High-quality heating is the key to a favorable climate in the house and the absence of cold weather even in the most severe frosts. Therefore, if you have an old and ineffective radiator in your apartment or cottage, then it is worth replacing it. At first glance, this seems to be a very complex job, accessible only to specialized specialists with significant experience. But with the right attitude and the availability of some tools, installing heating radiators with your own hands does not pose a serious problem.

Installing heating batteries with your own hands

Preparing to install heating radiators with your own hands

First of all, the owner needs to understand the type of wiring that was once used when arranging the heating supply structure. If the owner of a country house created it with his own hands, he knows which heating circuit is installed in the house - one-pipe or two-pipe. The choice of system elements and their quantity largely depend on the wiring diagram and design features of the equipment.

Additional design features

Some experts advise welding supports or brackets.

This is not very good, because it makes the structure more massive and not universal. Without welded supports and brackets, it can either be hung on the wall or installed on stands fixed to the floor. In some cases, the owner who dismantled the old sectional batteries. using a radiator key and made a device, he could have made a mistake in calculating the optimal dimensions of a homemade radiator. As a result, the design is not able to heat the air in the room to the required temperature. One way out is to make an additional heater. However, you can improve what has already been made.

To enhance heat transfer, vertical metal plates can be welded. They will also heat up and give off heat. Thanks to them, convection will improve.

These plates can be cut from a metal sheet with a thickness of 1.0-2.0 mm. Their features should be as follows:

- Height - greater than the height of the battery.

- Width - 10-15 cm.

- The presence of 3 cut out squares or rectangles on one side. The dimensions must correspond to the dimensions of the profile pipe.

Such plates are applied to the battery and welded. As for their quantity, the more the better, because the greater the heat transfer becomes.

Selecting a heating battery based on the area of the apartment How hot the heating batteries should be Making a solar battery Heating meters for batteries

Parts required for proper installation

The parts required to install the batteries yourself are purchased based on the design features of the heating system. For example, if the radiator is used in single-pipe heating, then a bypass is needed. Thanks to this element, if you need to repair or replace the heating battery yourself, the heating in the room does not need to be turned off. This point is very important, since in the winter cold it is undesirable to cut off the heating supply to the house.

The installation diagram of heating radiators and the type of heating device determine how many connecting and other functional parts will need to be purchased in order to carry out the installation correctly (about

Calculations and markings

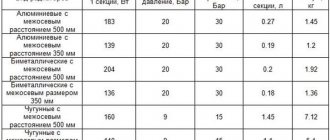

Before you buy a radiator, you need to calculate its power. This is done according to the generally accepted method: 100 W of power per 1 square of room. However, it is best to take a little with a reserve - 10-15%. Thus, your heating radiator installation scheme will better heat the room, and if the outside temperature thermometer drops very much, you will hardly feel it.

Important! For private owners and apartment owners, it is important to take into account the level of thermal insulation. Sometimes, when calculating power, you have to make a 20% cap so as not to freeze in your own home.

Having purchased the required radiator with the required number of sections, proceed to marking.

- The best place for installation is considered to be a niche or wall under the window. This, of course, is not necessary, but if such installation is possible, it is better not to neglect it. If you find it difficult to choose, look at photos of heating radiator installations on the Internet

Remember! The place under the window was not chosen by chance, because currents of cold air will mix with the heat emitted by the radiator and spread throughout your room. Thus, the microclimate improves, the air is always fresh, and excellent flow circulation is created.

- The installation location is calculated. During installation, you need to set the distance from the window sill and floor to the radiator. It must be at least 10 cm, so you, as a home owner and builder, immediately need to take this and the next parameter into account. The battery moves away from the wall by 6 cm.

Connection options for heating radiators

Important! Compliance with these numbers will reduce heat loss and create good air circulation in the room.

- Calculate the space for the brackets - according to the previous calculation, you need to decide where the brackets will be driven in or screwed in. Also consider the number of sections your radiator will have.

Important! Use a level to mount fasteners evenly, because the slope of the heating radiator depends on this, and therefore the coolant circulation and heat transfer.

- Check the levelness one more time and make a hole for the brackets, and then install them there.

Tip : If there were no brackets included with the radiator, buy them at a hardware store, or make them yourself.

The procedure for determining the installation location

Among the important installation points is the need to position the sections of supply pipes relative to the devices at a slight slope towards the movement of the coolant. It is also necessary that the central axis of the battery coincides with the axis passing through the center of the window opening. The permissible deviation is no more than 2 centimeters, provided that it is not determined visually. But this is just a recommendation, not a requirement. There are strict rules on how to install a heating radiator:

- The supply pipeline to the heating devices should be positioned with a slope of 0.5 centimeters per one meter of pipe in the direction of coolant circulation. Calculate the angle of inclination taking into account the length of the mounted pipe sections;

- the distance from the plane of the floor covering to the radiator cannot be less than 6-10 centimeters;

- it is required to maintain a gap between the bottom of the window sill and the top line of the battery equal to 5-10 centimeters:

- the distance between the wall surface and the radiator should be 3-5 centimeters.

Among the mandatory conditions for installing devices is strict adherence to horizontal and vertical directions. It is customary to install radiators in one room on the same level. To increase the efficiency of heat transfer by the radiator, a heat-reflecting shield made of a special material is placed on the wall located behind it. You can coat the wall surface with a composition that has similar properties.

Step-by-step instructions for replacing the radiator

Next, two algorithms are considered: the simplest and the most complex of those that you may encounter.

Replacing radiators with shut-off valves

Connection with American and shut-off valves.

The simplest option, which does not take more than 20 minutes, occurs if taps or thermostats with an American type are installed in front of the radiator on both pipes.

Operating procedure:

- Turn off the taps.

- Place a container under the bottom tap and spread a rag on the floor.

- Open the Mayevsky tap, located in the upper part of the radiator (if any).

- Using a lever wrench, gradually unscrew the lower connection.

- We drain the coolant from the battery - each section contains from 170 to 400 ml of liquid. Based on this volume, the container should be ready.

- Disconnect the radiator completely.

- We assemble a new battery, install plugs, threaded bushings (adapters) and a Mayevsky tap.

- Without installing new gaskets, we attach a new radiator. We place a support under the device - it is not allowed to hang the battery with the support only on the pipes.

- We carry out markings for the brackets (editor's note here about the correct marking and installation of the radiator on the brackets), if they need to be replaced.

- We mount the brackets.

- Having hung the radiator, we check that it is installed horizontally.

- Using new gaskets for the American one, we screw on the new convector. There is no need to apply excessive force when tightening - after the union nut is completely in the working position, turn it ½–3/4 turn.

- Open the supply taps and check for leaks. The item is suitable for private and apartment buildings during the heating period. If the radiators in a high-rise building were changed in the summer, then it is better to leave the taps closed. The coolant is supplied and the system is checked during the daytime, and if the owners are not at home and the connections are leaky, flooding of the neighbors will occur.

- We release air from the radiator using the Mayevsky tap.

If the work was carried out in the summer, then on the day of the pressure testing (you can find out in the Criminal Code or from announcements in the entrances) we open the taps and check the tightness, bleed the air. The same operations must be carried out after putting the heating system into operation.

About marking and fastening scheme

Radiators have a large mass due to the material and the circulating coolant, so you cannot simply hang them on the supply pipes. Brackets are used to mount devices on the wall; cast iron models are sometimes equipped with legs for installation on the floor.

Experienced builders recommend using 2 brackets installed under the upper collector to mount convectors of up to 8 sections. If there are more sections, then increase the number of supports at the rate of: 1 bracket per 5 sections. In addition, it is recommended to install hooks at the bottom of the radiator.

In this way, vibration from the coolant flow can be completely eliminated, extending the operating time of the radiators.

If one battery is changed, then markings are carried out locally using levels. When several radiators need to be replaced, it is recommended to make a template - this will significantly simplify the work and reduce installation time. How to do this is shown in the video:

Replacing old radiators

It may be impossible to remove old cast iron radiators connected to a steel pipeline without damaging the liner.

In this case, replacement may take up to several hours and will require plumbing skills.

The algorithm is as follows:

- We drain the water from the riser; in an apartment building, be sure to contact the management company - the work is carried out by full-time mechanics by order of the chief engineer of the enterprise. The work is paid and, depending on the region, can cost from 200 to 1,200 rubles per riser.

- We prepare a container for draining and rags.

- We are trying to unscrew the locknuts and bushing without damaging the pipeline.

- If necessary, we dismantle the battery by cutting the pipes with a grinder.

- We cut a new thread on the pipe of the required length using a clamp with a ratchet. We screw shut-off valves or a thermostat onto the finished thread.

- We try on the battery, make markings, and attach the brackets.

- We fasten the radiator and check for leaks (if possible).

- We paint the pipe sections.

The further process is similar: test run, de-airing.

There are alternative ways to threading to restore connection points:

- Weld the squeegee using gas welding.

- In private homes, use a coupling with a threadless fastening to the pipe - a GEBO coupling (see photo below). The devices are produced for pipes of different diameters with internal or external threads. The price of the product is from 600 rubles.

Coupling with threadless fastening to the pipe

Important! It is impossible to weld the squeegee using electric welding. Corrosion develops quickly at the joints and in multi-storey buildings with high pressure, such a connection may last for 1–2 years of operation, after which a leak will form.

How to use flax correctly

When connecting a tap to a thread on a steel pipe, plumbing flax is used as a sealant.

The procedure for working with it is as follows:

- Using a needle file or a small triangular file, we make notches on the thread (see photo below). On purchased parts, such notches are made in the factory.

Notches on the thread for linen. - We clean the threads from dirt and scale using a metal brush.

Metal brush. - Determine the direction of the thread.

- Apply a thin layer of plumbing paste.

- We separate a strand 30–35 cm long from a common skein of flax, this is enough for a thread up to 1 inch, and straighten the piece into a flat strip.

- We press the flax with our finger to the fold and wind the piece in the direction of the thread with a single strand.

- We tighten the winding with our fingers.

- Apply a thin layer of paste.

- Screw the required part onto the thread.

Instructions for sealing a threaded connection with tow and sealing paste (click to enlarge).

You can use FUM tape; in low-pressure networks it will last up to 10 years; for high-rise buildings it is better to use linen winding.

Tools and materials

The performer of self-installation of heating batteries must have torque wrenches with dimensions that allow the torque to be maintained with a high degree of accuracy. Since the liquid circulates through the system under significant pressure, poorly performed sealing leads to leaks in the form of a jet gushing from the joint. In case of excessive constriction, there is a high probability of a similar problem occurring.

For this reason, you should strictly follow the instructions for the devices supplied by the manufacturers, as they contain torque values. You will also need a sealant, tow soaked in oil paint. You can use a special sealing tape.

Useful tips

If the heating system of the house was assembled taking into account the use of forced movement of the coolant, that is, a circulation pump is installed in it, then the home-made device can be installed as desired (vertically or horizontally).

If the coolant in the heating system moves according to natural laws, then the battery must be mounted only horizontally. In this case, there is no need to install an air vent on it (Maevsky tap).

It is impossible to make a high-quality radiator from pipes if you have the skills to operate a welding machine at the beginner level. The seams must be welded well; the safe operation of the device and the entire heating system depends on this.

The thickness of a 100 mm pipe must be at least 3.5 mm.

Two bends can be welded to the ends of the pipes where the metal pancakes were welded. In this case, the holes in the ends are made not in the middle, but with an offset: the input bend (upper) is closer to the upper edge of the pipe, the outlet (lower) closer to the lower edge. It is better to make holes in the pancakes in advance, before welding them to the pipes.

When calculating heat transfer, there is no need to pay attention to the transfer area. It is clear that this figure will be higher for a cast iron radiator

All this is compensated by the high thermal conductivity of steel.

Welding seams need to be cleaned and given a presentable appearance. To do this, scale and smudges are knocked off with a hammer, and the entire surface of the seams is sanded with a grinder.

Carrying out installation work: diagram

Before starting work, completely shut off the heating circuit and drain the coolant from the system. The circulation pump helps remove any remaining liquid. Using a level, check the battery hung on the fasteners relative to the horizontal and vertical position. Then:

- remove all plugs from the radiator;

- if the heating circuit is single-pipe, proceed to connecting a bypass equipped with a valve. With a two-pipe scheme, the correct installation of heating radiators does not involve the use of a bypass, but for connection they use a squeegee with a valve attached to it.

The battery is connected to the heating structure using threaded connectors. The joints are sealed with tow or other sealant. If you have the skills, use welding at the junction of the pipes and the pipeline. Until the installation of aluminum, steel and bimetallic radiators is completed, the factory packaging shell is not removed from them.

Connecting heating devices

To solve the question of how to install a heating battery and connect it to the pipeline of the general system, use the following methods:

- Saddle connection.

- One-way connection of heating batteries.

- Diagonal connection.

If radiators with bottom connections are selected for installation, then the issue is resolved simply. The manufacturer himself determines the location of the supply and return pipes and requires unquestioning implementation of the recommendations. Otherwise, heating efficiency is not guaranteed.

When solving the problem of how to add a heating battery in an apartment, you should know that radiators with side connections can be installed using the above methods.

Features of installation of cast iron radiators

Despite the latest devices that provide space heating, such as ultra-light and aesthetic bimetallic and aluminum products, cast iron radiators are still in demand among property owners. And although cast iron products do not have an elegant design, the batteries remain hot for a long time, gradually transferring heat to the surrounding space. There are specific design features of cast iron appliances that must be taken into account when installing them:

- Before installation, the battery must be unscrewed, then the nipples must be adjusted and the device reassembled. For disassembly, you will need a workbench and a pair of radiator keys that fit the configuration of the nipple holes. To unscrew the lower nipple, it is necessary to insert a crowbar into the eye of the key and thereby increase the applied force. To avoid distortion, both nipples (upper and lower) should be unscrewed at the same time, so it is advisable to do the work together. The following point is important: on opposite sides of the cast iron product, the threads have the opposite direction. Then the section is removed;

- in the same way, you need to screw together all the sections and then connect them in the reverse order into a single radiator, based on the heating needs of a particular room. The assembled battery, consisting of a certain number of sections, needs to be tested. If a leak is detected in the device, the nipple located in the problem area should be adjusted;

- wall-mounted models of cast iron radiators can only be mounted on brick or foam concrete walls. Wooden enclosing structures will not support their weight, so the owner of such a house needs to purchase batteries with floor supports, but there must also be fastenings on the walls that support the devices (pro

Saddle connection

This option for connecting radiators to the heating system is more suitable for lower pipe distribution or when they are hidden.

Installation on a single pipe system can be done with or without a bypass jumper. If there is no bypass, installation of taps is necessary. Their presence will allow you to remove the radiator in the event of an accident and replace it with a drain.

The use of saddle connections for radiators with vertical wiring is considered ineffective, since heat loss in this case can reach 15%.

Complete set and assembly of a purchased battery

Most thermal equipment is sold ready-made or factory assembled. They are distinguished by high-quality soldering and fully assembled assembly. And everything that is necessary for installation - fittings for connecting to pipes - is included with them. Most often there is a description with all the recommendations for connection. For an open top hole, a Mayevsky tap is recommended to release the air accumulated in the coolant. It will not be superfluous instead of a plug, which is still installed on collectors that are not occupied by pipes.

Accessories for installing a heating battery

If a room heating device is sold without additional equipment, it will need:

- plugs (1 blind, 2 straight through the diameter of the pipes) and gaskets for them;

- Mayevsky tap with thread (possibly with fitting);

- reinforced pipes made of polypropylene (metal-plastic, other polymer);

- “American” (stop valves);

- limit switch for connecting to neighboring batteries.

For “Leningradka” and other schemes, mortise valves are also recommended, distributing the coolant for more uniform heating. In houses where payment is made based on the room temperature level, a heat energy meter is installed near the riser.

When everything is in place, all that remains is to collect the tools:

- pencil, square and tape measure for marking;

- universal building level;

- dowels and brackets;

- a special soldering iron for polymer pipes (many companies and stores rent them out);

- adjustable and torque wrench (prevention of thread displacement and leakage);

- electric drill or universal tool for attaching brackets to the wall;

- grinder with a metal disc (for dismantling old batteries).

Attention! Some models can be expanded in the number of sections, and this may be a priority when choosing new batteries. Most often, consultants from specialized stores suggest what additional parts and shut-off control valves are needed to shut off part of the system in the event of an accident.

After installing the radiator, you need to check all connections and tighten the nuts if necessary.

Types of heating radiators for an apartment or private house

The first thing you should decide on before installing a heating radiator in an apartment is the choice of the type of this device.

The following types of heating batteries and radiators are widely represented on the modern market:

- cast iron;

- aluminum;

- bimetallic;

- steel;

- copper;

- plastic.

Each of these varieties has its own advantages and disadvantages that you need to know in order to make the right choice. For example, cast iron batteries, which were widely used back in Soviet times, are characterized by a long service life and undemanding quality of coolant - the water in them can even be rusty or contain a large number of impurities. At the same time, due to the low thermal conductivity of cast iron, the fuel costs for heating such devices are quite high. Another disadvantage is the unaesthetic appearance of cast iron batteries, so nowadays they are not used so often.

Aluminum, steel, bimetallic and copper radiators have excellent thermal conductivity and an impressive appearance. At the same time, they also have disadvantages. For example, the disadvantage of aluminum batteries is their high sensitivity to water purity and instability to high coolant pressure. Bimetallic devices are somewhat more durable in this regard. Copper radiators are the most durable and most efficient in terms of heating, but at the same time they are also the most expensive.

As for plastic radiators, this is the most economical option, they are light in weight and easy to install, but they cannot be heated above 80 °C.

Having studied the features of various types of batteries before installing a heating radiator with your own hands, you can make a choice in favor of one type or another. A lot here may also depend on the interior of the room, the budgetary capabilities of the homeowners and other factors.

Calculation of the required radiator power

Having chosen the brand of batteries, it is worth calculating the power for specific premises. There are complex formulas that can be used to calculate how much heat energy is required to heat the area of a particular room. But you can roughly estimate: to heat 1 m³ of a modern house you need 20 W. Having calculated the volume of the room, we multiply the resulting value by 20 and divide by the power of one battery section. What we got in the end is the required number of sections for a specific room. If there are old wooden frames on the windows, 15% is added to the indicator.

To replace and install all radiators, the heating system is completely shut off in both a private and apartment building. The water remaining in the pipes is drained. And its remains are pumped out using a pump.

Hanging the radiator and fixing it to the wall

Next, you need to figure out how to hang a heating radiator and how to secure it to the walls. The process itself is simple, but even before hanging the battery, you should make sure that the wall surface behind it is level.

Next, on the wall, 10-12 centimeters below the window sill, a horizontal line is drawn, which serves as a location guide for the upper edge of the radiator. After this, in accordance with the intended position of the heating device, fastening devices are installed.

The radiator location must be strictly horizontal for heating systems with forced (pump) coolant circulation. If the system operates through natural circulation, then a minimum slope is provided for the battery - approximately 1-1.5°. The reason is simple - at the end of the heating season, the operation of the radiator stops and the water is drained. In this case, it is very important that the draining is complete and that the battery subsequently remains dry.

If the slope exceeds the recommended value of 1-1.5°, then stagnation that occurs during operation will interfere with the normal operation of the device. All these nuances should be foreseen and taken into account before hanging up the radiator and installing a heating system in the home.

To install the hooks, holes are drilled in the wall into which plastic dowels are mounted. Next, the hooks are screwed into them enough to ensure a distance of 3-5 centimeters between the radiator and the wall. In a typical case, the heating device is suspended so that the hooks are located between the sections.

If you use brackets to fix the battery, the installation process is slightly different from that described above. Before hanging the heating radiator, you should attach it to the wall and mark the locations for the fasteners. Next, holes are drilled in these places. Plastic dowels for screws are mounted in them, through which the mounting brackets are screwed.

Another important point regarding how to hang radiators on the wall. Although lower fasteners are also installed along with the upper ones, their role is rather auxiliary - they serve mainly to more reliably fix the radiator in a given position, including during the installation process. Their installation level should be 1-1.5 centimeters below the lower collector. Most of the weight load of the radiator falls on the upper fasteners.

Of course, the heavier the heating device, the thickness and strength of the fastening devices should be greater. For example, if the question is how to hang an aluminum radiator, you can get by with hooks that are not very thick. If a heavy cast iron battery is suspended from the wall, the brackets and hooks should be much thicker and stronger.