Home / Heating

Back

Published: 08/04/2019

Reading time: 5 min

0

12067

In autonomous hot water systems, for multi-level facilities, the wiring has an increased length, which affects not only the period of hot water supply, but also the excessive consumption of water and energy resources due to the fact that they have to be discharged into the sewer until water of the required quality comes out of the tap. .

Such actions are simply unacceptable today, when the whole world is fighting to preserve water resources on the planet. Simple calculations show that a family with four people per year can “drain” up to 14 thousand liters of water. This problem worries the scientific potential of the EU, so they are everywhere reconstructing DHW circuits with piping an indirect heating boiler with recirculation (BKNSR).

In this area, advanced, innovative technologies are being implemented in the hot water supply system in Russia.

- 1 Recycling principle

- 2 Power calculation and equipment selection

- 3 Drazice indirect heating boiler

- 4 Piping diagram for an indirect heating boiler with recirculation

- 5 Installation tips

Pipelines for the DHW recirculation system

It is worth keeping in mind that DHW recirculation will require significantly more money to be spent on its installation.

In addition to the cost of the plumbing circuit, it is additionally required to provide thermal insulation of the pipes in order to keep heat leakage within normal limits. The pipeline layout itself is quite simple. One part of it, supplying water to water collection points, is sequentially mounted in a continuous line from the thermal unit to each point. However, the pipeline does not end at the last water withdrawal point, but returns back to the heating unit.

Before installation begins, each pipeline segment is placed in a belt insulation made of foamed polyethylene or rubber. Rubber is more suitable for those sections of pipes that will subsequently be walled up. Not only the pipes themselves are insulated, but also the fittings, and all joints in the heat-insulating material must be sealed with metallized tape.

General principles

The procedure for piping a boiler means connecting it to the heating system and the water supply line. The productivity of the water heating system directly depends on the quality of the work.

That is why the installation of a boiler should not be carried out using arbitrary technology, but in compliance with the following mandatory principles:

- Water supply is through a pipe in the lower zone of the boiler.

- Hot water must be drawn in through a pipe at the top of the equipment.

- The recirculation point should be in the center of the boiler.

- The coolant enters the boiler tank from top to bottom - through a pipe in the upper zone. And to exit, that is, return to the system, through the lower zone.

Boiler design

If all four principles are followed, the water dispensed in the upper zone of the boiler will always be hot, which will allow you to achieve maximum equipment efficiency.

Let's look at the specifics of different strapping methods.

Hot water recirculation

Recirculating hot water will allow you to quickly get enough hot water. If you install a water heating boiler in your home, be sure to wire it up.

There are special diagrams that demonstrate how hot water is recirculated in the house

Thanks to recirculation, a pipeline is created through which water constantly flows and at the same time constantly heats up without having time to cool down. Because of this system, you will be able to get water as soon as you open the tap.

To make such a system, you need to install a recirculation pump. In this case, the flow of hot water must be directed in such a way that it constantly passes through structures that require heat. By fulfilling this condition, you will get maximum boiler efficiency.

Installation diagram with two pumps

Another common scheme for connecting an indirect heating boiler is using two pumps. In this scheme, two separate, parallel to each other, circuits are configured: heating and the boiler itself - each of them is equipped with its own recirculation pump.

Priority in this system is given to the boiler circuit, so the boiler system pump is mounted in front of the heating pump. A mandatory component of the circuit is a check valve, which prevents the two water flows from mixing and ensures the correct distribution of liquids along the circuits. Also, it cannot do without the already familiar temperature sensor, which sends signals to the valve, thereby controlling the operation of the pumps.

Installation diagram with two pumps

The piping scheme for a boiler device with two pumps is best suited for systems with two separate heating boilers. Each of them must have independent power and provide heating of the liquid in separate circuits: one boiler must be responsible for general heating of the home, and the second for heating boiler water for domestic use. In this case, the circuit functions as follows: when the water in the boiler tank cools to the lower level, the coolant flow is switched to heat it, and after reaching the programmed temperature it returns to the main heating circuit.

This type of piping is valued due to the rapid heating of water: due to the speed of operation of the equipment, when switching heating to the boiler circuit, the coolant in the main heating system will not have time to cool down.

DHW recirculation

Living in city apartments, we are accustomed to the fact that when we open a hot water tap, hot water begins to flow almost immediately. In most country houses this happens differently. Having opened the hot water tap, you have to wait for some time until hot water starts flowing from the tap, and the further the water tap is from the boiler, the longer this time. This happens because the water supply system of the house is not equipped with DHW recirculation. We’ll talk about how DHW recirculation works and whether it’s worth doing in this article.

DHW recirculation is the movement of hot water in a closed circuit, with the possibility of its selection. Thanks to this water supply scheme, there is always hot water in the DHW circuit and when opening the tap, the user receives hot water almost immediately.

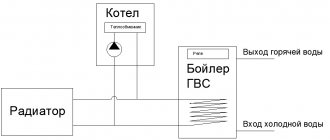

What happens when the boiler is running?

The way it works is incredibly simple. Cold liquid enters the tank through the inlet, the coolant circulates along the coil or between the walls of the tanks, depending on the design of the unit, and brings the liquid to the desired temperature, and then maintains it in this state. The coolant is heated by heating equipment.

Boiler operation diagram

In addition, the design provides input and output pipes that provide supply to a gas or other boiler and directly to points of consumption. The thermostat controls the temperature of the coolant. As soon as it drops below normal, this device gives appropriate signals.

It is worth noting that if the flow rate does not exceed 1.3 l/min, then the installation of such a water heater and a single-circuit boiler is irrational. In this case, preference should be given to dual-circuit heating equipment. There is also no point in giving preference to this system if you use electric heating equipment that runs on energy from a diesel generator.

Expansion tank for an indirect heating boiler: how to choose a design

In order to correctly install an indirect heating boiler in your home, the most important point is to correctly determine its volume. It depends on the intended purposes of using hot water, the number of people who will use this water supply and the type of premises.

Try to correctly calculate the amount of water consumed at a time. This will tell you exactly how much liquid will be needed for your needs. Then multiply this figure by the number of times you use hot water per day. You will get the desired result.

The approximate consumption of water for domestic needs at one time can be presented in the following form:

- Hand washing – 3-4 liters;

- Taking a shower – 30-50 liters;

- Sink in the bathroom – 10-15 liters;

- Bathtub – 130-150 liters;

- Washing dishes – 16-25 liters.

Be sure to add 15 - 20% of the resulting volume to the result you get, so that the boiler is not empty

When purchasing a GSV boiler, it is also important to choose the right material for making the tank. The best option for this is a stainless steel tank.

Based on performance characteristics, an enameled tank can also be used. It has high durability and low reactivity.

Useful qualities

The volume of the device can vary from 30 to 1500 liters, it depends on its purpose. Units with a volume of up to 200 liters are available as wall-mounted units, larger units – as floor-mounted units. As a rule, a 200-liter boiler is enough to satisfy the hot water needs of one family. The efficiency of this device is high and is about 90%.

Modern models are equipped with additional electrical elements, heating elements, or have the ability to connect them. This allows you to use them as an additional source of water heating and turn off the boiler in hot months, which significantly increases the service life of the boiler.

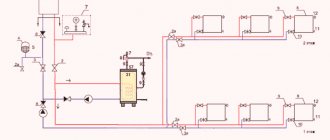

Piping an indirect heating boiler with recirculation

Piping for various types of indirect heating boilers with recirculation is made in accordance with the drawing

When choosing components, it is important to take into account the features of the home heating system

For piping the water circuit to the boiler, the following 3 installation systems can be used:

- Installation of three-way valves.

- Installation of a double circulation pump.

- Adjustment using hydraulic arrows.

The use of liquid recirculation systems significantly increases the performance of heating systems and by increasing the efficiency when heating liquids and rooms from boilers.

When installing indirect winding systems with three-way valves, it is worth considering that this method is intended for tanks with increased displacement. When developing such a system, it is calculated how the installation of a double-circuit type of heating will be carried out.

Connecting the boiler to boiler equipment

Monitoring water temperature information is very important. In a situation where the water in the boiler tanks has a set heating temperature much higher than in the heating circuits of the heating systems themselves, this can lead to the incorrect functioning of all equipment.

This will cause the switch to heating the heating circuits to fail. There are also options for installing indirect heating boilers using two circuits. The selection of the required option will also depend on the water in the plumbing system. In a situation where the liquid in the main channel is of a high degree of rigidity, it is better to use installation of systems with three-way valves, since dual-circuit systems can quickly break down due to blockages.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and the heating system in the house. It is necessary to choose the right installation location, focusing on the location of the boiler, pump insertion and existing wiring. Let's try to figure out what needs to be taken into account when installing heating equipment.

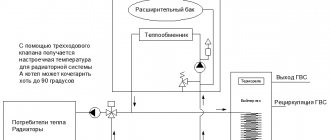

#1: Trim method with three-way valve

This is one of the most popular schemes, since when it is used, there is a parallel connection of the heating system and the BKN, equipped with shut-off valves. The boiler must be installed near the boiler, a circulation pump must be installed in the supply, then a three-way valve. This scheme is successfully used if several heating devices are used, for example, two different boilers.

A three-way valve is a kind of switch that is controlled by a thermal relay. When the temperature drops, the automation is activated, and the coolant flow from the heating circuit is redirected to the BKN (+)

Essentially, this is a priority system that ensures rapid heating of water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, the three-way valve is activated again and returns the coolant to its previous direction - to the heating system. This piping method is useful for those who use the boiler constantly.

#2: Option with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, use a circuit with two circulation pumps. The first is installed on the supply pipe, directly in front of the BKN, the second - on the heating circuit.

The circulation pump is powered through a thermal relay, so it starts to operate only when the temperature drops below the required one. Heating accelerates when forced circulation is turned on (+)

There is no three-way valve in this scheme; the piping is equipped using simple connecting tees.

#3: Piping with hydraulic boom

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example is the heating system in a two-story house, where, in addition to a multi-circuit radiator network, heated floors are used.

A hydraulic distributor (hydraulic arrow) is necessary to simplify the layout of the heating system and avoid installing recirculation pumps on each heating branch (+)

The water gun equipment allows you to avoid thermal shock, since the water pressure in each circuit will be the same. It is quite difficult to make the piping according to this scheme yourself, so it is better to turn to professional installers.

#4: Using coolant recirculation

Recirculation is useful when there is a circuit that requires a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

The use of recirculation has one big advantage - you don’t need to wait for the water to heat up to the desired temperature, it will always be hot (+)

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is mixing water in the boiler. Typically, hot water is located in the upper part, and from there it flows to the water supply points, where it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made connections for connecting a heated towel rail. But it’s cheaper to buy a regular tank using tees for connection.

#5: System for working with a non-volatile boiler

A distinctive feature of this scheme is the installation of the boiler at a higher level than the boiler and heating appliances. Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

Floor-standing models specifically within this scheme are inferior to wall-mounted ones in heating speed and quality. The water temperature is much lower (about the same as in the return pipeline), therefore, the supply of hot water is less (+)

The non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Boiler recirculation diagram

Recirculation of water in the DHW system is necessary in order to provide hot water to any point in the system without additional spillage. To do this, a circuit is installed through which water from the boiler passes throughout the entire system, and then returns back to the boiler. Recirculation is carried out using a small pump that operates completely silently. This system helps maintain a stable temperature of hot water anywhere in the house.

Among the common recycling schemes, there are several main options:

- Installation of a three-way or servo-motorized valve. This method is used for wall-mounted and floor-mounted boiler models. Two pipes (two circuits) are connected to the boiler. One circuit is intended for heating, the other for hot water. The water heater in this system acts as the main coolant. When the water temperature drops, a servo-driven or three-way valve is used, which begins to work to heat the water. The heating is turned off at this time. After heating the water to the desired temperature, heating is resumed;

- Installation of two circulation pumps in one system. With this scheme, one of the pumps is designed to recirculate hot water through the heating system, and the other - through the boiler circuit. This system initially ensures normal water temperature in the boiler, and then in the heating system. A feature of this scheme is the presence of a thermostat and a mode switch, which allows you to turn off, if necessary, one of the systems;

- Application of a hydraulic arrow. It is used if there are more than two circuits in the house (heating, hot water, heated floor). This scheme is aimed at heating water, due to which all circuits are heated. This system has a significant drawback - when analyzing water. The coolant may not be able to meet the needs of all people at the same time.

The choice of method of heating water and heating, as well as methods of its recirculation through the boiler, must be carried out in accordance with clear calculations of all consumers and the power of the coolant. Among the main schemes, boilers with three-way or servo-actuated valves have an advantage.

How does a boiler work in tandem with a non-volatile boiler?

If a non-volatile boiler is used as a heating source, in order for the hot water supply to be a priority, the boiler must be located above the radiators. This is easy to do if the model is wall-mounted. The best position is when the bottom of the hot water tank is higher than the heating boiler and radiators.

In a floor-standing model, the water will heat up, but it will take much longer. In addition, the water at the bottom of the tank will remain unheated. Its temperature will not exceed the return heating level in the heating system. With this scheme, the coolant flows by gravity, with gravity acting as the driving force. There is an installation method in which a circulation pump is connected to the boiler. But this is not a solution, because if there is no electricity, the water will not heat up. Experts have developed several schemes tailored to gravity heating systems.

The trick is that the diameter of the pipe intended for the water heater circuit is taken one step larger than the diameter of the heating pipe. According to the laws of physics, the coolant will “choose” a pipe with a large diameter, that is, the boiler will be a priority.

In another method, a thermostatic head with a built-in sensor, powered by batteries, is installed in the heating system. Everything is very simple: using the thermohead regulator, you set the desired level of water heating. While the water is cold, the thermostat opens the way for water to enter the boiler. As soon as the water warms up, the coolant is directed to the heating circuit.

Installation process

Installation of a recirculation piping is one of the stages of assembling a hot water supply and heating line. Usually, it is carried out simultaneously with the installation of the boiler, assembly of the heating circuit and other work.

It is recommended that assembly be entrusted to experienced personnel who have the necessary skills and training. However, sometimes home owners assemble the system themselves.

Tools and materials

To assemble the recirculation loop you will need:

- a welding machine of one design or another (depending on the type of water pipes);

- device for cutting pipes (grinder, electric saw, jigsaw);

- a set of plumbing windings, Unipack type thread paste;

- set of fittings, adapters, fasteners.

In addition, you will need tools to install load-bearing elements:

- hammer drill with drills;

- impact electric drill, etc.

Necessary equipment

To install the line you will need the following devices:

- pipes and fittings (different types are used, from copper to metal-plastic);

- circulation pump;

- shut-off valves (valves or ball valves, three-way valves, check valves, etc.).

The circulation pump should be low-power. It is only needed to create a slight pressure to move the flow. Models that are installed in a heating system cannot be used.

The choice of pipelines is dictated by operating conditions and personal preferences of the owner. For example, to install copper (brass) pipes you will need to solder connections, which requires a torch, solder and an experienced craftsman.

You can use compression fittings in combination with polyethylene or metal-plastic pipes. This does not require the use of complex equipment, but is only suitable for DHW systems with low operating pressure.

Algorithm of installation actions

The circulation loop is assembled in stages:

- marking walls or other load-bearing surfaces in accordance with the developed scheme;

- installation of load-bearing elements (brackets, clips, clamps);

- cutting pipes along the length of routing sections;

- serial line connection, connection of fittings and adapters;

- connection of mixing units, circulation pump, shut-off valves;

- connecting the return line to the boiler.

When assembling complex lines, some deviations from the given scheme of work are possible. As a rule, additional elements are added or control devices are connected.

Common installation mistakes

During installation or during the commissioning process, you should try to avoid a number of mistakes:

- The boiler and boiler are installed far from each other. Their installation should not only be done as close to each other as possible. But, to simplify installation, the pipes are positioned correctly.

- Incorrect connection of the pipeline with the coolant.

- Incorrect installation of the circulation pump.

Proper installation, adjustment and configuration guarantee a stable hot water supply and allow all systems and devices to operate normally. This will prevent wear of parts and save on premature repairs.

DHW recirculation. A simple solution to the problem

This article will describe a fairly simple technology for solving a common problem - hot water recirculation, or rather, the lack of hot water when you need it. If you live in a compact house and the water heater is located near water consumption points, you are not familiar with this inconvenience. If you live in a large house and the boiler is in the basement, 15 or more meters of water supply may stretch to the last consumer. Owners of large homes are familiar with long waits: they turn on the tap and wait two whole minutes for hot water to flow. This wastes energy and water resources.

As a rule, a series water supply connection is used. The main pipe extends from the heater to the farthest point. Consumers are connected from it using tees - a sink, a bathtub. The disadvantages are obvious - pressure drops if several taps are open at the same time, waiting for hot water. Another option is a balanced system using a collector, where each endpoint is served by a dedicated line from the collector. The price is several times higher than in the first case.

Water intake when the supply is turned off

Most storage water heaters are closed-type and do not drain water by gravity. However, there are a number of piping additions that make it possible to draw water in the absence of pressure. These same additions make it easier to empty the tank if it is removed for maintenance.

First of all, the theory: the hot pipe of the tank reaches the very top of the container, the cold pipe is located below under the diffuser cap. The water is drained through the cold pipe, and air is sucked into the container through the long hot outlet pipe.

Storage water heater design: 1 - cold water supply; 2 - heating element; 3 - tank; 4 — hot water intake; 5 - thermal insulation; 6 - body

The simplest solution is to cut a tee into the hot outlet to the location where the ball valve is installed. Using these two taps, you can provide air to the tank and use hot water from the “cold” pipeline. But this approach is not entirely safe: if you forget to turn off the air intake valve, you risk flooding your home when pressure appears in the cold water supply system.

The problem is solved in two ways. The first is to install a check valve on the air suction valve at the hot inlet. The problem is that there is almost always a small amount of water in the high tube of a filled tank, so the system does not work very stably - the water column prevents the valve from opening even if there is a relative vacuum in the tank. You have to bleed water from the tube manually when you first open the system.

1 - tee; 2 - check valve; 3 - valve for air intake

It is also possible to install a check valve bypassing the cold supply shut-off valve. In this case, the valve is installed opposite the normal flow of water, blocking its flow into the tank when pressure is applied. As before, this task can be solved with even fewer three-way valves.

Operation and mode of operation

After assembly and performance testing, the recirculation system is put into operation. It works continuously.

Some users, trying to save energy and equipment life, turn off the system at night or during a long absence.

This is a completely effective solution, but you will have to get up early in the morning to start the movement of water and raise its temperature. However, you can spend a little money and install a control unit. It will automatically stop the circulation and restart it according to the set program.

In private

For a private home, continuous circulation operation is recommended

This is especially important if the house uses an independent sewer system

Discharging excess water will require frequent pumping of the receiving tank, which will require extra costs and add to your worries.

In a multi-story

DHW recirculation in multi-storey buildings works automatically, without the participation of residents. The system is configured in such a way that all controls are located in the basement (in the boiler room) and do not require outside intervention.

All maintenance, repairs and other work are carried out by employees of the management company. This is convenient for apartment residents, as it relieves them of worrying about the condition of the equipment.

Connecting several boilers to one system

In regions where there is an unstable supply of gas or electricity, they resort to installing two boilers, for example, solid fuel and gas. Two units can operate according to different schemes:

- Serial connection - a thermal accumulator is installed between the units, into which heated coolant is supplied from the solid fuel boiler. Then it is sent to the system with a gas device, and then distributed to consumers.

- Parallel connection - in this case, the operation of the solid fuel unit is controlled by safety sensors. A three-way valve is also installed, with which you can turn off any of the units.

Multi-circuit heating systems are equipped with hydraulic distributors that compensate for pressure differences and balance coolant flows. Sometimes it is possible to organize a system without hydraulics, then the pressure is regulated by balancing valves.

How to do it yourself?

The piping of the boiler of a private house is done in each case according to its own scheme. The reason for this is the large number of projects, different configurations and layouts of houses. In addition, the choice depends on the design of the boiler, its features and volume.

Before starting work, you should draw up a wiring diagram and mark on it the installation points of all consumer devices, pumping equipment and other elements.

Typically two options are used:

- through an indirect heating boiler;

- through a storage boiler.

Let's consider both options in detail.

Through an indirect heating boiler

An indirect heating boiler is a container with a coil installed inside it. It is connected to the heating boiler, and the coolant circulates in a closed loop without mixing with hot domestic water.

This boiler is equipped with five pipes:

- a straight pipe running from the boiler to the coil;

- return pipe through which the return from the coil enters the boiler;

- cold water make-up pipeline;

- straight pipe (supply) of hot water to water collection points;

- return pipe leading to the boiler.

The circulation pump is installed in the return pipeline. This is done to create normal operation of the device and prevent overheating of parts.

The diagram shows a heated towel rail that always remains hot thanks to recirculation. This allows you to ensure a dry and warm microclimate in the bath, eliminating the appearance of dampness or mold.

Through a storage boiler

A storage boiler is a regular container with thermally insulated walls into which hot water flows from the boiler.

The reservoir contains a working volume of hot water sufficient for the household needs of the family. Typically its capacity ranges from 100 to 1000 liters, depending on the number of residents of the house and their needs.

The recirculation connection diagram to the storage boiler is a loop, where T3 is the supply, T4 is the return line.

It enters the make-up pipeline B1, and the entry point is located after the shut-off valve assembly with a check valve. A circular pump is also installed on the return line, along with shut-off and control elements.

The peculiarity of this scheme is that the temperature of H2O in the boiler and the make-up line are different. This is achieved by setting up a mixing unit that connects hot water from the make-up pipe to the cooled return pipe.

In this case, it is necessary to take into account the possibility of mixing layers of water in the container. If the water is made up with water that is not too hot, the temperature in the boiler will be noticeably lower than the standard value.

The specificity of the operation of storage boilers is such that water is heated only by replenishing it during disassembly.

Over a long period of time, a simple drop in temperature is inevitable, and recirculation becomes useless. Therefore, the use of storage tanks is recommended for houses with high and constant consumption of hot water.

What it is?

Recirculation is a heating circuit piping system , as well as a hot water supply line, designed for constant movement of coolant or hot water.

It is designed to increase the efficiency of boilers, as well as to increase the comfort of residents when using hot water.

For example, if the hot water supply tap is located remotely from the boiler, the water in the pipes quickly cools down.

You have to let it pass for a long time until the temperature rises to the desired value. If recirculation is used, water constantly moves from the boiler to the water collection point and back. It does not cool down, which makes it possible to use hot water immediately, without waiting.

In heating systems, circulation ensures optimal thermal conditions. A hot coolant enters the heating circuit, which passes through a cascade of radiators and releases its thermal energy.

Returning to the boiler, the cooled coolant heats up again and enters the heating circuit for a new cycle. The efficiency of heating and uniform heat transfer at the beginning and end points of the circuit depend on the speed of water movement.

In a private house

Recirculation of hot water in a private home is carried out by piping a boiler or, less commonly, a heating boiler.

There are single- and double-circuit models that can only prepare coolant for heating, or simultaneously supply coolant and hot water for domestic needs. In addition, there are volatile and non-volatile boiler models.

The former are capable of operating without being connected to a power supply and only require a fuel supply. The latter need to be connected to the power supply network. They are equipped with their own circulation pumps that ensure the movement of coolant through the heating circuit.

As a rule, the boiler itself provides coolant circulation. To recirculate hot water, use an additional piping equipped with a circulation pump.

It is connected to the boiler, carried to the most distant consumption device, and returned back to the boiler. There is additional energy consumption to power the pump, but there is a noticeable saving of water, and the convenience of using hot water increases.

In a multi-storey building

Modern hot water supply schemes use a boiler system , in which network hot water is not supplied to apartments. Water is heated indirectly in a boiler, from which hot water is supplied to the heated towel rail and hot water system.

Each apartment in a multi-storey building is one of the sections of the general recycling scheme. Its peculiarity is the vertical movement of water - from the bottom point to the top floor, and back. As a rule, circulation is organized along the line of heated towel rails.

It is powered from the DHW pipeline, so the water in the boiler never cools down and maintains its operating temperature.

Hot water rises up the riser, connects to the heated towel rail pipeline and goes back to the boiler.

However, it is impossible to organize its own circulation for each water supply point (kitchen sink, washbasin or bathtub) , so the water in the outlets from the riser often cools down.

The solution to this problem can be installing your own boiler and installing a recirculation loop. This is an effective measure if the apartment is large and the appliances are located far from the storage tank.

Boiler piping with recirculation

Experts consider an indirect heating boiler to be one of the most economical and efficient water heaters for home and garden use. The source of water heating can be gas, electricity or a heat exchanger. It is the heat exchanger that ensures the cost-effectiveness of using a hot water system with an indirect heating boiler.

The further functioning of the entire system depends on the correct piping of the boiler. The concept of piping can be defined as a feature of the installation and connection of a hot water supply system to a water heating source.

When installing the boiler and the entire recirculation system, you need to:

- Set the recirculation point. It is usually located in the center of the heating container;

- Cold water is supplied to the bottom hole of the boiler;

- The hot water outlet must be installed at the top of the boiler;

- The coolant pipe is connected from above and passes downwards (the water circulation of the heat exchanger will pass along a circuit, the inlet of which will be at the top of the boiler, and the outlet at the bottom).

- The supply of pipes to the energy source must be carried out according to the rules for installing materials, and connected using adapters. Valves and taps.

The piping of the recirculation boiler is carried out with a standard set of materials: taps, PVC pipes, adapters, fittings, pumps. You need to choose only high-quality certified products made from durable materials. The use of corrugated hoses and powder metallurgy material is strictly not recommended.

Connection features

An indirect heating boiler is a storage tank, inside of which one or more tubular heat exchangers are located. The hot coolant from the boiler circulates through the coil and heats water in sufficient volume for domestic and economic needs.

The principle of operation of the water heater is simple; difficulties arise during installation and wiring of heating equipment.

Therefore, it would not be amiss to find out the specifics of connecting a water heating device before starting work:

- The closer the boiler is located to the boiler, the more efficient the heat exchange from the heating system occurs.

- The installation of the water heater must be carried out in accordance with the manufacturer’s recommendations - wall-mounted models are attached to the wall, floor-standing models are installed on the floor.

- The flow of cold water should be supplied through the lower pipe, and the intake of hot water through the upper, then the recirculation point will be in the center of the container itself.

- The pipes for the coolant inlet and outlet should “look” towards the heating device. The movement of hot water or antifreeze along the coil should be from top to bottom.

Compliance with these simple rules guarantees the efficient operation of the boiler-boiler system, the efficiency of the heater will reach its maximum and there will be enough hot water for all consumers.

Circulation of hot water in the boiler

A DHW circulation pump is used to move water from the boiler through the pipes and in the opposite direction; it is prohibited to use a pump for the heating system. The pump is constantly connected to the network and consumes little electricity, about one hundred watts per hour.

The operation of the pump has no effect on the speed at which water flows out of the tap. It only ensures its movement from the boiler and back.

In a system with DHW recirculation, a heated towel rail is connected in series to the pipeline circuit. This connection ensures that the heated towel rail is heated even when the heating system in the room is turned off, but the hot water system is turned on.

Certain models of boilers are equipped with an electric heating element. This is very convenient when the gas is turned off or the boiler is undergoing maintenance, since then this boiler is able to function as a storage electric water heater.

The pipeline supplying cold sanitary water to the boiler system must be connected through a safety group, which must be equipped with:

- Shut-off valve.

- Check valve.

- Safety valve.

- The expansion tank of the hot water supply system, and it must have the required volume.

If in summer there is no need to heat the air dryer, then you should disconnect the circulation pump from the electrical network, and also close the ball valve on the circulation pipeline. When installing a hot water supply system, you need to keep in mind that all plumbing fixtures that consume hot water must be connected to the hot water supply branch, while the heated towel rail and circulation pump are mounted on the return pipeline. If the system is not installed in this way, then when using hot water, the heated towel rail and the air in the room where it is located will heat up.

A system with hot water circulation and a boiler is the most convenient and comfortable for users, but at the same time it costs an order of magnitude more than a simple system.

Did you like the material? Give us a thumbs up and subscribe to our feed! Every day we publish new and interesting materials with our original videos!

Additional water system improvements

To create an additional level of comfort and improve the performance of the water supply system, additional improvements can be made, such as:

- additionally take care of disconnecting the water heater from the system by installing ball valves in case of need for its maintenance, breakdown or simply shutdown to reduce energy costs;

- installation of additional heated towel rails that will be warm all year round;

- carrying out additional thermal insulation of pipes from the water heater to the water supply systems to reduce heat loss;

- installing the water heater as close to the water supply points as possible, otherwise you will have to drain cold water from the taps in order to wait for hot water. In this case, it is necessary to install a recirculation pump for more efficient and economical use of cold water drained from the tap into the hot water supply system to the water heater - to reduce its consumption and economical use, so as not to drain it into the sewer. Calculations indicate water savings per year for a family of 4 people at the level of 15,000 - 000 liters.

The results of these improvements:

- savings (on water, on gas - since the boiler will rarely turn on, on electricity);

- always warm water on taps;

- the service life of the main boiler increases, since the boiler will turn on less often and operate less often, so all components will last much longer.

Selecting a KN boiler

The choice of such a unit as an indirect heating boiler must be approached with all responsibility and, first of all, ask yourself the question: “Will it be convenient to use such a device?” The pros and cons of the unit are described above. In this section, we will note several aspects that you need to know in order to understand whether you need to buy it. They will also help you choose the most suitable KN boiler option.

To what extent will the purchase of such equipment be justified? The fact is that it makes sense to buy such a device if the water flow in the house or room is large enough and is at least 1.5 l/min. For comparison, this is exactly the water consumption observed in large families of 4 or more people.

The presence of such a boiler will certainly increase energy costs if it is connected to an electric boiler.

The volume of the boiler is also an important aspect. So, you need to calculate and take into account the hot water needs for your family. It must be selected taking into account the parameters of the room where it will be installed.

The materials from which the boiler is made also matter. So, those made of stainless steel will allow you to heat the water up to 90 degrees. In enamel, the temperature should be lower. But very heated water can always be diluted with cold water, which means that the efficiency of even a small tank in a boiler that warms up the water very much will be higher

It is also important to choose a boiler that will not rust. The power of the heating boiler itself should also be taken into account.

It should be enough to heat not only the unit, but also the heating system

The power of the heating boiler itself should also be taken into account. It should be enough to heat not only the unit, but also the heating system.

The pump for loading equipment should also be optimal

The operating instructions for the equipment will help you choose which one is suitable - it usually contains all the numbers you need to focus on.

The time for heating water will play a decisive role for many, so this point should also be taken into account. So, on average, it takes about 2 hours to heat 100 liters of water. But some models of tanks heat water faster - for example, a stainless steel tank will heat the same amount of water in 20-30 minutes.

The material for thermal insulation inside the unit can be represented by foam rubber, mineral wool or polyurethane foam. Foam rubber is found in cheaper models.

You can organize a constant uninterrupted supply of hot sanitary water in a private house using an indirect heating boiler

It is also better to buy boilers that have some protection elements - safety valves, thermostats, etc. Don’t be lazy and refuse to fill out the warranty card in the store when purchasing. The boiler is expensive, and it would be a shame to purchase it and find out that the quality of the product is inadequate. And it is difficult to change such equipment without a warranty.

Calculation of the main parameters of the boiler

Before you begin searching for material and directly manufacturing, you will need to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person uses up to 80 liters of water per day. For the calculated value, it is recommended to take 45–50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure in the plumbing system. If the pressure is low, then the use of homemade boilers with a square tank is allowed. If the pressure in the system is high, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can become deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical indirect heating models, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For DIY production, it is best to use a copper pipe with a diameter of 10 mm. This product can be easily bent by hand without using any tools. When using a metal-plastic pipe, it should be taken into account that the heating temperature of the coolant should not be more than 90 °C, otherwise the pipe will be deformed and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L = P / (3.14 ∙d ∙∆T), where:

- L—pipe length (m);

- d—pipe cross-section (m);

- ∆Т – temperature difference between heated and cold water (оC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. Taking this into account, you can calculate the length of the pipe for making the coil.

For example, let’s calculate the material for a coil that will be installed in a boiler with a capacity of 200 liters. The temperature of cold water supplied to the container will be 15 oC, and after heating it is necessary to obtain water with a temperature of 80 oC: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Typically, the coil is positioned so that the distance between the coils and the walls of the tank is at least 10–12 cm. The distance between the coils should not be less than 5 cm. The calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler needs to be equipped with a tubular electric heater, then the power is calculated based on the fact that to quickly heat 50 liters of water, a heating element with a power of at least 1.5 kW is required. In addition, any combi boiler must be equipped with a thermostat.

Schemes for organizing DHW recirculation

The principle diagram of DHW recirculation may differ depending on the equipment used. For example, in the design of some indirect heating boilers, a third outlet is provided for connecting the return recirculation pipe. If your boiler does not have such an outlet, the return flow can be connected through a tee to the cold water supply pipe.

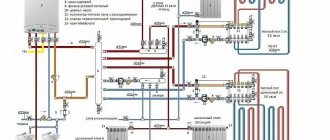

Piping diagram for an indirect heating boiler with DHW recirculation

The figure above shows a wiring diagram for an indirect heating boiler with DHW recirculation, where:

- Heating boiler;

- Boiler safety group with expansion tank;

- DHW system circulation pump;

- Boiler safety group with expansion tank;

- Hot water consumers;

- Heating radiators;

- Indirect heating boiler;

- Boiler circulation pump;

- Check valves;

- Heating system circulation pump;

- Coarse strainer

DHW recirculation scheme with storage boiler

If your dacha has an electric water heater with two outlets, then to organize recirculation, a detachable connection with a union nut and a safety group for boilers are first installed on the cold water supply pipe. A tee is mounted below, on two free branches of which ball valves are installed. One of them is intended for connection to the cold water main, and the other for the return pipe of the recirculation loop.

The figure above shows a DHW recirculation diagram with a storage boiler, where:

- Storage water heater;

- Air suction valve when draining the tank;

- Security Group;

- Check valves;

- Circulation pump;

- Daily timer;

- Hot water consumers

In the above scheme for organizing DHW recirculation, cold water is supplied to the system only when the pressure decreases; in other cases, hot water will circulate in a closed circuit, including the entire volume of the storage boiler. But such a scheme also has its drawbacks, since with such a connection, the boiler will not release 2/3 of its volume at a consistently high temperature, as it should, since when refilling the entire volume of liquid will be cooled evenly.

The nuances of connecting a boiler to pipes made of different materials

Depending on the material used to make the water pipes, the order in which the water heater is inserted will vary slightly. Familiarize yourself with the existing nuances to get the job done as efficiently as possible.

Connection to polypropylene pipes

Connection to polypropylene pipes

If the pipes are not hidden in the wall, there will be no difficulties connecting the boiler. All the work boils down to the fact that you cut the water supply pipes in the right places (depending on the installation height of the tank), solder tees into the prepared holes, and then run pipes from them to the heater. To connect to taps, use regular couplings.

Couplings

You will spend a little more time and effort on connection if the pipes are embedded in the wall. In such a situation, the procedure will look like this:

- pipes are opened;

- insertion is carried out according to the scheme discussed above;

- pipes are removed;

- the pipes close back.

Make the connection using tees and detachable couplings. Wait until the soldered joints have completely hardened, connect the connectors and connect the boiler to the water supply.

Soldering of polypropylene pipes

Connection to metal-plastic pipes

The technology does not allow the installation of metal-plastic pipes in a hidden way, so there will be no special problems with insertion.

Connection to metal-plastic pipes

It is enough to cut the pipes, insert tees and connect the water supply elements to the water heater. This completes the insert.

Connection to steel pipes

The most difficult case. In this case, the tank will be supplied through the kitchen faucet pipes. You need to put a tee on each pipe - this will allow you to connect the boiler and kitchen faucet to one pipe without cutting a thread.

Using a double-circuit gas boiler

When the number of water points in a private house is small and the simultaneous use of exclusively washbasins is expected, then it is best to choose a double-circuit boiler with instantaneous water heating. Such boilers are capable of producing hot water up to twenty liters per minute. This option is the simplest and most economical.

In order to install this hot water supply system, you need to make a pipe connection with cold water and it will be possible to receive hot water at the outlet of the boiler. It is necessary to take into account that over a certain time the hot water will cool down in the pipeline and therefore, in order for hot water to flow from the tap, you will have to wait for some time.

Hot water supply or DHW

In some low-rise buildings, hot water is connected in the same way, standing on a backwater without circulation, this explains the fact that when you open a hot water tap, cold, cooled water flows for some time. If we take the same house with 16 floors, then in such a house the hot water system is arranged differently. Hot water, like cold water, is also supplied to the house through a large pipe, and after the meter it goes into the house mains

which lifts the water into the attic where it is distributed along the risers and goes down to the very bottom into the return line. By the way, hot water meters count not only the volume of lost (consumed) water in the house. These counters also count temperature losses (gigocolors)

Temperature is lost when water passes through apartment heated towel rails, which act as risers.

With this scheme, hot water always circulates. As soon as you open the tap, the hot water is already there. The pressure in such a system is approximately 6-7 kg. on the supply and slightly lower on the return to ensure circulation.

Due to circulation, we get pressure in the riser in the apartment of 5-6 kg. and immediately we see the difference in pressure between cold and hot water, from 2 kg. This is precisely the essence of pressing hot water into cold water when plumbing fixtures malfunction

If you notice that you still have higher pressure on hot water than on cold water, then be sure to install a check valve at the cold water inlet, and at the hot water inlet you can include control valves in the system, which will help equalize the pressure to approximately the same figure as the cold one. Pressure regulator installation example

Boiler installation tips

It is important to install the boiler in accordance with current standards and rules, then the system will work for a long time and without failures. During the installation process, you must follow the following recommendations:

- Ground the boiler.

- To eliminate possible water hammer, a hydraulic accumulator should be provided on the output line.

- Provide for the possibility of connecting the boiler to an outlet if the gas boiler suddenly fails.

- Install shut-off valves on the supply and return lines of the container so that, if necessary, you can disconnect it.

- To heat the water faster, it is recommended to install the boiler as high as possible than the radiators.

- It is better to install it near a gas heating boiler.

The connection diagram of the boiler to the gas boiler is selected depending on the existing conditions and operating features of the system. In this regard, they think through all the nuances in advance and make the right choice. The best option is a system that consumes little gas and is maximally efficient.

Why do you need a booster pump?

A booster pump is used when there is insufficient pressure in the water supply. Nowadays, most booster pumps operate when there is water supply, that is, the pump will work until you turn off the water at the mixer. This is done using a flow switch built into the pump. With the help of such pumps it is possible to pump low-viscosity, non-aggressive liquids without the inclusion of solid particles and engine oil impurities.

Specifications:

- Pressure 2 meters.

- Ambient temperature from 2°C to 40°C.

- The temperature of the pumped liquid is from 2°C to 60°C.

- Maximum system pressure 6 bar.

Installation of a booster pump.

The booster pump is installed using union nuts directly on the pipe through which cold water is supplied. The standard connection size is 0.5 inches. After installing the pump, it is necessary to remove air from it. How to do this is described in detail and with pictures in the instructions, which I strongly advise you to read before doing the installation. Let's look at an example of correct incorrect installation in the figure:

Installation example of the UPA15-90 pump Correct installation of the booster pump

It is also necessary to remember that the pump shaft must be located in a horizontal plane. If this is not done, the bearings will not be lubricated and will quickly fail! Let's look at another drawing and draw conclusions.

Maintenance.

At home, it is limited to cleaning the flow switch. If you don’t want to do this, you can install a mesh filter in front of the pump that will trap sludge. More complex repairs should be carried out at an authorized service center.

Malfunctions

What problems in the operation of the water supply system can the apartment owner eliminate on his own? Here are some of the most typical situations.

Valves leaking

Description: leakage along the stem of screw valves.

A typical leak location is shown by an arrow.

- Reason: partial wear of the oil seal or wear of the rubber O-ring.

- Solution: open the valve knob all the way. In this case, the thread on the rod will tighten the seal from below, and the leak will stop.

Crane noise

Description: when you open a hot or (less often) cold water tap, you hear a loud noise and feel the vibration of the mixer. Alternatively, your neighbors faucet could be the source of the noise.

A noisy neighbor's faucet can become a source of a lot of negative emotions.

Cause: a deformed and crushed gasket on the screw valve in the half-open position causes a continuous series of water hammers. Its valve closes the seat in the mixer body at intervals of a fraction of a second. In hot water, the pressure is usually noticeably higher, so the effect is more pronounced.

Solution:

- Shut off the water to the apartment;

- Turn out the problematic valve housing;

- Replace the gasket with a new one;

- Use scissors to remove the chamfer from the new gasket. The removed chamfer will prevent the valve from beating in a turbulent stream of water in the future.

Replacing the gasket on the screw valve

The photo shows a ceramic crane box

Cold heated towel rail

- Description: The heated towel rail in your bathroom has cooled down and is not heating up.

- Reason: if the water supply scheme of a residential apartment building uses continuous circulation of hot water, the air remaining in the jumper between the risers after water is discharged (for example, for inspection and repair of shut-off valves) is to blame.

- Solution: go up to the top floor and ask your neighbors to bleed the air from the jumper between the DHW risers and heated towel rails.

If for some reason this cannot be done, the problem can be solved from the basement:

- Shut off the DHW riser passing through your apartment, to which your connections are connected;

- Go up to the apartment and open the hot water taps all the way;

- After all the air has come out of the riser through them, close the taps and open the tap on the riser.

If a vent is installed on the riser, it can be diverted directly from the basement

Immediately after the end of the heating season, the difference between the lines of the route may be zero

All-season operation of heated towel rails.

In order for heated towel rails to be constantly hot, they must be included in the recirculation system. Consistently, one after another. This will not lead to a significant increase in the hydraulic resistance of the route or any noticeable cooling of hot water at consumers. Simplified, it looks like this: Since there are a great variety of heated towel rails, I will not describe how to connect a heated towel rail. I can suggest that while they are not installed, before finishing, you can install jumpers made of pipes instead of them. The connection diagram for heated towel rails shown in the figure allows you not to worry about the accumulation of air in the upper part of them. Air will be expelled through the hot water taps when any of them are opened.

Types and model varieties of equipment

The most common type of device is a storage tank, inside of which steel or brass pipes (coil) with circulating coolant are placed.

The rate of heating of water depends on the number of turns on its spiral. The operating principle of this design of an indirect heating boiler is extremely simple: cold water enters the tank, and the coolant, moving along the coil, warms it up to the desired temperature.

But there are also devices designed according to the “tank-in-tank” scheme, where instead of a spiral pipeline, two containers of different diameters are used.

The system works like this: cold water enters a smaller tank, which is heated by hot coolant circulating between the walls of the tanks.

In such devices, water becomes warm in a matter of minutes - a large heating area allows the equipment to operate effectively in flow mode, guaranteeing an uninterrupted supply of hot flow.

Boilers operating on a “tank in tank” system not only quickly heat water to 90⁰C, but also have a self-cleaning function (+)

A combined BKN for heating water can use energy from several sources at once or be equipped with a built-in heating element.

Types of KN boiler

By location:

- Wall-mounted - usually this is a small device with a displacement of up to 200 liters. It is attached using special brackets to any vertical surface that is strong enough to support the weight of a fully filled tank (plasterboard partitions are definitely not suitable). It can be located high enough and not occupy the usable area of the room.

- Floor-standing - a capacious boiler designed for a large number of consumers. True, for a device with a capacity exceeding 1000 liters, it is recommended to allocate a separate room - to equip a boiler room. But such a system is usually installed to serve large cottages, enterprises, hotels and other institutions; for family use, you can get by with a 250-300 liter device.

According to the shape of the tank:

- Horizontal - takes up a lot of space, but it is easier to independently maintain the desired water level without resorting to connecting pumps.

- Vertical - saves free space, but is very limited in capacity.

Depending on the nuances of use, layout features and availability of free space, you can choose the optimal BKN model that will organically fit into the design of the room and provide your home with an uninterrupted supply of hot water.