For a tight connection and high-quality combination of sections, a specific sealant is used. Radiator gasket makes it possible to significantly increase the operating life of devices and eliminate leakage of heated water from the circuit. You need to be able to choose it correctly, paying attention not only to the size, but also to the permissible parameters of the media in terms of pressure and temperature. When purchasing a new heating device, the necessary gaskets are usually included in the kit, but in the case of replacing or extending sections, the consumer himself will have to make a choice.

Types of sealing gaskets

On the modern market you can purchase a gasket for a heating radiator of absolutely any type - made of cast iron, aluminum or bimetal.

Depending on the material of manufacture, the following types of products are distinguished:

- Silicone gaskets

. Such products are resistant to high coolant temperatures and well compensate for the thermal expansion of the metal. Such gaskets are used, as a rule, in autonomous heating systems with low operating pressure. - Paronite products

. They are made from pressed rubber containing asbestos and special powder. Such gaskets are used in radiators connected to a centralized heating system, where the temperature of the coolant can rise to 90-100 ℃. Paronite gaskets are suitable for cast iron heating radiators, as well as for aluminum and bimetallic products. - Fluoroplastic gaskets

. This type of product is made from heat-resistant plastic. They are intended for installation on bimetallic and aluminum radiators, without prior lubrication. They are characterized by high heat resistance, resistance to aggressive factors and pressure changes. - Cardboard gaskets

impregnated with oil paint for durability are used for aluminum and bimetallic radiators in autonomous heating systems. The production of products is regulated by GOST No. 9347-74.

Where can I buy?

News on the topic “intersectional gasket for radiator”

Starting next year, the Capital Repair Fund plans to use mainly domestically produced radiators when carrying out work on the heating system.

This was reported at a working meeting on the problems of major repairs in the city administration... This type of radiator is made of steel and aluminum, which has high thermal conductivity and perfectly warms the room. Moreover, the distribution of air masses occurs by convection. The radiator looks modern and laconic, it will fit neatly into…

Found on the Internet for the search “intersectional gasket for radiator”

Radiator gasket selection process

When deciding which gaskets to use for heating, you need to take into account not only the material from which they are made, but also the size.

The size of the product is determined by the following indicators:

- internal section of the gasket (d);

- outer diameter (D);

- product thickness (s).

It is worth noting that the internal cross-section of the intersection gasket for the radiator must completely coincide with the size of the inlet hole on the radiator section. It is also desirable that the edges of the gaskets do not extend beyond the section - otherwise, coolant leakage may occur in these places.

Sealing

How is the tightness of intersection connections ensured?

- Until the mid-20th century, plumbing flax with red lead was used for this purpose. The paint prevented natural fiber from burning out at high temperatures and rotting when moistened. The winding was placed near the nipple in a tight bundle and was securely pulled together when connecting the sections.

- For the next couple of decades, during the factory assembly of cast iron heating devices, gaskets made of paronite (hard heat-resistant rubber) were used. The solid resource of this material is combined with low elasticity, requiring enormous tightening force.

Manufacturing methods

The shape of gaskets for cast iron batteries can be flat or convex. They are used for different types of structures.

In particular, flat sealing elements are made from sheet materials such as plastic, rubber, paronite or leather. In their production, methods such as cutting with a stamp or punching knives, as well as cutting with a laser or circular knives are used.

The convex gasket for cast iron radiators and any other metal types of batteries is produced using thermoforming from polyvinyl chloride, as well as by vulcanizing raw silicone or rubber.

Installation and replacement

Under the traffic jam

How to install a gasket under the radiator cap of an aluminum battery with your own hands?

- Lubricate the end of the section collector and the plane of the plug with any neutral lubricant. Silicone plumbing grease, grease and even liquid soap will do.

- Place the gasket onto the threads of the plug.

- Tighten the plug with an open-end or adjustable wrench. The paronite tightens until the force becomes noticeable (but by no means insurmountable: you risk breaking the pipe threads in the section manifold). The silicone is pulled until the edges are visible squeezing out from under the cork.

Intersectional

Instructions for eliminating intersectional leaks are somewhat more complicated.

The diagram will make it clear how the sections are connected.

- Shut off the heating riser and remove the plugs or open the vents. If there are valves on the connections to the battery, simply close them.

- Place a basin or other container with low walls under the lower blind radiator cap, unscrew the cap a few turns and allow the remaining water to drain. Unscrew the plug completely; If necessary, use a stick or any other handy tool to free the lower collector from dirt.

Attention: blind plugs in most cases have left-hand threads; they unscrew clockwise.

- Repeat the operation with the top plug.

- Mark on the radiator key the distance from the edge of the battery to the nipple you need.

- Insert the key into any of the manifolds and, turning, push it into the radiator until it engages with the desired nipple.

- Unscrew one turn. The direction of rotation is the same as that of the cork.

- Repeat the operation with the nipple on the second manifold.

- Unscrew the nipples one turn at a time, one at a time. If unevenly unscrewed, the skew will jam or tear the nipple.

- Remove the outer sections; put new gaskets on the nipple and thread the nipple onto one thread.

- Install the end sections, press them against the nipples and use a wrench to tighten the latter until securely engaged.

- Reassemble the heater in reverse order.

Cast iron battery overhaul.

Cutting blanks using the stamping method

In the process of work, special stamps are used, that is, special devices precisely adjusted to the required size and consisting of several elements. In addition, a press is used to cut out blanks, on which a stamp is installed.

Before starting production, it is necessary to take into account the dimensions of future gaskets - for large products you will need a more massive stamp and a powerful press.

It is worth noting that this method of manufacturing sealing gaskets is considered cheap and highly productive. Due to this, it is used for mass production.

How to properly install an aluminum battery with your own hands?

This process takes place in stages.

Preparatory work

They begin with determining the location of the future installation of the radiator and fixing the brackets.

To correctly calculate the installation of the battery, the following construction indentation indicators must be taken into account:

- from 10 cm or more - from the window sill;

- 3–5 cm from the wall;

- approximately 12 cm from floor level.

The bracket is fixed to the wall using dowels . The holes left by the drill are filled with cement.

If the battery is a floor-standing type, then it is placed on a special stand and lightly attached to the wall, only to establish its stable balance.

Radiator assembly

Before directly starting the battery, you need to install it step by step:

- screw in plugs and radiator plugs;

- connection with shut-off valves;

- collection of thermostats;

- nipple stability control;

- fixing air bleed valves.

Attention! For further correct operation of the valves, it is necessary to install their outlet heads so that they face up.

After completing all the steps, the radiator is fixed to the brackets.

Hooks are located between the sections. Detailed instructions for assembling an aluminum room heating source should come with it.

Application of punching knives

The operating principle of this method is similar to die cutting, but in this case a simpler and less expensive tool is used. The production of seals in this way is inexpensive and quite fast. However, the pants are quite short-lived, so this technique is used for the production of small and medium-sized batches of gaskets.

Maintainability

Welding is considered a common procedure when repairing radiators. Aluminum is lighter than copper, and this provides better maintainability to aluminum radiators without subjecting them to unnecessary wear. This also helps aluminum radiators withstand the stress of repairs more easily and increases the lifespan of the aluminum radiator. In addition, an aluminum radiator lasts longer than its copper “colleague” even after several repairs. However, copper is softer in nature, and this property is very useful when the need for repairs arises.

Cutting with circular knives

Only large round seals can be produced using this method. In the process of work you will need fairly cheap and high-performance equipment. Cutting is carried out with standard blades. Therefore, the production of gaskets of this type can be carried out independently and in any volume. Radiator leaks are often caused by a damaged gasket. And if you don’t know what to do if the heating battery leaks, first of all you should pay attention to the gaskets.

What it is

Sectional radiators have become extremely popular, among other things, due to the possibility of flexible adjustment of the heat transfer of the device. If its efficiency turns out to be insufficient, it is always possible to add a couple more sections, increasing the thermal power. It is clear that their price is not comparable with the costs of a new convector or panel radiator of enormous size.

The nipple for the radiator, in fact, provides their connection to each other. It is a small tube with counter-directional threads, which at one point are screwed into two adjacent sections, attracting them to each other. It is equipped with a pair of protrusions for the radiator key.

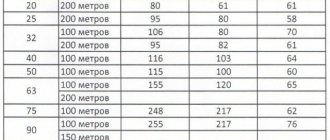

The thread diameter of the nipple and section collectors is:

| Radiator type | Thread size |

| Cast iron | DN32 (1 1/4 inches) |

| Aluminum, bimetallic | DN25 (1 inch) |

The following materials are used in the production of nipples:

- Ductile iron;

- Steel.

Thermal molding

In this case, you will need an injection molding machine with a mold for casting products. The cost of a molding press is quite high, so in order to make production economically feasible, the production of gaskets using this method must be large-scale or even mass-produced.

The production of products in small batches using this technology is relevant only if they cannot be produced in any other way. It is noteworthy that only PVC seals are produced by thermoforming.

Our production:

- 2.52

- 3.24

- Paronite gasket DN-10 14*38mm 0.1-0.63MPa 2mm

Retail price 2.90 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 2.77 rubles VIP price (for purchases from 100,000 rub.) 2.52 rub.Manufacturer:PRS / Russia

PC

2.90

Buy

- Paronite gasket DN-10 14*45mm 1.0-4.0MPa 2mm

Retail price 2.90 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 2.77 rubles VIP price (for purchases from 100,000 rub.) 2.52 rub.

Manufacturer:PRS / Russia

PC

2.90

Buy

- Paronite gasket DN-10 14*45mm 1.0-4.0MPa 3mm

Retail price 3.38 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 3.24 rubles VIP price (for purchases from 100,000 rubles) 2.94 rubles.

Manufacturer:PRS/Russia

PC

3.38

Buy

- Paronite gasket Du-15 13*20mm 1.5mm

Retail price 3.24 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 3.11 rubles VIP price (for purchases from 100,000 rub.) 2.82 rub.

Manufacturer:PRS/Russia

PC

3.24

Buy

- Paronite gasket DN-15 20*43mm 0.1-0.63MPa 2mm

Retail price 3.73 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 3.56 rubles VIP price (for purchases from 100,000 rub.) 3.24 rub.

Manufacturer:PRS / Russia

PC

3.73

Buy

- RUB

VIEW ALL

To increase the mechanical strength of paronite, metal mesh reinforcement can be used. The resulting material is called ferronite or, as defined by GOST, reinforced paronite (PA).

Paronite gasket (GOST 481-80) is divided into several types, suitable for different types of connections:

- seal for flanges;

- gas seal;

- for radiators;

- for water.

produces and sells paronite gaskets for the oil and gas industry, public utilities, metallurgical industry, food industry, for repair and construction tasks, trading houses, shops.

Rubber

Rubber gaskets are still the most popular and are produced in a wide range of shapes and sizes. Round seals (o-ring) are cast directly at the factory, flat seals are cut from rubber technical plates of suitable thickness. To produce such seals, hard or semi-hard rubber grades are used.

Advantages of rubber gaskets:

- low price;

- electrical insulating properties;

- low permeability to gases and moisture;

- high wear resistance and fatigue strength.

The disadvantage of such seals is the tendency of the rubber to age, especially when exposed to high or low temperatures. Due to aging, the material loses its elasticity, crumbles, and the connection begins to leak. Also, rubber seals can “stick” to the surfaces being sealed, which makes them difficult to replace.

The service life of rubber gaskets is short (usually manufacturers guarantee 1–2 years). They also cannot be reused - even if the seal is relatively new, it must be replaced when disassembling and assembling the joint.

In conclusion

Thus, intersectional sealing gaskets on radiators of various types ensure their durability and efficient operation. When selecting a gasket, it is necessary to take into account its type and scope of application.

Specifics of contact-butt welding of band saws and knives

2022-01-31 09:48:35

TV lathes for metal: how are they designed and what are they good for?

2022-01-31 09:48:35

Saratov Plant of Heavy Gear Cutting Machines, SZZS Plant of Gear Cutting Machines

2022-01-31 09:48:35

Problems

The list of typical problems with radiator gaskets is short:

- When installed under a plug, paronite or silicone can be squeezed out on one side. This happens especially often in cases where the thread axis of the plug or section deviates from the perpendicular to the plane of the collector end.

- Paronite loses its elasticity somewhat during prolonged use under conditions of strong heating. As a result, after several dozen cycles of heating and cooling the sections, the intersection gaskets are capable of leaking when the batteries cool down again: a decrease in temperature leads to a slight change in the linear dimensions of the sections.

Cast iron battery leaking between sections.

Paronite seals from Promresursservice

is the largest supplier of asbestos, rubber and polymer products in Russia and the EU. We offer paronite seals for various purposes and configurations. All products are manufactured using modern, high-tech equipment and undergo quality control at every stage of production. An individual approach, a flexible system of discounts, fast delivery, simple payment are just some of the advantages of cooperation with Promresursservice. To order or consult on products, you can call or use the feedback form. Our managers will call you back at any convenient time.

Fluoroplastic

PTFE gaskets have a number of advantages over other options:

- high chemical resistance;

- temperature stability (can be used in the range -200...+200 °C and at pressures up to 160 bar);

- the ability to seal connections even with uneven, worn, damaged sealing surfaces;

- ease of machining and a variety of release forms (sheets, tapes, bundles, bushings), which makes it possible to produce gaskets of any configuration from fluoroplastic sheets;

- low adhesion, which prevents the gasket from “sticking” to the surface being sealed;

- no aging problem;

- durability and reusability (in the absence of visible damage).

Fluoroplastic also has excellent dielectric and antifriction properties. It is harmless, does not emit hazardous compounds or odors, and is therefore suitable for installation in drinking water supply systems.

The only drawback of fluoroplastic gaskets is their higher price compared to other materials. But it pays off with a long service life and reliable sealing. The connection will not leak after several years, as when using a rubber gasket. This difference is especially noticeable in systems with hot media - radiators, heated towel rails, etc.