Articles

All photos from the article

If in summer few people worry about heating in the house, then in winter the problem of heat comes to the fore, otherwise it is simply impossible to live in such a room. Thanks to a variety of systems, it is possible to maintain comfort not only in the main rooms, but also in the hallway or even the basement.

In this article we will not touch upon electric and solid fuel (liquid fuel) heating systems; today our main character is a gas boiler for a wooden house.

In the photo there is a wall-mounted gas boiler

With its help, you can easily maintain the desired temperature anywhere in the building. At the same time, the efficiency of the device is higher than the rest of the above equipment. The disadvantage is that permission to install it is required from various departmental organizations (see also the article “Inputting electricity into a wooden house: overhead and underground methods. Cable protection”).

Advice: in order to get the most out of a gas boiler and not waste a lot of fuel, you need to insulate the room as best as possible. One option involves replacing old windows with new plastic ones.

Installation of a gas boiler in a wooden house must be carried out in accordance with safety requirements

Premises requirements

The first task is choosing the installation location.

The basic standards are set out in SNiP 02/31/2001. Installation in residential areas, bathrooms or toilets is prohibited. Installation in the basement room is possible, but not in the basement. It also cannot be installed in the attic. For powerful equipment over 36 kW, you need to equip a separate boiler room. It is necessary to take into account the basic requirements - a gas boiler in a wooden house with a power of up to 60 kW can be installed in a room with the following parameters:

- Minimum volume – 15 m?. For every kilowatt of energy above the norm, you need to add 1 m?.

- Ceiling heights are from 2.5 m and above.

- Availability of forced and natural ventilation.

- Artificial lighting should be complemented by natural lighting.

The installation site is isolated from the living quarters by a door; if the installation is carried out in a separate boiler room, there must be an exit directly to the street.

Article on the topic: Never before have I seen how terribly a wooden house burns, a new house that has grown before my eyes

Installation of a wall-mounted gas boiler in a wooden house in a separate boiler room is carried out according to the following rules:

- standard requirements for the volume and height of ceilings – 15 m? and 2.5 m;

- interior wall decoration with fire-resistant material with a fire resistance limit of 0.75 hours;

- normal room lighting - artificial and natural;

- the presence of ventilation systems.

In addition to the door to the street, there may be an additional doorway into the house. It is important to ensure tightness - combustion products should not enter the building. Ventilation parameters depend on the type of combustion chamber - closed or atmospheric. For the second, the air exchange value should not be less than 3 boiler room volumes per hour. Additionally, combustion air consumption is taken into account. This parameter is indicated in the boiler passport. The distance from the heating equipment to the ventilation hole is at least 2 meters. The glazing area depends on the volume of the boiler room. At 1 m? 0.03 m required? light opening. Important - this is an indicator of the net influx of light, without taking into account the width of frames and imposts.

Permits

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. Connection to the gas main should only be carried out by certified specialists, but installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining technical conditions. It indicates the requirements for connecting to the gas main. It is necessary to provide a house plan with its characteristics.

- Drawing up a gasification project. This work is performed by specialized licensed organizations.

- Based on the project, permission is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, representatives of the gas service must check the building and the main line for compliance with the technical conditions and the agreed project. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of Gorgaz subsidiaries. Their representatives know the nuances of design and the latest changes in requirements for premises and equipment.

Types of boilers for heating a private home

The principle of operation of the boiler is always the same - heating the coolant, most often this is standard tap water, in the best case, passed through a filtration system. Various types of fuel can be used for heating. Depending on this they distinguish:

- Gas boilers. Stable leaders in the field of heating units. The reason for its popularity is the low (relative to other energy sources) price in Russia. By the way, in Europe and other countries where natural gas is purchased at the state level, such boilers are much less common. Pros - stability of operation, price, features - you need to equip a gas outlet channel, obtain permits, and cut into the gas supply line. Despite the high costs at the initial stage, gas boilers are one of the fastest to pay for themselves.

A gas boiler

- Solid fuel boilers. A wide range of materials can be burned in these devices: from coal and firewood to special granules called pellets. One of the advantages is complete autonomy from both gas and electricity. A solid fuel boiler can be used in any conditions if there is gravitational circulation of the coolant in the system. Disadvantages - increased fire hazard when loading fuel, special requirements for the premises and the presence of an exhaust chimney. Unlike gas, which is supplied automatically, a solid fuel boiler must be periodically filled with fuel. Installing thermal accumulators and automatic supply systems allows us to solve this issue, but only partly.

Solid fuel boilers

- Liquid boilers. The fuel in such devices is liquid fuel, most often diesel fuel (diesel fuel). It is used because its flammability risk is lower than that of gasoline. After the diesel-air mixture is supplied through the nozzle, it is burned in the combustion chamber, outside of which there is a heat exchanger with a water circuit. Advantages: high efficiency and the possibility of long-term operation in automatic mode. Disadvantages - the need to equip tanks for storing fuel reserves, increased requirements for the placement of units and exhaust gas extraction systems.

- Electric boilers. They have many advantages during installation and placement. Electrical units do not require a separate room or exhaust ducts because nothing is burned. They are the most environmentally friendly among boilers. Thanks to their operation on electric current, they have a high level of automation, and the absence of pipelines for supplying burned energy carriers significantly simplifies the design, excluding nozzles, burners, furnaces and similar elements of fuel boilers. They have only two disadvantages, but they are significant: the high cost of electricity when paying utility bills and the vulnerability of the heating system during a power outage. If there is no “light” in the house, the electric boiler stops functioning.

Despite the differences in fuel, all boilers that produce heat by burning something have much in common, including installation rules. A parameter such as power can also be determined without taking into account the type of boiler.

Table 1. Required boiler power for heating a house by area

| House area, sq. m | Boiler power, kW |

| 90 — 200 | Up to 25 |

| 200 — 300 | 25 -35 |

| 300 — 600 | 35 — 60 |

| 600 — 1200 | 60 — 100 |

Installation diagrams

After preparing the premises and obtaining permits, you can begin installing the boiler. The equipment installation site is finished with fireproof materials. For wall-mounted models, the use of reliable fasteners is mandatory.

How to hang a gas boiler on a wooden wall, and what standards must be followed? To do this, you need to familiarize yourself with the general rules:

- Drawing up a diagram. The location of the pipes for connecting to the pipeline and the location of the gas main are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for domestic hot water, a circulation pump, an expansion tank and a protection group.

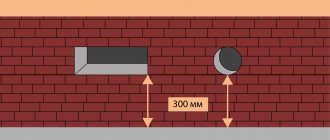

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side ceilings this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling 45 cm.

- The hole in the interfloor ceiling or wall for the chimney is protected by a special fire-resistant sleeve. Its function is to prevent direct contact of wood with the heated surface of the chimney.

- Use of plastic pipes in heating. To protect the surface of the main from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

Article on the topic: How to replace the lower crown of a wooden house

In practice, the same installation of a wood-burning boiler in a wooden house will be easier. But in the future, heating and maintenance costs will be higher than for gas heating.

Wood boiler installation instructions

Regardless of what type of TT boiler you bought - direct combustion, pyrolysis or pellet, the installation procedure remains the same and consists of the following steps:

Note. Depending on the model of a wood-burning or coal-fired boiler, it may be necessary to connect to the electrical network.

The first 3 items on the list relate to preparatory work, which does not at all detract from their importance. If you choose the location of the unit incorrectly and do not provide for normal ventilation, then you will have to solve the problems that arise during operation, in the middle of the heating season. So we suggest looking at each point separately.

To correctly select a heat source based on power, we recommend calculating the heating load using a suitable method.

Where is the best place to install a TT boiler?

It is noteworthy that to this day no country of the former USSR has developed a specific regulatory document regulating the installation of solid fuel boilers in private and apartment buildings. The main part of the requirements is set out in SNiP “Heating and Ventilation”, certain standards are found in the document SNiP 31–02-2001 “Single-apartment buildings” (for Russia) and in other scattered acts.

An example of installing a pyrolysis heat generator with convenient access to the expansion tank and chimney

Reference. Many online resources send us to read the huge SNiP “Boiler Installations”, without taking into account that its effect extends to heat generators with a capacity of over 360 kW (clause 1.2). Others suggest that we follow the rules for gas heaters. Both options are wrong: the requirements for the placement of domestic TT boilers are not so stringent.

We analyzed the regulatory documentation regarding the placement of wood-burning hot water heaters, added to them the practical experience of our experts and compiled a list of recommendations for the location of the unit:

Advice. Before purchasing and installing a long-burning boiler of the Stropuva type, compare its height with the premises. Consider the location of other large equipment - a heat accumulator, a buffer tank and an indirect heating boiler.

In small-area furnaces, move the boiler with the unattended side to one of the walls (minimum distance - 10 cm), and leave an opening at the back with a width of at least 250 mm, as shown in the photo.

About preparing the premises

What needs to be done before installing a TT boiler in the intended room of the house:

Recommendation. If only lighting is provided in the furnace room, then connect an electrical line from the electrical outlet there. You will still have to power the circulation pump, or even the automation of the new heat generator.

It is not necessary to tear off the wooden cladding of walls and floors. If the boiler is moved closer to a combustible wall than 38 cm, cover the latter with one of the materials listed above. Place the same sheet on the floor below and in front of the TT boiler with a protrusion of 80 cm. This is protection against heat particles flying out of the open door.

Wall backing material

The main requirement in finishing walls, floors and ceilings is fire protection. For this purpose, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process and protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. A layer with a thickness of 50 mm or more is installed on a rigid base (metal sheet). The density of wool is maximum.

- Basalt fireproof sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is prohibited to use polymeric materials – polypropylene, foam. For floor-standing models, special attention is paid to preparing the floor surface. It is leveled and fire-resistant material is installed. In this case, basalt wool is not recommended, as it will shrink under the weight of the boiler. The solution is to install basalt sheets.

How to install a floor-standing gas boiler in a wooden house

More and more owners of personal plots prefer to build reliable, warm, high-tech, energy-efficient wooden houses. The key feature of such buildings is considered to be low thermal conductivity, which is how they differ from stone structures.

For this reason, houses made of timber, when organizing heating, do not require the installation of high-power boilers, and the existing floor structures of a log house simplify the installation of heating pipes.

Wooden walls are sensitive to temperature changes and humid environments, so the installation of a floor-standing gas boiler in a wooden house must be carried out using a special technology.

- 1 Installation standards for gas mounted boilers 1.1 Height

- 1.2 Fire safety standards for installation

- 2.1 Installation on a reinforced concrete wall

- 4.1 Installation work

Article on the topic: How to insulate the floor in a wooden house under laminate

Features of the parapet boiler "Lemax Patriot 16"

This model of equipment costs consumers 21,000 rubles. The boiler can work in conjunction with forced or natural heating systems. No connection to the electrical network is required. The rectangular heat exchanger is based on high-quality 2 mm steel, which meets the European standard.

The heat exchanger is coated with anti-corrosion enamel and treated with an inhibitory compound, thanks to which the material is reliably protected from the effects of aggressive factors, namely mineral oils and salt solutions. The boiler can only be used in conjunction with a heating system that is equipped with original gas burner components. Heating can be connected from both sides.

The boiler power is 16 kW. The heated area reaches 160 m2. The front panel has holes that create a convection effect. You don’t have to worry that the boiler will overheat, because the manufacturer has equipped it with a special protection system. Servicing the boiler is quite simple, since the design has removable cladding elements and profile equipment. You can observe the combustion of the pilot and main burners through the viewing window.

Standards for installing gas mounted boilers

The basic standards for the placement of gas boilers are determined by the requirements of SNiP. However, it is prohibited to install boilers in living rooms, bathrooms, basements and attics. For units with a thermal power of more than 36 kW, a separate combustion chamber will be required.

Basic requirements for installing a floor-standing gas boiler in a wooden house up to 60 kW in a house made of timber:

- the smallest volume of the combustion chamber is 15 m2. For every kW of power above the specified power, an additional 1 m2 is added.

- the furnace room must have supply and exhaust ventilation with 3 air changes per hour;

- the furnace room must have artificial and daylight lighting. There must be at least 0.03 m2 of window openings per 1 m2 of area.

Height

When planning the building, it is necessary to take into account the future placement of the furnace so that it meets the minimum requirements regarding the distance to the ceiling, walls, windows and doors.

A gas boiler in a wooden house is installed taking into account the following indicators:

- The base is placed against a blank wall.

- To ensure the required air volume, the unit is placed with the front wall opposite the door, with a minimum distance of 3 m.

- The shortest distance to the ceiling is 0.8 m.

- The ceilings are covered with fire-resistant material.

- The wooden floor is covered with thermal insulation material.

Fire safety standards for installation

Installation of a gas boiler in a wooden house must take into account the requirements of the Fire Safety Rules, which apply to the combustion room, installation of units, gas equipment and smoke exhaust system.

The boiler room must be constructed using non-combustible building materials. If this is not possible, partial installation of fire-resistant surfaces at the location of the boiler and chimneys is allowed.

In this case, the walls and base of the floor are protected with fire-resistant basalt heat insulators. When placing smoke ducts through the floor slabs and roof, specialized fireproof cutting is used.

Installation on different walls

The rules for installing a boiler on the walls of a wooden house require strict compliance with all fire safety regulations and factory instructions. The unit must be firmly fixed to the wall, ensuring a vertical/horizontal level.

Article on the topic: What roof color to choose for a wooden house

At the same time, there are differences in installation and fastening requirements for partitions made of different wall materials, and similarly for hollow walls.

Installation on a reinforced concrete wall

Reinforced concrete is the ideal building material for the walls of buildings intended to house a gas unit. Such building structures are distinguished by excellent strength characteristics, belonging to the class of fire-resistant materials.

Installing the unit on such wall material does not require any special measures. The installation is carried out using steel anchors, on which, according to the level, the prefabricated strip is strengthened and then the unit is hung.

Such a wall is perfect for placing a heating device of any design and power, including large models with a built-in hot water storage tank.

Installation on a brick wall

In existing regulatory directives for installing heating units on a brick wall, the conditions for installing a gas boiler are specified separately. Brick, like reinforced concrete, is a fire-resistant building material, so it is possible to install the boiler directly on the wall.

However, sometimes representatives of the gas service, who are responsible for issuing permission to operate the unit, require plastering of the unit’s site. During the process of plastering the areas, a mounting plate for the mounted unit is installed. After the plastering is completed, two bolts come out of the wall, on which you need to install a gas boiler in a wooden house.

Is it possible to hang a boiler on a wooden wall?

Despite the fact that such walls are flammable materials, fire safety rules allow the installation of a gas boiler on a wooden wall, provided that a heat-resistant substrate is first placed.

To thermally insulate the unit from wooden walls, it is recommended to install a base of the following thermal insulators:

- Basalt wool with a rigid base made of steel sheet, on which a layer of material over 50 mm is placed.

- Basalt refractory sheet material.

In the event of an emergency with an open flame, they are fully capable of protecting the surface of timber walls from fire.

We install the heat generator and chimney

As such, installing a heating boiler on the floor or foundation is not difficult - the unit must be placed in the design position and aligned vertically using adjustable legs or metal pads. It is not necessary to scrupulously maintain the alignment of the chimney pipe and the hole in the wall: they can be combined without problems by turning the knees.

Important point. To avoid problems with the formation of condensation during operation, it is strongly recommended that the chimney of a wood-burning heater be assembled from insulated pipes - sandwiches. The second option is to make a chimney with your own hands: take an ordinary pipe and cover it with basalt fiber.

The easiest way is to install an external chimney duct of an attached type. That is, attach the pipe vertically to the wall and connect the gas duct from the TT boiler through a tee. In a wooden house, the passage through the outer wall or ceiling for access to the roof is carried out in compliance with fire safety rules using the following technology:

Note. A chimney is laid through a wall made of brick or foam block using a steel liner and seal.

Below we list the requirements that must be met when installing a chimney duct:

The correct installation and assembly of a modular chimney is reflected in two connection diagrams, which show external and internal installation through the ceiling.

Mounting the chimney of a wall-mounted boiler

The rules for installing a chimney directly depend on the model of the boiler. Atmospheric units with an open firebox operate on natural draft, and structures with a closed combustion device are connected to a coaxial type chimney, in which simultaneous forced air intake and removal of flue gases occurs using a blower fan.

Article on the topic: Is it possible to put tiles on a wooden floor in a bathhouse?

The height of the chimney head outlet depends on the distance of the boiler smoke pipe and the location of the ridge or parapet:

- If it is no more than 1.5 m, then the pipe is installed with an elevation of 0.5 m above the parapet/ridge point.

- If the distance is in the range of 1.5-3 m, then its highest point should not be below the parapets.

- If the gap is more than 3 m, the pipe is mounted so that its upper level is located no lower than the line at an angle of 10 degrees from the ridge to the horizon.

Types of parapet units

Parapet gas boilers have some features that distinguish them from conventional units:

- A closed combustion chamber, in which the installation of a coaxial pipe is sufficient to remove flue gases. It simultaneously ensures the supply of combustion air to the burner from the street and the removal of flue gases.

- The devices do not depend on electricity and can work autonomously.

- They can be used to heat rooms as an independent device without radiators.

Parapet-type units may differ in other characteristics. They are:

- single-circuit and double-circuit;

- power from 4 to 40 kW;

- on the outlet side of the pipe: left-handed, right-handed;

- floor and wall.

Such units can be equipped with burner devices of different types: single-stage, two-stage and modulating. Also, different models differ in the automation equipment.

Installation of a floor-standing gas boiler in a wooden house

Due to their massive size, floor modifications require a special approach to installation in a wooden house. If the owner of a large house decides to install a floor structure, he must take care of this at the stage of building the house, since some boiler designs require the installation of not only a powerful foundation, but also a separate furnace.

In addition, for these devices there are additional requirements for the installation of supply and exhaust ventilation, which must ensure 3-fold circulation in the area where the boiler is located, as well as the presence of doors and windows in the room.

Installation work

The gas floor-standing boiler is connected in accordance with the manufacturer’s recommendations; the work must be carried out by a specialized service organization that has the appropriate license to carry out such work. The guarantee for boiler equipment and the issuance of permission to connect gas will depend on the fulfillment of this condition. Basic requirements for installing a floor-mounted boiler structure in a wooden house:

- The base for the boiler is made of fire-resistant material, usually reinforced concrete.

- The boiler is placed in such a way that the passage distance between the structure and the wall allows for maintenance of the unit: from the side and rear walls at least 70 cm, in front of the boiler front 1.2 m.

Installation of a chimney

To install the chimney, holes are made: in the wall, ceiling and roof. Their area should be slightly larger than the diameter of the chimney.

A steel metal adapter is installed on the outlet pipe from the boiler to connect to the chimney. After this, a tee and an “inspection” are placed to carry out inspection and cleaning of the gas ducts. In areas where pipes pass through the ceiling and walls, close attention must be paid to fire safety. These areas are insulated with fire-resistant materials.

Article on the topic: Is it possible to upholster a new wooden house with siding?

The chimney should be located at a slight slope from the wall of the building. This requirement is necessary to remove condensate formed in chimneys due to temperature differences. The design degree, as a rule, is indicated in the factory instructions of the boiler.

The smoke exhaust device is thoroughly secured to the outside of the walls or ceiling covering with clamps every 2 m and brackets every 4 m. A tip must be installed on the exhaust pipe to protect it from external influences of the atmosphere.

Heating system connection

A simpler boiler piping is carried out for single-circuit models; only the supply and return pipelines of the intra-house heating network are supplied to them.

For double-circuit units, among other things, there is also a cold water supply for the DHW system. For efficient and long-term operation of the boiler, it is recommended to install a mud filter or filter to clean the water from sludge and corrosion products before introducing network water into the boiler.

Shut-off valves are installed on the supply and return pipelines in order to prevent air from entering the heating system and to simplify the process of repairing a gas boiler. All connections must be well sealed on the boiler unit.

If the water is too hard, to prevent scale formation on the heating surface of the boiler, install a water descaling filter at the inlet to the boiler.

Next, the automation system sensors, a circulation pump, air vents and an expansion tank are installed at the points specified by the manufacturer and the boiler's thermal circuit diagram.

Connection to the gas main

This stage is carried out only by specialists from the gas supply organization who have a special permit to carry out the relevant work on gas equipment.

A filter must be installed on the internal gas pipeline in order to protect the gas equipment of the boiler from debris and condensate.

Before connecting the boiler safety automatic sensors, new gas pipelines must be purged so that debris does not clog the calibrated channels of the burner device.

A gas meter is installed at the gas fuel inlet into the house, and a shut-off valve is installed in front of the boiler for emergency shutdown of the boiler. Gas equipment is connected with steel gas pipes with threaded connections.

Conducting a trial run

After the connection of the boiler with the heating and gas systems is completed, it is connected to the electrical network. To protect electronic control units from power surges, it is recommended to connect the boiler through a voltage stabilizer.

After completing the installation work, fill the heating circuit with coolant, perform pressure testing of the system with a pressure of 1.5 of the operating pressure in the boiler, but not higher than the indicator specified by the manufacturer. During this stage, the density of the assembled heating circuit is checked.

Article on the topic: How to make a partition in a wooden house with your own hands

The commissioning and first start-up of gas equipment is carried out by a representative of Gorgaz, after positive results of commissioning tests, he issues permission to supply gas to the subscriber, and it will be possible to operate the boiler equipment.

Connecting to the heating system

When the installation of the solid fuel unit and the installation of the chimney are completed, proceed to piping the boiler. The main rule applies here: cold water should not get into a working heat generator (especially with a cast iron heat exchanger). Then, condensation forms on the walls of the firebox due to the temperature difference, which turns into a viscous crust after mixing with soot.

For reference. Sticky deposits are difficult to clean off, and in addition, it significantly reduces the efficiency of a solid fuel installation.

The release of condensate during operation of a solid fuel boiler is minimized using a standard piping scheme with a bypass and a three-way valve set to a fixed coolant temperature of 50 or 55 °C. The water circulates in a small circle until it heats up to the specified temperature, then the valve begins mixing in cold water from the heating system.

All the details of connecting a solid fuel boiler are described in a separate publication. There are also diagrams for connecting the heater with a buffer tank and parallel heat sources - gas and electric.

Advice. When piping the pellet boiler, pay attention to the connection of the control unit and burner. In products of European manufacturers, there is an automatic fire extinguishing system powered from the water supply network. To avoid making mistakes, before installing a TT pellet boiler, you should consult with a technical specialist of this brand.

Your task is to install shut-off valves, an expansion tank for a closed heating system and a circulation pump in accordance with the diagrams, fill the pipeline network and create a pressure of about 1 Bar in it. Next is trial lighting and performance testing. The full range of work on installing a wood-burning boiler is reflected in the next video:

Advice from professionals

Proper operation of gas equipment is not only reliable and durable, but also, above all, the safety of everyone living in a private wooden house. According to existing legislation, the user is responsible for the safe operation of boilers.

Therefore, experts advise boiler owners to adhere to a number of simple rules:

- Carry out periodic maintenance of the unit within the time frame and in the amounts established by the equipment manufacturer, as a rule, at least once a year.

- There is no need to save money on filters. Both the gas pipeline and the heating circuit must be provided with similar protective devices.

- It is unacceptable to use rubber hoses to connect gas.

- During the operation of the boiler, the quality of combustion, draft in the furnace and ventilation in the furnace room are monitored.

If there were previously doubts about installing gas boilers in houses made of timber, then they are a thing of the past. Innovative gas heating today is most suitable for such a facility, since it has reliable automatic protection and a thermal process control system.

All this allows you to completely prevent the creation of emergency and fire hazardous situations in the house.

Installation of electric boiler rooms

Electric boiler equipment does not require insulation or special operating conditions. During the heating process, the coolant does not emit combustion products, and therefore does not require a ventilation system. Due to silent operation and ease of installation, electrical equipment can be installed in the kitchen, in the hall, near the bathroom - anywhere in a wooden house. The disadvantage of boilers is their high level of energy consumption (for a house with an area of 150 sq. m, you will need a model with a power of at least 15 - 17 kW).

Main characteristics

Important elements of the house that need to be taken into account when choosing such heating are:

- Floor material. As a rule, the floor is made of boards, plywood or OSB, which are laid over the foundation beams. Such a base is quite movable, which eliminates the possibility of installing a water-based underfloor heating system, because it must be mounted with a screed.

- Insulation of walls and windows. Basically, such surfaces are made of logs or beams, which have a high level of thermal insulation. The coldest place is considered to be the opening, both window and door. That is why heating of a wooden house should be centralized in such places.

Article on the topic: How to cover the facade of a wooden house

It is also important to note that a large amount of heat is also lost through the roofing areas, so the surface of the floor and attic should also be carefully insulated.

Moreover, a material such as wood has good flexibility, which allows the entire system of pipes and air vents to be installed without much interference.

Gas boiler

This design consists of a centralized boiler that heats the heating compartment. In this case, the gas is liquefied and distributed through the pipes, thereby releasing thermal energy. The radiators themselves, being heated to a safe temperature level of 80 degrees, heat the room. The safest solution in this case would be to use main gas, since it is located in a special room - the boiler room - and does not need to be carried through all rooms of the house.

However, heating a wooden house with gas using a gas boiler has some features that must be taken into account:

- It is necessary to choose a boiler that operates on the convection principle, since condensing boilers, although they are less expensive, require a low temperature of the pipeline system, which cannot be done while maintaining the optimal level of heat. The heated floor system can operate at low temperatures, but it is difficult to install it in wooden houses (for more details: “Warm floors in a wooden house are the key to comfort”).

- The heating system should, as a rule, be single-pipe, barrack-type. The main pipe runs along the entire perimeter of the house, and heating radiators are cut in the direction of this pipe. All this is suitable for a convection boiler, with heating of 60 degrees and above.

- You can purchase boilers with electronic ignition. That is, they do not need to constantly maintain the combustion mode of the main burning part, which in turn increases the level of safety. In case of frequent power outages, you can simply install an uninterruptible power supply system

Operating principle of a parapet boiler

When purchasing a non-volatile boiler, you need to turn on the device using the piezo ignition button. If the device is volatile, then the automation automatically turns it on. Boilers of the first type are common in Russia.

So, the parapet boiler works as follows. First, the pilot light ignites the main burner, which heats the water circulating in the heat exchanger. As soon as the water temperature reaches the required level, the burner automatically stops working. After some time, the temperature of the coolant drops again, and the igniter once again ignites the burner.

Convector with gas

The main disadvantage of such a heating system is that it only heats the room in which it is located. So, if there is more than one room in the house, then a gas convector will have to be present in each room, which in turn increases the number of gas cylinders that supply the gas itself.

At the same time, a significant advantage of such a system is its low cost, especially compared to a bimetallic radiator. Moreover, the gas convector does not require the location of additional boilers and pipes. It can even be installed in non-insulated rooms; the heating itself will depend on the power of the convector.

Advantages and disadvantages

Advantages of parapet boilers:

- No need to connect to the mains. The autonomous system is powered by a battery, and the fuel is supplied from the gas pipeline, or cylinders are connected to the system.

- Such boilers are easier to install, connect, and do not require maintenance. To regulate the operation of the system, the necessary sensors and controllers are installed on them.

- The design of the device is simple, which simplifies the task of maintenance.

- Universal equipment can become a heat source for a heating system made of pipes and radiators, or an individual means of heating due to convection windows.

- The equipment is installed in small rooms (small apartment, small private house or cottage). You can place it where it is more convenient. There are floor-mounted and wall-mounted varieties. Such devices are compact.

Convection holes

Disadvantages:

- Weak internal pressure, which needs to be artificially increased by a circulation pump.

- Possibility of icing of the chimney during severe frosts.

A detailed overview of the parapet installation model can be seen in the following video:

Basic fire safety rules

- Firstly, it is necessary to carefully protect the surface on which the boiler will be installed from fire. The best option is galvanized steel and asbestos substrate. It is also important to take into account that the dimensions of the substrate and stand should be 10 centimeters larger than the heating system itself around the entire perimeter.

- Secondly, all other electrical appliances must be located at a distance of at least 30 centimeters from the boiler itself. All electrical wiring should not be carried out above or below the boiler, since such an insulation system will quickly fail under the influence of hot air.

- Thirdly, the diameter of the chimney must correspond to the pipe on the gas boiler, and also have three bends, but no more. The section type should be round, stainless steel is selected as the material.

- Fourthly, the chimney opening must be larger than the chimney itself. This will make it possible to lay an additional layer of insulation using asbestos or a piece of cement-asbestos pipe, which will reduce the level of heating of gas combustion products.

- Fifthly, the gas boiler must be located in a separate room with an area of 4 m2, and it must also have a door, the width of which must be 80 centimeters, and a window.

- And finally, sixthly, the height of the chimney should exceed the height of the roof by 50 centimeters.

How to install a gas boiler in a wooden house: requirements and installation basics

If the question arises of how to install a gas boiler in a wooden house, it is worth noting the basic requirements for such a structure. They must be completed for personal fire safety and for the gas inspection service.

Installation Requirements

- The parameters of the building in which the device will be located in the future must be at least 4 sq m, the ceiling height must exceed 2.5 m;

- The door width is not less than 0.8 m;

- The device is provided with natural light through the window;

- Providing quality ventilation;

- Gas pipes are made only of metal;

- The cross-section of the chimney must be in accordance with the power of the unit;

- In the room with the device there should be a gas analyzer to warn in the event of a gas leak, as well as an electric valve that helps shut off the gas supply;

- The ventilation system should be located in the upper area of the room.

- To install the device, you must have a gas supply, and the room must be built in accordance with the standards and requirements. The units must be installed in special rooms, the so-called combustion rooms, which have ventilation holes for air flow and combustion product removal. Relatively free space, the boiler is not demanding and can be placed in a wall-mounted version above another appliance.

Article on the topic: How to make a partition in a wooden house with your own hands

Wall-mounted gas boiler

Installation

Attention!

It is possible to install wall-mounted devices in cascade for convenience and greater power.

- Mount the gas unit in a cascade 20 cm from other gas appliances and easily flammable materials. The distance between the wall and the device can reach 30-50 cm, depending on the power and model. The power source must be located nearby.

- It is necessary to check the equipment of the device before installation, read the instructions and compare the technical characteristics.

- Before installation, the unit must be completely rinsed with water so that unnecessary particles are removed and do not interfere with operation.

- The fastening strips should be nailed at a height of 0.8-1.6 m from the flooring.

Important!

The wall must be perfectly flat and vertical, as well as strong to support the boiler and components.

- If the wall is made of flammable material, it is worth attaching a gasket made of non-flammable components, the thickness of which should be at least 3 mm.

- Before connecting the boiler to the gas pipelines, you need to remove the plugs from the corresponding pipes.

- To prevent clogging of the heat exchanger when liquid enters, it is recommended to install a corner strainer.

- Ball valves should be installed on both sides of the filter to facilitate future maintenance.

- Experts advise checking whether the device is level, because tilting to one side can cause dangerous consequences.

- Gas pipes must be connected to the device using a metal pipe with a rigid connection.

- Don't forget to use a parotene gasket.

Attention!

Connection of the device is carried out exclusively by authorized representatives after appropriate verification of all standards and requirements.

Installing a wall-mounted gas boiler in a wooden house is generally not difficult; the main thing is that you must adhere to all the rules and regulations during operation.

Next, you should install a chimney, the material for which is selected depending on the combustion fuel and the type of apparatus.

For gas boilers, it is better to choose cylindrical pipes made of metal or stainless steel. These chimneys are safer and more durable.