Situations in which you cannot do without an additional water heater occur quite often - this could be a private house or cottage, where there is simply no centralized hot water supply, or in apartment buildings where it is often turned off.

Homemade indirect heating boiler

If you are tired of running with buckets and pots from the kitchen to the bathroom, and you don’t have enough money to buy a boiler in the store, you can try making an indirect heating boiler with your own hands. Believe us, this is not such an impossible task!

There are two types of such a boiler - heated with coolant from the heating system and wood-burning.

Features of DIY boilers

- Installing such a device saves the home owner’s finances.

- The device is connected to the heating system of the house and must be installed next to the heating boiler.

- From such a device the user receives water at a constant temperature.

- If the boiler capacity is large, heating the water in it takes quite a long time. Moreover, during this heating, the intensity of heating the premises of the house decreases.

- Scale is gradually deposited on the heat exchanger tube, so it will have to be cleaned mechanically or using chemicals 1-2 times a year.

- Hot water from such a boiler can only flow during the heating season. In order for the device to provide water in the summer, a heating element should be built into it.

Advantages of homemade heaters

Why do owners often prefer to make a boiler with their own hands? A homemade boiler has many advantages over factory ones:

- Connects to the heating system.

- Placed next to the boiler.

- Costs much less than purchased

- Allows you to save energy resources.

- Allows you to maintain a constant water temperature.

If we talk about the disadvantages of a DIY boiler, they are:

- You need a fairly spacious room to install or hang the heater.

- If the device is not powerful enough, the water takes a long time to heat up.

- Scale forms quickly, so it is better to soften the water

Important! A home-made unit is also good because during the heating season it operates from a central heating supply, and in the summer – from the electrical network.

Advantages and disadvantages of an indirect heating tank

The system is not powered by electricity, but operates from the heating system. With proper design, a water heater has high performance at minimal cost. The advantages also include the durability of the device due to the isolation of the device from running water. At the same time, there is always hot water in the bokeh; you just need to open the tap. The boiler can be powered by a boiler or central heating; sources can be changed.

Among the advantages of an indirect heating tank, one should note the long service life and efficiency

- Re-equipment of the system requires financial investment;

- An indirect heating device is more expensive than a gas or electric boiler;

- The first heating may take several hours, which may cause damage to the heating system;

- With large system volumes, the design takes up a lot of space.

When buying a boiler, first pay attention to its size. Next, take into account the material of manufacture of the internal tank

This is what determines the quality and durability of the device. It is best when the inner walls are made of stainless steel.

Electric indirect heater

The use of heating elements does not apply to indirect heating methods, since there is direct contact of water with the primary heat source. An exception is the induction water heater. The liquid receives energy virtually, as it were, without touching the internal thermoelement. In fact, it is not in the design at all.

A do-it-yourself instantaneous water heater is made according to the principle of induction hobs. Only instead of a pan of water, a metal pipe is heated.

The main advantage of the system is that heating occurs not due to direct thermal contact with a source of electrical energy, but with the help of eddy currents. Losses on the heat transfer coefficient are minimal, efficiency tends to 100%. At the same time, both the metal pipe and the liquid itself are heated (if it is sufficiently thermally conductive). In addition, flow-through induction heaters are significantly safer than boilers with a traditional electric heater: there is no contact of water with an element connected to the electrical network.

The disadvantage is obvious: heating requires an electrical connection. That is, the option of indirect heating using a wood-burning (gas) boiler does not work. The room must be electrified.

The simplest heat exchanger

A homemade heater looks like this:

A larger diameter shell is welded onto the central heating pipe. The result is a sealed vessel with hot coolant flowing inside it. On opposite sides of the outer pipe (in fact, this is a boiler), flanges are installed for supplying (draining) cold water. When the coolant is hot enough, the water in the boiler heats up quickly. After which the top tap can be opened and the hot water supply can be used until the hot water is replaced by cold.

If we leave aside the legality of re-equipping the collective heating network (there is hardly any serious liability for this), the system works effectively. Hot water is conditionally free, minus one-time investments in materials, and a bottle of strong drink for the welder.

If you install such a instantaneous water heater with your own hands in a private household, there will be no conventional problems.

The only limitation is the volume of the outer container. In real time, the water will not heat up; the reserve of thermal energy in the heating pipe is too small. Therefore, the system works cyclically: heating - use - heating. The higher the diameter ratio (or the longer the pipe), the greater the supply of hot water. Accordingly, the longer it will take to warm up.

Another serious drawback: in the summer (with the heating turned off) such heaters do not work.

Design and principle of operation

Modern electric storage boilers, which are perfect for constant or periodic use, both in private households and in apartment buildings, are extremely popular at the moment.

The usual volume of the storage tank can vary, and is selected based on the number of consumers.

A similar type of household water heating device is connected to the water precisely after the main pipeline system, which allows hot water to be supplied to several points of distribution. Additional options in such a water heating device are shown by special automatic valves for the radiator.

What can BKN materials be made from?

- preparation of storage tank;

- heat exchanger production;

- installation of heating elements;

- thermal insulation of the body.

How to make an indirect heating tank

- suitable for food water;

- withstands heating up to 90°.

| Dimensions | Description | 1500 l |

| N | Height | 2285 mm |

| ø ext | External diameter (including insulation) | 1200 mm |

| ø int | Inner diameter | 1000 mm |

| F | Cold water inlet (1″1/4) | 315 - 1″1/4 mm - » inch |

| G | Water outlet from the lower coil (1″1/4) | 470 mm |

| L | Hole for bottom temperature sensor (1/2″) | 582 mm |

| M | Water supply to the lower coil (1″1/4) | 1180 mm |

| N | Water outlet from the upper coil (1″1/4) | 1330 mm |

| P | Hole for top temperature sensor (1/2″) | 1500 mm |

| Q | Recirculation (1″) | 1460 - 1″ mm - » inch |

| R | Water supply to the upper coil (1″1/4) | 1735 mm |

| S | Domestic hot water outlet (1″1/4) | 1935 - 1″1/4 mm - » inch |

| A | Inspection flange (ø internal 114 - ø external 168) | 520 mm |

| B | Additional electrical resistance (1″1/2) | 1255 mm |

| C | Thermometer (1/2″) | 1825 mm |

What material is the heat exchanger made of?

L = Q / D* (Tg – Tx) * 3.14

- coil length - L;

- thermal power - Q;

- heat exchanger diameter - D;

- the expected hot and cold water temperatures are Tr and Tx, respectively.

Heating element for combined BKN

P= 0.0011*m*(tk-tн)/T

- P is the power of the heating element;

- M is the mass of heated water;

- tk is the desired water temperature;

- tн - initial water temperature;

- T is the water heating time.

Indirect heating boiler with electric heating element

How to make thermal insulation BKN

- The body is coated with heat-insulating paint - it contains ceramic components that retain heat. At the same time, the paintwork protects the surface of the tank from corrosion.

- Mineral wool - a thermal insulation layer of about 5 cm. It is optimal to use basalt insulation. The material prevents heat loss, is resistant to moisture and at the same time allows steam to pass through, preventing liquid from accumulating in the layers of the material. The mineral wool is covered on top with any material with a foil base. You can use Penofol and derivatives.

- Instead of three-layer insulation, the use of Polinor is allowed. The insulation is similar to polyurethane foam. Easy to apply and prevents heat loss.

Installation procedure

Installation of an indirect heating boiler, in which the coolant is supplied through a coil, begins with its installation. A thread is cut at the ends of the coil, onto which a lock nut is screwed, and then they are inserted into the prepared holes in the tank so that the lock nuts have a stop.

The threaded part of the coil should extend beyond the surface of the tank. Rubber gaskets are put on them, and threaded couplings are screwed on top of them. As a result of these manipulations, the coil is securely fixed, and it becomes possible to connect it to the heating system.

The next stage of work is to connect the tank to cold water and drain the hot water tap to the required location. The final part of the installation will be insulating the water heater, but before that you should check the tightness of all connections.

This way you can provide your home with enough hot water at minimal cost. The cost of purchased materials will cost a small amount, especially if you compare it with industrially manufactured models. The price of a factory-made boiler starts from 20 thousand rubles for models from Drazice OKC.

We have selected eight more useful articles for you, see below.

- How to weld polypropylene pipes: instructions and tools

- Copper pipes and fittings for water supply - quality guarantee for 200 years!

- PVC pipes and fittings for water supply: product descriptions, current prices and installation

- How to install water pipes in a private house with your own hands

- Have you decided to install a new faucet in your kitchen? We'll show you how to do it right

- Which pipes are best to choose for water supply in a private house?

- Installation of the washing machine and connection to the water supply

- Let's figure out how to increase the working pressure in the water supply system: reasons for the decrease and solutions

Similar articles:

- Indirect heating boiler device and principle of operation

- Heating element for a washing machine: tips for choosing, instructions for replacing it yourself

- Do-it-yourself garage stove, homemade stoves and manufacturing diagrams

- Do-it-yourself pipe bender for profile pipes, homemade options

Do-it-yourself drawings and calculation of an indirect heating boiler

Making the device with your own hands is based on the drawings drawn up. You will also have to carry out certain calculations of the system. But first you have to decide on the design parameters.

Required characteristics of the boiler for operation:

- Water consumption and storage tank dimensions;

- The position of the coil and its dimensions;

- Additional design elements - thermostat, heating element.

This data will help you decide on the design of the boiler. Taking them into account, a drawing of the future design is created. The optimal capacity for the tank and the material for constructing the boiler are also selected.

The volume of the tank is determined by calculating the daily water consumption. It is believed that each family member spends 50-80 liters of water per day. This amount will be enough for bath procedures, laundry, and washing dishes.

If hot liquid is used exclusively for household needs, a smaller water heater will be required. A 50-70 liter boiler will be enough. No need to purchase a larger tank unnecessarily. Precious heat is wasted on heating water, and this increases the cost of operating the device.

Selection of capacity

A reservoir or storage tank basically has almost any size and volume. Another sign depends on the number of consumers and the standard consumption of hot water. For the most part, hot water consumption is about 50-70 liters per consumer, as a result of which the approximate volume of the tank for a family of four is approximately 200 liters.

DIY boiler body from a gas cylinder

The body of the product is made of steel. The walls can be thin, since the water temperature should not exceed 70 degrees. A homemade boiler can be made from a gas cylinder or a plastic barrel. To clean the tank, you will need to weld a large flange on one end. But this is not a prerequisite.

Required holes in the housing:

- Heating connections;

- Hot water supply;

- Hot water circulation;

- Supply of tap fluid;

- heating element and magnesium anode;

- Temperature sensors.

The heat exchanger can be located below or along the entire surface of the internal structure. The hot water outlet is located at the top, and a little lower there is a pipe for circulation. Cold water is supplied from below. The heating element must always be in water, so it is mounted at the bottom. Temperature sensors occupy a place in the middle of the structure.

A metal pipe is welded to the holes that work with water and sensors. The diameter of all pipes must be the same. A large tube is provided under the anode; a cover, bolt and anode are mounted on it.

Before buying a boiler, you need to ask the seller for a certificate that confirms its quality

The heat exchanger is secured with a clamp or nuts. The first option is considered more reliable. It is not necessary to install a drain. For these purposes, you can use a tee, which is mounted on the liquid supply.

Required materials and tools

The storage tank of the device is made of heat-resistant plastic, stainless steel, aluminum or ceramic-coated steel. As blanks for the tank, you can take plastic barrels for food products, aluminum tanks or an unnecessary gas cylinder.

To make a heat exchanger, as mentioned above, it is better to use a round or square copper pipe. When assembling a heat exchanger from square pipes, 90° bends will be required.

As a tool you need to prepare:

- angle grinder;

- electric drill with core drill for metal;

- argon-arc welding machine;

- set of wrenches;

- disc for grinding and polishing metal;

- sandpaper.

To assemble the boiler you will need the ability to work with a welding machine.

Fittings, drain valve and other connecting elements are selected based on the size of the connected pipe. Additionally, FUM tape, a safety valve, a magnesium anode and a nozzle for its installation are purchased.

Manufacturing of an indirect heating boiler

The process of assembling a water heater may vary depending on the type of design, but in most cases, equipment for gas and electric boilers is manufactured in the following sequence:

- Two holes are drilled in a pre-prepared cylinder using an electric drill with a crown attachment. One hole will be located in the lower part and used for supplying cold water, the other - in the upper part for discharging hot water.

- The resulting holes are cleaned, fittings and ball valves are installed in them. Then another hole is drilled in the lower part, into which a tap is installed to drain stagnant water.

- To make a coil you will need a copper pipe with a diameter of 10 mm. It is better to make a spiral bend using a pipe bender. If such a tool is not available, then you can take any round piece - a large diameter pipe, a log, a barrel, etc.

- The coil is being manufactured according to the previous calculations. The ends of the heat exchanger are bent in one direction at a distance of 20–30 cm. To mount the coil, two holes are drilled in the bottom of the cylinder. Threaded fittings are installed and welded into them.

- Before installation, the coil is lowered into a bucket or large container with water and blown out. If the structure is sealed, then the coil is lowered into the cylinder, aligned with the inlet and outlet openings and welded.

- If the cylinder was cut in the middle, then an anode is mounted in the upper part. To do this, a hole is drilled into which a threaded nozzle is screwed in, and a magnesium anode is mounted into it. If the container is assembled from three separate parts - bottom, lid and central part, then the anode can be installed at the last stage.

- Thermal insulation material is installed on the outside of the boiler. It is best to use spray polyurethane. Before application, all pipes are protected with thick polyethylene and cloth. If funds are limited, then you can use regular polyurethane foam, which, after hardening, is wrapped in reflective insulation.

- Fastenings for hanging on brackets are welded to the back of the boiler. For floor-standing boilers, support legs made of angle steel or reinforcement are welded to the bottom of the equipment.

At the final stage, fittings and taps are screwed on and the top cover is mounted. If possible, you can not weld the lid, but make clamping fasteners from steel wire with a cross-section of 3 mm.

When making a boiler for use with solid fuel boilers, instead of a copper coil, a U-shaped steel pipe is used, which is mounted at the bottom of the device. From the side of the furnace or boiler, the pipe is connected to the outlet pipe. The pipe is taken out from the boiler and connected directly to the chimney.

Useful tips from professionals

There are a number of important nuances, without knowledge and compliance with which connecting the boiler to the water supply will be incorrect. You should know that the hot water supply system does not need to be equipped with any additional elements, with the exception of a shut-off valve. It is installed on the boiler pipe.

The cold water pipe is installed after preliminary installation of the tee. The tap for draining excess cold water from the water heater cuts into the side outlet of the splitter. A return valve and a shut-off valve are also connected to the tee. The latter is connected to the water supply.

How to drain water from a water heater

When connecting the tank to the water supply, do not do the following:

- open the protective window when the heater is on;

- test an empty boiler. The tank must first be filled with water, otherwise the heating element may burn out;

- drain the water without first turning off the heater;

- equip the water heater with parts from other boilers. The exception is the same models, as well as tanks with compatible spare parts.

Diagram of a homemade boiler

The standard design of a water heating device in the form of a boiler may have significant differences depending on the type and design features. Indirect heating devices are not capable of independently producing thermal energy, but can be equipped with built-in heating elements, through which the water temperature is effectively maintained within predetermined limits.

The device diagram assumes the presence of the main components in the design, represented by:

- storage tank;

- outer casing;

- thermal insulation;

- heat exchanger;

- a place for connecting an additional heating element;

- inspection hole;

- cold water inlet;

- input and output for thermal fluid;

- thermometer connection point;

- recirculation line;

- hot water outlet;

- magnesium anode.

A heating element with a supplied coolant is built inside the insulated tank. Cold water enters through the lower part of the tank, and hot water is taken from the upper part.

Water heating equipment of this type is equipped with a protective magnesium anode. The most modern and expensive models are equipped with a pair of redundant coils. Maintaining the temperature is ensured by a heating element with a thermostat built into the upper part of the tank.

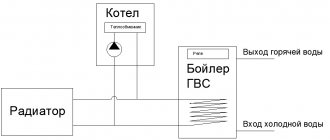

Heating diagram for two types of boilers

Boilers with an indirect heating type are also produced, completely devoid of a coil. This special design is called a “reservoir in a tank”, which is due to the presence of a second tank inside one tank. Water heating in such water heating devices occurs inside the tank, and the coolant moves between the walls.

Factory models of boilers with indirect heating and a circulation pipe are equipped with mandatory elements, represented by a magnesium anode and a safety group, as well as a temperature sensor.

Design

The boiler design is quite simple. In a tank made of non-corrosion material, there is a heat exchanger in the form of a coil or a smaller tank. To increase heat transfer, the heat exchanger is made of a material with high thermal conductivity, usually copper.

The tank is equipped with fittings for water inlet and outlet. The cold water inlet is located at the bottom of the tank and is equipped with a check valve, through which, using a bypass valve, drainage is performed. The outlet pipe for hot water is located at the top of the tank.

To reduce heat losses, the walls of the tank must be well insulated. For this, you can use various materials, but the best option is polyurethane; it has high thermal insulation qualities, is not afraid of moisture, well dampens the noise of water that occurs when heated, is durable and environmentally friendly.

To make a boiler with your own hands, the easiest way is to place the storage tank in a tank or a slightly larger body of a similar shape and fill the space between them with polyurethane foam from a cylinder.

To measure and regulate temperature, the boiler is equipped with a thermometer and thermostat. This element is not required, but significantly increases the ease of use of the heater. To reduce internal corrosion, you can also build a magnesium anode into the tank, designed for heating element type water heaters. They are sold at service centers or hardware stores.

What container to make a tank from?

Any corrosion-resistant container is suitable for this.

- The tank can be made of enameled metal, stainless steel, plastic or other containers.

- Containers coated with a layer of glass ceramics and enamel will require replacement within a year after use, since they are not particularly resistant to corrosion.

- If the tank is made from a metal container, then a welding machine will be needed to manufacture the structure.

- Much more durable and reliable than stainless steel containers.

- To make a boiler, you can use a gas cylinder. It is advisable to purchase a new one, but if this is not possible, then you can make a tank from a used cylinder. The cylinder is cut into two parts, thoroughly cleaned and primed. This should be done so that the water entering the container does not smell of propane.

Four holes are made in the selected container:

- one for the tap through which hot water will be poured;

- one for supplying cold water;

- two for mounting a coil with coolant.

What materials will you need?

First of all, you need to select a container for making the tank. The best material choice is stainless steel. You can use a ready-made barrel, order a tank of the required size, or purchase a gas cylinder. It has sufficient strength, suitable dimensions and shape. Another option for making a tank could be a container made of heat-resistant plastic.

Holes of the required size should be made in the tank. Two holes will be needed to connect the cold water supply and hot water supply pipes. One of them is done at the bottom of the tank, and the other at the top of it. Two more holes will be needed for the installation of a coil intended for the passage of coolant.

A tube made of brass or copper is perfect for making a coil. These materials transfer heat well and can be easily shaped into the desired shape. You can also use small diameter plastic pipes.

In order to make a coil, a pipe of the required length is wound on a base, which can be a strong metal pipe or a rounded log.

In order for the tube intended for the coil to be bent evenly, without creases, it is completely filled with sand before starting work. Then the coil will be of the correct shape, with the same diameter along its entire length.

Based on the volume of the tank, the temperature of the coolant and the temperature of the incoming water, the required length of the coil is calculated. To do this, use a special calculation formula. For a container with a volume of 200 liters, when using a coil with a diameter of 10 mm, its length will be about 15 meters.

Even before installing the storage boiler, you should decide how its thermal insulation will be carried out. It will not be possible to do without it, since natural heat losses are high and the efficiency of the water heater will be too low. The ideal way to insulate a tank is to place it inside a suitable container and then fill it with foam.

To assemble the boiler, you should ensure that you have fittings, nuts, rubber seals, and ball valves. When making a structure from a gas cylinder, welding equipment will be required.

Watch a video on how to make an indirect heating boiler with your own hands:

Do-it-yourself coil for a boiler

For the heat exchanger, a copper or brass tube is used. The diameter of the pipe can be from 8 to 20 mm. At the same time, a calculation is made of the pipe molding so that there is enough power to heat the tank.

Data for calculation:

- Diameter (the parameter is taken in meters);

- Fluid temperature in the heating system;

- Temperature indicators of tap water.

To determine the length of the heat exchanger, a special formula is used. In this case, the thermal power is divided by the number Pi, then multiplied by the diameter and by the temperature difference between the heating and water supply. It is better to round the obtained data and take the pipe with a margin.

To give the heat exchanger a spiral shape, the pipe is wound onto a blank. The diameter of the coil must correspond to the diameter of the tank. A small distance is provided between the spirals. The end of the coil is equipped with fittings. Before welding the system, its functionality is checked.

Coil manufacturing

To make a round steel coil yourself, use a pipe bender, but if necessary, prepare a square tubular heating element, all parts of which are shown connected by electric welding, parts of stainless steel pipes.

The heating power level is calculated naturally with the formula: Q = K x A x dT , where the indicators are shown:

- K - heat transfer index;

- A - area of the total surface of the heating element;

- dT is the temperature difference between the coolant and the heating water.

The coil can be placed either in the very center of the tank or along its walls.

The configuration and dimensions of the tank affect the total number of turns, and in addition the diameter of the heating element.

Operating principle of an indirect heating boiler

This option is ideal for an apartment building, but it can be used without extra costs only during the heating season. For the period when the central heating is turned off, an electric heating element can be provided. In this case, you will have to pay more for electricity, but you can turn on the heating as needed.

Schematic diagram of the operation of an indirect heating water heater

The same system can be installed in a private house if it has autonomous heating from a boiler.

Construction and materials

A boiler of this type consists of a container that can have any volume. It is better to make it from stainless material, so it will last longer, and the heated water will always be clean. For the boiler capacity, they usually use a barrel, a new gas cylinder, or a custom-made tank.

- A pipe twisted in the form of a coil is installed in the middle of the container, and the coolant will circulate through it. It is good to use copper or brass as a pipe - metals with good heat transfer. However, as an option, it is possible to choose a small-diameter metal-plastic pipe for this purpose.

- To make a neat coil, a long tube (about 15 meters) is wound onto another pipe of larger diameter, onto a flat wooden log or onto another suitable cylindrical object.

Coil winding

- The number of turns on the coil depends on the shape and height of the container, but the longer the pipe twisted into the coil, the faster you can get heated water.

- The ends of the pipe come out of the tank in different places. On top of the container there is a pipe into which coolant from the heating system will flow. Having passed through the coil, it returns to the heating circuit through another pipe located at the bottom of the tank.

- There are two holes in the tank: for filling it with cold water and for taking heated water. The first is located at the bottom of the tank, and the second at the top, from where hot water is distributed to the required points: shower or kitchen tap.

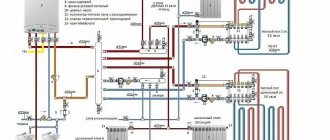

Connection diagram for an indirect heating boiler

The diagrams provide a good look at the connection and circulation of water and coolant in the heating system.

Another option would be a boiler of the same type, but without a coil. It will require two containers - a large and a compact size. A small container is installed in the middle of a large tank, and it will act as a heat exchanger. The coolant will not circulate through the tubes - it passes through the internal compact container. The principles of operation and installation of pipes for circulating heated water are identical to the first option.

It must be said that the design principle of such a device is quite simple, therefore, based on it, you can invent your own design of an indirect type water heater.

If desired, you can equip the boiler with a heating element

In these boiler options, it is also possible to use an electric heating element, which is built into the container from below. Therefore, it is better if the boiler is hung on the wall using brackets. You can also install the body on high legs, which can be easily made from angle iron or fittings. A heating element, in fact, is the same as a boiler, you just need to choose its power correctly - it will depend on the volume of the boiler. This heating element can be purchased at a specialized store.

Diagram of an indirect heating boiler with heating element

Calculation of the main parameters of the boiler

Before you begin searching for material and directly manufacturing, you will need to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person uses up to 80 liters of water per day. For the calculated value, it is recommended to take 45–50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure in the plumbing system. If the pressure is low, then the use of homemade boilers with a square tank is allowed . If the pressure in the system is high, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can become deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical indirect heating models, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For DIY production, it is best to use a copper pipe with a diameter of 10 mm. This product can be easily bent by hand without using any tools. When using a metal-plastic pipe, it should be taken into account that the heating temperature of the coolant should not be more than 90 °C, otherwise the pipe will be deformed and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙d ∙∆T), where:

- L—pipe length (m);

- d—pipe cross-section (m);

- ∆Т – temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. Taking this into account, you can calculate the length of the pipe for making the coil.

For example, let’s calculate the material for a coil that will be installed in a boiler with a capacity of 200 liters. The temperature of cold water supplied to the container will be 15 oC, and after heating it is necessary to obtain water with a temperature of 80 oC: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Typically, the coil is positioned so that the distance between the coils and the walls of the tank is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler needs to be equipped with a tubular electric heater, then the power is calculated based on the fact that to quickly heat 50 liters of water, a heating element with a power of at least 1.5 kW is required. In addition, any combi boiler must be equipped with a thermostat.

Preparing the tank for water heater assembly

To make an indirect type boiler, you can use a new or old gas cylinder. This container is made of thick stainless steel 3-4 mm thick and is perfect for working with hot water.

Before assembling the heating structure, you will need to carefully prepare the cylinder. To do this, the product is cut in half using a grinder. The inner surface of the container is cleaned using an angle grinder with an appropriate attachment.

Before assembling the boiler, the cylinder must be opened and the inner surface cleaned

After this, the inside of the cylinder is washed, dried and coated with nitro primer paint. This work must be carried out without fail, otherwise after putting the boiler into operation, the heated water will smell like gas.

When using a tank from other metal containers, preparation is carried out according to a similar scheme.

Thermal insulation

The category of the most affordable and highly effective insulation materials includes modern foamed polymers, such as expanded polystyrene or foamed polystyrene, and in addition polyurethane foam and polyisocyanurite.

When using heat insulators of this type, it is considered necessary to use a sealed protective casing that completely prevents toxic fumes from entering the room.

Installation methods and shapes of boilers

Boilers come in wall-mounted and floor-mounted versions, horizontal or vertical models. The capacity of the product, which is mounted on the wall, is naturally lower: it does not exceed 200 liters. Floor-standing devices can hold one and a half thousand liters. Boilers are mounted on the wall using standard brackets and suitable dowels. The most common boilers are cylindrical in shape.

Working pipes for connecting the system are located at the rear of the unit for convenience and aesthetic purposes. There is a temperature sensor and a thermostat on the front panel. There are models with the possibility of additional connection of heating elements if the power of the main heat source is not enough.

Installing a water heater safety valve

This small device plays an important role in the boiler connection diagram. When the water in the tank begins to heat up, it expands in volume and as a result the pressure increases.

When it reaches a critical value, the safety valve is activated and releases some of the water to reduce the pressure. Therefore, the valve pipe must be connected with a flexible tube to the sewer outlet.

In large-capacity tanks, it is customary to additionally install a membrane expansion tank (expanzomat). It is able to compensate for a larger volume of expanding liquid. It is important when buying a tank to choose one that is intended for water supply systems, not heating. It can be recognized by the maximum operating pressure of 7-8 Bar (for heating tanks 3 Bar).

Stages of work on creating a boiler

The boiler drawing may look like this.

Creating a Heat Exchanger

When choosing the diameter of the future coil, it is important that the water in the tank comes into maximum contact with such a pipe. To do this, leave free space between the turns of the pipe.

To make the work easier, you can use a log or pipe around which the heat exchanger tube will be wrapped. One end of this tube is fixed, and then turns are smoothly created, controlling the density of the resulting spiral.

Preparing the boiler tank.

Having chosen a suitable container, you need to make two holes in it for cold water in and hot water out. Ball valves should be built into each of them for ease of operation. You also need two holes for mounting the heat exchanger. Another hole will be needed for the drain valve, which is located at the bottom of the device.

Connection

At the last stage, the heating element is connected to the heating system circuit, naturally with an ordinary circuit. Then you need to connect the inlet and outlet pipes, and in addition carry out wiring to all water distribution points.

Possible connection diagram for an Omicron indirect heating boiler

Before you begin testing the performance of a self-made water heating device, you need to check that all elements are connected correctly.

The operating principle of the safety valve for a water heater and its functions are described in this topic.

Instructions for replacing the magnesium anode in a water heater are provided in this article.

The defining stages of boiler manufacturing are shown by preparing a suitable container, making a coil, providing thermal insulation and assembling the device, including connecting the coil to the heating system, organizing the cold water supply and hot water output.

Choosing a tank for the boiler

The volume of the storage tank of the water heater should be calculated based on the daily consumption of hot water in the house. If several people live in an apartment or house, a tank of 100 liters will be sufficient. And for a family of 4-5 people, you should choose a container with a volume of 200-300 liters.

The tank used should be made of an aluminum alloy, stainless steel or other metal that is resistant to corrosion. You can use a large-sized gas cylinder, the walls of which are additionally cleaned and primed. If the walls of the cylinder are not primed, the hot water may have an unpleasant gas smell.

Five holes must be drilled in the selected tank. Two at the bottom for the inlet pipe and emergency drain, two at the side for installing the coil and one hole for water extraction at the top. If you plan to use such a boiler outside the heating season, you must also make holes for installing an electric heating element. For the heating element, one or two holes are drilled from below. Ball valves or shut-off elements are installed in the holes made, after which the tightness of the storage container is checked.

How to calculate the volume of produced BKN

According to rough calculations taken into account when designing a private house, an average family of 4 people spends an average of 280 liters per day. For normal water supply to a family, you will need a 200 liter boiler. If you plan to use hot water only for showering and washing, 100-120 liters will be enough. containers.

To calculate the approximate needs for domestic hot water, use the following table:

Approximate water consumption (l)

Water consumption from the boiler (l)

When calculating the volume of the boiler, another factor is taken into account. If you plan to install a mounted BKN, then its capacity is limited to 150-160 liters, which is due to the load on the wall. If a larger volume is required, install a floor-mounted boiler.

DIY assembly and connection instructions

The boiler is assembled after preparing all the components.

Holes are drilled in the tank: for the water filling tap, coolant inlet and outlet. If you decide to install a heating element, then a hole is also made for it at the bottom.

- Next, a coil is installed in the container, and the tubes are passed into the holes using special adapters, which it is advisable to weld into the boiler body. Other options are possible, but the main thing is that the holes are sealed hermetically.

- The legs are welded to the bottom (if provided).

- A heating element is installed if this was planned.

- Then the coil is connected to the heating system circuit, according to the diagram.

- A pipe for cold water supply and a tap for heated water are connected. You can immediately make connections to water collection points - to the kitchen and bathroom.

Thermal insulation

To keep the water warm for a long time, the container is thermally insulated. For it, foiled mineral wool or polyurethane foam is used. The boiler body must be completely covered in thermal insulation material - the efficiency of the device will directly depend on this. To make the insulation look neat, you can place a casing made of thin sheet metal (for example, galvanized) on top of it - you get something similar to a sandwich pipe. A visual example is in the first picture of the article.

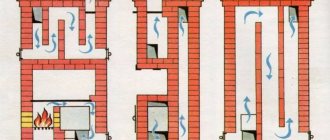

The principle of operation of a wood boiler

Wood boiler

Another type of indirect heating water heater is wood-burning titanium, which will only require the cost of creating a supply of solid fuel. This boiler has a samovar design and operates autonomously from all power sources, so it is ideal for installation in a private home.

The principle of operation of a titanium boiler

To build such a device with your own hands, you must first build a stove, which will heat the water inside the tank. Such a boiler can have a round or square tank, and it can be installed either on a small stove made of brick or on a stove like a potbelly stove welded from a piece of metal pipe of a sufficiently large diameter.

The second option is more complicated due to the fact that sections of metal will have to be cut out of the pipe to install firebox and vent doors in these places. In addition, using welding inside the pipe, you need to strengthen the brackets for laying the grate. The bottom and top of the stove pipe are welded with solid sheets of metal. A round hole is made in the upper part, a chimney pipe is welded into it, which will pass directly through the container with water and heat it to the desired temperature.

The tank must also be welded to the furnace lid.

If you decide to make the stove out of brick, the boiler tank can be either round or square. The top of the stove is covered with a metal panel, into which a chimney pipe is also welded. Next, a container without a bottom (water tank) is hermetically welded to the upper metal plane of the furnace.

The chimney, after passing through the water tank, is discharged to the street.

Two or three pipes with valves must be welded into the tank: for water inlet, for outlet to the mixer tap and to the shower.

Water can enter the boiler either from the main line or be filled in manually. In addition, a water storage tank can be installed above the boiler, from which water can also flow into the heating tank.

If such a water heater is installed in the bathroom, it will not only provide hot water, but also heat the room.

Anyone who has used geysers or flow-through heaters powered by electricity is familiar with the situation that when the tap opens, you have to wait a while for hot water to flow. When installing an indirect heating water heater, this factor is completely eliminated - by opening the tap, you can immediately get heated water.

Compared to water heaters running on gas or electricity, this type of boiler will help you save on energy.

Peculiarities

Unlike water heaters, an indirect heating boiler uses the energy of a coolant used for heating. To do this, a heat exchanger is built into the storage tank, in many cases having the shape of a coil. Passing through it, the heating system coolant heats the water in the tank.

Heating of water in a boiler, as in a storage water heater, occurs within several hours, but its temperature then remains stable for a long time, which increases the convenience of using hot water for showers and baths.

An indirect heating boiler is not only economical, it is also more or less dangerous than a storage electric water heater. In the event of an automation failure in heating element heaters, water may boil and destruction of the device itself or the connections from the connectors, which leads to leakage. In a boiler, the water cannot heat up hotter than the coolant; in many cases this figure is within 60-90 degrees, which is safe for both pipes and humans.

Advantages of using an indirect heating boiler:

- the heat exchanger can be connected to both central heating and various types of boilers;

- heating water does not require electricity, gas or other fuel, which reduces the cost of installing and operating the boiler;

- the water temperature is stable, without sudden changes;

- safety of use even without installing expensive automation - the water does not boil, and if there is a leak or interruption in the supply of cold water, the device does not fail;

- ordinary design and installation provide the opportunity to save additional money by making and installing an indirect heating boiler yourself.

Minuses:

- quite large dimensions and weight, comparable to a storage-type water heater;

- an indirect heating boiler is used exclusively during the heating season; for summer use it is equipped with a heating element;

- long heating of water, during which the temperature of the coolant in the radiators decreases;

- salt deposits on the coil require constant cleaning and maintenance.

There are many models of boilers on the market that use indirect heating. However, if you have minor welding and installation skills, you can make a boiler for your home or cottage with your own hands.

Final assembly

The process of self-assembly of a water heating device consists of the following step-by-step activities:

- coil installation;

- soldering pipes on inlet and outlet pipes;

- welding of support legs or hanging loops;

- installation of a heating element;

- tight fit of the lid.

It should be noted that special attention should be paid to thermal insulation of the tank with basalt mats and their fixation on the surface of the outer walls.

To make the operation of the water heating device completely safe, it is necessary to screw on a protective steel casing coated with powder paint or galvanization.

Conclusions and useful video on the topic

A used gas cylinder is often used to make homemade devices. We present a video on how to make a BKN from a cylinder body.

Here we describe only one option out of all the possible ones that exist and are successfully used. It should be noted that there are many options for independent designs of indirect heating boilers.

For example, instead of a cylindrical storage tank, rectangular vessels are used. The winding of the coil spiral is not single-layer, but multi-layer. The water heater is supplemented with an electric heating element. Design ideas have no boundaries.

Would you like to share your own experience in making an indirect heating boiler or useful information on the topic? Please write comments in the block below. Here you can ask questions, express your opinion and post photos.

Hot water supply is one of the comfort factors, both in a city apartment and in a country cottage or country house. But if in the city it is enough to connect a tap to a centralized water supply system, in the country you have to solve the problem on your own.

Installing a heating boiler is an expensive procedure that is not always cost-effective. Therefore, many country property owners decide to make an indirect heating boiler with their own hands. It perfectly solves the problem of supplying the house with hot water, but is much more economical.