Insulating a brick garage using modern building materials is not difficult and not as expensive as it might seem at first glance. Brick itself is a warm building material, and high-quality insulation will help reduce humidity in the garage and prevent corrosion and freezing of the car in winter.

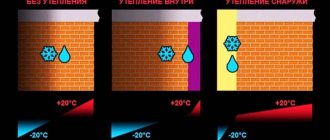

If possible, try to insulate the garage walls from the outside, since internal wall insulation without quality ventilation can cause excess dampness and the appearance of fungus.

Optimal temperature inside the garage

A garage is a non-residential premises in which it is recommended to maintain the temperature at +5 degrees oC in winter. It is not necessary to increase it: driving a car into the garage from the street should not be accompanied by sudden changes in temperature. Recommendations must be followed to prevent condensation on the metal and avoid the development of corrosion. According to the requirements for the equipment of premises for storing cars, the garage must be:

- Warm. It is difficult to work in the cold; subzero temperatures will lead to liquid freezing. The air temperature in the garage should be positive; while the car owner is working, the room warms up to 16–20 degrees C.

- Dry. Getting water inside will lead to rapid corrosion of the metal, so the walls, floors, and roofing of the building must be waterproofed.

- Ventilated. The presence of ventilation will save the car owner from inhaling harmful exhausts, unpleasant odors and will allow moisture vapors to be removed outside. Forced ventilation is required in the garage.

Properly performed thermal insulation of a garage will create optimal conditions for preserving the car and will make it possible to quickly heat the room for a person to work in it.

Insulating walls with foam plastic from the outside: instructions and photo gallery

Traditionally, before starting work, we prepare surfaces for insulation: we remove peeling pieces, repair chips and potholes, and clean the walls of dirt. Brickwork or concrete with their absorbent properties must be additionally treated with a penetrating primer. After this, insulation is performed in the following order:

- Attach a metal corner to the bottom of the walls - it will serve as a support for the rows of foam plastic.

- Prepare the adhesive mixture according to the instructions given on the package.

- Apply the composition to each sheet using one of the methods shown in the photo.

This method is only suitable for polymer adhesives in cylinders. The glue is applied with a notched spatula in a layer of 3–4 mm. The “blots” of glue should be evenly distributed on the sheet. - One after another, sheets of foam plastic are glued along the lower edge with emphasis on the metal profile. Work is carried out starting from the corner.

- All subsequent rows of polystyrene foam are attached with the seams staggered.

- The joints between the sheets are sealed with polyurethane foam.

Don’t forget to check the verticality of the foam “wall” with a level - this will make further finishing easier - After about a day or two, when the glue has set, the foam can be additionally secured with dowel mushrooms. They are screwed into the corners of each sheet and in the center.

- Reinforcing the foam is a mandatory step, at which the insulation is covered with another layer of glue.

While the reinforcing composition has not dried, a fiberglass mesh is embedded in it. After the top layer has set, they proceed to finishing.

Basic tips for insulating a garage

When insulating a garage, it is not recommended to skimp on the quality of the material. It is better to buy dense insulation: the higher this indicator, the better the material retains heat.

The most effective heat insulator is high-density polystyrene foam 35 kg/cub.m - PPT-35 and PPT-35N (N - for external use). When choosing insulation, it is important to correctly calculate the costs and take into account additional costs. To work with polystyrene, you only need fastening materials and a standard set of tools. The use of other thermal insulation materials - stone wool, polyurethane foam spraying, foam insulation - will require additional costs for the purchase of waterproofing and vapor barrier films, sprayers, and sometimes payment for the services of third-party organizations.

What types of insulation are suitable for a garage?

Everyone's garage is different - some are metal, others are brick and block. You can insulate a garage with any type of heat insulator. More often, expanded polystyrene (foam) and extruded polystyrene foam (penoplex) are used for insulation.

Foam plastic and penoplex are materials that have two important advantages: they cut off the cold well and are not hygroscopic. Using them as insulation inside the garage will create a reliable separating barrier between cold and heat. The temperature inside is maintained above zero, and moisture does not condense on the cold walls because the insulation does not get wet.

If you use breathable mineral wool for insulation, then wet vapors pass through it without hindrance. Condensation forms on the walls, and the insulation gets wet and loses its thermal insulation properties. To avoid this, mineral wool is protected with vapor barrier and waterproofing films - their purchase means additional costs.

No. 4. Thermal insulation paint

Another modern material that amazes not only with its ease of use, but also with its efficiency. Here are just a few striking examples: a layer of paint equal to 1 mm is equivalent to a layer of mineral wool of 50 mm, and a layer of paint applied according to the instructions is the same as a wall of 1.5 bricks. The unique properties of this insulation are based on the structural features and operating principle .

All thermal insulation materials known to us work on the principle of a barrier, preventing heat from leaving the space. Thermal insulating paint becomes not only a barrier to the penetration of infrared rays outside, but also their reflector, making it much more difficult for heat to escape the confines of such a room. This effect was made possible due to the presence of a vacuum inside, which prevents the passage of infrared rays. The advantages of thermal insulation paints can be listed for a long time. They have excellent adhesion to most building materials, have good thermal insulation performance, are not afraid of moisture, are vapor permeable, and protect metal from corrosion. A layer of such insulation is very light in weight, so it does not weigh down the structure, and the application process itself is as simple as possible and is not much different from using conventional paints. The list of advantages is complemented by resistance to ultraviolet radiation, ease of restoration of damaged coating, resistance to high temperatures (paint does not burn, but only chars at 2600C or decomposes at 8000C), environmental friendliness. But one cannot note such a minus as the rather high cost of paint, its high consumption, and it cannot always be used as an independent insulation material, but nevertheless, this option is being used more and more often for insulating a garage.

Pros and cons of different types of insulation

To insulate a garage, you can use any known insulation materials: mineral wool, polystyrene foam, penoplex, penoizol. It is easier to choose a material after becoming familiar with the advantages and disadvantages of different insulation materials and weighing the main pros and cons of the product.

Mineral (stone wool)

Mineral wool is made from stone fiber glued with synthetic resins and is produced in slabs and rolls. This is a popular type of insulation. Mineral wool is environmentally friendly, non-flammable, and inexpensive. Among the disadvantages is low moisture resistance - cotton wool is hygroscopic, and when moistened, its thermal insulation properties decrease. Therefore, the mineral wool heat insulator needs protection: a vapor barrier film is laid on top of it on the room side, and a waterproofing membrane is placed on the wall side.

Foam plastic (expanded polystyrene)

A large number of car owners insulate their garages with foam plastic. The material has many advantages:

- Light weight. The material is lightweight, does not weigh down building structures, and is easy to work with.

- Ease of processing. The foam sheets are cut with a regular knife (hacksaw, jigsaw) and glued onto liquid nails or polyurethane foam.

- Low price. There are no insulation materials on the market cheaper than expanded polystyrene.

- Low thermal conductivity coefficient. The material perfectly cuts off the cold, remaining warm to the touch.

- Non-vapor permeability. In non-residential premises, this parameter is considered a basic advantage - the material does not absorb moisture.

- When wet, the material does not lose its properties. Foamed polystyrene in a garage retains its thermal insulation properties for a long time. Additional procedures for thermal insulation of structures will not be needed for many years.

Among the disadvantages of polystyrene foam is its low strength. The issue of sheet strength is solved by purchasing more rigid high-density polystyrene foam - from 35 kg / cubic meter. m.

Extruded polystyrene foam (penoplex)

The properties of penoplex are similar to polystyrene foam - it is a lightweight porous insulation material with a high thermal insulation coefficient, non-vapor permeable, and moisture resistant. The density of extruded polystyrene foam is higher and it is more expensive than traditional polystyrene foam. The material can be easily cut with a knife, and can be attached to any building structure using liquid nails or umbrella dowels.

Polyurethane foam PPU

Polyurethane foam insulation is called liquid spraying. Its advantage is that the sprayed liquid has good adhesion (adhesion) to different surfaces: polyurethane foam can be applied to metal, brick, timber, plastic, gas blocks, foam blocks, it sticks to a polymer film. Sprayed thermal insulation penetrates into hard-to-reach places and insulates building structures of complex shapes. The disadvantage of the material is that complex mixing and spraying installations are used to apply polyurethane foam. The prices for the services of companies operating in this area are high.

No. 3. "Warm" plaster

Warm plaster is a relatively new type of insulation that looks like regular plaster, but instead of sand it contains materials with low thermal conductivity: vermiculite, polystyrene foam, sawdust, expanded clay, pumice , etc. Plaster with polystyrene foam granules has become the most popular , as it has universal properties, can be used both inside and outside, and has the best thermal insulation properties. Sawdust-based plasters are also common, which also contain components such as paper, clay and sand. This composition is just suitable for internal insulation, but you should be prepared for the fact that such plaster takes a long time to dry, and to speed up the process you will need good ventilation. Vermiculite-based compounds can also be used to insulate a garage from the inside.

This option has many advantages . Thus, the walls do not need to be leveled or prepared in advance; “warm” plaster has excellent adhesion to wood, metal and stone, and it does not require the use of reinforcing mesh (except for some difficult cases). In addition, it is very simple and easy to apply and can be done without outside help, completing it in the shortest possible time. But with all this, the material is clearly inferior to traditional insulation , and it is better to use it in combination with other thermal insulation materials. Applying a thick layer is not an option, since if its thickness is more than 5 cm, there is a risk that the plaster will begin to crack and peel under its own weight.

Where to insulate - inside or outside

Insulation of garage walls can be done outside and inside. The choice of location for installing insulation depends on several criteria:

- the building material from which the garage is built (metal box, solid brick structure, block, wooden);

- destination (only a parking lot or also a working workshop);

- room area.

A garage for car enthusiasts is not only a place to park a car, but also a room that performs additional functions: a workshop, a storage room, storage for bicycles, skis, spare tires, electrical equipment, and various tools. The multifunctionality of the room places special demands on its insulation. If the garage is used as a workshop and is heated, then it is better to insulate it from the outside. A metal unheated garage, intended only for parking a car and carrying out minor maintenance work, is insulated from the inside.

How to insulate a garage from the inside

The classic way to insulate a metal garage from the inside is to create a sealed loop of foam sheets along the walls and ceiling. All work on insulating a garage can be easily done with your own hands, having purchased materials and tools in advance. The work is carried out in the following sequence:

- A frame made of wooden bars or metal profiles is installed along the walls.

- Sheets of foam plastic (or other insulation) are mounted between the frame elements. Expanded polystyrene, penoplex are attached to mounting foam with adhesive properties, umbrella dowels or liquid nails. Mineral wool slabs are installed between the frame posts.

- Seams and joints are sealed with polyurethane foam.

- Sometimes it may be necessary to lay foil penofol on top to completely eliminate cold bridges.

Some garage owners complete the insulation here, others cover the insulation with plywood, clapboard, OSB boards to improve the aesthetic characteristics of the room and equip the walls for hanging modules, shelves, and tools.

External insulation

Expanded polystyrene for walls is suitable for outdoor use, but it is worth considering that the material is destroyed when exposed to sunlight. Therefore, it is protected with finishing cladding (PVC panels, lining, plywood, OSB boards) or plastering.

The technology of applying plaster to the outside of a building on insulation is called “wet facade”. This is an effective way to insulate both a residential building and a garage. First, a frame is attached to the facade to prevent subsidence of the insulation. Then sheets of foam plastic are fixed to the wall with umbrella dowels, a reinforcing mesh is applied, and a layer of plaster is laid. After the solution dries, a monolithic layer is formed on the outer part of the wall of the garage or house, characterized by high strength and good thermal insulation parameters.

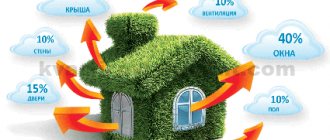

Garage roof insulation technology

To insulate the roof, you can use mineral wool with a density of 90 kg/m3. m, polystyrene foam 25–35 kg/cu.m. m or extruded polystyrene foam. Expanded polystyrene sheets are preferable as they are non-hygroscopic. The structure of expanded polystyrene is formed by closed cells, so the material does not absorb steam, which makes it possible to do without waterproofing. The sheets are simply glued to the surface - this is how a foam ceiling is formed. To ensure increased tightness of the formed layer, you can use samples with a tongue-and-groove lock at the edges or lay them in two layers, provided that the joints on different rows do not coincide.

What to consider

Before we talk about how you can cheaply insulate your own garage with your own hands, you need to note several important nuances.

When a garage is built, materials such as brick, cinder blocks, or metal structures are mainly used. Walls made of cinder blocks and bricks usually vary in thickness from 120 to 250 mm. They provide virtually no protection from the cold. That's why we insulate the garage.

And you already know enough about insulating an iron garage. Therefore, I will not repeat myself.

Before insulating the garage from the inside, many actively seal the holes. In fact, this will not have much effect on the thermal insulation. But it can lead to other problems. If you close all the cracks, the air circulation inside will be disrupted. This will promote the appearance of condensation, which will ultimately lead to the formation of rust on the car.

Ventilation is also needed to prevent harmful and dangerous gases from accumulating inside the box.

Garage door insulation scheme

Thermal insulation of gates with polystyrene foam is carried out according to a simple scheme:

- Along the perimeter of the gate, wooden slats are attached to the side metal strips with self-tapping screws. Pre-holes in the steel elements are made using a drill with metal drills. A wooden frame is needed to cover the inside of the doors with clapboard, plywood, OSB boards or plastic panels.

- The polystyrene foam is cut into pieces of the desired shape and glued to the inner surface of the gate with liquid nails.

- The gaps at the joints between the sheets become foamy. After drying, the remaining foam is cut flush with a knife.

- The thermally insulated and hermetically foamed surface is sheathed with clapboard or panels. When attaching wooden or plastic panels, self-tapping screws are screwed into wooden slats, which were mounted at the first stage as a frame.

Our company produces and sells polystyrene foam of any density, which can be used as insulation for floors, walls, ceilings and garage doors. To ask questions and order polystyrene foam of the required density, call TM-StroyPlast by phone +375 (33) 661-98-08 or +375 (44) 78-78-333.

Protection of the ceiling and floor from the cold

An example of insulating a garage ceiling with mineral wool

The final stage is insulating the garage ceiling. The process is almost identical to the construction of thermal insulation of walls, but there are still some nuances. So, how can you insulate the ceiling in a garage:

- It is safer to use glass wool rather than polystyrene foam.

- When insulating along the sheathing, it is advisable to leave several holes through which air will circulate.

- It is necessary to create good waterproofing; it is best to use roofing felt.

As sheathing, as in the case of wall insulation, it is best to use plywood.

Floor insulation

Expanded clay as insulation is often used in private garages for floor insulation

Most often, floors in garages have a soil base, so they must be insulated. An excellent option would be expanded clay and other rigid insulation materials using reinforced concrete screed. How to properly insulate a garage floor:

- The thickness of the insulation plus the height of the screed is measured, and the top layer of soil is removed exactly to this depth.

- The soil is thoroughly compacted;

- A layer of waterproofing is laid, it is best to use roofing felt;

Important! It is necessary to make an allowance of roofing felt on the walls of at least 25-30 cm. The material is laid with an overlap.

- Installation of beacons;

- A layer of expanded clay is poured, it should have a height of more than 30 cm;

- Installation of beacons for reinforced concrete screed;

- Installation of the concrete layer;

A water heated floor system would be a good option. It is installed under a concrete screed. True, this system cannot be installed in every garage.