in frame walls, interfloor ceilings and attics.

- Izoruf . Minslabs are used as a thermal insulation layer for equipment in horizontal structures. These can be flat roofs, multi-layer insulation is allowed. Another example of use is thermal insulation of floors if the rough foundation is made using the dry method, that is, there is no cement-sand screed. Isoruf is recommended for use in single-layer coatings. In multilayer insulation, two types of this insulation are usually used: the top layer is laid with Izoruf B brand material, and the bottom layer with Izoruf N brand material. These varieties can also be used as a heat-insulating layer in “sandwich panels” with a metal shell.

- Isoflor . High-density mats used in construction work as an intermediate layer in reinforced concrete structures for sound and heat insulation of interfloor floors. The same material is used to insulate the floor when installing a wet screed or self-leveling floor. Isoflor can also be an element of “sandwich panels” with a metal shell.

Insulation for external work.

- Isovent . Mineral wool boards, the brand of which is used in construction in the form of heat and sound insulation of various structures, such as layered or well masonry. The same option will be the most suitable if the building insulation work is carried out using a system of suspended ventilated facades.

- Isophas . Minslabs are recommended to be used for insulation of the outer perimeter of the walls of a building if the work is carried out using the wet method. Isophas and Isophas 140 slabs are used mainly as thermal insulation for facades where plastering is used. Brands Isophas 90 and 110 - respectively in cases where the plaster layer is thick. Plastering is carried out using steel reinforcing mesh.

The most popular insulation boards among private construction are isorok 50 (density 50 kg/m3) and isorok 75 (density 75 kg/m3). On average, their cost is 350 rubles/pack. They are suitable for indoor and outdoor use

Technical thermal insulation Isorok. These products are represented by pierced mats and heat-insulating cylinders.

- Isorok M1-100, M2-100 . This is a heat and sound insulating material, the scope of which includes the insulation of building structures of various types, as well as industrial equipment used in the temperature range from - 180 to an impressive +700 C. Another option for insulation is M2-100 tufted mats, among other things, are produced on a metal mesh. And the last representative from this line - M3-100 mats - have an additional coating made of another heat-insulating material - fiberglass.

- Ishell - C and Ishell - CF. Foil-coated heat-insulating cylinders and half-cylinders are designed for insulation of process pipelines. Operating temperature range from -180 to +400C. The price of isorok insulation of this brand ranges from 400-500 rubles/pack.

Installation of Izorok insulation

There are rules for performing insulation using Isorok slabs for different types of surfaces. Most technologies require the use of vapor and waterproofing to maintain the quality of the insulation. To ensure the best performance, it is imperative to use products from the same company.

Cement floor screed with Isorok insulation

- Before you begin laying the insulation, it is necessary to remove the worn-out floor covering, clean the old screed from any contaminants located there, seal the cracks and cracks, level the entire surface, lay waterproofing material, then lay the isor mats, which should be located close to each other, thus so that there are not even minimal gaps between them. Then the waterproofing layer is laid again, and a reinforcing mesh is placed on it, onto which the cement screed is poured.

- If under the screed there is a room in which it is warm and humid, for example a sauna, then there is a need for additional vapor barrier, which in this case is located under the insulation sheets. If there is a cold and damp room below, such as a cellar, then the vapor barrier is located on top of the insulation.

Isorok insulation of external walls of frame buildings

- Isorok slabs have proven themselves to be the best in wall structures of this type. The highest quality insulation is when it is made of two layers of material.

- A sheathing made of wooden slats 5 cm wide (according to the thickness of the mats) or a metal profile is mounted on the walls. The distance between them is equal to the length or width of the insulation.

- Laying is done in such a way that the slabs located outside overlap the seams of the layer of material located inside. The sheet is secured using self-tapping screws at 5 points.

- The outer layer of insulation must be protected by wind and waterproofing film.

Isorok insulation of walls of frame buildings from the inside

- As a rule, even at the stage of constructing the frame, the distance between the wooden posts is set equal to the width of the insulation, that is, 60 cm.

- Therefore, there is no need to make a lathing; the isorok is simply placed in 3 layers (15 cm) in these niches and is not attached in any way. It is fixed on top with a vapor barrier film, which is tightly stretched.

- Although they talk about the environmental friendliness of the material, when mineral wool particles come into contact with the skin, severe itching begins, which cannot be washed off within 24 hours. Therefore, it is important to use personal protective equipment and work in rubberized gloves.

Dry method of floor insulation Isorok

Floor insulation is carried out according to the following scheme:

- A layer of waterproofing is laid on the existing wooden floor with tightly laid boards. Logs are laid on top of the boards, in the gaps of which insulation is placed close to them. This must be done at random so that there are no cracks or gaps left;

- the next layer is a vapor barrier. Its presence prevents moisture from penetrating from a warm room into the cold insulation layer. This must be done in order to protect the insulation from moisture, since when moistened, it loses its original thermal insulation properties;

- then the subfloor is laid along the joists. This could be plywood, OSB, etc. A finishing coating is placed on top of this material. It can be represented by laminate or any other coating at the request of the homeowner.

Insulation of interfloor ceilings with Isorok

- Mineral slabs can be used to insulate interfloor wooden floors. For this purpose, they are laid between the beams.

- It is not necessary to place a layer of protective vapor barrier for insulation between rooms of different levels, but with the same temperature in them.

- If one of the rooms is warm and the other is humid, for example, a bathroom or kitchen, vapor barrier is simply necessary. If the wet room is located at the top, then a layer of waterproofing will be required.

- From the side of the second floor, the order of arrangement of materials looks like this: floor covering, joists, if necessary, a layer of hydro- or vapor barrier, insulation between the beams, if necessary - a layer of vapor barrier, planking, finishing coating of the ceiling.

Insulation of flat roofs with Isorok

- High-density isoroc can be used to insulate flat roofs. The base on which the insulation will be mounted is reinforced concrete floor slabs or profiled metal sheets.

- First you need to lay a vapor barrier layer. It is necessary here in order to prevent the penetration of moisture vapor into the layers of thermal insulation. After all, only dry insulation can retain its properties, and wet insulation significantly reduces its characteristics. Large accumulations of steam cause unwanted deformations of the slabs. It is advisable to perform vapor barrier with fewer seams and select thicker membranes to provide the highest quality protection.

- The edges of the film must be placed above the insulation in order to prevent steam from penetrating into it. With multi-layer insulation, the joints of the slabs are positioned with a slight offset. The top layer should be denser than the bottom layer.

- The last thing to apply is waterproofing. To preserve the material, it is advisable not to walk on it.

Insulation with Isorok slabs of pitched roofs

- The first step in insulating pitched roofs is the installation of a waterproofing film, which is laid over the rafter system. The material is laid across the slope with an overlap, so that the upper ones are layered on the lower ones. The individual panels are connected with self-adhesive tape.

- Counter-lattice bars are placed on top, which provide the necessary small ventilation gap in this case, which will pass between the roofing covering and the future insulation layer.

- Isorok is installed between two rafters. This is done to securely fix the elements and to ensure better thermal insulation results. It is necessary to prevent ruptures of the thermal insulation layer or loose contact with the rafters. The insulating material must be the same over the entire surface.

- The next stage is installing a vapor barrier. The material is fixed with brackets on the inside of the rafters. The strips are joined with an overlap. The joints are secured with self-adhesive tapes. The last thing to do is install the ceiling trim. A roof covering is installed on the outside of the roof.

Insulation of a wet facade with Isorok

- The external method of insulating buildings is more preferable as the most effective in terms of thermal insulation of buildings. If you can choose between internal and external, it is recommended to choose it.

- You need to start work by preparing the surface. It must be cleaned of all existing contaminants and cracks, if any, must be repaired. If there are any unevenness, level them out. Prime the dried finished surface.

- The next stage is the installation of a profile strip around the perimeter of the building. It is mounted at a height of about half a meter from the ground level. The bar is needed to distribute the uniform load coming from the thermal insulation slabs. Plates are installed on it, which are attached to the base using dowel nails with a wide head. The insulation is placed in rows, starting from the base profile.

- Next is a reinforcing mesh, which is attached to a special adhesive composition. First, slopes, corners, etc. are strengthened. After installing the mesh, you can begin applying plaster layers in accordance with all the rules necessary for carrying out such work.

Ventilated facade with Isorok

- Mineral wool boards are also used in ventilated facade systems. This is another option for high-quality external thermal insulation of buildings. The system itself consists in the fact that between the layer of insulation, which is attached to the wall, and the decorative facing layer, there is a layer of air. It is needed for the free outflow of moisture from the insulation layers. On the other hand, the moisture that penetrates under the cladding cannot reach the thermal insulation material, since air serves as a barrier. Another advantage of this method is that all work is performed at any temperature.

- Installation of insulation is carried out similarly to the installation of a heat-insulating layer, typical for the wet method. The only difference is that after installing the slabs, the frame of the ventilated facade is mounted on top.

- The question of installing steam and wind protection films remains open. Here opinions differ. Whether to install it or not, you should focus on the installation technology provided for slabs and facade systems and the recommendations of manufacturers and specialists.

Isorok mineral slabs are a reliable and high-quality material. A large selection of products with different indicators and technical characteristics makes it possible to successfully use them in a wide variety of areas of construction work. This is an easy-to-work and affordable material that can be appreciated by both professionals and people who build on their own. In addition, in recent years, Izorok products have received extremely positive reviews.