Operating principle of liquid thermal insulation

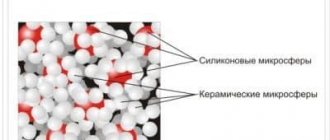

The structure of thermal paint

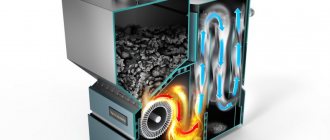

When using thermal paint, several methods of heat transfer can be distinguished. Thus, the most common is thermal conductivity, that is, the transfer of heat from a heated section of the wall to a cold one. The paint contains about 20% of binding components that are involved in this process.

There is also convection (heat transfer by the substances themselves). Thanks to the careful development of the thermal insulation material, fairly small losses are allocated to this process, due to the large presence of hollow balls. The most common principle is radiation, during which heat is transferred due to the internal energy of the substance. This process is ensured by microscopic balls. They play the role of heat reflection and dissipation.

Liquid thermal insulation "Magniterm": reviews and characteristics

There are several types of Magniterm composition on the market. Liquid thermal insulation, reviews of which will be below, is produced for building facades, balconies, floors and basements.

Magniterm Nord deserves detailed consideration. This composition can be used from - 30 to + 80°C. The resins that make up the heat insulator create a thin layer on the surface that allows steam particles to pass through. Moisture does not pass through Magniterm Nord.

Before applying thermal insulation, you need to carefully prepare the surface, that is, clean it of loose areas, oil stains and metal chips. It is advisable to cover everything with a layer of acrylic primer for concrete.

It is worth keeping in mind that before use it is necessary to dilute Magniterm. Liquid thermal insulation, reviews of which are not always positive precisely because this stage of work was carried out incorrectly, is diluted only with high-quality non-toxic liquids. Otherwise, the smell may cause intoxication among residents.

Areas of application and method of use

Thermal insulation reflects infrared rays in both directions.

Most often, thermal insulation is used to insulate pipelines and walls of premises. The characteristics of liquid thermal insulation ensure the service of Akterm coating for many years. The manufacturer guarantees the preservation of the properties of the material for up to 15 years.

Thermal insulation is used for insulation:

- balconies;

- apartments outside and inside;

- pipelines;

- steam pipelines;

- metal, brick, concrete garages;

- hangars;

- metal roofs

- air conditioning systems;

- cars and other vehicles;

- drinking water tanks;

- foundations.

There are good reviews about Akterm thermal insulation; it is often used to insulate apartments. In winter, the walls do not freeze, dampness and mold are eliminated, and the formation of condensation is eliminated. In many apartments where wallpaper peels off due to dampness, the problem is perfectly solved after using such insulation outside, and the rooms become much warmer. Also read: “How can you insulate the walls of your house from the inside?”

Applying the material to walls in private homes significantly reduces gas consumption for heating. Using Akterm on the outside in 2 layers will perfectly insulate the house. If we talk about metal garages, they are also insulated from the outside or from the inside. Akterm insulation is perfectly applied to any surface - wood, brick, plasterboard or concrete. Also, this protective material can be applied to any wall decoration: wallpaper, paint or tiles.

It is applied in a thin layer. The layer thickness should be no more than 0.5 mm. It is necessary to wait until the first layer has completely dried before applying the next one. Akterm can be applied to walls even in poorly ventilated areas.

Scope and features of Akterm thermal insulation

Universal liquid thermal insulation Akterm Standard.

This type of thermal insulation is used to cover any type of surface: metal, wood, concrete. It has sound and heat insulating properties. Also, Akterm liquid thermal insulation is easily applied to a surface of any shape.

Used on pipelines, walls, roofs and vehicles. Due to its properties, thermal insulation significantly reduces heat loss in the room. It prevents walls from freezing and helps to significantly reduce heating costs. It prevents condensation from forming on pipes and any steel surfaces.

Existing types of thermal insulation:

- standard;

- facade;

- north;

- NG;

- volcano.

“Standard” is used for insulating building facades, interior decoration and insulating concrete floors. Also used for coating surfaces on roofs. This ultra-thin thermal insulation Akterm is used for hot and cold water supply pipes.

If you cover the wall with a thin layer of Akterm insulation, it will stop freezing and becoming covered with condensation. 1 mm of insulation can replace a 2.5 mm layer of polystyrene.

A more effective insulation material is “Facade”. It can be applied in a thick layer, which is a real boon for concrete surfaces. It has a high coefficient of heat reflection and is used to insulate walls and facades of buildings. The Nord type is suitable for work at low temperatures. It is often used to insulate outside rooms, as well as heating pipes or any metal containers.

At facilities where it is necessary to use non-combustible materials for thermal insulation, the “NG” type is used. For cases with high thermal conditions up to +600 degrees, Akterm liquid insulation of the “Vulcan” type is used.

Liquid thermal insulation does not reduce the usable area of the room.

The features of the insulation are:

- thermal insulation;

- thermal mirror;

- anti-corrosion;

- use in hard-to-reach places;

- antifungal coating;

- does not reduce space;

- high temperature resistance;

- reduces and eliminates condensation formation.

- adhesion (or adhesion) to almost any material.

If you cover the walls of a building from the outside, then in summer this material will reflect heat, and in winter, on the contrary, it will return it indoors. Thus, it performs the function of a thermal mirror. Coating indoor walls will not only provide excellent thermal insulation, but can also act as a finishing and antifungal coating. The majority of reviews about Akterm liquid thermal insulation are good. And not only due to excellent insulation, but also the possibility of application in hard-to-reach places.

The use of Akterm thermal insulation will not reduce the usable area in the apartment.

When using this thermal insulation, the risk of rust is significantly reduced, because it prevents the formation of condensation. High heat resistance (up to +260 degrees) and the possibility of application to any objects distinguish it from other heat-insulating materials.

Regulatory documents according to which pressure testing of the heating system is carried out: SNIP, GOST, sanitary standards.

There is special equipment for washing and pressure testing heating systems. Some cleaning methods can be done manually. Read more here.

How comfortable is AKTERM Concrete liquid thermal insulation to use?

Application of AKTERM Concrete thermal insulation is carried out with the same degree of comfort as using conventional surface paint. So, all you need is:

- ordinary spatula;

- device for spraying an airless type product.

Thermal insulation fabric applied to the surface being treated acquires the following properties:

- flexibility;

- elasticity;

- obvious adhesion.

Therefore, it is convenient to use subsequently, since maintenance procedures for this material are reduced to zero.

It should also be said that applying AKTERM Concrete as thermal insulation deprives you of not only the need to pay hefty bills for heating or electricity, but also prevents the formation on the treated surfaces:

- fungus;

- condensate;

- mold.

When exposed to environmental conditions, AKTERM Concrete, daily faced with natural factors negatively affecting it, can be used for at least 10 years with full preservation of its properties. If we are talking about using the material inside rooms, then the desired indicator can be safely doubled and another 3-5 years added to the resulting value. The thing is that, when applied to the wall, the desired coating is resistant to:

- ultraviolet radiation;

- increased level of air humidity;

- temperature changes.

At the same time, no additional layer is required to protect the thermal insulation, since this composition is able to cope with all the “attacks” of the environment itself.

This liquid insulation can be applied to both flat and textured surfaces, and the final effect will not be affected.

Akterm (Facade) Concrete

Liquid insulation is created for insulating and decorating the facades of buildings, structures and premises from the inside. It is perfect for surfaces made of brick, concrete and other materials. Thanks to antifungal additives, you don’t have to worry about removing mold - its appearance is excluded. The antiseptic additives included in the composition eliminate harmful bacteria, which helps improve the indoor microclimate.

The thermal insulation layer will also protect against freezing and moisture condensation on the walls. The product will retain its attractive appearance for a long time, because it is resistant to UV radiation. After drying, the paint does not require additional processing; it is used for:

- insulation of premises from the inside;

- insulation of floors under screed;

- insulation of loggias, balconies, basements;

- as a vapor barrier for underfloor heating;

- insulation of facades of residential and industrial buildings and structures;

- elimination of condensation, fungus;

- thermal insulation of surfaces of domestic and industrial facilities;

- thermal insulation of children's rooms, schools, hospitals, etc. institutions;

- thermal insulation of interpanel seams, facades;

- protecting walls and floors from freezing;

- insulation and insulation of window slopes.

The operating temperature of the finished coating is not as high as that of previous materials - up to +140 degrees. The color of the film is white; paint can be applied manually or mechanically.

Mistakes that are most often made when performing work

In order to get a high-quality result, it is better not to make the following mistakes:

- Incorrect insulation thickness. If you lay the material at a minimum thickness, you are unlikely to get the desired result. It's better to count everything.

- Incorrect fastening of material. Each insulator requires its own approach during the installation process and it is advisable to understand this before starting work.

- Partial insulation of the house. If you insulate only the walls, but do not touch the basement and roof, then heat conservation will also be partial.

- The gaps and cracks between the insulation boards will become bridges through which heat will leak out. Therefore, the material is laid as tightly as possible, but without creases.

- Unprepared base.

- Reliable thermal insulation is achieved through three conditions: quality - timely execution - professional approach. This means you shouldn’t be fooled by advertisements that say we’ll get the job done quickly and inexpensively.

- Lack of control over the execution of work.

Rules for applying liquid thermal insulation

Wall insulation

For insulating walls using liquid materials, insulation with ceramic components is more suitable. Liquid ceramic insulation with a water base is ideal for internal wall coverings, and for external facades the option with a varnish base is suitable. With this material you can easily insulate hard-to-reach places and do the work yourself.

Before starting work, you should prepare the surface. To do this, you need to remove all irregularities and, if necessary, plaster using a dry gypsum mixture. Afterwards you need to apply a primer. When the wall is completely prepared, you should start mixing liquid insulation. It should be mixed immediately before application and follow the manufacturer's instructions. Thermal paint is applied in several layers; a new layer can be formed after the previous one has completely dried. Also, the paint layer should be about 1 mm thick. The number of layers depends on the material and thickness of the walls. You can apply the product with a foam roller or spray, then there will be an even coating.

To insulate the walls externally, you need to not only level the surface, but also get rid of mold and mildew, and then treat it with a special antiseptic. After this, the wall is primed. When the primer has dried, you can begin thermal insulation. The weather during work should be warm; in the presence of wind or rain, it is prohibited to apply thermal paint. The layer of applied paint should be no more than 1 mm. It is recommended to use a brush or spray. Each layer takes about 24 hours to dry. Complete drying of the finishing layer depends on the number of layers applied.

Insulation of floors

To reduce heat loss, it is possible to insulate floors using liquid thermal insulation; this option goes well with a heated floor system. But this method can be used in rooms where there is no floor heating.

Before starting work, you should clean off dust and dirt and remove all uneven surfaces. Then a primer in the form of acrylic impregnation is applied. After it has completely dried, you can apply thermal paint. It is best to use a spray bottle here. It should be kept at a distance of 50 cm from the floor, and should be worked at one angle. Then the paint will be evenly distributed over the entire floor area.

Pipe insulation

Liquid thermal insulation is used for insulation of pipelines in the gas and oil industries, as well as for water supply pipes. This coating reduces heat loss and also provides protection from chemical and mechanical stress. For this purpose, a special line of thermal paints designed for pipes is produced.

Before starting work, remove dirt and rust, then prime the pipe. After the primer has completely dried, you can begin the insulation process. Ceramic thermal paint is applied using a brush or a special sprayer. It is necessary to apply about 5 layers, each layer dries in about 4-5 hours. After this, the pipe is coated with special enamel.

Liquid thermal insulation “Armor”: reviews and recommendations for use

Among all brands of liquid thermal insulation, Bronya is the most popular. This is due to the availability of the material at cost and a wide range of products. At official dealers you can find varieties for processing facades, metal structures and other types of surfaces. Every buyer will find a suitable option.

Reviews from home owners about this type of thermal insulation are most often positive. Negative opinions about the coating usually arise because it was applied incorrectly by the builders.

Manufacturers recommend applying ultra-thin insulation with a soft natural bristle brush or airless sprayer. You should definitely check with the company’s regional representative about the preferred brand of the latter.

AKTERM insulation paint and its advantages

Liquid thermal insulation in Moscow is represented by numerous products from various manufacturers (CORUND, ASTRATEK, TEPLOMETT, TEPLOSIL, ISOLLAT, RE-TERM, etc.). The materials are in many ways superior to roll and panel insulation. Understanding the variety of liquid ceramic thermal insulation materials offered today is not always easy. Liquid ceramic thermal insulation is used for various purposes: insulation of balconies, insulation of apartments from the inside and outside, elimination of condensation on walls and pipes, thermal insulation of pipelines, containers, warehouses, hangars, tanks, tanks.

Our company’s employees will select the most optimal material for the implementation of your tasks free of charge.

To insulate walls and pipes from the outside, we recommend using AKTERM Standard insulation paint, which is a completely non-flammable modification that ensures a high level of safety.

| Thermal insulation inside the apartment |

- AKTERM Nord on silicon-organic - allows you to carry out work at temperatures down to -35 C. Liquid insulation can be used in winter to insulate any surface at subzero temperatures.

- AKTERM Metal - can be applied to any metal surface. AKTERM Metal reduces heat loss on metal surfaces by up to 45%, is applied to surfaces with a temperature not lower than + 7 C, operating temperature from – 60 ° C to + 260 C.

- AKTERM Concrete for internal and external surfaces of concrete and brick. The material is water-based, non-toxic, applied to the surface at an ambient temperature of at least +7 C. Effective for thermal insulation of concrete and brick surfaces, contains fungus and mold inhibitors.

- AKTERM Standard is an energy-saving water-based paint, a universal modification, can be applied to any metal and concrete surfaces, as well as walls, floors and ceilings from inside the room at least + 7 C. AKTERM Standard works perfectly at temperatures from – 60 ° C to + 260 C.

- AKTERM Facade has high vapor permeability and was developed specifically for the facade of buildings. The material is water-based, applied to the surface at an ambient temperature of at least +7 C. Contains fungus and mold inhibitors.

- AKTERM Anticor on silicon-organic is a thermal insulating energy-saving paint with anti-corrosion properties, which is used on surfaces subject to corrosion and as a primer layer before applying other AKTERM thermal paints to rusty surfaces.

- AKTERM Vulcan is a liquid heat-saving paint on a silicon-organic basis, used on objects with a peak temperature range of up to + 600 C.

- AKTERM NG is a completely non-flammable modification of AKTERM NG on a water or silicon-organic basis. (made to order)

Akterm Anti-condensate

The material prevents the formation of condensation on all types of surfaces, including concrete, brick, and metal. The scope is wide:

- interior work in the room (walls, ceiling, floor);

- containers, tanks;

- pipelines;

- metal structures;

- outbuildings – garages, cellars, basements.

Application of 2 mm paint 100% guarantees the absence of condensation when operating surfaces in the temperature range of -60...+150 degrees. Indoors, this helps create a comfortable microclimate and provide protection from fungus and mold.

The material is diluted with water and can be easily applied with a brush or airless spray. Drying time is a day.

Price

To calculate how much it will cost to finish and insulate the facade of a house, you can use an online calculator, which can be found on the websites of construction companies or material manufacturers. The price of the issue depends on many factors:

- Foundation conditions.

- Scope of work.

- Technologies for performing work.

- The type, and therefore the cost, of the insulation.

- Facing material.

- The work will be done with your own hands or by a professional team.

Therefore, calculations are made individually for each house. You should not buy all the components by eye, because it is not always possible to choose the finish of the same color.

Selection rules

First of all, you should decide on the place where the thermal paint will be applied. Usually, the jar with the product is labeled by the manufacturer. Look carefully at what surface this product can be applied to.

Carefully inspect the contents of the jar. It should be uniform, there should be no plaque or any inclusions. It is desirable that the color be white, but light shades of gray or beige are allowed. Otherwise, the product will not meet the declared qualities.

The density of the product should not be ignored. A low indicator of this criterion will give greater heat transfer. In addition, you should familiarize yourself with the service life and interaction with external environmental indicators. For example, ultraviolet light, fire or water.

Not all liquid thermal insulation has an easy application method. Make sure that the product not only meets the required protection and density parameters, but is also convenient to use.

Since there are a large number of manufacturers of this insulation on the market, it is better to give preference to a time-tested brand. This way you can be sure of the quality and reliability of the purchased product.

Characteristics and features of liquid insulation materials

Polinor in cylinders is an effective liquid thermal insulation for external walls with a 60 mm single layer. Consumption is economical in proportions 1:1. One bottle treats 1 m2 of area. The manufacturer prepares Bronya products, a liquid insulation with its homogeneous mass that dries in the form of a white suspension and forms a dense matte film.

Polinor in cylinders is an effective liquid thermal insulation for walls.

The effectiveness of liquid-reinforced materials is achieved by retaining heat from the inside, under a layer of protective coating, a mini amalgam. Ceramic granules have an energy saving rate 5 times higher than a standard layer of plaster and retain heat 3 times longer. Moisture, condensation, mold and mildew do not form under layers of liquid insulation. There is no damage or rotting of the base.

Ceramic granules have an energy saving rate 5 times higher than a standard layer of plaster.

Liquid insulation is suitable for exterior walls and interior work. Thermal insulation service life is at least 10 years. The third example of the residential construction project “TERMO RON Facade”, one layer of coating on the outside saves energy resources by 1.3 times. It is suitable for insulating walls and foundations. When added in the correct concentration of dyes to the finishing layer, it can be painted to suit any modern style or design.

Thermal insulation of balconies, loggias, and slopes of residential goods is carried out easily and naturally. Little material is used to create a durable protective shield against heat loss. Infrared emitters and thermal imagers have shown that a 65-75 mm layer is enough to protect against the destructive effects of sunlight and save energy.

It is beneficial to use the products, ready-made in the form of cylinders and buckets, available in volumes of 5, 10, 20 liters. What is convenient, practical, profitable and low cost. The payback period for the product is 3 years.

Liquid insulation is suitable for exterior walls and interior work.

How to choose quality material

To choose the right good material, you need to understand where the product is taken from, you need to understand it. Sellers sell products dishonestly; they may advise you to buy liquid insulation that is not suitable for finishing. The description on the product container, passport, and certificate discloses the characteristics and properties of the product.

Main indicators: consumption per unit area, layer sizes, adhesion, thermal conductivity, moisture protection criteria. The description always makes reference to external and internal work, a universal amalgam. The most reliable product, which is selected for specific types, bases, and work. That liquid insulation for external walls, which describes the technology of applying layers of coating.

Don’t make a mistake when choosing a metallurgical material; make a purchase from a specialized company, providing a receipt, passport, certificate of conformity, from a dealer, manufacturer.

The most reliable product, which is selected for specific types, bases, and work.

Pros and cons of insulation from the inside

The advantages of liquid insulation include:

- The ability to resist fire, so there is no need to worry about fire safety.

- Low thermal conductivity, due to which this material is in great demand.

- Liquid insulation can be applied to any surface, which opens up wide possibilities for application.

- There are no costs when installing the material.

- Liquid heat insulator is not susceptible to mechanical damage and sudden temperature changes, due to which it has a long service life.

The video shows instructions for using liquid thermal insulation for walls from the inside:

Liquid heat insulator has certain disadvantages, which include:

- The long service life is not particularly long, but it can be increased if the material is applied correctly.

- There is no guarantee of thermal conductivity. Today there is not a single manufacturer who would indicate in their documentation the exact amount of stored thermal energy.

- Sensitivity of the material to negative conditions of transportation and storage.

- To obtain high-quality insulation, the material must be applied in a thick layer. This sometimes leads to high consumption of heat insulators. At the same time, the difference between actual consumption and practically is quite large.

Information from the article will help you understand what a disc dowel for thermal insulation looks like and how it is used.

This article describes which heat-insulating plaster for interior work is one of the best and how to choose it correctly.

But what is the density of Izover insulation and where exactly is it used is indicated here: https://resforbuild.ru/paneli/utepliteli/izover-texnicheskie-xarakteristiki.html

For those who want to learn more about comparing thermal insulation materials for walls, you should follow the link and read the contents of this article.

Work execution technologies

How to insulate a house from the outside? Two methods are used for this. Both can be used for almost any insulation material. The type of heat insulator has almost no effect on the technology. But you need to take into account certain recommendations from the manufacturer. For example, as is the case with mineral wool, when a ventilation gap is required.

There are two technologies:

- insulation of facades using the wet method;

- dry method, when a decorative coating is used, fixed to the frame.

Wet facade

This method has a relatively low cost and puts less load on the foundations of the building.

But it is important to note that a decorative coating cannot guarantee reliable protection against mechanical stress.

In this case, the insulation of external walls is covered with a layer of plaster. Its thickness is usually 40 mm. To ensure strength, a reinforcing mesh (fiberglass or metal mesh) is used.

The wet method of thermal insulation involves covering the walls with decorative plaster

Insulation and finishing of the facade of the house are carried out in the following order:

- cleaning the wall from dirt, leveling defects, treating the surface with a primer;

- fixing vapor barrier material if necessary (for foam plastic and mineral wool);

- installation of insulation boards with an adhesive composition (irrelevant for ecowool, it is simply sprayed onto the surface);

- additional fixation using plastic dowels;

- applying an adhesive solution to the surface of the insulation;

- mesh reinforcement;

- applying an adhesive primer after the glue has dried;

- plastering the surface.

How to insulate the facade of a wooden house with mineral wool? Only the wet method is suitable here. For other materials, you can choose one of two options.

It is better to choose fiberglass mesh as a reinforcing layer.

Finishing and insulating the facade of a house using this technology has one important drawback: over time, the plaster may begin to fall off. This is especially true if the external insulation of facades was carried out using metal mesh. It is recommended to choose a more expensive but modern fiberglass one.

Dry method

Insulation and finishing of facades in this case requires the presence of facing material. The most commonly used materials are siding, lining, composite panels, etc. Insulating houses from the outside with your own hands will require constructing a frame for fastening the cladding. The step-by-step instructions are as follows:

- Cleaning the surface from dirt, leveling large defects.

- Attaching a vapor barrier material, if needed.

- Installation of a frame for insulation from wooden blocks or boards. When using a metal profile, the racks are installed after fixing the material for insulating the walls from the outside. At this stage, you only need to provide brackets for mounting the racks.

- The next stage is attaching the heat insulator with glue. From below you need to provide a starting profile, which will serve as a support for the first row. After the adhesive composition has dried, the facade insulation is additionally fixed with plastic mushroom dowels with your own hands.

- Waterproofing and wind protection should be fixed on top of mineral wool or polystyrene foam. For these purposes, it is recommended to choose a modern vapor diffusion hydro-windproof membrane. How to attach it correctly? The membrane or film is fixed to a construction stapler. The joints are made with an overlap of at least 10 cm and taped.

- After completing all the steps, you can begin installing the cladding. How to finish the facade in each specific case should be indicated in the manufacturer's instructions.

The dry method of thermal insulation of walls involves the use of cladding and the installation of a ventilation gap.

You can insulate walls using the dry method in almost any weather. This makes this option stand out from the previous one. Deciding how best to insulate a home depends on the type of finish chosen.

Insulation application technology

Insulation is applied to a previously prepared surface, cleaned of dirt, dust, old paint, and plaster.

As evidenced by reviews of liquid thermal insulation, the material is easily applied with a brush, even with a roller or sprayer (special apparatus).

The liquid insulation is diluted with water in accordance with the instructions and completely polymerizes after application to the surface within 24 hours. The manufacturer recommends applying 5-6 layers. The more layers, the better the heat is retained. A decorative coating, for example, plaster, can be applied on top of the insulation.

Liquid thermal insulation in Russia

Mineral wool mat MP(MS) lined with metal mesh...

In stock

Mats M1-75 (without lining) Mineral wool mats stitched with thermal insulation..

In stock

Stitched mineral wool mat lined with metal mesh M-75 thick. ..

In stock

Stitched heat-insulating mats made of basalt super-thin fiber (BSTV) ..

In stock

Stitched heat and sound insulating mineral wool mat MP without lining..

In stock

Rocklight thermal insulation board, thick. 50 mm

390 rub./pack.

In stock

Related Categories

|

Work execution technologies

Before choosing a material for insulation and finishing, you should first decide on the technology that will be used to process the facade. The set of materials that will be needed will depend on this. There are two main technologies:

- wet facade;

- dry.

Let’s figure out how they differ and, of course, their features.

Wet facade

This technology acquired its name because liquid mixtures are used in the construction process. After drying, no traces of moisture remain, so there is nothing to worry about. The main components of this technology are:

- glue;

- dense insulation;

- waterproofing layer;

- reinforcing mesh;

- waterproofing;

- soil solution;

- decorative material.

Most often, facade plaster is used as decoration. But you can also use decorative tiles, which are light in weight.

Each element of a “wet” facade is an important component, without which it is impossible to create a reliable structure

Therefore, they finish the façade, adhering to exactly this plan. After applying one layer, it is allowed to dry thoroughly. Even a small amount of moisture in the previous layer will deteriorate the attractiveness of the finish.

Dry method

This technology involves the use of mechanical fasteners to secure the layers. To do this, a frame is built, which is both the basis for attaching decorative materials, such as siding, corrugated sheets or other panels, and support for the insulation.

The dry façade consists of:

- waterproofing;

- any insulation;

- windproof membrane;

- frame made of wood or metal (the sheathing can be installed before or after fixing the insulation);

- ventilation gap - the space where the air flow removes moisture from the interior;

- decorative cladding.

If the task is not to insulate the house, but only to update the appearance, then you can do without thermal insulation material. But still, insulation will allow you to keep the rooms warm much longer.

What to do if external insulation of facades is impossible

To insulate the facade of a single apartment in an apartment building, it is necessary to obtain permission from several official authorities.

Moreover, carrying out the work yourself can result in a deterioration in the overall appearance of the structure. Among other things, there are residential buildings that, in principle, are prohibited from insulating them, since they belong to the category of cultural heritage sites.

In such situations, it is necessary to use materials that can be used to insulate the home from the inside. It is desirable that they have:

- minimum coefficient of vapor permeability;

- low thermal conductivity.

Especially so that you can live in a comfortable and warm home, no matter what the weather is like outside, we have developed an innovative mixture for thermal insulation, AKTERM Concrete, made on the basis of special glass microspheres. This insulation has all the characteristics required for total heat and vapor barrier of premises.

The product "AktermBeton" consists directly of microspheres of the following composition:

- silicone;

- glass;

- ceramic.

Each sphere contains rarefied air inside. The balls are connected to each other using a high-quality binder. After complete polymerization of the composition on the treated surfaces, AKTERM Concrete forms a protective cushion of rarefied air, which acts as a barrier that retains heat in the premises.

The application of this material is very comfortable and easy, since working with it is no more difficult than with ordinary wall paint. To reliably protect a room, it is enough to apply just 1 millimeter of the composition to the walls; heat will accumulate inside the apartment, without dissipating along the walls. After the coating has completely dried, without any preliminary preparation, you can immediately paste the wallpaper, or use other materials for decoration.

You can immediately stick wallpaper onto the hardened coating without any preliminary preparation, or use other materials for decoration.

How does the new technology “work”?

A modern solution, known as thermal insulation nano paint, allows you to create thermal insulation for a room to maintain a comfortable room temperature with lower energy costs.

|

The liquid insulation, which hardens after application to the wall, is based on an acrylic binder with evenly distributed ceramic and silicone calibrated microspheres. As evidenced by reviews of liquid thermal insulation, in high-quality brands of insulation the proportion of microspheres reaches 80%, which provides the necessary protection from the cold.

|

Work execution technologies

There are two main ways to carry out external insulation work. For each of them, it is possible to use any of the existing insulating materials for walls, since its type is not related to the technology of work

It is only important to follow the manufacturer's recommendations. For example, when using polystyrene or mineral wool, you will need to provide a ventilation gap

Wet facade

This technique is characterized by a relatively low cost and does not place increased loads on the foundation of the building. You need to know that applying a decorative coating cannot be one hundred percent protection of walls from mechanical loads and influences. When arranging a wet facade, a layer of insulating material is covered with a plaster finish, about one centimeter thick. To ensure durability of the coating, it is additionally reinforced with a special acid-resistant fiberglass mesh. Work on insulation and finishing of the facade of the building is carried out according to the following algorithm:

- The walls are well cleaned of all types of contaminants, with existing defects leveled and the surface coated with a primer solution.

- An adhesive composition is mixed onto which the slabs of the selected insulation are attached.

- Plastic dowels are used as additional fastening elements.

- It is necessary to apply another layer of glue to the fixed insulation boards and reinforce them using a mesh, pressing it into the adhesive composition.

- After the glue has completely dried, it is coated with a quartz primer, which improves adhesion to the surface, and decorative plaster or bark beetle is applied.

Dry method

Insulation and finishing work in this case also involves measures for cladding the facade. You can use various types of siding, lining, panels made of composite materials. External thermal insulation can be arranged independently by installing a special frame to secure the cladding. Detailed instructions are given below:

- The surface is cleaned of dirt and dust, significant defects are subjected to a leveling procedure.

- If this is provided for by the type of insulation material, then attach a vapor barrier film.

- Install a wooden plank or timber frame under the insulation. You can also use a metal profile, but its racks are installed after the heat-insulating boards are fixed. This stage of work also involves the installation of brackets for subsequent installation of racks.

- The heat insulation slabs are fixed into the spacer between the frame, as well as the mushroom dowel.

- A film must be fixed on top of the mineral wool or polystyrene slabs, which will serve as insulation from moisture and protection from blowing. It is better to give preference to a high-tech and modern material - a vapor-permeable membrane. Its correct fastening is done with the staples of a construction stapler. At the joints, overlaps are arranged, 10 to 15 centimeters wide, which are insulated with adhesive tape.

- Now you can start installing the facing material. Instructions from the manufacturer for finishing the facade are usually attached to the packaging with cladding.

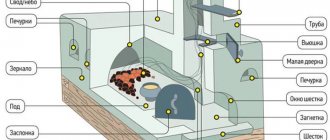

Akterm Vulcan

Unlike the previous paint, Akterm Vulcan liquid ultra-thin insulation is a high-temperature modification of the insulation, including organosilicon additives. Paint is applied to metal and brick bases. Its distinctive property is protection against burns upon contact with a hot surface. The scope of use of the product is as follows:

- heat pipes in everyday life and industry;

- chimneys;

- product pipelines;

- engine parts;

- transport and ship hulls;

- roofing and metal structures.

Thermal insulation can be used on any substrate exposed to heating up to +450 degrees, as well as the influence of aggressive substances: petrochemicals, salts, oils. Exposure to temperatures up to +600 degrees is allowed for a short time. The paint is applied with a brush, foam roller, or pneumatic spray. It is recommended to apply 2-3 layers of coating.

Description and features of the composition

The product is available in the form of a liquid composition that looks similar to sour cream. After hardening, it forms a continuous layer on the surface, similar to foam material. This texture is formed after contact with air. The product is applied to the surface in two layers, after the first has completely dried.

The suspension contains:

- The filler is a microscopic hollow sphere made of silicone, glass and ceramics. Each hollow particle inside is filled with rarefied air and has a different diameter.

- The binding component is acrylic or latex, colored with a colored pigment. The manufacturer may add other components to the composition, in accordance with certain conditions of use.

Liquid heat insulator "Akterm Beton" is used on various surfaces: concrete, brick base, plaster, limestone. After application it acts as a reliable thermal barrier.

Advantages:

- a thin layer of coating, does not put additional load on the walls, does not hide the area;

- protects metal from corrosive processes;

- effectively protects against freezing;

- easy to apply;

- does not contain harmful impurities;

- has no foreign odor;

- protects against the appearance of fungus and mold;

- suitable as a finishing layer;

- anti-condensation paint is suitable for indoor and outdoor use;

- used in hard-to-reach places;

- no professional skills required.

Liquid thermal insulation is applied like regular paint, with a brush or roller. When working on concrete, use a spatula. On average, the layer dries within 24 hours.

Akterm Metal

Liquid ultra-thin insulation "Akterm Metal" is designed specifically for thermal insulation of metal bases. perfectly protects surfaces from aggressive factors - sun rays, wind, moisture. A unique property of the paint is protection against burns upon contact with heated metal. Due to its environmentally friendly composition, the material is widely used inside production facilities and workshops. Other operating possibilities:

- steam lines;

- hot and cold pipelines;

- tanks and hangars;

- storage and cold storage facilities;

- air conditioning systems;

- trailers and refrigerators.

In addition to metal, paint will help protect glass and plastic surfaces from damage and heat loss. The minimum layer of material is 1 mm, peak application temperature is +260 degrees for 2 hours.

What to consider when choosing insulation for thermal insulation

Materials for insulating external external walls are characterized by low thermal conductivity. This is an important, but not the only parameter that needs to be taken into account.

Characteristics on which the service life, quality and efficiency of insulation depend:

- vapor permeability and water absorption;

- how the material affects the microclimate in the house;

- resistance to aggressive environments and fires;

- environmental cleanliness and harmlessness;

- resistance to biological influences (mold, mildew, rodents);

- physical and mechanical properties;

- noise absorption;

- complexity and ease of installation;

- Is it possible to make a seamless thermal insulation coating;

- is the material suitable for a house whose façade has a complex configuration;

- strength indicator and service life.

Each material has one or another thermal conductivity parameter, which is taken into account when determining the required thickness of the thermal insulation layer. The properties of water absorption and vapor permeability also play a significant role - the technology for installing insulation will depend on this.