Liquid fuel boilers using diesel fuel occupy about 20% of the market. With a reliable power supply and regular maintenance, they are extremely reliable and durable. Diesel boilers, on average, have a higher efficiency than gas or solid fuel boilers - 90-96%, they do not require costly organization of a gas pipeline and paperwork, large rooms for storing fuel, and after startup they are completely autonomous.

However, the high cost of diesel fuel causes high operating costs: higher than gas and even solid fuel boilers, but cheaper than electric boilers. High operating costs can often be offset by purchasing diesel fuel at wholesale prices or from local friends.

What are diesel heating boilers?

Why are they needed and how are they used?

Diesel Kiturami Turbo and plastic fuel storage tank.

Diesel is supplied using a fuel pump. The main reasons for choosing diesel fuel boilers are:

- absence of a gas main in the place of residence;

- lack of desire for constant heating with wood or coal, increased care and cleaning of heating equipment, organization of storage of large volumes of solid fuel;

- availability of free access to diesel fuel or the opportunity to purchase it at a favorable price (from agricultural enterprises, tractor drivers, KAMAZ or bus drivers);

- small heated area, ranging from 40-100 m2.

Even if there is a gas main in a residential area, the cost of connecting to it (permit, design, materials, etc.) is quite high. At the same time, the initial costs of organizing heating with a diesel boiler are minimal: no permit is required, only a tank for storing diesel fuel is needed (up to 0.8 m3 can be stored directly in the boiler room; when heating 100 sq. m., this volume is enough for almost the entire heating season).

Design and principle of operation

The design of diesel boilers using the Viessmann Vitorond 200 as an example.

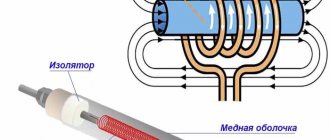

Diesel heating boilers differ from gas boilers only in the burner: it is equipped with a turbocharger, which provides the necessary pressure and sprays fuel throughout the combustion chamber.

Also, diesel fuel requires preheating before spraying; special nozzles are used for spraying. This burner design implies a constant supply of power, so boilers running on diesel fuel cannot be energy independent. In domestic conditions with a high probability of power supply interruptions, it is recommended to additionally purchase a diesel generator.

Due to the differences only in the design of the burner, universal gas-diesel models are common, in which the conversion from gas to diesel and back is carried out by simply changing the burner. Models with a replaceable burner are justified for the temporary use of diesel fuel, when in the future it is planned to connect to the gas mains or when there is free, but not constant access to diesel fuel.

Otherwise, the operating principle of household diesel boilers is standard:

- The fuel sprayed by the burner nozzles is ignited and burned.

- The walls of the combustion chamber are a heat exchanger, inside of which there is a coolant.

- The heat exchanger transfers thermal energy to the coolant, which naturally or forcedly (using a circulation pump) circulates through the heating system.

Specifics of operation

The burners of diesel heating boilers operate quite noisily; even with the combustion chamber closed, they fill the space with the smell of diesel fuel, so for the operation of the boiler unit it is necessary to allocate a separate boiler room. The requirements for the premises are the same as when installing a gas boiler, i.e. in accordance with SNiP 42-01 and MDS 41.2-2000, namely:

- ceiling height – at least 2.5 m for a room area of more than 4 m2;

- the presence of an openable window with an area of 0.03 m2 per cubic meter. meter of room volume + structures with a fire resistance limit of at least REI 45, protecting the boiler room from neighboring ones;

- There should be a free space of 1 meter in front of the boiler;

- doors with a width of at least 80 cm and a bottom gap of at least 2 cm;

- supply ventilation at the rate of at least 8 cm2 for each kW of boiler power, from neighboring rooms - at least 30 cm2/kW.

- The boiler is connected to the electrical network using a separate three-wire cable (as a rule, included in the kit), through a separate RCD (the rating of which is always indicated in the boiler passport).

- the presence in the boiler room of a separate grounding bus, to which the boiler body is subsequently connected. In general, grounding a diesel boiler is carried out similarly to a gas boiler.

Organization of a boiler room with a fuel storage tank.

A fuel storage tank is also installed in the boiler room. If the volume is more than 0.8 m3, it must be taken outside, but it is worth considering that in this case the choice of diesel models is greatly narrowed: the boiler fuel pump must have the appropriate suction power. Special tanks for storing diesel are used as containers, usually made of strong plastic that is resistant to aggressive liquids and external influences.

For external storage, 2 options are used: a set of plastic tanks connected by a pipeline or an underground plastic/metal tank (like a gas holder).

When storing above ground, it is necessary to insulate the tanks and pipeline, since already at +5°C the viscosity of diesel fuel increases, which complicates its transportation and increases the load on the fuel pump. It is not recommended to place containers in direct sunlight. You can also use frost-resistant diesel fuel, but the cost of using such fuel is simply unjustified.

The most profitable and widespread is the underground storage option, since the layer of earth provides a stable temperature both on hot days and on cold days. In addition, the fire hazard of an underground tank is minimal, and the cost of organization is often cheaper than in the above-ground version.

Most diesel boilers have a closed combustion chamber, so to remove combustion products, an inexpensive coaxial (side) chimney is sufficient, the diameter of which must correspond to the boiler outlet pipe. The only caveat is that the chimney must be positioned at a slight angle to prevent condensate formed in the chimney from flowing back into the boiler.

The formation of condensation is a natural process, the phenomenon is also called the dew point, its value is usually 7-10 degrees lower than the temperature of the exhaust gases (for example, at a smoke temperature of 85°C, the dew point is 78°C). Therefore, during cooling, condensation forms in the outer part of the chimney, which is dangerous for the metal components of the boiler.

In addition to placing the chimney at an angle of 2-3 degrees, the formation can be prevented by insulating the outer part of the chimney. The formation of condensate is characteristic only of convection models; in condensing boilers, the temperature of the exhaust gases practically corresponds to atmospheric temperature.

How to choose a room thermostat and save up to 30% per month on heating

Fuel capacity

The choice of a container for storing diesel fuel must be treated as carefully as the choice of a boiler. So what are the requirements for the tank?

Firstly, you need to decide on the storage location of the container. Regardless of whether the tank is located in the boiler room or is located next to the house, one of the main conditions must be met, namely, unimpeded access to the fuel refueling truck. And although the length of the hoses of modern tankers can exceed 30 meters, the experience of the user ar_ca is interesting.

ar_ca user FORUMHOUSE

Since the fuel tanker hose is quite heavy and dirty, if you drag it into the house you need to put something on the bends and thresholds. The diameter of the nozzle of the filling pistol is 50 mm and 1400 liters of diesel fuel were poured into me in less than 10 minutes. In case of a fuel spill, you can fill the area with sawdust.

ar_ca also advises paying attention to the following point. After refueling, approximately 50 liters of diesel fuel remain in the tanker hose, and if you do not want to “gift” it to the driver, then the fuel must be drained into a previously stored container.

Diesel fuel consumption

Specific heat of combustion 1 liter. diesel fuel - 10,300 kcal or 11.9 kW. This means that to obtain 1 kW of thermal energy, it is necessary to burn 0.084 liters. diesel fuel. It is also worth considering the efficiency, which, depending on the model, averages 90-95%, which means that about 5-10% of the thermal energy is not transferred to the coolant.

Total, according to approximate calculations, fuel consumption of a diesel boiler = Boiler power, kW / 10 .

Often the indicators are already indicated in the boiler passport. For example, the well-known budget Kiturami TURBO 13R (13 kW) with an efficiency of 86% consumes 1.97 kg/hour or 2.25 l/hour. However, this is only with continuous operation at full power. In practice, the boiler is active on average only 1/3 of the time, so the result can be safely reduced by 2-3 times.

For example, according to reviews from owners of houses with an area of 100-120 m2, Kiturami TURBO 13R consumes from 5 to 7.5 liters of diesel fuel per day, depending on the degree of insulation of the house, temperature settings and the activity of using hot water.

The principle of operation of the “miracle stove”

The miracle stove is designed to heat rooms for a long time with minimal fuel consumption.

The wood-burning stove is equipped with two chambers. In the first chamber, the smoldering of firewood is ensured under conditions of limited access to oxygen; in the second chamber, secondary combustion occurs. Here the released flammable gas is burned. Thus, the furnace allows you to use the thermal energy released during combustion to the fullest extent. The efficiency level of such a stove reaches 75% (the efficiency of classic potbelly stoves barely reached 15-20%). The pyrolysis process increases the combustion period of wood. Therefore, one load of firewood is enough to operate the stove for 6 hours, and with proper settings – up to 8 hours. Heating of the room is carried out by heating the air against the furnace body.

This model has a number of positive properties

- Capable of working on all types of solid fuel - firewood, wood chips, peat briquettes, wood products;

- Heats the entire room evenly;

- Allows the home owner not to depend on centralized supplies of gas and electricity;

- Provides control over the fuel combustion process;

- Does not require significant costs for system installation;

- You can cook food and heat water on the surface of the stove;

- It is easy to maintain on a daily basis;

- It is characterized by low cost.

Such wood-burning stoves can be used for quick heating and stable heating of country houses, residential buildings, greenhouses, workshops and small businesses.

Date: September 25, 2022

Reviews of boilers running on diesel fuel: advantages and disadvantages

| Advantages | Flaws |

| High autonomy - after startup, the boiler requires absolutely no attention and can operate for weeks, you just need to provide the required amount of fuel | High cost of fuel – when purchased at a gas station or even at wholesale prices by ordering a fuel truck |

| High reliability - diesel engines have one of the longest service lives, on average 10-14 years (with a steel heat exchanger) and more (with copper or cast iron) | All models are exclusively energy-dependent - for the boiler to operate, it is necessary to ensure a continuous power supply |

| High efficiency - on average 90-95%, although budget models still have figures of 85-89% | Increased noise – the noise from the burner is noticeable not only during ignition, but also during operation |

| Availability of fuel in any region of the country | The need for a separate room for the boiler room - not only because of the noise, but also because of the smell |

| A simpler and more cost-effective installation process, no need to obtain permits or project approvals | Almost all models are floor-standing |

| Almost all models are equipped with protection against overheating and freezing, stopping the circulation pump |

Basic faults

A diesel boiler is considered a reliable technology, easy to operate, but with careful handling of the unit, which requires high-quality maintenance and preventive repair work. However, it is not possible to protect the boiler 100% from breakdowns.

The most common causes of malfunctions:

- Using low-quality diesel fuel leads to boiler failure.

- Feeding a boiler with hard water leads to scale formation and rupture of boiler pipes.

- A voltage drop disables the automation and protection system and damages sensors for monitoring environmental parameters.

- Low-quality diesel fuel clogs the nozzle nozzle, worsening fuel atomization, flame separation or a complete stop of fuel supply, creating an emergency fire situation in the boiler room.

- Disruption of coolant circulation due to a breakdown of the circulation pump or disruption of the natural circulation of water in scale-clogged pipes leads to a sharp increase in coolant temperature, steam formation, a sharp rise in pressure and a boiler explosion.

Therefore, it is important for each user not only to choose the right boiler equipment, purchase and install it, but also to carry out regular maintenance with the involvement of specialized specialists.

How to choose a diesel heating boiler for a private home

Convection or condensation

The operating principle of conventional convection and condensing boilers.

The efficiency, and therefore the economy, of a diesel heating boiler depends on the method of using the thermal energy released during the combustion of diesel fuel:

- convection - a standard type of boiler in which the coolant is heated by direct combustion of fuel, part of the heat is lost with combustion products (exhaust gas temperature is about 75-110°C);

- condensing - a modern boiler design that implies the presence of an additional heat exchanger that extracts heat from condensate, which in turn is formed from combustion products leaving the chimney. Thus, it is possible to accumulate almost all the heat obtained during combustion (the temperature of the exhaust gases is on average 35-45°C).

As a result, the efficiency of condensing boilers is 15-20% higher, however, the cost of such models is 1.5-3 times higher: usually from 100 thousand rubles. Therefore, the payback of such technology depends on the volume of fuel burned.

Wall or floor

Due to the larger dimensions of the burner and the greater weight of the boiler unit as a whole, diesel boilers are usually floor-standing. There are also wall-mounted models, for example, the Swedish CTC 950 RU. However, at the moment we do not recommend considering them for purchase: it is difficult to find them on sale, wall-mounted models are 1.5-2 times more expensive than floor-standing analogues, and the service structure is often not so developed even in Moscow and Moscow Region, not to mention the regions .

Single-circuit or double-circuit

A visual principle of operation of double-circuit boilers with priority for hot water supply (DHW).

Single-circuit models are designed exclusively for heating. Double-circuit systems have an additional hot water supply (DHW) circuit and when the tap is opened at the point of consumption, they begin to heat sanitary hot water, which does not mix with technical water in the heating circuit. Of course, the choice depends on the requirements for the boiler.

At first glance, it is better to choose a single-circuit boiler, since the cost of fuel is already high. However, dual-circuit models are still more effective, this is confirmed by the significantly greater demand for them. The cost of a double-circuit boiler in the budget and mid-price category is only 5-15% higher, while to organize hot water supply in a house in another way you will need from 15 to 50 thousand rubles, and the cost of electricity that will be spent on heating is higher than the cost diesel fuel.

Heat exchanger material

The heat exchanger is a key element; not only the efficiency but also the durability of the boiler depends on the material of its manufacture; it is partially impossible to replace it, and a full-fledged element is expensive. So, the heat exchanger can be:

- steel - the simplest, lightest and most inexpensive to manufacture, installed on all budget and some models in the mid-price segment. The steel heat exchanger is thin and most susceptible to corrosion; even with an anti-corrosion coating, it rarely lasts more than 12-14 years. However, a steel heat exchanger is more resistant to temperature changes and mechanical shocks, heats up quickly (but also cools down quickly).

- copper - more expensive to produce, but more thermally conductive and more resistant to corrosion. The service life of copper heat exchangers is up to 15-17 years (or more).

- cast iron is the heaviest and thickest, practically invulnerable to corrosion. Cast iron heat exchangers take a long time to heat up, but also retain heat much longer, their service life is more than 25 years. In addition to heaviness, the disadvantage is vulnerability to temperature changes and mechanical stress; simply put, the alloy is quite fragile (with the exception of expensive gray cast iron alloys).

How to choose a waste oil boiler for heating a private home

Open or closed combustion chamber

The type of combustion chamber determines the environmental friendliness of the boiler, ventilation requirements and the choice of chimney:

- an open combustion chamber is classic and most common among gas and heating oil analogues, but is not always justified for diesel boilers. The air required for fuel combustion in the open combustion chamber is taken from the room through holes in the boiler body, and the exhaust is discharged through a classic vertical chimney. This means that in addition to organizing a more complex chimney, high-quality ventilation of the room is necessary; it is also worth mentioning that soot formation and contamination of a boiler with an open combustion chamber is higher.

- closed combustion chamber - most models are equipped with it. To organize the work, a simpler and more cost-effective coaxial chimney is sufficient. Air intake occurs through the internal chimney pipe, and exhaust through the external one. With this operating principle, the room is less polluted, although the characteristic smell of diesel fuel is still present.

Efficiency

Efficiency factor (efficiency) is the ratio of the volume of fuel consumed to the volume of heat released and accumulated by the coolant, i.e. heating boiler efficiency. If for gas or solid fuel boilers efficiency is not the most important indicator, then for diesel, due to the high cost of each extra liter of fuel, this is a significant selection criterion.

As mentioned earlier, the average is 90-95%. However, there are excellent models from well-known manufacturers Kiturami and Navien with an efficiency of 86-89%. Despite their lower efficiency, they have an extremely low initial cost, are known for reliability and ease of maintenance, have a developed service structure and readily available spare parts.

It makes no sense to consider models with an efficiency lower than 86%, otherwise, due to inefficient energy conversion, the cost of their operation will be comparable to electric boilers.

Minimum required power

For a standard uninsulated house with 2 bricks and a ceiling height of 2.7 m, located in the climatic zone of the Moscow region, the required power is calculated quite simply: 1 kW for every 10 m2 of heated area. We also recommend setting aside a power reserve of 15-20%.

For example, for a house with an area of 150 m2, the minimum required power of a diesel boiler = 150:10*1 * 20% = 18 kW. Please note that it is also undesirable to overdo it with power; the boiler will cycle too often, which will lead to faster wear.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Additional criteria

Having decided on the main criteria, you can pay attention to such features as:

- the presence of heat and sound insulation - an additional layer of thermal insulation reduces heat loss through the boiler body itself and increases efficiency, and sound insulation will eliminate the noisy operation of the burner, which is especially important if there are thin walls between the boiler room and the living room;

- automation functionality - the presence of autodiagnostics, heating modes, the ability to program work for a day or a week in advance, the presence or possibility of connecting an external thermostat, weather-dependent control.

Camper Heating Options

The following sources of thermal energy can be used to heat motorhomes:

- Electricity;

- Solid fuel (firewood, pellets, pressed sawdust, coal);

- Liquid fuel (gasoline, diesel fuel);

- Gas.

Let's briefly consider each of the sources of thermal energy and try to choose the most optimal option for heating the camper.

Camper heating with electricity

Electric camper heating is not even considered as the main source of heating. Electric radiators and underfloor heating systems require connection to a 220 V network and a current power of at least 10 A. This is only possible in equipped parking lots.

When installing solar panels, you don’t have to worry about finding a comfortable campsite, but can use electric heating and any electrical appliances anywhere in the campsite

While on the road, electric heating is out of the question, but in established campsites, electric convector heaters can come in handy to maintain a supply of the main heating source.

Solid fuel for the stove

Basically, firewood is used as solid fuel. The heater is not a full-fledged fuel boiler, but an ordinary potbelly stove.

This heating system is only effective for short trips of 2-3 days.

A wood boiler does an excellent job of heating a camper, but is only suitable for short trips due to the need for a supply of firewood, which takes up a lot of useful space and burns out very quickly

For a long trip you will need a lot of firewood, their placement will reduce the spacious area of the module. And the autonomy of such heating is out of the question, since the firewood burns out very quickly and you constantly need to be distracted by servicing the stove.

An alternative to firewood can be pellets or pressed sawdust, called Eurofirewood. Although they are consumed much more slowly, they will still require a large area to accommodate their supply.

Liquid fuel heaters - gasoline, diesel fuel

Gasoline or diesel fuel can be used as liquid fuel. They are taken directly from the tank. The advantage of such a system is its location.

It is located under the floor of the camper, which allows rational use of the space of the motorhome. During the cold season, such a system can be used to warm up the engine before starting.

Diesel heaters are distinguished by their compactness, do not require additional space and do not reduce the useful volume of the module, but create quite a lot of noise during operation

The disadvantage of liquid fuel heaters is the high noise level during their operation. Even with perfect sealing of the windows and door of the camper, it will not be possible to completely avoid the smell of gasoline or diesel fuel in the room.

In addition, you will have to constantly monitor the fuel level in the tank, since in the cold season its consumption increases significantly. Stopping with an empty tank several tens of kilometers before a gas station is not the best travel option.

Gas-fired camper heaters

The main advantage of gas heaters is their higher efficiency compared to electricity, liquid and solid fuel. In addition, such heaters are characterized by their autonomy.

Modern automation of gas equipment allows you not only to select the operating mode, but also to fully automate the operation of the heating system.

Gas heaters allow you to regulate the heating intensity, and modern automation not only automates the operation of the system, but also ensures its safe operation

Compact standard-sized gas cylinders can provide camper residents with heat and a sufficient supply of hot water for a week, even in the cold season. If necessary, standard cylinders can be replaced with cylinders of larger capacity, thereby increasing the fuel supply by 8-10 times.

Due to their autonomy, comfortable operation and high efficiency, gas heaters for garages and campers are the most popular among most caravanning fans.

Therefore, we will dwell on gas camper heating in more detail, consider the principle of operation of the equipment, installation features, as well as safety measures during their operation.

The best known manufacturers and models: characteristics and prices

Kiturami Turbo 13R

The most common and time-tested Korean double-circuit diesel boiler with a power of 13 kW (there are versions of other powers). Since the boiler is in the budget price category, its heat exchanger is made of steel, although the secondary one (for hot water supply) is copper. Despite the efficiency of 86% and consumption up to 1.97 kg/hour (2.25 l/hour), the model is popular due to its reliability, wide automation functionality and affordable price, one of the lowest on the market.

The main advantage is the factory-installed room thermostat, with which you can more accurately and conveniently regulate the temperature (which also affects efficiency). The automation also has various heating modes, self-diagnosis, overheating protection and a freeze prevention mode.

Navien LST-17KG

Another common Korean double-circuit diesel fuel boiler with a capacity of 17 kW. Equipped with a steel heat exchanger. It has a higher efficiency of 90% and lower consumption - 1.93 kg/hour (2.2 l/hour). The model is still equipped with remote control via a room thermostat. A significant advantage is the ability to program the operation of the boiler, which allows you to significantly reduce fuel consumption, for example, by programming a temperature decrease to 15°C when the owners are away from home (work, rest, travel).

According to reviews from owners and installation practice, for more than 6 years of operation of these models, almost no single malfunction was observed.

De Dietrich EFU 22 (B-Control)

One of the best diesel boilers for heating a private home, especially those with an area of more than 200 m2. This is a French low-temperature single-circuit model with a power of 22 kW. It features a durable cast iron heat exchanger and high efficiency - up to 97.3%. The boiler complies with the highest environmental standards, in practice it operates almost silently (thanks to a heat exchanger with three-way gas removal and sound insulation). It has functional controls, auto-ignition, and the ability to connect an external thermostat (it is not included in the kit). The only disadvantages are the heavy weight (185 kg) and high cost.

Please note that the boiler has an open combustion chamber and an atmospheric burner, and therefore requires natural ventilation through a classic vertical chimney.

Cost : 116,000-135,000 rub.

Ferroli ATLAS 32

A universal Italian single-circuit model with a replaceable burner (diesel - SUN G burner, gas - SUN M) with a power of 32 kW. It is characterized by high reliability and efficiency up to 94.3%, as well as a durable cast-iron heat exchanger. There is protection against overheating and freezing, it is possible to connect an external thermostat. The boiler operates almost silently, but has an open combustion chamber. No obvious deficiencies were identified during installation and operation experience.

Cost : 53,500-61,000 rubles. + Ferroli SUN G burner – 25-29 thousand rubles.

Lamborghini AX 3 32

Another Italian universal single-circuit boiler with a replaceable burner (gas-diesel) with a power of 32 kW. It is practically no different from the previous analogue, it is equipped with the same cast-iron heat exchanger with three-way gas exhaust, is known for its reliability, and has a stylish design. However, it has a lower efficiency of 91.6% and more limited functionality (connecting external control is possible). There is a layer of thermal insulation under the body, and ease of operation and maintenance can also be noted.

Cost : 51-65 thousand rubles + Lamborghini Fire 3 burner – 22,600-27,000 rubles.

Advantages

One of the options for heating private houses is a diesel boiler. The system is attractive for several reasons:

- The equipment is inexpensive. Only boilers with heating elements can be cheaper, and even then not all of them. But only the simplest boilers with a single-stage burner are inexpensive. The cost of more complex models with high-performance simulated burners is already considerable. But such equipment is more economical and has a much longer service life.

- You can install a diesel boiler for your home without approval from the fire inspectorate (this is required, but practically never done, as is the case with solid fuel boilers).

- When installing, it is not necessary to make a full-fledged chimney. The specific design of a diesel fuel boiler is such that combustion products fly away into a low chimney under decent pressure. To remove smoke, it is necessary to lead the sandwich pipe from the boiler into the wall, then raise it a little, and equip the top with a metal umbrella to prevent precipitation from getting inside. That's the whole chimney.

Liquid fuel boilers are domestic and industrial

Modern boilers have automation that monitors the operation of the system. But you can leave such boilers unattended for 8-12 hours. A longer absence is possible with a configured warning system. Modern automation has such an opportunity. In this case, if an emergency occurs (the boiler goes out, etc.), an SMS message about the problem is sent to the specified phone number. This equipment costs a lot. In addition, if you plan to use a diesel boiler for your dacha, be prepared that you will have to visit the site several times during the heating season to start up the stopped system. Quite often, burners become clogged, electricity goes out, or other emergency situations occur that cause the boiler to shut down.

Prices: summary table

| Model | power, kWt | Number of circuits | Efficiency, % | price, rub. |

| Kiturami Turbo 13R | 13 | double-circuit | 86 | 43 000 |

| Navien LST-17KG | 17 | double-circuit | 90 | 40 000 |

| De Dietrich EFU 22 (B-Control) | 22 | single-circuit | 97,3 | 116 000 |

| Ferroli ATLAS 32 | 32 | single-circuit | 94,3 | 63 000 |

| Lamborghini AX 3 32 | 32 | single-circuit | 91,6 | 74 000 |

Installation and connection

The installation process of diesel boilers does not differ from gas or solid fuel analogues and is carried out in accordance with SNiP 41−01−2003 “Heating, ventilation and air conditioning” and SP 7.13130.2009 “Heating, ventilation and air conditioning. Fire safety requirements." Work is carried out at a temperature not lower than +5°C.

The boiler wiring also does not differ from that used when installing analogues; an example of a classic connection diagram to a closed-type system is shown in the photo below.

Connection diagram of a diesel boiler to a closed heating system.

All overall and connecting dimensions, as well as a detailed installation algorithm, are always described in the boiler operating instructions; today, an electronic copy of the instructions for any of the models can be found on the Internet. Please note that installation, adjustment and first start-up must be carried out by a certified specialist who will put the appropriate stamp in the boiler passport: without it, most manufacturers refuse warranty obligations.

Maintenance

A feature of boiler equipment using any fuel is the formation of soot inside the combustion chamber and chimney, the formation of scale inside the heat exchanger, clogging of injectors and fuel filter, all this not only reduces efficiency by 25-30%, but can also lead to more serious malfunctions. Therefore, regular maintenance consists solely of inspection and cleaning; it can be carried out not only by calling specialists, but also by yourself, while the warranty remains valid.

Regularity - at least once every 3-5 years; we recommend cleaning the boiler every 1-2 heating seasons and flushing the heat exchanger every 4 years.

- Cleaning and flushing the heat exchanger. When using hard, untreated water as a coolant, scale and other salt deposits form on the inner walls of the heat exchanger, which reduce its cross-section and thermal conductivity. It can be cleaned mechanically, using a solution of citric or hydrochloric acid, or without removing it from the boiler, using hydrodynamic washing. We have already described the detailed algorithm for cleaning the heat exchanger earlier; it is the same for boilers using any fuel.

Soot and rust inside the cast iron heat exchanger sections. - Cleaning the burner, combustion chamber and external walls of the heat exchanger . During operation, soot forms on these elements, debris and dust from the room are retained; a layer of at least 0.5 cm reduces efficiency by more than 10%. The cleaning process also does not differ from analogues, with the exception of a different burner design (we also described it earlier).

- Cleaning or replacing the fuel filter . The fuel filter is not installed in many models of diesel boilers, but it is an extremely important component, since both the degree of soot formation and the service life of the boiler depend on the quality of fuel purification. And given the quality of domestic diesel fuel, fine and even coarse filters, their regular cleaning or replacement is simply a necessity.

The most common consequences of lack of regular maintenance are:

- Parasitic flame . The logic is to receive a signal from the ionization sensor about combustion before the board sends a signal to open the fuel valve / operate the injectors. To solve the problem, simply clean all burner components. Rarely, the cause may be liquid entering the electronic control board.

- The boiler smokes a lot. The classic consequence of clogged injectors: due to the absence of a fuel filter or during soot formation. In open combustion chambers, clogging can also occur due to dust in the room or repair work. To solve the problem, just remove the burner, carefully clean and blow out the nozzles.

Location of the nozzle in the diesel burner.

Features of the top combustion boiler system

The production of these mechanisms began quite a long time ago, and the very scheme of their operation is extremely simple and consists of the following: the boiler furnace should be filled with fuel (coal, firewood), and then set it on fire only from above. In this case, only the top layer will burn, where, among other things, the air necessary for combustion must also be supplied.

The combustion area is separated from the upper chamber, where the remaining combustion products are burned, by means of a large metal disk, and the ash formed during operation simply disappears thanks to the hot gases in the furnace.