Reducing heat losses in heating communications of enterprises, utilities and private homes allows you to save significant financial resources on heating the coolant, so any methods of thermal insulation of pipelines are always relevant. In heating systems of private houses, the main way to maintain the temperature of the coolant in the system is thermal insulation for heating pipes; when used, it is installed on the outer surface of the pipeline.

It is useful for any homeowner whose heating boiler is located at some distance from heat exchange devices (for example, in a separate utility room on the street) to know the main types of heat insulators used to protect pipelines from environmental influences and how to insulate heating pipes. Depending on the material used to make the thermal protection, various methods of its installation are used; most of them are easy to do with your own hands if you know the appropriate technology.

Fig. 1 Thermal insulation for heating pipes in individual houses

Requirements for thermal insulation materials for heating pipes

Thermal insulating materials placed on hot pipes must meet the following requirements:

- Have low thermal conductivity - the lower its value, the more efficiently the shell retains heat. The material’s high resistance to heat loss helps save money on fuel for boilers.

- Heat resistance to high temperatures is the main requirement for an insulating coating; it should not melt or decompose when the object is heated to a boiling water temperature of 100 ° C.

- Water resistance is the main criterion for choosing a thermal insulation material when placed in soil; in this case, an insulator that is not capable of absorbing water is used.

- Biological resistance is important when using thermal insulators in any conditions; the insulating material should not be an environment for the development of various types of bacteria, microorganisms, mold and be of interest to rodents.

- Chemical resistance is also beneficial to insulating materials when installed under soil containing a wide range of chemically active components.

- The service life of thermal protective coatings is important from the point of view of financial savings - the material will not have to be changed too often, incurring additional cash costs for purchasing a new one.

- Physical and mechanical strength is the main criterion for choosing pipe coatings used in underground conditions.

- Environmental cleanliness is important when using thermal insulators indoors; they should not emit harmful chemicals both under normal conditions and when used on hot pipes.

Rice. 2 Thermal insulation of heating pipelines - comparison of thermal conductivity by thickness

Functions of heat insulators for heating pipelines

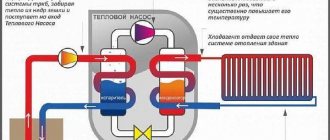

If we consider a private house, the heating boiler can be located inside the building in the basement or outside in a separate technical extension. The latter option is often used in the absence of a gas pipeline and the use of solid dirty materials as fuel - coal, firewood, peat, briquettes, pellets.

Many private houses have outdoor baths or saunas, so as not to complicate the design by installing a separate tank for heating water; it is supplied into the premises from the boiler, and the distance between the objects can be quite significant. When deciding how to insulate heating pipes, choose materials that meet the conditions below.

Reduced heat loss

The principle of operation of any insulation is to protect the insulated surface of the protected object from contact with the environment. At the same time, due to the low thermal conductivity of the insulator, heat loss is reduced, and the equalization of air temperatures and the hotter pipeline proceeds much more slowly than in the absence of a heat insulator.

Any heating main can be placed on the surface of the earth or under the ground; in the first case, soft insulation is usually installed for heating pipes in the open air; when placed underground, protection from hard materials is installed due to soil pressure.

Rice. 3 Mineral wool is a popular thermal insulation material for heating pipes

Frost protection

If hot water in an individual heating system is supplied from the boiler to an object located at a considerable distance from it, the water supply is usually laid underground at a distance from the surface below the freezing point. At the same time, it is not always possible to place the pipeline at a sufficient depth, so if the supply of hot water is interrupted for a long time, the remaining and cooled liquid in the pipes may freeze in severe frosts. To protect the underground line from freezing, it can be thermally insulated by placing it in hard shells or soft shells located in pipe channels.

Prevents condensation formation

Construction regulations prohibit the laying of metal pipes in the ground in the absence of insulation or protection of the outer shell with auxiliary materials; the situation is different indoors, where steel, galvanized steel, and copper pipelines are quite often laid. When the heating is turned off, the liquid in the metal pipes cools down and condensation appears on their surface, water drops cause corrosion of the outer wall and, if there is a large accumulation, fall down to form puddles on the floor - this can cause damage to the flooring.

To combat this phenomenon, porous heat-insulating materials for pipelines that are resistant to water or with good vapor permeability are used.

Rice. 4 Foamed polyethylene - thermal insulation for outdoor heating pipes

Protection against thermal burns

In municipal and household services, the temperature of the coolant transported through pipes can reach values close to 100 ° C, so the task of protecting service personnel or residents of a private house from burns when coming into contact with pipes becomes urgent. To do this, their outer walls are covered with thermal protection from various types of heat insulators, the shell of which cannot have a high temperature by definition.

Neutralization of geometric deformations

The ability of all materials to expand when heated is well known, so a hot pipeline, when passing through walls or floor slabs, is placed in steel sleeves of larger diameter. A heat-insulating shell is placed on the pipe, protecting the assembly from hard contact of the enlarged shell with the wall of the sleeve.

When laying pipelines in walls or under the floor, their expansion can lead to cracks in the plaster or screed, so the use of an elastic shell that absorbs part of the thermal expansion helps to avoid problems associated with geometric deformation of the pipes.

Rice. 5 Expanded polystyrene shell - thermal insulation for heating pipes in the ground

Results

Mineral wool for pipeline insulation comes in two types: glass wool and stone (basalt) wool. Any glass wool can be used (plates, mats, rolls, with or without foil). It is soft and elastic, you can wrap it around communications without any problems. Stone wool is inelastic, so only lamella mats can be used. There are also thermal insulation cylinders made of mineral wool - these are sleeves, the nominal diameter of which must be equal to the outer diameter of the pipe. Cylinders come in different diameters, thicknesses, with or without foil.

Types of thermal insulation materials for heating pipes and their characteristics

For thermal insulation of pipes, industry and individual production produce a wide range of materials that differ from each other in their physical and chemical characteristics, scope of application, and installation features.

Mineral wool

Mineral wool fibers are thermal insulators often used in the construction industry; for example, basalt slabs cover the external facades of buildings; in individual houses they are laid under the roof and floors of attics. Often, pipelines are wrapped with soft sheet insulation made of any type of mineral wool, which is fixed with protective films and ties.

Usually they use glass and basalt wool, made respectively from fine glass threads and natural fibers of mountain basalt; in residential buildings, the third type of wool for technical premises - slag - is not used, due to its harmful acidic effect on metals and environmental hazards.

Stone mineral wool is formed from fibers with a length of about 16 mm and a thickness of 4 - 12 microns, it corresponds to the following technical parameters:

- thermal conductivity depends on the form of manufacture and ranges from 0.033 to 0.05 W/m K

- heat capacity: 1059 J/kg K;

- moisture absorption: within 24 hours no more than 0.01% of the volume;

- operating temperature range: from -60 to +450 °C for mineral wool made of glass fibers and from -100 to +700 °C for basalt fiber;

- density depends on the form of manufacture (rolls, plates, cylinders) and ranges from 30 to 225 kg/m3;

- sound absorption coefficient: 0.75 - 0.95;

- flammability class: NG – non-flammable;

- content of binding components (formaldehyde resin): 0.25 - 10% by weight.

Mineral wool is produced in the form of rolls, mats, slabs; for use on pipelines, hard varieties made of basalt are made in the form of shells from individual segments.

Rice. 6 Physical characteristics of various grades of mineral wool

Foamed polyethylene

Materials made from PE foam polyethylene are widely used in the construction industry; it is used for water and sound insulation, as substrates for laminate flooring, insulation outside and inside buildings, and objects of various shapes. Foamed polyethylene has the following physical characteristics:

- thermal conductivity depends on the brand name of the product and is associated with the manufacturing technology (cross-linking) of PE, the range of its values is from 0.30 - 0.55 W/m K;

- operating temperature range: from -60 to +75 °C and above;

- the density of PE depends on the brand and lies in the range of 25 - 100 kg/m3;

- vapor permeability: 0.001 mg/m·h·Pa;

- water absorption coefficient: no more than 1%;

- flammability group: G1 – low flammable, G2 – moderately flammable;

- if there is a foil coating, its reflectivity for infrared radiation: 80 - 97%;

- water absorption: 0.6 - 0.9% of volume

Is mineral wool harmful?

Environmentalists claim that the product is harmful, demanding the cessation of production and use in construction.

Research results show that the danger of insulation is caused by the toxicity and carcinogenicity of raw materials:

- in the first case, small fractions of cotton wool are unfavorable for human lungs;

- in the second, harm to health is caused by the release of carcinogens from formaldehyde-based resins used in the production of the material as a binder.

The State Department of Hygiene of the Russian Federation regulates the use of heat insulators as follows:

- allows the use of mineral wool in individual, industrial, housing and civil construction;

- recommends installing insulation in closed structures;

- Only open laying of basalt, glass, and slag wool is prohibited.

Following the recommendations of specialists, you can buy the material, protecting the operation of your apartment or cottage from these harmful influences, significantly saving the construction and repair budget.

According to the classification of the international agency IARC, mineral wool belongs to the third group, that is, they are not carcinogenic to humans along with tea and caffeine. For comparison: the second group (probable concentrates) includes vegetables in brine, exhaust gases, the first (dangerous for the human body) includes asbestos, tobacco, and wood dust.

Thermal insulation for external heating pipes

The insulation of pipes laid outside buildings on the street is exposed to environmental temperatures, direct solar radiation and precipitation, therefore, for their insulation, materials are used that are not influenced by the factors listed above.

From the above list of all insulation materials, polystyrene foam shells can be excluded due to their decomposition under ultraviolet irradiation. Mineral wool and polyethylene foam, which absorb moisture without external protection, can also be excluded from the list of suitable ones.

In municipal and industrial services, for the external laying of heating mains, pipelines in polyurethane foam insulation with a steel shell are used; in everyday life, with the cheapest and most accessible option, the surface of the pipes is wrapped with soft glass wool in combination with an outer polyethylene film, which can be secured with tape.

A slightly more expensive option for household use is the use of soft shells made of polyethylene foam with a foil or PE film surface, which at the same time protects the material from moisture penetration. During installation, the shell is placed on the pipeline, and the joints are wrapped with tape for reliable fastening and sealing from precipitation. Shells made of foiled glass and mineral wool are used and installed in the same way.

Rice. 13 Spraying polyurethane foam

A little about plumbing

In private construction, an open water supply system is often used to supply water from a well. It is simpler, faster and easier to assemble, and does not require the use of special equipment, for example, an excavator, etc. There is one big drawback to such a system: it is extremely sensitive to temperature changes, so it requires reliable insulation to maintain functionality. In some cases, especially when violations were made during insulation, freezing still occurs, which can lead to a pipeline rupture.

You can minimize the risk of rupture during freezing; to do this, you need to choose the material from which the pipe is made. Metal and metal-plastic pipes are most susceptible to rupture; their use is not recommended. Plastic pipe options are capable of expanding slightly under ice pressure, so their rupture when freezing occurs extremely rarely.

Water supply made of plastic pipes

Thermal insulation for underground heating pipes

GOST 30732-2006 regulates the direct underground installation of heating networks using pipelines with polyurethane foam insulation in a polyethylene shell or sealed channels with a galvanized steel outer protective layer.

For domestic use, laying steel pipes underground with unsealed protection is prohibited; if a pipeline made of PP polypropylene is used, it can be placed in a rigid shell made of regular or extruded PS polystyrene foam, PPU polyurethane foam.

In underground installation, many companies and individuals use a combination of a large-diameter external rigid pipeline and soft polyethylene foam insulation, similar to factory pipes with a PPU thermal insulator and a protective PE sheath. When laying a pipe, a tube made of soft foam polyethylene is placed on the pipeline, secured with tape, and then the resulting structure is inserted into sewer pipes of larger diameter.

Rice. 14 Factory insulated pipe with PPU insulation

Advantages and disadvantages of individual insulation materials

Each of the insulation materials has its own advantages and disadvantages that limit their scope of application; these factors are taken into account when choosing a suitable material for specific conditions.

Fiber wool

Insulation materials made from glass and basalt wool are widely popular among consumers due to their affordability and environmental friendliness, allowing their use inside residential premises. Mineral wool has the following properties:

- Fire-resistant, in case of fire they do not burn and release substances harmful to health; they melt when exposed to too high a temperature.

- Glass wool has low rigidity and easily wrinkles, basalt-based material is stiffer, both types restore their shape after physical impact.

- Mineral wool has a high degree of moisture absorption; because of this disadvantage, shells made of quartz and basalt are not laid directly underground.

- Cotton wool is resistant to most aggressive chemicals and the biological effects of microorganisms, bacteria, fungi, and mold.

- With the exception of slag wool, mineral wools are environmentally friendly natural materials and are safe for human health.

- The material allows air to pass through well and prevents the accumulation of moisture and condensation under its surface.

Rice. 15 Thermal insulation of heating pipes on the street

Soft foam materials

Foamed polyethylene materials for pipeline insulation are produced in the form of tubular shells with a longitudinal slot; their characteristic differences from other types of insulation are:

- Polyethylene in its normal state is harmless to health.

- PE is a chemically and biologically neutral material that is not subject to rotting and resists the appearance of fungus and mold.

- It is moisture-proof, therefore it is often used as vapor and waterproofing in combination with materials with high adhesion (mineral wool).

- Depending on the manufacturer, foamed polyethylene does not support combustion or is slightly flammable (groups G1, G2), while during its ignition substances that are harmful and dangerous to human health are released.

- Foamed polyethylenes and rubber do not shrink and quickly regain their shape after applying physical force.

- Porous rubber is designed to adhere to metal surfaces - thus providing long-lasting and reliable insulation of pipelines.

- For ease of use, some tubes at the longitudinal seam are coated with an adhesive composition (self-adhesive varieties) - this allows you to hermetically isolate objects without cold bridges.

- For external use, tubes made of foamed polyethylene are produced in moisture-protected versions with surface films of various colors.

- Protection made of tubular foam polyethylene is quickly installed, has a beautiful aesthetic appearance of a closed shell, and is therefore widely used in households.

- Due to its low rigidity, the material is used on surface pipelines, popular brands: Energoflex, Jermaflex, Porilex, Vilaterm.

Rice. 16 Application of mineral wool for pipe thermal insulation

Hard shells made of polystyrene foam and polyurethane

Durable and rigid foam plastic, polyurethane shells in the form of a shell from several segments have the following qualities:

- The manufacturing material is biologically inert and resists most aggressive chemicals.

- They do not allow water and moisture to pass through, being vapor and water insulators.

- Polystyrene foam is one of the cheapest materials.

- The material is divided into several groups according to density and rigidity; its extruded variety has the highest parameters.

- Foam plastics are low-flammable; in case of fire they release a large amount of toxic substances in the form of black smoke.

- Due to the destructive effect of ultraviolet radiation on their structure, foam and polyurethane foam shells are recommended for use in underground pipeline laying.

- The low maximum permissible temperature of foam plastic, about 70 °C, is an obstacle to the use of PS in metal pipelines transporting steam or boiling water.

- For outdoor use, given the low strength and fear of ultraviolet radiation by polystyrene foam and polyurethane foam, they are placed in a hard shell made of thin-walled galvanized casings.

- Almost all foam shells are manufactured by commercial small businesses, so if a suitable diameter is not available, the protection can always be made to order in the required size and configuration.

Rice. 17 PE insulation on a heating pipe in a private house

Thermal insulation paint

Domestic manufacturers produce a wide range of thermal paints, the most famous brands being Bronya and Corundum, which have the following advantages and disadvantages:

- Thermal paints are applied to objects by brush or spraying; due to their high adhesion, they adhere well to surfaces made of any materials.

- The cost of paints sold in plastic buckets is too high due to imported raw materials; the price for a 5-liter bucket starts at 1,500 rubles.

- Manufacturer's recommended paint consumption: 1 liter per square meter to obtain an optimal layer of 1 mm thickness.

- Thermal paint is convenient to use on surface hard-to-reach and non-standard sections of pipes, insulation of flange joints, and its underground use is practiced for insulating steel pipelines.

- In addition to thermal insulation, thermal paint provides anti-corrosion protection for objects.

Heating electric cable

One of the most effective ways to ensure long-term protection of pipes from freezing is the use of a heating cable. The advantage of this solution is that installation can be done both on top of the pipe and inside it. It all depends on the condition of the pipeline and the diameter of the pipes. When choosing an internal installation method, keep in mind that the cable may reduce the permeability of the pipes if their diameter is too small. The recommended minimum pipe internal diameter size is 40 mm. The heating cable itself can be of two types:

- Resistive;

- Self-regulating.

The latter type is more advanced, convenient and cost-effective. Its cost exceeds the cost of a resistive cable.

However, given that the finished heating system can operate almost completely without human intervention and requires minimal attention, it can be argued that the expense is justified.

A more complete description of both types of heating cable and the features of its selection and installation can be found in our article by following this link.

Technology and installation of insulation in everyday life - the best options

Owners of private houses, in order to save money on heating their premises, often have to decide how to insulate heating pipes, considering various types of pipeline insulation. In this case, heating networks can be located anywhere on an individual plot: inside a house or outbuilding, underground or on its surface.

Rice. 18 Applying Warm Paint

Insulation of heating pipes on the street

When deciding how to insulate heating pipes on the street with your own hands, you should first of all consider PE shells of a suitable internal diameter with closed cells. They have a surface film of various colors to cover the longitudinal seam, use tape, staples, self-adhesive types of tubes or any polyethylene glue. Depending on ease of use, PE tubes are purchased in standard lengths of 2 or 10 m; installation work is carried out in the following sequence:

- Clean the pipeline from dirt and dust and put a PE tube of the required size on it; when the seam is about to be coated with glue, it is placed at the top.

- If you use a non-self-adhesive variety, coat the walls of the longitudinal cut with glue and connect them until completely dry, then turn the shell over with the seam down.

- In a similar way, the ends of entire tubes or cut sections are glued together, resulting in a solid and aesthetically beautiful protective shell.

Rice. 19 Installation of PC tubes - main steps

Insulation of heating pipes in an unheated room

Indoors, to insulate pipelines, you can use PE tubes with open cells, which are cheaper than the option discussed above, and options for installing protection with a foil-coated surface layer are also often used. Some manufacturers, for example Energoflex, sell together with their tubes a special glue for joining PE products and an additional tool in the form of a special knife for cutting PE shells and a plastic miter box for cutting tubes straight or at an angle of 45 degrees. PE thermal insulation for heating pipes in an apartment or private house of the Energoflex brand is installed as follows:

- An additional longitudinal seam is cut in the tube using a special knife.

- Pull the seam apart and place the product on the pipe.

- The edges of the seams are secured with special plastic clamps in the form of half rings; to do this, they are connected together and clamping brackets are inserted in the amount of 4 - 5 pieces per linear meter.

- If it is necessary to insulate a corner section of the pipeline, proceed as follows:

- A piece of pipe is inserted into a special miter box and the middle fragment is cut out, and the ends of the joined elements are cut at the desired angle.

- The resulting parts are glued together, coating their edges with special Energoflex glue.

- The resulting corner element is cut lengthwise with a special knife, its longitudinal ends are coated with glue and the parts are placed on the corner of the pipeline; the halves can be wrapped with tape for 2 - 3 hours until the glue dries, after which the shaped unit is ready for use.

Rice. 20 Installation of Energoflex corner insulation element inside the building

Insulation of heating pipes underground

When deciding how to insulate heating pipes on the street when laying them underground in households, they usually use hard shells or place soft porous materials in polymer pipes of larger diameter. To thermally insulate pipelines with foam shells, proceed as follows:

- The pipeline lying on the surface is cleaned of dirt and shell segments are placed on it using a tongue-and-groove connection so that the upper and lower elements lie offset.

- As the fragments are laid, they are tied together with tape; for connection, you can also use special glue for foam plastic.

- After installation on the surface, the pipeline is placed in a trench on a pre-filled sand bed and covered with earth.

Rice. 21 Installation of hard shells

When thermally insulating heating pipelines, materials used in the construction industry are widely used; for ease of use on pipelines, they are produced in the form of cylindrical shells or hollow tubes of various lengths. To insulate external and internal heating pipelines, the most rational option is to use soft tubes made of polyethylene foam; the underground pipeline is usually insulated with hard shells made of polystyrene foam or polyurethane foam.

Which insulation option is better?

When choosing insulation for heating system pipes, you must consider:

- Location of the line (in the ground, in the basement, in the attic).

- Presence of problems with rodents.

- Financial opportunities.

- Pipe diameter and pipeline configuration.

- Coolant heating temperature.

In practice, rats and mice only avoid glass wool. Plus the paint is simply too much for them. They may well chew through the rest of the insulation in order to fill their nest.

If the street heating line is being insulated, then it is recommended to use moisture-resistant rigid foam or polyurethane foam, which are less likely to get wet

Polyethylene in all its variations is resistant to the aggressive effects of cement. If a pipe with insulation is laid in a wall and then the hole is filled with concrete, then polyethylene material should be preferred.

Polyurethane foam allows you to reach all sections of the highway, reliably covering it with a monolithic thermal insulation layer. However, special equipment is required to apply it. Plus, it is difficult to spray such insulation onto thin pipes; most of the foam will end up on the surrounding walls.

When installing a heating system in areas with unstable soils and connecting several buildings to one boiler, the most optimal insulation is lightweight polyethylene or thin polystyrene foam. It is not worth using heavy stone wool here. When the soil moves, highways may not withstand additional loads and burst.