An indirect heating boiler is considered the most economical and practical for heating water, since it does not have a heating element in its design. It heats the water by interacting with external thermal units, such as central heating, a boiler or a solar panel. Although some models are improved with an additional heating element, these are already combined models.

In our article we will look at the principles of operation, design, selection rules and popular models of these units. As well as questions about descaling them and other important points.

Indirect heating boiler

Many owners of private houses are wondering how to use a heating system to supply their home not only with heat, but also with hot water. Why does such a question arise at all, since the market is simply teeming with offers of electric and gas storage and instantaneous water heaters? Everything is very banal - electricity is not cheap, and geysers are not able to provide a constant temperature that is comfortable for use. Therefore, indirect heaters are an excellent option for a home with heating from a gas boiler , moreover, they are economical.

Some useful nuances

Before connecting an electric boiler to a regular outlet, be sure to check the condition of your wiring. A mismatch between the power of the heater and the old wiring can lead to a short circuit and even a fire.

It is necessary to check not only the outlet, but also the distribution meter. In old Soviet-built houses, it may be necessary to install an additional circuit breaker.

Most models of storage boilers are wall-mounted - but some of them can be installed in the space under the sink.

The shape of tanks in storage boilers can be not only classically cylindrical, but also oval. The boiler can also be installed horizontally, so you can fit into almost any interior.

It is desirable that the inner surface of the boiler tank have an antibacterial coating. This will prevent the water from “blooming” when it stagnates or the formation of mold.

The coating in the boiler tank made of the following materials most effectively prevents the development of corrosion:

- Glass porcelain will delay the formation of rust for 3 years.

- A tank enameled on the inside will last up to 5 years.

- Titanium-based enamel will protect the tank for up to 7 years.

- A stainless steel tank will last about 20 years.

In any case, extending the life of your heating device will be helped by regular maintenance and cleaning, and preventing the formation of limestone deposits.

Video - How to choose a water heater

Device

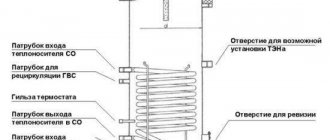

An indirect heating boiler is a large cylinder-shaped tank. Its design consists of the following elements:

- frame;

- thermal insulation;

- stainless steel tank;

- heat exchanger;

- magnesium anode;

- thermometer.

Thermal insulation is laid between the body and the boiler tank to minimize heat loss to 3-4 degrees per day. The heat exchanger is a curved spiral tube made of steel or brass , which is also called a coil. The coil itself is the most important part of the boiler and the more curls it has, the more efficient the heat exchange. Usually it has a very complex structure and is located closer to the bottom, which makes it possible to evenly heat the entire volume of water.

The magnesium anode, which is also used in conventional electric water heaters, is designed to combat tank corrosion caused by galvanic processes. The anode will take over all electrochemical reactions, leaving other metal parts of the system untouched. especially important to protect welding seams from destruction , so periodically it will be necessary to replace the worn magnesium anode with a new one.

Modern boiler models combine several heat sources. They can work even after the heating season, using electricity, gas for heating, and some models even heat water using the sun. Such modifications have two tubular heat exchangers at once, one for water from the heating system, the other for an alternative source.

What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant that fills the heating system. A single-circuit boiler does not prepare water for hot water supply. In rooms where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh just over 40 kilograms. The wall-mounted single-circuit boiler fits organically into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

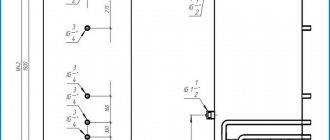

A single-circuit gas boiler does not have any complex elements or mechanisms in its design. This boiler consists of:

Wall-mounted single-circuit boilers can be equipped with an expansion tank, which is hidden under the boiler casing. Also, the expansion tank can be part of a floor heating device, which has low power.

Work principles

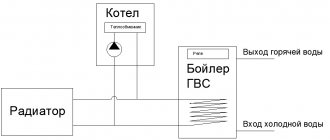

Usually an indirect heating boiler is purchased together with the boiler. There are also double-circuit boilers that can provide households with still warm water. But the volume of heated water in double-circuit boilers is small, and an indirect heating boiler can heat much larger volumes , due to which the supply of hot water will be carried out without interruptions.

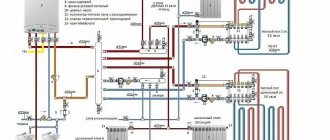

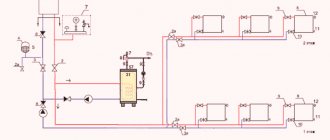

As indicated in the title of the article, an indirect heating boiler is a type of water heater that operates through external heating systems. The coolant (water) is supplied from these heating sources through a coil located inside the tank. The water in the boiler is heated by circulating coolant through the coil , which is possible thanks to the pump. The walls of the coil serve as a heat exchange surface. Once the water temperature reaches a certain point, the pump automatically turns off. Naturally, during operation of such a boiler, the temperature in the heating system decreases slightly. But there is no need to worry about this; if everything is installed correctly, the temperature changes are almost unnoticeable.

To ensure that such a system has as little heat loss as possible, it is insulated with special insulation materials, such as polyurethane, polystyrene foam, etc. In fact, it resembles a huge thermos that holds heat perfectly.

Water is supplied to the boiler through the inlet pipe, which is connected to the heating system. Through this pipe, hot water enters the coil and heats the water, and the outlet pipe supplies hot water to the place of its use.

What is a double-circuit boiler

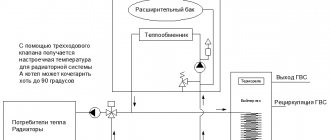

This heating device not only heats the coolant, but is also intended for preparing hot water. A double-circuit boiler has a more complex structure than its single-circuit counterpart. The most complex device has a dual-circuit heating device, which is equipped with a three-way valve.

There are dual-circuit heating devices that are equipped with a pair of heat exchangers. One heat exchanger is responsible for heating water in the heating system, and the second heats water for water supply. The most rational design has dual-circuit heating devices that are equipped with a bithermal heat exchanger. Such a heat exchanger is two in one. Inside the bithermic heat exchanger there is another heat exchanger, which is designed to heat water for domestic purposes. But boilers with separate heat exchangers are considered more popular models.

Double-circuit gas boilers are good because they solve all the problems associated with preparing hot water for heating a room. Such heating devices are quite compact and fit organically into any interior. The design of a double-circuit heating device resembles the design of its single-circuit counterpart, which is also supplemented:

How to choose the right boiler?

Important characteristics of an indirect heating boiler are:

- volume;

- coil material;

- tank material;

- insulation material;

- the presence of an additional heating element and alternative heating sources.

Boiler volume

You need to choose the volume of the boiler based on the power of your heating system , since it accounts for the load of water heating. If you buy a unit whose volume is too large, then there is a possibility that your heating system may not be able to cope with it. This risks the fact that the temperature of the water in the heating devices will be too low to heat the room. In order not to make a mistake, you need to find out the volume of the boiler coolant; it should be no more than 30-40% of the volume of water in the heating system, otherwise its performance will noticeably suffer.

It is very easy to determine what size boiler your family needs. On average, there are 60-80 liters per person for a shower. Heating 200 liters takes about 6 hours. Based on these figures, you need to take the volume of the boiler, which is enough to cover the needs of the family, taking into account the time until the next heating.

Materials

One of the most important parts of the boiler is the coil, so you need to inquire in advance about what it is made of. Cheap models have a steel coil that is simply welded to the tank. In more expensive models it is removable and made of brass , which is much better in many respects. Moreover, the removable version can be dismantled and descaled.

What the tank is made of is also very important, since a common problem with any water heater is leakage. Inexpensive models have a layer of enamel inside, but it quickly forms cracks due to temperature changes. And this, in turn, is fraught with rapid corrosion of the metal. It is best to buy those options in which the tank is made of stainless steel. It may be more expensive, but it will also last longer, provided that the magnesium anode is replaced in a timely manner.

The quality of the insulation is also an important factor in the effectiveness of such a system. Sometimes they use ordinary foam rubber, but it loses on many points. It is best if polyurethane and similar materials are used as thermal insulation.

Other options

In addition to the fact that the boiler can have two sources of indirect water heating, it can also be equipped with a heating element as a heat source outside the heating season. Such designs are much more expensive than conventional ones, but they are extremely practical.

The type of boiler can be of two types: wall-mounted or floor-mounted. It must match the type of heating system. So, if the system is wall-mounted, then the boiler should be of this type. Only models with a volume of less than 200 liters can be wall-mounted.

How much hot water do you need?

The main characteristic of the boiler, which influences the correct choice, is the volume of hot water it produces. If you choose a boiler that is not large enough, then queues for hot water may form in your family’s bathroom, and if you choose a device with an excessively large volume, then you will simply throw some money down the drain.

In order to understand the amount of hot water you need, you need to sum up the amount of hot water consumed daily by all members of your family. The daily consumption figure ranges from 20 to 80 liters, depending on your needs. Also remember that this volume of water is not consumed immediately, but throughout the day, and not simultaneously by all household members.

After calculating the required water consumption, estimate how much it will cost you to heat this amount of water. On average, to heat 20 liters of water you will have to spend about 1 kilowatt of electricity.

By multiplying the amount of energy required by the cost per kilowatt-hour, you will get the cost of operating an electric boiler. For heating devices powered by gas, the numbers will be different.

Advantages and disadvantages of indirect heating boilers

Like any other unit, such a boiler is in some ways better than other water heaters, and in some ways worse. Having assessed all the advantages and disadvantages, you can decide whether such costs are justified.

Advantages

What are the strengths of an indirect heating boiler?

- The main advantage of indirect heating is the low cost of hot water. No additional source of electricity or gas consumption is connected, so the consumption of these resources practically does not increase. The additional load on the indirect heating source is minimal. In winter, this method of heating water is very relevant.

- During the heating season, an indirect heating boiler makes it possible to reduce the load on the electrical network , because it uses the energy of the boiler to heat water.

- Possibility of heating large volumes of water.

- Supply of hot water to several points.

- Possibility of using alternative heat sources: sunlight, gas or electricity.

- There is no contact of the coolant with the heated water, so the inner surface of the coil always interacts with prepared water with a low percentage of salts.

As you can see, there are enough advantages; in fact, this is an ideal design for providing a family with hot water. Although there are also disadvantages, especially in those designs where only one indirect source is used.

Flaws

This boiler also has its weaknesses.

- The cost of such a unit is quite high. In addition, you need to take into account that it adds to the cost of the heating system. It is cheaper to buy an electric storage water heater or a double-circuit boiler separately.

- Heating of water takes longer than in electric storage boilers. To heat 100 liters of water, it will take several hours, during which the temperature in the heating system will be slightly reduced.

- The design of indirect water heating itself is quite cumbersome. It is usually installed near the boiler, sometimes a separate room is needed for this. At the very least, you need a carefully thought out place for this.

Gas instantaneous water heater (gas water heater)

For a gas instantaneous water heater there are no such problems with supplying the required power - gas can easily provide you with a power of 24 kW. But for normal use, 17-18 kW is enough (simultaneous use of a washbasin and sink, or taking a shower - about 8 liters of water heated to 40˚C per minute). If you have a very large family and it’s not uncommon for you to take a bath and wash dishes at the same time, choose more powerful options with a power of about 8 kW.

The installation of a gas heater must be carried out by suitably qualified specialists.

It is also necessary to take into account some of the inconveniences associated with instantaneous boilers - the temperature will fluctuate during use. Therefore, in order to avoid not very pleasant surprises when taking a shower, it is better to install a mixer that will maintain the set temperature.

Gas instantaneous water heaters must be equipped with sensors:

- Chimney draft reduction sensor - if the draft decreases and carbon monoxide begins to be drawn back, the system turns off the heater.

- Ionization and combustion sensor - used to protect against leakage of unburned gas (for example, the burner has gone out), installed both separately and together (duplicating the security system).

- Flow detector - automatic switching on when the DHW tap is opened.

- Water pressure reduction sensor - if the pressure is too low, the column will not turn on (prevents the heat exchanger from burning out).

- Fluid overheat detector - shuts down when the water in the system overheats.

Main head ignition method

- With the help of a small, constantly burning duty light, the so-called candle - a reliable old-fashioned method. The head itself is ignited using piezo ignition or manually (with a match), which is not very convenient and there is a constant gas flow, but there is no connection to electricity.

- Electronic arson is a very good method, but if there is no electricity, there is no hot water (there are options with a battery, or with a mini-generator started by flowing water - very expensive). True, you can purchase an uninterruptible power supply, especially if you also have a gas heating boiler connected to electricity.

Adjusting the power of a gas flow-through heater

- Automatic - allows you to provide the specified water temperature when its flow changes (the most important thing is that there is enough power), but the system will most likely be tied to the electrical network.

- Manual - the power is set manually, so the output temperature will change depending on the speed of water flow.

Types of heat exchangers

The main indicator that characterizes the heat exchanger is the material from which it is made:

- Steel is a very high-quality heat exchanger, at a low cost we get excellent corrosion resistance and reliability, the only negative is weight (not too much);

- Ordinary copper - since copper has a number of impurities, the heat exchanger heats up unevenly, which ultimately leads to its bursting. Any additional coatings with heat-resistant paint in this case do not help much. Heat transfer is naturally higher than steel, but less reliable.

- Highly purified copper has excellent heat transfer, which increases the efficiency of the device, while the mechanical properties of this heat exchanger are similar to steel.

Carbon monoxide removal method

Through the chimney

A classic, reliable method of removing carbon monoxide. The only negative is that in most apartments there is no physical possibility to remove gases through the chimney due to its absence.

Chimneyless (parapet)

In this case, the exhaust gases are forced out through a hole in the wall using a turbine or fan. At the same time, the room itself where the gas instantaneous water heater is installed must have good forced or natural ventilation.

Main head ignition method

- With the help of a small, constantly burning duty light , the so-called candle - a reliable old-fashioned method.

- Electronic arson is a very good method, but if there is no electricity, there is no hot water (there are options with a battery, or with a mini-generator started by flowing water - very expensive).

Note: Storage gas boilers are generally available on the market , but they are not so common due to the more complex installation compared to electric ones. Otherwise, the parameters for their selection are practically the same as those for electric storage boilers, so I won’t dwell on this too much.

Manufacturers and prices

Indirect heating boilers have a huge range of sizes - up to 900-liter giants and more.

The most popular manufacturers and models of indirect heating boilers:

- 70 liters Valliant (Germany) – 32 thousand rubles;

- 160 liters “Drazice” (Czech Republic) ≈ 30 thousand rubles;

- 100 liters with QUATTRO heating element (Sweden) ≈ 45 thousand rubles;

- 500 liters combined Hajdu (Hungary) ≈ 90 thousand rubles;

- 210 liters of ACV (Belgium) ≈ 50 thousand rubles.

Interestingly, only the Belgian ACV models do not have a spiral coil as a heat exchanger, but a barrel with a corrugated surface, which is installed inside the tank, that is, this is a “barrel-in-barrel” design, which is a very interesting alternative to a coil.

Types of water heaters

Gas water heaters are not new. Previously, speakers were bulky and inconspicuous, but today they are compact devices with an aesthetic appearance. The principle of operation remains the same. It consists in the fact that cold water, entering a copper heat exchanger, is heated by natural gas. The undoubted advantages of such equipment are instant heating of any volume of water and the low cost of natural gas.

These products, from both domestic and foreign manufacturers, are widely represented in the distribution network. To be completely confident in the quality of such devices, you should choose products from well-known and reputable companies. Among them are brands such as Neva, Ariston, Elektrolux and many others. High productivity, high power and low cost of gas resources contribute to high consumer demand for this equipment. Modern speaker models are divided according to the ignition method. They can be:

- automatically - the device starts working the moment the mixer tap is opened;

- semi-automatic - manual ignition of the wick is required to start the equipment.

Relatively new equipment is turbocharged speakers.

The operation of this device is not affected in any way by the presence of draft in the chimney pipe. A turbine is a built-in fan designed to pump air masses into the combustion chamber and remove combustion products from it. The automatic operating mode of the system ensures the reliability and safety of the device. The column is equipped with sensors that record such important indicators as: pressure and temperature of the water, as well as the heat exchanger. Increasing the standards of these indicators leads to automatic blocking of the system.

For consumer convenience, manufacturers supplement the equipment with special options. These may include a convenient display, various indicators (on and heating) and a thermometer.

Boiler – storage water heater. Available in two types: gas and electric. The electric heater includes: a thermally insulated tank, a tubular heater and a water heating regulator. Water entering the tank is heated and used as needed. Gas boilers can be:

- with a closed combustion chamber and forced draft;

- with an open chamber and natural draft.

The second heater option requires a chimney. Some models have additional options that ensure comfortable and safe use.

An electric boiler is used to supply hot water not only to residential buildings, but also to industrial facilities. Water enters the internal tank and is heated to a set temperature. Automatic operation of the heating elements allows you to maintain the temperature regime. Periodic heating contributes to economical energy consumption. This device is installed in the water supply system. A dense layer of thermal insulation of the tank helps reduce energy consumption for heating. The inner surface of the tank is treated with a special anti-corrosion coating. Devices with a tank whose flask is made of stainless steel are considered more reliable. They are distinguished by reliability and durability, unlike specimens with an enameled tank.

Boiler maintenance

Once or twice a year, an indirect heating boiler needs maintenance - replacing the magnesium anode and descaling. How can this be done at home?

First of all, you need to check whether there is scale on the heat exchanger experimentally. Scale significantly reduces heat transfer, so you need to measure the temperature at the boiler inlet and outlet. In this case, the difference should be approximately 15 degrees, that is, if the coolant enters at 80 degrees and leaves at 65 degrees, then so far everything is in order. But if the coil is “overgrown” with salts, then heat transfer occurs ineffectively and the temperature of the coolant at the inlet and outlet has a difference of only 5-10 degrees, and the water will heat up more and more slowly.

If the temperature at the input-output differs by 12-14 degrees, then things are not so bad yet and you can cope with the thermal shock method. To do this, you need to completely drain the water from the boiler and run the coolant from the boiler through the coil at good power for about 10 minutes. So, the coil will warm up well, having no place to give off the heat, and then you need to fill the boiler again with cold water for 3-5 minutes. Such a sharp jump in temperature should peel off the scale from the coil. Now you need to rinse the boiler and repeat the procedure.

If the situation with deposits is more complicated, then more effective methods need to be used. It is necessary to use chemicals recommended by the manufacturers of a particular model. If you use random means, you can damage the parts of the unit. Special products for cleaning indirect heating boilers are diluted in water and poured into the boiler container to completely cover the coil. You need to wait from 4 to 8 hours and the dirty water should be completely removed, and then you need to fill it with cold water 2 times and drain it. Cleaning complete!

Flow-through or storage boiler - which is better?

Instantaneous water heaters heat water instantly , i.e. they turn on as soon as the tap opens and heat the water in the pipe that passes through the boiler. They take up relatively little space (about the size of a shoebox), are cheaper compared to storage ones (in the segment of electric water heaters), but at the same time they are more difficult to install and they require a lot of energy to instantly heat up the water - from 8 kW and more ( if the water heater is electric, then it is necessary to pull separate wires from the meter - otherwise the wiring will most likely not withstand). The energy source for flow-type boilers is gas or electricity - there are no indirectly heated flow-through boilers.

Depending on your needs, you need to choose the right instantaneous boiler of appropriate power, because a 3.5-4 W instantaneous boiler is only enough to wash dishes and wash your face (capacity is about 1.5 liters per minute); it will be quite difficult to bathe even in the shower - for Therefore, choose a boiler with a power of at least 6 kW (we are already 100% pulling a separate wire from the meter).

Storage water heaters are a container of water protected by thermal insulation material, which is heated to a given temperature by an external energy source, and then the temperature is maintained at this level. Such water heaters are quite easy to install and use, the only drawback is that it takes time to heat the water (the approximate time can be seen in the table below).

Water heater volume (storage boiler)

If you choose a boiler in a store with a volume that is too large for you, you will wait a long time for the initial heating and overpay for wasted energy (even though you don’t insulate the boiler, it will still cool down). But if you choose a small-capacity water heater, you will most likely constantly run out of hot water - you must admit, this is not very pleasant. Therefore, you need to choose a middle ground, thanks to which you can meet your needs for hot water.

The volume of the boiler mainly depends on the number of people who will use it, but the number of points that discharge hot water (shower, washbasin, kitchen sink, etc.) also greatly influences. But you also shouldn’t forget about such additional parameters as the duration of a shower (5-25 minutes) and the need for a hot bath.

- A 30- liter is quite enough for the needs of one person, well, at a stretch, two, but you definitely won’t be able to run a hot bath. Also, such a boiler can be purchased to provide hot water in unforeseen situations (hot water was turned off for a couple of days), even for a large family, but keep in mind that you will have to take turns taking a shower while waiting for the water to heat up (since a small volume of water heats up quite quickly).

- Water heaters with a volume of 50 liters are a fairly universal solution for a family of 2-3 people (even four, but you may have to wait). It’s quite difficult to heat a bathroom from this boiler, unless you drain it completely into the bathroom and dilute it with cold water (usually boilers heat water to 70-80° - check!).

- The price tag for a boiler with a capacity of 80 liters is not too different from the cost of 50 liter water heaters, and it is confidently enough for 4 people. But you need to take into account that with the same heater power, 80 liters will take longer to heat up.

- Water heaters with a capacity of 100-150 liters or more are usually installed on the floor, or on a specially made stand - hanging such a colossus is quite dangerous. At the same time, a 150-liter boiler is enough for a large apartment inhabited by about 6 people. Large-volume water heaters are designed for installation in private homes - they take up a lot of space and consume a lot of energy. Large-volume water heaters (150-250 liters) are designed for installation in private homes - they take up a lot of space, consume a lot of energy and have a corresponding price tag.

The internal coating of the storage water heater tank is enamel VS stainless steel?

Naturally, a tank made of stainless steel will have great customer confidence - in general, such tanks are simply ideal (their warranty period is 10 years or more). But there is one caveat - corrosion along the seam, so it is advisable that the manufacturer carry out passivation (protection against corrosion - ask a consultant, find out on the Internet).

But you shouldn’t think that steel tanks with an internal enamel coating will be worse or much cheaper than their stainless steel counterparts - the process of high-quality enamel coating is quite complex and includes the addition of special additives, thanks to which the enamel adheres well to the steel and expands when heated. same expansion coefficient. In addition, there are branded enamel coatings - sputtering of silver ions (as a result, excellent antibacterial + anti-corrosion properties); titanium coating (increases heat resistance and ensures uniform heating of the liquid in the tank); glass ceramic coating.

It should also be noted that most enamels repel scale and it will gradually accumulate - but the service life of such water heaters is very long.

About repair and maintenance

Storage water heaters require periodic maintenance - once every 1-2 years . They install a so-called “anti-corrosion anode” that collects rust and various active chemicals, protecting the tank. This anode is a consumable item and must be replaced, otherwise the tank will be destroyed in the future. Also, when replacing this anode, it is very advisable to rinse the tank and descale the heating element.

Alternative for an indirect heating boiler

Is there an alternative to an indirect heating boiler? Let's compare different options for heating water:

- a gas water heater or gas storage water heater requires a separate project to install it. The gas water heater also does not provide a stable water temperature. An indirect heating boiler, although it heats through gas, does so indirectly, and therefore does not require separate projects;

- instantaneous electric water heater is not the most economical heating method, and water can only be supplied to a limited number of points;

- in many cases, an electric storage water heater is a real alternative to an indirect heating boiler , but its energy consumption is high;

- A double-circuit boiler simultaneously heats the room and a certain amount of water. But compared to a double-circuit boiler, an indirect heating boiler provides heating of a much larger amount of water - 200, 300 or more liters. And if you consider that many models are combined and have additional heating elements, then they replace 2 units at once - an indirect heating boiler and an electric storage water heater.

It is up to you to decide whether you need an indirect boiler or some other water heater. If you look at the advantages and features of this method of heating water, we can definitely recommend an indirect heating boiler for large private houses. In winter, hot water will be an additional bonus from the operation of the boiler, and in summer you can turn on heating from a heating element or other additional source.

Pros and cons of a double-circuit boiler

A dual-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from additional costs that may be associated with the purchase of a boiler. Also among the undeniable advantages is the external attractiveness of dual-circuit heating devices. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have high efficiency, which can significantly reduce utility costs. Double-circuit boilers allow you to ideally adjust the temperature inside the room, as well as regulate the temperature of the water in the DHW pipeline.

These heating devices are not without several disadvantages, the list of which includes:

Comparison factors

Each type of device has its own disadvantages and advantages. All of them directly depend on the conditions in which they are planned to be used.

Although, if you look at this situation from the other side, such equipment becomes the only source of hot water if the house does not have a centralized gas supply.

As you can see, both devices have a sufficient number of advantages and disadvantages, both in operation and in maintenance. The obvious disadvantage of the boiler is its size. An undoubted advantage is that its installation is possible on any surface of the house where there are water pipes and an electrical outlet. A wide range of storage tanks, presented in retail chains, allows you to choose the optimal shape for your home (there are round and flat boilers) and size. The correct shape of the device will ensure optimization of the internal space of the room. It is important to remember that this storage tank should be located at a level that will not complicate the process of cleaning the tank and replacing the magnesium anode.

According to safety requirements, it is recommended to place the gas heater in the kitchen. To use this heater safely, it is necessary to have a good ventilation system.

Another mandatory safety requirement is the presence of a chimney. Using the column requires the presence of an open flame. This leads to oxygen burning. To eliminate negative consequences, regular ventilation of the room is necessary.