When choosing a gas boiler for heating a country house or city apartment, many people prefer domestic developments to imported ones. Moreover, it is economically beneficial: domestic gas boilers cost much less than European brands.

One of the leaders of domestic manufacturers of household heating equipment is, which produces wall-mounted gas boilers of the luxury series. It is important to note that the technical characteristics of these units are in no way inferior to foreign analogues in terms of functionality, economy and efficiency.

A little about the Neva company

The company has existed for more than half a century, and initially it was a state-owned enterprise called Gazapparat. This enterprise specialized, as the name suggests, in the production of household gas equipment: water heaters, various heaters, and also produced heating boilers.

At the end of the 90s, the enterprise became the property of the Baltic Gas Company concern, while maintaining production facilities in the city of St. Petersburg. It was under the management of this giant that the company, one might say, received a second life and began to develop rapidly.

New types of Neva gas boilers, equipped with modern automation, saw the light. Errors and shortcomings of the first models were taken into account, and the equipment was seriously improved. As a result, today the domestic consumer has the opportunity to purchase a reliable single-circuit or double-circuit luxury series boiler at an affordable price. And the company is seriously thinking about entering the global sales market.

Neva service centers

Especially for your convenience, we have collected all the necessary information related to the service of tools and equipment. Here you will find the addresses of licensed service centers located in your city (the locality is determined automatically or by your choice).

Select your city: ArkhangelskBalashovBarnaulBlagoveshchenskVeliky NovgorodVelskVladimirVoskresenskVyaznikiGagarinGus-KhrustalnyDmitrovZhukovkaIvanovoKalugaKasimovKineshmaKovrovKolomnaKorolyovKostromaKubinkaLobnyaLyudinovoMalakhovkaMaloyaroslavetsMoscowMuromNovomoskovskObninskPavlovsky PosadPo chepPuchezhRzhevRostovRybinskRybnoyeRyazanSasovoSerpukhovSkopinSmolenskSobinkaTorzhokTulaTutaevUglichElektrostalYaroslavlYasnogorsk

Model range of boilers Neva Lux

The luxury series, well known to consumers, is divided into two categories:

- For heating an apartment or house, a wall-mounted single-circuit Neva boiler is best suited. Instead of a DHW circuit, you can install an indirect heating boiler. The modulation burner installed in such boilers, thanks to automatically changing combustion intensity, makes it possible to achieve high efficiency of the equipment. The 8618 single-circuit gas boiler attracts buyers with its low cost and simplicity of design, as well as the absence of complex energy-dependent automation.

- The double-circuit boiler 7218 luxury series from the Neva company has extremely positive reviews due to its practicality and efficiency. Modern automation allows you to accurately monitor the temperature of the coolant and water in the DHW circuit. In addition, some models provide additional outlets for the underfloor heating system. The installed automation is capable of controlling each circuit separately. The most popular models are 7218 and 8224.

Advice! You can install a separate thermostat that will monitor the temperature in the room and transmit a signal to the gas boiler to turn on only when the temperature drops. This feature allows you to significantly reduce heating costs.

Now let's take a closer look at which models of Neva boilers are most popular among consumers.

Model Neva Lux 7218

For heating a living space up to 180 m2, the Neva Lux 7218 unit is best suited. The hot water circuit is designed to increase comfort and provides residents with hot water. This dual-circuit device is equipped with a bithermal heat exchanger, which reduces the cost of the 7218 boiler and maintains all user functions at a high level.

The heating gas apparatus Neva 7218 has the following technical characteristics and design features:

- A closed combustion chamber is used.

- The operating temperature range in the heating and DHW circuit of device 7218 is from 30 to 85 °C.

- Additional settings will help convert the unit to operation on liquefied gas.

- The efficiency of the model 7218 is 90%.

- The electronic safety unit continuously monitors the flame. This happens both during heating and DHW circuit operation.

- The ergonomic boiler Neva 7218 Lux goes on sale with European components, which has positive customer reviews.

Model Neva Lux 8224

This wall-mounted device Neva Lux 8224 has the following design features:

- The increased power allows the use of double-circuit boilers 8224 for heating an area of up to 250 m².

- The unique combustion chamber is water-cooled, which significantly increases the service life of all parts.

- Microprocessor software installed in 8224 boilers ensures that the set temperature is maintained. The error is less than 1 degree.

- In addition, the gas apparatus 8224 is equipped with two heat exchangers: a copper one for the heating circuit and a stainless steel plate one for DHW.

Also, equipment management in the 8224 model has reached a new level: the ability to remotely control and connect a PC has been added for diagnostics and more precise settings.

Advice! The Neva 8224 Lux units have a digital display; all current information from the automatic self-diagnosis system is displayed on it.

All these innovations have received praise from consumers.

Model Neva Lux 8618

The Neva Lux model 8618 is a single-circuit gas boiler. Compared to floor-standing units of the same power, the Neva 8618 model has a higher efficiency (up to 90%) and is characterized by reduced gas consumption.

Wall-mounted boilers Neva Lux 8618 have the following features:

- Compact dimensions allow the unit to be installed even in small rooms without cluttering up the space.

- The reliability and complete adaptation to domestic operating conditions of the 8618 model is confirmed by numerous positive reviews about this device.

- The circulation pump built into the gas boiler 8618 from the Neva company allows installation in already installed heating systems.

In addition, such wall-mounted boilers have the ability to connect:

- Indirect heating boiler.

- Forced smoke exhaust fan.

- A room thermostat, which makes the unit even more economical.

Advice! Another feature: gas boilers of this model are capable of operating at a pressure drop of up to 0.3 bar in the gas main.

e2

Error e2. Ignition failed, check the following:

- Open the shut-off valve on the gas pipeline; if you are using liquefied gas, the cylinder may be empty. There is a breakdown in the gas line, contact the gas service.

- The spark plug is broken, replace it with a new one.

- There is a fault in the electrical circuit of the spark plug. Using a multimeter, test the contacts for an open or short circuit.

- There is insufficient distance between the spark plug and the burner section, set the gap to 5 mm.

- Dust accumulation on the spark plug, clean it from deposits and degrease it.

- Disturbance in the electrical ionization circuit. To check, do the following: while the device is operating, remove the wire from the spark plug. The boiler operation should stop and 01 will appear on the monitor.

Then connect the wire back and hold down the K6 and restart keys, after which the device will turn on. The flame is detected by the principle of monitoring the ionization current. Its measurements are carried out using a microammeter, alternately connecting ionization candles into the circuit.The optimal value is from 3 to 5 microamps. A possible reason for the decrease is its leakage or insufficient connection, incorrect connection (swap the spark plug and ionization plug).

- Insufficient distance in the ionization candle and separation by the burner. Set it in the 3mm range. Ionization candles for boilers Neva Lux

- The ignition transformer has failed. Replace it with a new one.

- Damage to the electrical circuit in the ignition transformer. Check it for breaks and check the integrity of the connectors.

- Burner block clogged. Clean it.

- There is a malfunction in the electrical circuit of the fuel supply regulator. Check the circuit with a multimeter and test the controller board. Repair if you find a break; if the board is faulty, purchase a new one.

- The electronic board is broken. Needs to be replaced.

Features of installing wall-mounted gas equipment

It is worth noting that a wall-mounted double-circuit boiler is a self-sufficient system and the installation of such equipment and its connection to existing networks does not cause difficulties. In order to install and connect a gas boiler, the following components are used:

- ball valves for cutting off water lines and heating circuits;

- various surges;

- coaxial chimney that comes with the boiler.

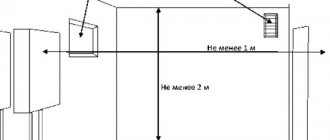

To ensure the protection of the boiler from various impurities, it is necessary to install a number of filter elements: gas, magnetic and coarse filter. Gas wall-mounted boilers are installed in the following sequence:

- The Neva Lux boiler is installed on the wall using special strips that are included in the kit. To securely attach the mounting strips to the wall, it is best to use anchors.

- Ball valves are installed at the inlet and outlet of the boiler of the DHW and heating circuits. This will facilitate further preventive maintenance of the unit.

- Then comes the installation of all the necessary filters using suitable filters.

- After this, you can begin installing the heating circuit and DHW, or make a connection to existing pipeline systems.

All gas connections and filter installation must be carried out by gas company employees who have permission for this type of work.

Advice! It is best to install the Neva Lux boiler in the kitchen or in another room of a private house where there is a ventilation hole. This is due to the rules for using gas equipment and general safety. Also, when choosing an installation location, you should take into account the convenience of supplying communications: water and gas pipes, electrical wiring.

The simple design and reliability of Neva Lux gas boilers is confirmed by numerous consumer reviews. After proper installation, there is no need to worry about the safety of the equipment. Modern automation allows you to avoid emergency situations even in the event of emergency situations: a power outage or a drop in pressure in the gas line.

e1

Error e1.

This malfunction indicates low fluid pressure in the heating circuit. The reasons may be as follows:

- The heating circuit has become airy or the pressure has dropped to its minimum point. Increase the fluid pressure in the system, remove air from the heating circuit.

- The bypass valve is installed incorrectly or is faulty; to check, follow these steps: set the boiler to heating mode, then close the shut-off valve to the heating circuit.

The bypass should redirect the liquid not into the heating circuit, but pass it through the bypass line (at the same time it will heat up). And, if it is faulty, replace it with a new one, installing all the taps in the position in which they were before the check. - Pump failure. It is necessary to remove it from the device, disassemble it, wash it, and clean it of accumulated deposits. If this does not work, replace it.

- There is a breakdown in the electrical circuit of the pressure sensor.

Using a multimeter, test the circuit for an open; if found, repair it. DHW sensor Visually check all contacts and connectors. If this does not give the expected result, replace it with a working device. Occurs often in Neva Lux 2073. - A slow-moving rod or sticking of the measuring device rod in the heating circuit, the cause could be a failure of the membrane on the flow sensor.

To begin, remove this sensor from the device, turn the boiler (pump) on and off, in a similar way you can remove the boiled rod. If this does not work, check the condition of the membrane; if it is worn or deformed, replace it. - There is a malfunction in the flow sensor, or the integrity of the connecting wire is broken. Perform an electrical circuit check and also check the connections of the controller board connectors. If the problem persists, replace the flow sensor. Typical for the Neva Lux 2083 model.

- Failure in the electric motor of the three-way valve. Repair is not possible, complete replacement is necessary.

Possible faults

The more complex the equipment, the greater the likelihood of it failing. This is especially true for the electronics included in the control system. Despite the fact that Neva Lux heating boilers are considered extremely reliable, some types of malfunctions cannot be avoided. More often for reasons not related to the equipment itself. These include:

- Low gas or water pressure in the system;

- Breakage and attenuation of the flame;

- Mechanical breakdowns.

The built-in self-diagnosis system displays an error code on the display, which is identified by the table on the last page of the instructions. If there is no warranty, you can fix some simple malfunctions yourself, but it is still better to contact the manufacturer’s customer support service or directly to the service center.

Maintenance and operation

Regardless of which model you prefer, installation of a wall-mounted boiler is carried out in the shortest possible time without any additional costs.

The manufacturer places the main emphasis on ease of installation and subsequent operation of the unit. That is why the heating devices of the Neva Lux company are a completely ready-to-use station. All you need to do is connect the equipment to the heating system and power supply and start heating the room. As practice shows, all work takes 3-4 hours. After installation has been completed, there is no need to worry about the safe operation of the station. Consistent operation of the automation reduces to zero the risk of gas leaks and emergency situations, even in the event of an unplanned power outage.

Structural components

From a technical point of view, the Neva wall-mounted gas boiler is impeccable. It implements all the technical advances in heating engineering, as well as developments in the field of electronic control of heating circuits.

Structurally, the Neva double-circuit gas boiler consists of the following interconnected systems:

- a control system consisting of an electronic unit that controls the operation of the boiler and ensures safety, and an electrical harness that connects sensors, an electronic board and other devices into a single system;

- hydraulic system, including a pump for forced circulation, an automatic valve for removing air, a heat exchanger for heating the coolant, a secondary heat exchanger for the hot water system;

- the gas system includes a burner unit, which ensures uniform and complete combustion of the gas-air mixture in the combustion chamber, and an ignition transformer to create a spark on the spark plug, which automatically ignites the gas mixture;

- smoke removal system, which includes a fan for forced removal of combustion products and a chimney;

- a setup and adjustment system consisting of a gas supply regulator to the burner block, a heating circuit temperature sensor, a DHW temperature sensor, and a DHW circuit flow sensor.