Heat conservation inside buildings and structures is ensured by compliance with building codes and regulations, as well as through careful quality control of the finishing materials used.

One of the modern developments called “Corundum” - ultra-thin liquid thermal insulation - has decent performance characteristics.

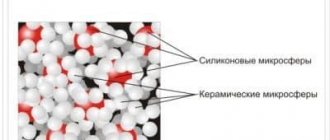

The main component of the coating is a polymer-latex composition in which microscopic hollow spheres bind acrylic polymers together. This explains the high adhesive and physical-mechanical properties of the material.

Applies like paint - acts as a thermal barrier!

The use of insulation is appropriate when constructing utility networks , oil and gas pipelines , and industrial facilities . The material is also used in many other areas related to construction.

Technology of applying material to the walls of a house

To apply corundum, the façade and walls must be properly prepared. Preparation of the concrete base includes:

- Areas with peeling or loose finish are removed.

- Cracks, even minor ones, are sealed with mortar.

- Coating the wall surface with an acrylic primer to reduce material consumption.

Preparation of the wooden base is as follows:

- Removing old paint.

- Then you need to sand the surface of the wood manually or mechanically.

- Treatment of the entire surface of the walls with antipyrines and antiseptics. It is advisable to use water-based products.

Application of corundum facade consists of layer-by-layer application with drying stages of at least 24 hours between each layer. Water is used as a solvent. In this case, the instructions allow you to add:

- For the first layer, no more than 20% solvent.

- For all subsequent ones - no more than 15%.

Next, we proceed directly to applying corundum to the walls:

- The paint in the bucket is thoroughly mixed with a drill with a special attachment until the consistency of thick cream is obtained.

- Thinned paint is applied with a brush, roller or spray.

- The first primer layer can be made a little thinner than all subsequent ones.

- After completing the last layer and letting it dry, the instructions allow you to apply any decorative or textured paints to it.

Safety precautions when working

Since the corundum facade material is largely synthetic, when working with it, the instructions require that you follow certain personal safety rules:

- When working with this material, you must use special glasses to protect your eyes from accidental contact with paint.

- When working outdoors, respiratory protection is not required. When applying liquid insulation indoors, it is necessary to use a respirator. In this case, you need to ventilate the room.

- It is also necessary to work in protective clothing with long sleeves and rubberized gloves.

The properties and scope of heat insulator corundum suggest its versatility. It is advantageous to mix some types of this material. For example, anticorrosive corundum can be added to a facade or classic look to increase the protection of metal surfaces from rust. At the same time, all thermal insulation properties remain at the same level.

Application

Metal Clean the surface from rust, dirt, old paint, remove crumbling elements. Clean the metal surface from rust using metal brushes or abrasive wheels, removing the loose layer of rust until a metallic shine appears.

For surfaces made of ferrous metals, use a primer coating - “Corundum Anticor” or adhesive primer VL-02 or VL-023.

For surfaces made of non-ferrous metals, use a primer coating - adhesive primer VL-02 or VL-023

Concrete, brickwork:

Clean the surface using a sandblaster, metal brush or abrasive wheels to remove the gloss on the surface and remove flaking and crumbling structural elements.

After removing the dirt and completely drying the surface, it must be treated with Yakhont primer.

The Corundum material is ready for use; it must be mixed, if necessary, adding a little distilled water, immediately before application to a previously prepared surface.

Use a drill with a paddle attachment or a mixer. The maximum permissible mixing speed is 100 rpm. Approximate mixing time - with a mixer 3-8 minutes, manual mixing 7-10 minutes. Stir the product until it looks like cream.

It is recommended to work with a soft brush with long natural bristles or an airless sprayer with a working pressure of no more than 60-80 bar. It is impossible to work in wet weather, because the material is excessively diluted with water and dries out after installation.

For better adhesion of the material to the surface being treated, it is recommended to apply a primer layer to the prepared surface using a liquid (like milk) composition of the material, diluted with 40-50% distilled water.

The time for complete drying of one layer of coating with a thickness of 0.4-0.5 mm is at least 24 hours at an ambient temperature above +7 ° C and humidity not higher than 80% throughout the entire drying time, i.e. 24 hours. The next layer can be applied only after the previous layer has completely dried.

A layer of about 0.4-0.5 mm (optical density thickness) is obtained with three “passes” of the sprayer or brush. Applying the material in a thicker layer is unacceptable, since this leads to the formation of a moisture-proof film on its surface, which in turn prevents the complete evaporation of the moisture contained in it, which will lead to the annulment of the thermophysical properties and deformation of the coating. The thickness of a layer of 0.5 mm can be determined by a thickness gauge of the “painting comb” type, a material consumption of 0.55 liters per 1 m2 (approximate consumption when applying the coating with a brush on a flat surface) or the thickness of the “optical density” of the material (so that the underlying base does not show through the material) . The material consumption is affected by the type of surface and method of application.

The total thickness of the coating and the number of layers is determined by thermal engineering calculations or recommendations of certified regional production representatives.

Source

Composition and properties of liquid thermal insulation

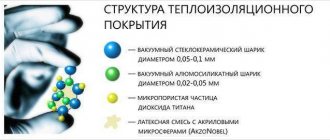

Let's start with the fact that liquid heat insulator has unique thermophysical properties that create plasticity and flexibility of the coating. The composition of the thermal insulation material is as follows: • high-quality acrylic binder • original texture of catalysts and fixatives • ceramic fillers of ultra-thin-walled microspheres.

Therefore, the unique thermal insulation properties are the result of the molecular action of rarefied air, which is located in the hollow spheres of the ceramic filler. In addition, special additives introduced into the composition of Corundum eliminate the formation of fungus and the appearance of corrosion in conditions of high humidity. Thermal insulation material in appearance resembles ordinary paint with a creamy consistency and is an opaque white suspension.

Regardless of the areas of application of liquid thermal insulation, corundum is a basic composition with stable adhesion to metal surfaces and building materials. Thermal insulation coating Corundum: • temperature-resistant (operating temperature from - 60°C to + 200°C) • vapor-tight • weather-resistant.

LKMFLOT

Code: 100992475

Category:

Other

Brand:

Corundum

Packaging:

20

Package:

1

Heat-insulating material Corundum Classic

DESCRIPTION:

CORUND CLASSIC M is a film-forming coating intended for thermal insulation of metal, plastic and other surfaces with operating temperatures from -60°C to +200°C (in peak mode (duration up to 10 minutes) up to +260°C). CORUND CLASSIC M fits well on all types of surfaces. Specially manufactured for coating insulated surfaces using airless sprayers or manual spraying. Insulation work can be carried out on surfaces with temperatures from +7 °C to + 120 °C.

Ultra-thin thermal insulation CORUND CLASSIC The best ultra-thin thermal insulation today.

Liquid heat insulator Corundum Classic has unsurpassed thermal physics, plasticity and lightness.

A plastic Euro bucket of 20 liters of heat-insulating paint Corundum Classic weighs only 10.3 kg.

During transportation and storage, liquid thermal insulation Corundum practically does not break down into fractions.

APPLICATION:

Ultra-thin thermal insulator Korund Classic is highly effective in thermal insulation of building facades, roofs, internal walls, window slopes, concrete floors, hot and cold water supply pipelines, steam pipelines, air ducts for air conditioning systems, cooling systems, various containers, tanks, trailers, refrigerators, etc.

It is used to eliminate condensation on cold water supply pipes and reduce heat loss in accordance with SNiP in heating systems.

The material is used at temperatures from – 60C to + 250C.

The service life of the material is from 15 years.

PACKING:

Plastic buckets 20 l

SURFACE PREPARATION The surface to be insulated must be cleaned of dirt, rust, dust, old paint, crumbling elements must be removed, etc. Pay special attention to ensure that there is no “loose” rust on the metal in the form of a “fungus”, which, after applying CORUND CLASSIC M, will peel off from the metal along with the coating. Clean the metal surface from rust using metal brushes or abrasive wheels, removing the loose layer of rust until a metallic sheen appears. The rust-free surface is treated with a rust converter and, if necessary, kept for 2 hours. New metal surfaces may require the removal of preservatives. The finished surface should not contain crumbling elements, should be dry (including not condensing), should not contain oil and greasy elements, and should not be excessively plastic. In case CORUND CLASSIC M is intended to be used on ferrous metal surfaces, with operating temperatures up to + 120 ° C, then the surface must first be dedusted and degreased, coated with the modification CORUND ANTIKOR M (preferred). If the coating is intended to be applied to the surface of non-ferrous metal, then it is necessary to treat the surface mechanically to remove gloss, remove dust, degrease. If CORUND CLASSIC M is intended to be applied to concrete, brick and similar surfaces, it is necessary to: remove loose areas, open cracks, remove oily inclusions, clean concrete from cement laitance, repair the surface, including inter-brick joints to reduce material consumption and excavations deeper than 5-7 mm, with cement-plaster compounds. After mechanical treatment of the surface, thorough dust removal should be carried out using brushes or blowers. Afterwards, it is necessary to rinse with water to remove dirt, remaining dust, etc. After complete drying, it is necessary to prime with a deep penetration primer YAKHONT. For application to the façade of enclosing structures of buildings and structures made of vapor-permeable materials (concrete, brick, etc.), it is recommended to use the CORUND modification FACADE.

PREPARATION OF INSULATING COATING CORUND CLASSIC MCORUND CLASSIC M is ready for use. To achieve the required viscosity of the composition (the material should have the consistency of “liquid sour cream”), it is possible to add a small amount of distilled water. It is recommended to add water in small portions (50 - 100 ml), alternating topping with thorough mixing, bringing the composition to the desired consistency. The amount of distilled water depends on the temperature of the application surface, the temperature and humidity of the surrounding air, subsequent operation and other factors. When applied to a surface with a temperature from +7 °C to +80 °C, the amount of distilled water added to the material can be no more than 5% of the volume. When applied to surfaces with temperatures above +80 °C, it is necessary to first lower the temperature by applying several primer layers of CORUND CLASSIC M material, diluted with 40-50% distilled water according to the scheme specified in paragraph 3 “Coating Application”. For detailed recommendations, contact your nearest representative or manufacturer. If the storage period is long, the composition may be separated into fractions inside the container. *********************** DO NOT OVERSTIX!*********** **********When using a drill with a paddle attachment or a mixer (for recommendations on choosing equipment, check with a CORUND representative in your region) - the maximum permissible mixing speed is 100 rpm. Exceeding the rotation speed will lead to the destruction of functional fillers and a significant reduction in the performance characteristics of the thermal insulation coating. Using vertical movements of the blade so as to immerse the thickened part in the liquid, turn on the drill and slowly begin to rotate the blade, mixing the clots with the liquid.

Stir until the product resembles liquid sour cream. Approximate mixing time - with a mixer 3-8 minutes, manual mixing 7-10 minutes. If the task is to eliminate condensation, a “coat” of frost, the material is applied with minimal addition of water and an increased period of interlayer drying (36 hours or more). APPLICATION OF COATING Throughout the entire period of work on applying the thermal insulation coating CORUND CLASSIC M and its drying, the ambient temperature should not be lower than +7? C, relative air humidity should not exceed 80%. It is recommended to apply the coating to small surfaces or areas with complex configurations using a soft brush. To apply the coating to surfaces over an area of 100 m2, it is recommended to use airless sprayers. IMPORTANT!!! Not all airless sprayers are suitable for working with heat-insulating coatings of the CORUND series!!! Recommendations on the selection, configuration and operation of airless sprayers should be obtained from your nearest CORUND representative. Also see “Technological map for applying the CORUND series of housing complexes using high-pressure airless sprayers” (www.korund34.ru, section “Technical documentation”). It is allowed to apply the CORUND CLASSIC M coating to surfaces with temperatures from +7? C to + 120? C. For better adhesion of the material to the surface being treated, it is recommended to apply a primer layer to the prepared surface with a liquid (like milk) composition of the material diluted with 40-50% distilled water. The complete drying time for one layer of coating with a thickness of 0.4-0.5 mm is at least 24 hours at ambient temperatures above +20 °C and humidity not higher than 80% throughout the entire drying time - 24 hours. If environmental conditions change (lower temperature, higher humidity), the drying time must be increased. The next layer can be applied only after the previous layer has completely dried. To check the degree of drying of the applied coating layer, the following steps must be taken: Before starting work, it is necessary to select a flat horizontal section of the protected surface measuring at least 200 mm in length and 200 mm in width on which the degree of drying will be assessed. If there is no such area, it is necessary to prepare a test sample from a material identical to the material of the protected surface with a size of at least 200 mm in length and 200 mm. When carrying out work, at the end of painting each single layer, it is necessary to apply a coating to a selected flat horizontal section of the protected surface or a test sample. The degree of drying is assessed as follows: When testing, a piece of paper measuring 150 mm in length and 150 mm in width is placed on the painted test surface. A rubber plate measuring 140 mm in length and 140 mm in width is placed on a piece of paper, in the middle of which a load weighing 2 kg is placed, while the maximum linear dimension of the base of the load should not exceed 130 mm. After 60 seconds, remove the weight and rubber plate. The sheet of paper is removed from the surface. If the paper does not stick to the coating and does not leave a mark from the load, then the required degree of drying has been achieved. A layer of the order of 0.4-0.5 mm (optical density thickness) is obtained with three “passes” of the brush. Applying the material in a thicker layer is unacceptable, as this leads to the formation of a moisture-proof film on its surface, which in turn prevents the complete evaporation of volatile components, which will lead to a significant reduction in performance properties and deformation of the coating. When applying the coating to a surface with a temperature of +80 ?C to + 120?C, the material boils and “sets” very quickly, so the composition must be diluted with distilled water. It is recommended to prime the surface with a 40-50% aqueous solution of the material CORUND CLASSIC M. When applying CORUND CLASSIC M on surfaces with temperatures above +80 ° C, the thickness of the maximum layer in 24 hours should not exceed 0.5 mm. The higher the temperature of the application surface, the stronger the material is diluted with water. The diluted composition is applied with quick short movements, with this application the layer thickness will be minimal. The drying time of one such layer is at least 1 hour. Coating layers with a minimum thickness are applied until the applied material stops boiling on the surface. After this, the coating is allowed to dry for 24 hours. Next, the material is applied according to the usual scheme - with the addition of 3% to 5% distilled water in layers up to 0.5 mm with interlayer drying for 24 hours. It is recommended to control the thickness of the applied composition with a paint comb type thickness gauge. The material consumption is affected by the type of surface, method and location of application. The total thickness of the coating and the number of layers is determined by thermal engineering calculations or recommendations from certified regional representative offices of the manufacturer. The approximate ratio of the thicknesses of the wet and dry layers of the material CORUND CLASSIC M is: with a thickness of the wet layer of 0.5 mm, the thickness of the dry residue of the coating layer is 0.45 mm. Technological losses at application by airless spray equipment on a vertical metal surface in calm weather is at least 20%.

SAFETY INSTRUCTIONS WHEN WORKING WITH CORUND CLASSIC Individual protection. Under normal conditions, the product is safe. If the room is well ventilated or work is carried out outdoors, respirators are not required. In a room without ventilation, use standard respirators. Use chemical safety goggles to protect your eyes. There must be access to running water to wash the eyes. To protect the skin, use chemical gloves and protective clothing. Wash protective clothing before reuse. Critical situations. If the product gets into your eyes, immediately rinse your eyes with running water for 15 minutes. If irritation persists, consult a doctor. In case of contact with skin, wash with soap and water. Wash contaminated clothing before reuse. If inhaled, move to fresh air. The product in liquid state is not flammable. In case of fire in structures or structures on which the coating has been applied, use water, foam, dry chemicals and carbon dioxide to extinguish. In case of product spillage, use any absorbent material such as sand, soil, etc.

STORAGE AND TRANSPORTATION CONDITIONS OF CORUND CLASSIC M Material storage of CORUND CLASSIC M is carried out in a tightly closed container at a temperature from +5 ° C to +30 ° C, air humidity no more than 80%, away from direct sunlight. Transportation is carried out by any type of transport at temperatures above +5 ° C away from direct sunlight. Packaging of cargo for transportation must ensure the correct installation of containers and the safety of the container. Violation of the integrity of the container leads to damage to the material. If the instructions for applying and storing the material are not followed, the manufacturer is not responsible for the quality of the coating.

Types of materials CORUND

Thermal insulation products of the KORUND company have several varieties:

CORUND ANTIKOR

A universal material applied directly to rusty surfaces. Before application, you just need to walk over the surface with a regular wire brush to remove the dry layer of rust.

The insulation has an additional anti-corrosion property. Thanks to this, the cost of preparing the surfaces to be treated is significantly reduced.

CORUND CLASSIC

The heat insulator is an ultra-thin material with good thermophysical properties. During transportation, the liquid composition of the insulation is practically not divided into fractions.

CORUND FACADE

This type of material is applied in layers (thickness from 1 mm), so it subsequently looks like high-quality facade paint. FACADE heat-insulating paint also has only positive reviews from customers. This ultra-thin liquid heat insulator is used for concrete surfaces.

FACADE paint also received excellent reviews in combination with ANTIKOR paint.

Reviews about the use of Corundum brand insulation

“In our house, the risers for cold and hot water supply are very poorly located - almost right next to each other.

Naturally, the cold water pipe constantly “cries”. Rusty streaks and growths are not just unsightly, they are a harbinger of leaks. I solved the brewing problem myself by painting both pipes with Anticor Corundum thermal insulation. I made an agreement with several neighbors above and below to buy together - the price was quite high.” “And we used Facade paint of this brand not for warmth, but for coolness. It’s hot here in the summer, and even the apartment faces south, and this makes my mother, who has hypertension, feel bad. We painted two exterior walls, plus glued mirror film to the windows. The first summer showed that the idea of buying an air conditioner can wait - the apartment has already become more comfortable, so insulation in our case really works.” “I was hooked by the promise that there are no problems when applying Corundum - as long as there is a brush. But in reality it turned out that the composition is very finicky: unpainted paint is unacceptable, but a thick layer of insulation cannot be done in one pass. Yes, and it’s difficult to distribute it evenly over the surface if you’re not used to it. After several days of torment, I finally repainted the pipes in the basement. Recently we started heating: there is no condensation, the branches all feel cool or barely warm to the touch. Verdict: Corundum justified its price.” Alexey, Moscow region.

“I am one of the distrustful people, “space technologies” in construction alarm me, so when Corunda appeared on the horizon, I tested it myself, despite the rather high prices. What can I say: it fits wonderfully on all surfaces - from wood and slate to glass and an aluminum beer can. The heat insulator made from it is really good - at 2 mm on the back side you don’t feel any heating either after standing in the sun or when pouring boiling water. But over a large area, it’s really going to be a pain to apply all these thin layers.”

Thermal insulation Corundum must be applied to thoroughly cleaned and dry surfaces at a temperature not lower than +7 °C. Old coating and dirt are cleaned off with a wire brush and must be degreased. Liquid ceramics are painted in thin layers of approximately 0.3-0.5 mm, up to 1 mm is allowed on the facade. This is very important, since the latex film formed on the plane will no longer allow moisture to evaporate from the thickness of the insulation. The result will be bubbles and cracking of the insulation. After each layer, you must wait 18-24 hours and only then continue working.

Source

How to choose Corundum thermal insulation

Liquid thermal insulation should be selected according to its intended purpose, namely where and for what purpose the material is planned to be used. Here are the following recommendations for use from the manufacturer of liquid thermal insulation: • for insulation of pipes under the foundation, it is recommended to use Corundum Classic, Facade and Anticorrosive, with a layer thickness of 1.5 mm. • to eliminate the phenomenon of condensation for cold water supply pipes, use Corundum Classic and Anticor with a layer thickness of 1-1.5 mm. • for coating pipes located indoors or outdoors, it is possible to use all modifications of Corundum with a layer thickness of up to 1.5 mm. • to create comfortable conditions in the presence of a “Cold Wall”, choose Corundum Facade with a coating of 1-1.5 mm. • Corundum Facade with a coating thickness of 2.5 to 3.5 mm will allow you to completely eliminate wall freezing. • Corundum Facade with a layer thickness of up to 1.5 mm will help with thermal insulation of the floor.

The consumption of corundum thermal insulation material depends on the modification. Rules and techniques for applying thermal insulation corundum are presented in the instructions for use from the manufacturer. Let us remind you that the thermal insulation can be applied using a paint brush, roller or paint sprayer for significant volumes and areas of thermal insulation. The basic rule when applying liquid heat insulator is that the thickness of the applied layer should be 0.3 mm and not thicker than 0.5 mm. The next layer is applied after the previous layer has completely dried.

The consumption rate when applying liquid insulator Corundum is: • when applying a layer with a paint brush (one layer) – 0.5 l/sq.m. • when applied by roller (one layer) – 0.4 l/sq.m • when using a sprayer – 0.26 l/sq.m.

Product line and its features

When developing thermal insulation, manufacturers took into account all possible problematic situations that most often arise when insulating buildings and utility networks.

6 main types of Corundum coating were created

- " Classic ". Suitable for processing metal surfaces. Universal for thermal insulation of buildings and utility facilities. The composition is used in the process of interior finishing of premises, and is also highly effective in protecting self-leveling coatings and window slopes from cold.

- " Facade ". Used for application to concrete, wood, brick or plaster surfaces during the finishing process. The material is characterized by low fluidity, which makes it possible to “spread” it with a thick layer (up to 1 mm) on a large surface area with the least amount of labor.

- " Facade-Lotus ". Acts as a final coating for the “ Facade ” composition. It has a microstructured surface and good water-repellent properties.

- " Antikor ". The best option for metal surfaces with corrosion damage. Does not require pre-treatment. Creates a reliable insulating and protective layer.

- " Winter ". Application of this type of “Corundum” is possible even at temperatures below zero (up to - 100 °C). The resulting coating is highly durable and resistant to mechanical damage, as well as aggressive chemical substances.

- " Fire protection ". It is used to increase the fire resistance limits of structures at industrial and civil construction sites. Mix with water before processing.

Liquid thermal insulation Corundum Facade

Ultra-thin thermal insulation Corundum Facade. For the first time in the world, an ultra-thin ceramic thermal insulation material has been developed that can be applied in layers of 1 mm thickness at a time, and has the vapor permeability of high-quality façade paint. Ultra-thin heat insulator Corundum Facade - designed specifically for concrete surfaces

Thanks to its high heat-reflecting properties and reduced labor costs for application compared to similar ultra-thin thermal insulators, it will be an ideal solution in the field of professional construction thermal insulation for you and your clients.

Ultra-thin thermal insulation CORUND FACADE is an ultra-thin liquid ceramic thermal insulation material that can be applied in layers of thickness from 1 mm to 3 mm at a time (depending on application modes), and has the vapor permeability of high-quality façade paint (0.03). CORUND FACADE is a weather-resistant, highly viscous composition specially designed for thermal insulation of vertical surfaces. The coating, applied to the wall from the inside or outside, forms a single seamless surface, retains heat throughout the entire volume of the room, which has a positive effect on the microclimate. The CORUND FACADE coating reflects up to 80% of the visible solar and infrared spectrum of radiation. This leads to a significant reduction in the heating of interior spaces in the summer, the cost of air conditioning, and in cold times it can reduce heat loss by up to 30%. Thermal insulation coating CORUND FACADE is a durable material with high adhesion to any building materials, along with good vapor permeability. hydrophobic (water-repellent) properties.

Liquid ceramic heat insulator CORUND FACADE is used for thermal insulation of plastered, concrete, brick, wooden and other surfaces of building envelopes and structures during external and internal work. Ceramic heat insulator CORUND facade can be coated on top with acrylic paint on a water-dispersion basis, pasting with wallpaper is allowed. Tinting Corundum Facade is permissible only subject to strict adherence to our technical map, following our recommendations for the selection of tinting pastes and technical nuances.

The use of CORUND façade coating allows you to:

– perform thermal insulation of walls both outside and inside;

– maintain the volume of usable area (with thermal insulation of walls from the inside);

– do not increase the load on the building structure;

– isolate facades with complex architectural solutions (including during reconstruction work);

– increase the temperature comfort of the room;

– reduce costs and time for construction work.

Thermal insulating paint Korund Facade also showed excellent results together with the Korund Anticor modification. For example, the calculated thickness of ultra-thin thermal insulation for a ferrous metal tank is 2.5 mm. mascoat, alfatek, tsm ceramic, thermal top, etc. , like our basic modification Korund Classic, it was necessary to apply at least 6 layers (1st layer of primer + 5 layers of 0.5 mm each with interlayer drying for 24 hours. Our solution is only three layers! -

1st layer. 0.5 mm Corundum Anticorrosive (Not only fixation of corrosion but also a converter, adhesive agent and waterproofing (due to the high rate of film formation).

2nd layer, after 24 hours – 1 mm Corundum Facade

3rd layer, after 24 hours – 1mm Corundum Facade

Application of insulation

Having studied the description of the paintable compositions, you can already roughly imagine where they will work most effectively. Corundum insulation is used in somewhat non-standard conditions - where other materials do not give the desired result:

Branched pipes, adapters, tie-ins and fittings - all this also requires the use of insulation. Liquid ceramics creates a continuous, tear-free layer on any complex surfaces. It is much easier to paint pipes than to try to squeeze and secure rolls of glass wool into a confined space, risking leaving “cold bridges”.

Ultra-thin liquid thermal and waterproofing Corundum not only maintains the temperature inside the containers, but also reflects external IR radiation, protecting the contents from dangerous heating. By the way, the same effect made it possible to find another application for it - painting metal roofs, which on a sunny day heat up to +70..+90 °C.

Absolute vapor and water resistance, as well as the thermal insulation properties of ceramic paint prevent not only steel elements from getting wet, but also the appearance of condensation on their surface. We mentioned this at the beginning of our review. Thus, Corundum plays the role of an anti-corrosion coating, ensuring a long service life of metal structures, as well as reducing the costs of their maintenance and repair.

For example, protection of loggias and balconies from freezing is carried out from the inside. But mineral wool and polystyrene “steal” a few centimeters on each side of the room. The use of Corundum compounds allows you to achieve the desired effect by simply painting the walls with insulation and thereby preserving the usable area. In addition, liquid ceramics, according to reviews from residents of panel houses, helps to cope with fungus that constantly appears on the damp surface of concrete. And on the facades it serves as a separator of different temperature environments and a reflector of sunlight in summer.

Insulation or heat insulator

Being a complex multi-level structure that minimizes existing methods of heat transfer, the heat insulator is of increased interest: “Is corundum an insulation or a heat insulator?”

However, these concepts should be distinguished. The operating principle of insulation is based on the physical thermal conductivity of the material. Therefore, the effectiveness of insulation depends on the thickness of the insulation. The operating principle of a heat insulator, on the contrary, is based on wave physical properties. The thickness of corundum ultra-thin thermal insulation ranges from 1 to 6 mm. The shocking limits of the minimum thin thickness of the insulation layer are, perhaps, the main advantage of Corundum over existing thermal insulation materials.

Properties of corundum

This material is essentially ordinary facade paint, which is applied in a thin layer. But at the same time it acts as a good layer of insulation. The applications of this thinnest heat insulator are very diverse:

- Insulation of buildings for any purpose made of all types of building materials (concrete, wood, metal and even plastic walls).

- Insulation of equipment subject to vibration.

- Insulation of various pipelines, which operate in a wide temperature range: from -70 to +250 °C.

- The coating also has waterproofing properties and prevents corrosion of the treated surfaces.

It is thanks to such unique characteristics that corundum facades quickly found their niche among other building materials and began to be in high demand.