Good thermal insulation reduces heat loss by 20–40%, and in some cases more. At the same time, correctly selected floor insulation in a wooden house not only reduces heating costs, but also directly affects the microclimate in the rooms. You need to know how to pick it up. Do you agree?

You will learn everything about thermal insulation options suitable for arranging a wooden floor from our proposed article. We will tell you what criteria influence the choice and how to take them into account. Our recommendations will help you correctly arrange the lower floor in a structure made of timber or logs.

Types of insulation for wooden floors

A wooden house was previously considered a very warm structure that did not require any additional insulation work. True, not all modern developers know that the floors in old houses were made from logs cut in half, and the thickness of such coverings reached 20–25 cm. The walls of the log house were assembled from round timber Ø 55–60 cm. Currently, the thickness of the timber rarely exceeds 20 cm, and for floors, boards no thicker than 2.5 cm are used. Such thin lumber cannot in any way meet the requirements of current regulations.

According to existing standards for heat conservation of residential buildings (SNiP II-3-79), to achieve energy saving R = 3.33 ° C m2 / W, the thickness of the timber in the Moscow region should be 50 cm. To avoid installing such thick walls, you need to use modern insulating materials . 12 cm of expanded polystyrene has the same heat saving effect as a 53 cm thick tree or a 210 cm thick brick wall.

The construction industry offers consumers a wide range of thermal insulation materials that differ in structure, manufacturing technology and thermal conductivity parameters.

Table. Types of floor insulation

| Type of insulation | Brief description of physical and operational characteristics |

| Rolled | In terms of cost, they belong to the middle category; they are quite technologically advanced and effective insulation materials. Rolls make it possible to cut materials exactly according to the size of niches; due to this feature, it significantly reduces the amount of unproductive losses. To insulate floors in a wooden house, roll insulation made of mineral wool is most often used. There are also rolls made from cork tree bark, but such materials are recommended to be used when installing heated floors only as additional lining insulation, since their thickness does not exceed a few millimeters. For basic insulation this is very little. Often, roll insulation materials have a foil coating. This is reliable protection against moisture penetration; in addition, it is possible to slightly reduce heat loss due to infrared radiation. |

Pressed | Using special equipment, lightweight and porous insulation materials are pressed into slabs with standard dimensions. Plates, unlike rolled materials, can maintain their geometry, which simplifies and speeds up the installation process. The dimensions of the slabs are taken into account at the design stage of the house; taking into account their dimensions, the distance between the floor joists is selected. Most often, mineral wool and glass wool are pressed, but you can also find slabs made of ecowool. The price is slightly higher than the roll ones, the thermal conductivity parameters are almost the same. Pressed polymer insulation based on foam plastic is located separately. Modern technologies make it possible to make them safe for health and do not support open combustion. Such performance properties make it possible to use these materials for floor insulation in wooden houses. |

Liquid | The main difference is that the materials harden or polymerize after application to the surface. The insulating layer has no gaps; the technology makes it possible to isolate the most inaccessible places of complex configuration. Polymer thermal insulation and ecowool are applied in liquid form. The disadvantage is the complexity of the polymer insulation technology. According to actual characteristics, these materials occupy the last places and are not recommended for use by professional builders. |

| Bulk | The traditional and cheapest insulation materials are most often expanded clay and slag. The main advantage is that they are absolutely non-flammable. In terms of thermal conductivity, they occupy the last place among all existing insulation materials. |

To insulate floors in wooden houses, many types of insulation are used, but not all with the same frequency. The most common are mineral wool and polymer materials; expanded clay is less commonly used, and in very isolated cases, sprayed liquid insulation is used.

Most often, floors are insulated with penoplex

Insulation of the ceiling of the upper floor from the inside

Installing insulation from the inside does not provide maximum protection for structures, but it can be used as a second option for laying insulation. In this case, the insulation is mounted on the beams from below the floor.

It would be correct to arrange the layers in this order:

- vapor barrier;

- insulation;

- waterproofing;

- beam-based floor structure.

Popular types of insulation

| Photo | Name | Rating | Price | |

| #1 | Mineral wool | ⭐ 96 / 100 | More details | |

| #2 | Styrofoam | ⭐ 97 / 100 | More details | |

| #3 | Tepofol | ⭐ 98 / 100 | More details |

Mineral wool

One of the most popular materials among builders, it has both positive and negative sides.

Mineral wool has a number of advantages

pros

- does not burn, can be used as a barrier to the spread of fire;

- has high heat saving rates;

- easy to cut and install, installation does not require the use of special equipment and devices;

- the relatively small mass minimizes the amount of additional loads on the logs.

Minuses

- high cost, belongs to the class of the most expensive materials;

- easily absorbs moisture and dries for a long time - wet cotton dramatically increases thermal conductivity;

- prolonged contact of wet mineral wool with wooden structures provokes their rotting and rapid failure.

When wet, the fibers become denser and the wool loses its thermal insulation properties.

To prevent negative phenomena due to the shortcomings of mineral wool, it must be very carefully waterproofed and at the same time provide a free outlet for moisture. These are complex technological operations; only professional builders can perform them correctly. Mineral wool can be rolled or pressed, thickness 5 and 10 cm; to reduce heat loss, several layers of different sizes must be used.

Ecowool floor insulation

rockwool mineral wool

Styrofoam

This group of materials includes all polymer insulation materials; they are almost the same in their physical and operational characteristics. In addition to those used for insulation of loaded structures: exploited flat roofs, facade walls for cladding, etc.

Extruded foam

pros

- the material does not absorb water;

- does not require vapor and waterproofing;

- has low weight;

- cuts perfectly with an ordinary mounting knife;

- modern types do not support open combustion;

- do not release harmful chemical compounds into the air.

Minuses

- not durable enough;

- attracts rodents.

Foam plastic does not require installation of waterproofing

polystyrene foam for insulation

Tepofol

The most modern insulating material allows you to create an airtight coating, is not afraid of moisture, and is completely ready for use. The polymer material meets the requirements of users and designers in all operational parameters.

pros

- small thickness;

- light weight;

- ease of installation;

- environmental Safety;

- low price.

Minuses

- insufficient rigidity;

- poor adhesion.

tepofol

Tepofol - a modern insulation with improved properties

For example, let's consider two options for floor insulation: expanded clay with polystyrene foam and tepofol. These methods are considered the most optimal and are often used during the construction of wooden houses.

Sprayed thermal insulation – polyurethane foam

It is convenient to insulate your private village house with polyurethane foam. Polyurethane foam is one of the best insulation materials.

It is applied to the surface using special equipment.

Spray polyurethane foam

- sprayed thermal insulation takes the form of a structure: floor, wall, easily adhering to the surface;

- does not require leveling the surface, can be sprayed onto flooring and walls of any geometry;

- The material is not flammable and fireproof. But if exposed to open fire, it may release toxic gases;

- it has a low thermal conductivity coefficient;

- mold and mildew do not form on it;

- An important advantage of polyurethane foam is its seamlessness. It fills all the voids and cracks. Thanks to its solidity, it has excellent thermal insulation and sound insulation properties;

- thermal inertia is high. It protects against cold in frosty weather, gives coolness in hot weather;

- it has high strength. Therefore, it gives the building and structures on which it is sprayed increased strength;

- serves as a good waterproofer because it does not absorb moisture.

Step-by-step instructions for floor insulation with expanded clay and expanded polystyrene

This option can be considered complex; for insulation, two materials with very different physical properties are used, and this combination ultimately gives an excellent result.

Initial data. The height of the wooden logs is 20 cm, the elements are laid on brick columns with concrete foundations. There is no basement under the premises; vents have been made to ventilate the underground space. Constant air flows cool the room, and therefore high-quality insulation is done to increase comfort.

Subfloor requiring high-quality insulation

Step 1. Protect all wooden floor elements with any antiseptic. This operation must always be done; insulated floors are very poorly ventilated; lumber without impregnation quickly deteriorates. There are many antiseptics available, they all do their job well. But practice shows that the most effective remedy is ordinary training. To make application easier, it is recommended to preheat the oil. As for the unpleasant odor, while the floors are being laid, it will completely disappear.

The logs and the lower crown of the log house must be treated with an antiseptic

Step 2. Attach 25x40 mm bars to the bottom of the logs; boards for waterproofing will be laid on them. The bars can be taken used, antiseptic impregnation is required. You can fix it with ordinary nails: quickly, reliably and cheaply. Self-tapping screws take much more time; professionals rarely use them in such situations.

Stuff bars along the bottom edge of the joists

Step 3. Prepare the base for waterproofing. For these purposes, it is allowed to use any lumber; the load on the elements is negligible. There may be gaps between the boards, this is not critical, the waterproofing will be made of a relatively durable material.

The space between the joists is covered with boards

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

If during the construction of the structure the calculated thickness of the insulation has significantly decreased, then instead of large slats, metal corners can be screwed to the beams. The thickness of the rolled shelves is only a few millimeters, due to this the depth of the niche for insulation increases by 4–5 cm. This is quite a lot and significantly affects heat saving indicators.

Step 4. Place roofing felt on the boards - a time-tested, reliable waterproofing material. In addition, it costs much less than modern membranes. And one more advantage of roofing felt - it reliably closes the cracks between uneven boards, thereby preventing the spillage of expanded clay granules or other bulk insulation.

Cover the boards with roofing felt

Step 5. Fill expanded clay between the joists. We have already mentioned that we use two types of insulation materials. You should leave room for laying the second one; you don’t need to add expanded clay to the top by about 5 cm. Level the surface of the granules.

Fill the space between the joists with expanded clay

Step 6: Place extruded polystyrene foam boards on top. The cracks must be foamed with construction foam. To prevent the pieces from moving while the foam hardens, press them down with bricks.

Sheets of foam plastic are laid on the expanded clay, trying not to leave gaps between them

Now the floor is warm, you can lay the rough and final coating.

Reviews

User reviews on the use of different types of insulation indicate that you need to take their choice seriously. One of the important points is to ensure a long period of operation while maintaining heat-insulating properties. For some, the main message is to resolve the issue of which is better against rodents.

Many owners of wooden houses praise polystyrene foam. If you lay it without gaps, it will reliably protect the floor from the penetration of cold air. Ecowool, if laid correctly, will also retain heat well, according to users.

The correct choice of insulation and its thickness will make wooden floors warm and the atmosphere in the house cozy and comfortable. All types of insulation retain heat almost equally.

Classification of mineral wool by density

The market is filled with offers from domestic and foreign manufacturers. To systematize hundreds of items, below is a list of materials produced in Russia that differ according to the criterion under consideration, as well as some recommendations for use.

P-75

The density of this brand of insulation is 75 kg/m3. A low indicator allows the use of wool only in lightly loaded surfaces, including horizontal ones (attic floors, pitched roofs). The material is more popular in the oil and energy industries - it is used to wrap pipes of heating plants, as well as joints of gas and oil pipelines.

There are insulation materials of lower density (15, 25, 40 kg/m3), but they are practically not used, because they lose their shape and properties even with minimal load.

P-125

The density of this mineral wool is 125 kg/m3. The material is good for covering ceilings, floors, walls, partitions, frame buildings in a temperate climate zone. In addition to decent thermal insulation properties, it perfectly suppresses extraneous noise.

PZh-175

Material of increased rigidity (this is reflected in the name). It is used for cladding walls or ceilings made of metal, reinforced concrete, concrete, brick.

PZh-200

It also has increased density (200 kg/m3), rigidity and is used in the same situations as the previous one. There is one advantage over the previously mentioned one - PZh-200 serves as additional fire protection.

Mineral wool slabs with a density of 75 to 200 kg/m3, described above, are quite sufficient for insulating any premises of a private or apartment building. However, on the market you can find unfamiliar markings for products manufactured abroad.

Classification of mineral wool produced in other countries:

- VL, TL (suitable for structures with a maximum load of 8 and 12 kN/m2, respectively);

- EL, ELD, ELUS (good for insulating concrete elements, maximum permissible load - 5 kN/m2);

- IM, IMP (rafters, floor structures, foundation);

- AKL, KKL (high-rigidity materials used for thermal insulation of pitched roofs);

- TKL (flat roof thermal insulation);

- VIL (reminiscent of AKL and KKL, but has cut corners; used if the roof needs to be sloped);

- TSL, VUL, IRL (thin slabs, used for wind protection of light structures - walls or rafters);

- ILP (pressed between elements of concrete, brick, metal buildings);

- A, IL (classic mineral wool boards used for wall insulation; recommended for areas where space for material is limited).

The specific density of the insulation is not indicated, since in terms of compatibility with various structures it is not difficult to compare its indicator with its domestic counterpart.

Styrofoam

Usually this word refers to foamed polystyrene and extruded polystyrene (penoplex). In terms of chemical composition and thermal insulation properties, these materials are practically the same, however, penoplex has much greater bending strength and resistance to crumbling than traditional polystyrene foam. For this reason, recently most consumers are abandoning foamed polystyrene (foam) in favor of extruded polystyrene (penoplex).

The advantage of this type of thermal insulation is its low price, ease of installation and moisture resistance. The disadvantages include the flammability of this material, and when polystyrene burns, a large amount of toxic substances is released.

Polystyrene slabs are produced in thicknesses from 5 mm to 50 mm; a special chamfer is made on the edges of the slabs so that during installation, gaps and, consequently, “cold paths” do not appear at the joints.

If a layer thickness of more than 50 mm is required, then two or even three layers of polystyrene are laid, with each new layer being laid offset relative to the previous one so that the joints of the slabs of the upper row fall on the centers of the slabs of the lower one.

Screed diagram with foam plastic

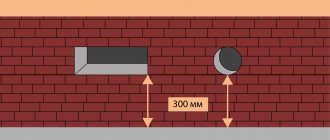

When insulating a floor located directly above the ground, the foam layer must be at least 300 mm for a house with a wooden floor, and 200 mm for a house with self-leveling concrete floors. You should lay at least 4 layers of the thickest foam panels, offset from each other.

If there is a cold basement under the floor, then the foam layer can be reduced by 50mm.

To insulate floors between floors of a private house, 150 mm of foam is sufficient for wooden floors and 100 mm for concrete floors.

If you are insulating floors in an apartment building, then for all floors except the first it is enough to lay one layer of foam plastic 50 mm thick. On the ground floor the thickness can be increased to 80-100 mm.

| Index | Polyspen | Polyspen Standard | Polyspen 45 | Control method |

| Density, kg/m3 | 30-38 | 30-38 | 38,1-45 | 5.6 each |

| Bending strength, MPa, not less | 0,4 | 0,4 | 0,4 | 5.8 each |

| Water absorption in 24 hours, % by volume, no more | 0,4 | 0,4 | 0,4 | 5.9 each |

| Thermal conductivity at 25+-5 degrees Celsius, W/m * °C, no more | 0,028 | 0,028 | 0,030 | at 5.10 |

| Toxicity, Hcl 50, g/m3 | T2 moderately hazardous | T2 moderately hazardous | T2 moderately hazardous | at 5.11 |

| Flammability group | G-3 normal-flammable | G-4 highly flammable | G-4 highly flammable | at 5.12 |

| Flammability group | B-2 moderately flammable | B-3 flammable | B-3 flammable | at 5.13 |

| Smoke coefficient | High smoke generating ability | High smoke generating ability | High smoke generating ability | at 5.14 |

| Compressive strength at 10% linear deformation, MPa, not less | 0,2 | 0,2 | 0,3 | 5.7 each |

Calculated thicknesses of Penoplex thermal insulation

What is the basis for calculating the thickness of thermal insulation?

Even those readers who are not comfortable with physics and mathematics will be able to independently make such a calculation. Moreover, we invite them to take advantage of the built-in online calculator.

What is the basis for determining the required thermal insulation thickness?

The fundamental principle of the implementation is this: the total thermal resistance (or, more correctly, heat transfer resistance) of the enclosing building structure should not be less than the established value. This value is called normalized, and it is calculated for all regions taking into account their climatic characteristics. In addition, this indicator also takes on different values depending on the type of structure - there are standards for walls, coverings and ceilings.

It’s easy to find out this normalized value for your region of residence. Such information is probably available at any local construction organization. But it will be even easier to take the value from the schematic map below, covering the entire territory of Russia.

Normalized values of thermal resistance for building structures of residential buildings by regions of Russia

So, the normalized thermal resistance is known, but what does this tell us? The fact is that this total value is the sum of the thermal resistance indicators of each of the homogeneous layers of the structure.

If we look at a wooden floor by floor beams or joists, it will look something like this:

Schematic diagram of insulation of a wooden floor on joists or floor beams

1 – floor beams or joists – load-bearing parts of a wooden floor.

2 – cranial bars or support boards. Necessary for laying subfloors.

3 – subfloor boards. They can be mounted as a continuous flooring or sparsely. Sometimes, instead of boards, sheet material is used, for example, OSB boards or plywood. In some cases, for example, when thermally insulating the floor with rigid polystyrene foam blocks, the subfloor is completely abandoned - only a few jumpers are left to support the insulating layer.

4 – windproof membrane, which must have the property of vapor permeability - for the free release of moisture into the atmosphere. Not used when insulating with vapor-tight and wind-resistant materials, for example, extruded polystyrene foam or polyurethane foam.

5 – insulation layer. Different materials can be used - bulk, block, roll, sprayed. But in any case, it is the thickness of this layer that we will calculate.

6 – hydro-vapor barrier membrane that protects the insulation from moisture from the premises.

7 – flooring. These can be boards attached directly to the joists. Another option is plywood or OSB flooring with a thickness of 15÷20 mm, which becomes the basis for any chosen floor finish.

Which of these layers can have a significant impact on the degree of thermal insulation of the structure? There are not many of them - three or two. And one of them is the layer of thermal insulation itself.

- First, a subfloor made of boards or wood-based sheet material. But only if it is made solid, without gaps.

- Secondly, this is the flooring itself on top of the joists - boards, plywood or OSB.

We will not take membranes into account - they do not have any serious insulating qualities. Let's also take the finishing floor covering out of the equation - due to its insignificant thickness or, for some decorative materials, too high thermal conductivity.

It should be correctly understood that the diagram shown above demonstrates only the principle of floor thermal insulation, but does not in any way reflect the entire possible variety of options. Just off the top of my head - two more schemes. Changes are obvious, but the general principle of the structure of the “insulating pie” does not undergo any special “transformations”.

Two more possible schemes for the structure of an insulated floor on floor beams and joists. In fact, there may be much more options.

The thermal resistance of each homogeneous layer of the overall structure can be determined by the formula.

Rc = hc / λc

hc is the layer thickness expressed in meters.

λc is the thermal conductivity coefficient of the material from which this layer is made. These coefficients are tabular values. And finding them for almost any building or thermal insulation material is not at all difficult; there are plenty of these tables on construction sites.

Instructions for carrying out thermal insulation work in different situations

The floor design of a wooden house can have a wide variety of appearances. Consequently, the procedure for carrying out thermal insulation work will also differ. We present to your attention instructions for insulation in the most common cases.

Insulation with low underground

Due to the limited height of the subfloor, the insulation cannot be fixed from below to the joists. This leads to the need to dismantle the existing flooring, which makes this method the most labor-intensive.

In general, the work is performed in the following sequence.

- First step. Remove baseboards and flooring elements. If replacing the decking is not in your plans, work as carefully as possible. For greater convenience, sign the boards to avoid problems during their reassembly.

- Second step. Examine the condition of the lag. Dismantle rotten and deformed areas.

In place of the removed elements, install pieces of timber of similar sizes. To fasten parts of the structure, use wooden boards and galvanized screws.

- Third step. Attach a support block to the bottom of each joist.

- Fourth step. Prepare lumber for arranging the rough flooring. An unedged board works well. Saw it into pieces 10-20 mm long less than the installation pitch of the joists - the flooring elements should be laid quite freely.

- Fifth step. Assemble the subfloor. There is no need to attach the boards to the support beams.

- Sixth step. Cover the flooring and joists with a vapor barrier material. If the building is located in an area with high groundwater, instead of vapor barrier, install waterproofing - glassine or roofing felt. Lay the insulation with a 10-15 cm overlap on the walls. Tape the joints of individual strips of material with tape.

- Seventh step. Install finished floor joists. Lay the selected thermal insulation material.

- Eighth step. Cover the insulation with a second layer of vapor or waterproofing.

- Ninth step. Stuff counter battens to create a ventilation gap between the insulation “pie” and the finishing flooring. The recommended gap thickness is 20 mm.

- Tenth step. Reinstall the previously removed floorboards or install new flooring.

| Floor board thickness, mm | Distance between lags, cm |

| 20 | 30 |

| 24 | 40 |

| 30 | 50 |

| 35 | 60 |

| 40 | 70 |

| 45 | 80 |

| 50 | 100 |

43 44

Detailed description of the technology

First of all, the base (subfloor) is prepared.

The floor needs to be repaired, all cracks repaired, and leveled. Treat the wooden floor with an antiseptic. Cracks in a concrete floor can be repaired with cement mortar or polyurethane foam, with further removal of excess. Coat the dirt floor with clay. At the final stage, dry and clear of debris. After preparation, waterproofing is carried out - a polyethylene film or membrane is laid on the base. If one sheet is missing, and in most cases this is the case, the film is laid overlapping, that is, so that one edge of the film lies on the other, at a distance of 10-15 cm. The sheets are fastened together with adhesive tape or double-sided tape. This process requires maximum care when working on concrete floors, as it is easiest to tear the film or membrane on them.

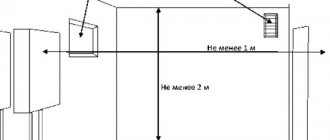

Installation of logs is the most important stage of work. The logs are made of wooden beams and installed between the walls in increments equal to the width of the insulation sheets. Most often, the width of the sheets is 1 meter. This means that the logs should be installed in increments of 1 m. Sometimes it is recommended to do a little less so that the gaps are minimal. To fasten the lags, dowel-nails with screws are used.

It is extremely important that all joists are strictly horizontal. This is the main condition for a flat floor to be installed on them.

A long liquid or laser level is used to level them.

Work begins with the installation of side joists running along the walls. Drive short ones between the long bars so that you get cells slightly smaller in size than the size of the insulation sheets. If cotton wool in rolls is used as insulation, there is no need to make jumpers between the joists.

At the end of the work, the entire system is thoroughly treated with an antiseptic. Once again check the horizontal position using a level.

Insulation sheets are laid. If the cells were made slightly smaller than a sheet of mineral wool, then it is enough to slightly compress the wool. When it falls into place, it straightens out and fills all the cracks. It is better to cut the foam at the place of installation. This will help avoid even the slightest cracks.

A hydrobarrier is also installed on top of the insulation. It can be either polyethylene film or specialized materials with or without a metallized layer. This is necessary to protect the insulation in cases where something is spilled on the floor.

As with the bottom film, the sheets are laid overlapping so that the edges overlap each other by 10-15 cm. The joints are sealed with double-sided tape or adhesive tape.

A lining for the finished plywood floor is mounted on top. Plywood sheets are fastened with self-tapping screws or clamps. As a rule, the distance between the walls is first measured. The plywood sheets are marked so that the plywood covering is approximately 1 cm away from the walls. The fact is that the plywood lining can expand as it is installed, and it is better to compensate for this expansion in advance. And the remaining gap will then be closed with skirting boards.

When laying plywood, you need to ensure that the joints are located in the center of the joists. To achieve this, the sheets are trimmed with an electric jigsaw or circular saw.

In addition, we must not forget that as you move around the room, its width may change up or down. Accordingly, the width of the plywood sheets should be adjusted.

The biggest challenge will be installing the last sheets of plywood. They will have to be cut not only along, but also across. The entire resulting structure is once again treated with an antiseptic solution.

The finished floor can be installed on the resulting plywood lining.

In some cases, in order to eliminate possible gaps, two-layer floor insulation is done. In this case, the second layer is located across the first. That is, another joist structure is attached on top of the first layer and another layer of insulation with appropriate waterproofing is laid.

How to choose mineral wool products

First you need to pay attention to several characteristics:

- Thickness of mineral wool for wall insulation. The thicker the insulating layer, the higher its fire safety, sound insulation and strength. For interior partitions and frame structures, mats of 5 cm are suitable. For facades - from 5 to 10 cm.

- Density (P). We wrote about it above. The rigidity of the structure and its ability to withstand loads depend on it. For facades, the indicator should be in the range of 100-125 kg/m³. If plaster is chosen as finishing, then 150 kg/m³. For interior partitions - 75-90 kg/m³.

- Thermal conductivity. The smaller it is, the better. In this regard, basalt and fiberglass products have proven themselves well.

- Vapor permeability. The coefficient suitable for private buildings is that of stone wool. Designated MU1. The larger it is, the better the product.

- Fire resistance. The fire resistance level of fiberglass is 600⁰ C, material made of rock alloys is 1000º C.

What else to pay attention to

If you are planning work on the outside of the building, choose basalt slabs. When it is necessary to insulate from the inside, fiberglass coating is also suitable. When purchasing, look at the storage conditions.

- If the product gets even a little wet, there is no point in purchasing it. Check that there are no tears in the packaging.

- Blocks and rolls should be kept under cover and not outdoors.

The most famous manufacturers of mineral insulation are Isover, URSA, Rockwool, Knauf. Their products are certified and quality tested.

Wood-based

This is the simplest and highest quality thermal insulation. These include:

Sawdust

This is a safe natural material. Based on them, various mixtures with sand, cement, lime, and other components are prepared.

The sawdust must be dry, without mold, of medium size, and aged for at least one year.

This is an environmentally friendly, cheap and reliable insulation that retains heat well.

Chipboard is wood chips pressed into boards with a binder and special additives. It insulates sound and heat well. Despite its strength, chipboard is easy to cut and cut.

It is perfect for working with concrete pavement, but since it tends to absorb moisture, you need to start working with waterproofing.

Plywood

Plywood is simple and easy to use. It is easily covered with linoleum, carpet or any type of paint.

For the floor, you must choose a waterproof grade of plywood made from environmentally friendly materials.

Ecowool

Based on sawdust, a modern environmentally friendly material is produced - ecowool. It is made from newspaper waste paper with the addition of antiseptics and fire retardants. Does not deform during long-term use, retains heat well, and is an excellent sound insulator.

Ecowool is easy to use and can be easily poured manually between the joists. It has one drawback - high cost.

Cork

In an era of environmental concern, it is not surprising that many people opt for natural materials. The bark of the cork tree has excellent thermal insulation properties. Cork differs from other natural materials in its honeycomb structure, which includes large and small cells filled with air.

Technical cork absorbs sound and vibration well, it is strong and durable. Available in the form of rolls, it has a small thickness and good density. The small thickness of the product allows you to insulate floors in rooms with maximum height. It is easy to install on any surface. Like any natural material it has a high cost.

Basic criteria and building standards

The lower the density of mineral wool, the lower the thermal conductivity and the higher the sound insulation.

The thermal transfer resistance of the walls of buildings under construction is regulated by the current standards of SNB 2.04.01 (Chapter 5.1), which provides information for all types of walls and ceilings. In addition, for external fences and coatings, parameters for air and vapor permeability must be calculated. In multilayer protective structures, the materials used are calculated as a single whole, consistent with the main technical indicators.

The selection of products that are supposed to be used to insulate walls is preceded by thermal engineering calculations. Based on their results, the type of material needed and its specific brand are determined. When using synthetic substances (polystyrene or polyethylene), it is taken into account that they are impermeable not only to water, but also to steam. Therefore, when choosing them, it will be necessary to take special measures to create good air exchange in the rooms.

Materials formed into slabs (including glass wool) have special requirements:

- the geometry is chosen so that the corners and edges of the workpieces do not have clearly visible damage and noticeable irregularities;

- the structure of the slabs is dense, the presence of poorly connected fibers and falling out granules is considered completely unacceptable;

- the surfaces on both sides are made rough, or one of them is made with a complex texture.

Fulfillment of the last requirement guarantees good adhesion to insulated walls.