The Lemax Patriot parapet gas boiler has a great advantage over conventional floor-standing boilers with an open combustion chamber because such a boiler does not require the installation of a chimney going into the roof; it already comes with a coaxial pipe with a diameter of 25 cm. The boiler can be installed in a residential area, because The air intake for combustion is taken from the street and combustion products are also discharged to the street thanks to a coaxial chimney. The boiler is equipped with Italian automatic Euro Sit 630, which does not require an electrical connection. The boiler is ignited manually thanks to a piezoelectric element (piezo ignition).

The pipe of such a boiler must go out into the street and not interfere with the movement of people; for this, one of the installation requirements must be met: 1) at the outlet to the pipe from the ground there must be 2 meters or 2) at the outlet the pipe is at a height of 0.5 m from the ground, but in this case is outside the movement zone of people or behind a fence.

In this video, using a clear example, you will see how the Lemax Patriot 10 kW , how it is installed and what the coaxial pipe (chimney) to it looks like.

Parapet, or as they are sometimes called, chimneyless, gas boilers make it possible to organize heating in rooms where the installation of gas heating appliances was not initially planned, and therefore chimneys are not provided.

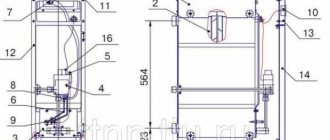

Figure 1. Schematic diagram of a parapet boiler: 1 - boiler; 2 — air duct pipe; 3 — air duct section; 4 - chimney pipe; 5 - chimney section; 6 — protective casing of the gas duct.

This makes parapet-type boilers the only type of boiler available for organizing heating in premises unsuitable for this, for example, in apartments of apartment buildings, garages or country houses.

The modest dimensions of such devices also contribute to their popularity. Another feature of parapet boilers is that they are equipped with a closed combustion chamber, the essence of which is that the combustion chamber of a parapet boiler communicates with the environment exclusively outside the heated room. This eliminates the possibility of natural gas itself or its combustion products entering the premises, which significantly increases the safety of their operation (Fig. 1. Schematic diagram of a parapet boiler.).

Figure 2. Installation diagram of a parapet boiler.

As a rule, parapet-type boilers have a power ranging from 6 to 40 kW. The efficiency of such gas boilers is somewhat lower compared to other types of gas installations, which in practice is almost imperceptible. Parapet gas boilers do not need to be connected to an electricity source. Some of their models have convection openings, which makes it possible not to install radiators in the room where the boiler itself is located (Fig. 2, 3. Appearance of parapet boilers.).

Gas floor-standing boilers Lemax with a steel heat exchanger

This class is represented by five categories, each of which has its own gradation in terms of unit power. Thus, you can select the heating device to suit your needs as accurately as possible. The main thing is that the pressure in the heating system does not exceed 2 atmospheres. Let's look at the categories of heaters with a steel heat exchanger in more detail:

- Lemax premium boilers;

- premium nova;

- patriot;

- gas worker;

- clever.

Lemax premium steel boilers are divided into two groups. The first is from 7.5 to 60 kW, the second is from 70 to 100 kW. The units are made of steel 2 mm thick. For greater efficiency, the heat exchanger is made in the shape of a cylinder, just like Conord boilers.

The inner surface of the heat exchanger is protected with inhibitory compounds, which prevents the deposition of scale and salts.

The heater is non-volatile and equipped with Italian SIT automatic equipment. The smoke temperature in Lemax heating boilers is at least 110 degrees. Maximum water temperature 90 degrees. The unit operates at a nominal gas pressure of 1.3 MPa.

Some improvements have been made to the Lemax heating boiler of the premium nova series. The temperature regulator is now located on the front of the housing, and it is now possible to connect a thermostat and a turbocharger for the chimney. In addition, the heater is equipped with a soft start system. The power of the units in this series ranges from 7.5 to 30 kW.

The peculiarity of the Patriot series boilers is that they have a closed combustion chamber. The unit does not need to be connected to the electrical network and does not require the installation of a full chimney. This is a parapet boiler that takes combustion air from the street through a special pipe (similar to a chimney). At both ends there are outputs for connecting to the heating system. Power varies between 6-20 kW. All models are single-circuit.

According to reviews, infrared quartz heaters for summer cottages are less reliable than carbon ones.

Read this article about how to choose a heater for your room.

The gas worker series is a classic AOGV with a power from 6 to 29 kW. Accordingly, the device is volatile, the combustion chamber is of an open type, the operation is controlled by a thermocouple. Compared to models of other series, the gas line has a slightly lower efficiency (87% versus 90%). The heaters are equipped with draft, gas and water pressure sensors. Available only in single-circuit version.

The clever series heaters have the widest functionality. An indirect heating boiler, indoor and outdoor temperature sensors, a turbocharger for the chimney, and a control unit via the Internet can be connected to the boiler. Thermal power from 20 to 55 kW. Consumes 9 W of electricity per hour.

Gas floor-standing boilers Lemax with cast iron heat exchanger

Heaters of this class can operate in heating systems with a pressure of up to 4 atmospheres. The wall thickness of the heat exchanger is 4 mm, which makes it very durable. Cast iron, unlike steel, is less susceptible to contamination, and its service life is much longer. There are two types of heaters in this category: leader and wise.

In a solid fuel boiler, coal is loaded through the top.

Lemax leader gas boiler, technical characteristics:

- non-volatile;

- power 16-50 kW;

- Efficiency 91%;

- overheat protection;

- traction sensor;

- maximum water temperature 80 degrees;

- nominal gas pressure 1.3 MPa.

The temperature control is located on the front part, with a pressure gauge located nearby. It is possible to connect a room thermostat. Thanks to this, you can set the required temperature in the room, which will be maintained at the same level. If necessary, you can install a fan to improve smoke removal.

Wise series boilers are connected to the electrical network, consumption is 7 W/hour. They can heat the coolant up to 90 degrees. They have an uninterruptible power supply installed, so voltage drops are not a problem for these boilers. The unit has connections for connecting an indirect heating boiler, various types of thermostats, and wireless control units. The option of switching to another type of energy carrier (liquefied gas) is also allowed.

Causes of clogged heating system

The main source of contaminants that disrupt the operation of thermal circuits is the coolant. This is most often tap water. When filling the system, small debris from the water supply can easily get in with it. As the water circulates, this debris is transferred to the radiators, where it accumulates.

Another source of contamination is scale. It is formed in the boiler, where water comes into contact with the hot walls of the heat exchanger. Gradually, the inside of the boiler becomes covered with a layer of scale, which has relatively low thermal conductivity. A heat exchanger coated with scale transfers energy to the coolant much worse. With a thickness of salt deposits of several millimeters, the efficiency of the boiler can decrease by almost a third. During the process of cyclic heating and cooling, the scale crust is destroyed. The exfoliated particles enter the pipeline and are deposited both on the inner walls of the pipes and in the radiators. Accordingly, their heat transfer decreases and there is reason to think about how to flush the heating system in a private house with your own hands.

In addition, due to the oxygen contained in the water, rust gradually forms in the metal elements of the system. Like scale, rust increases the hydraulic resistance of pipes and is an additional source of contamination.

Source

Gas wall-mounted boiler Lemax

The Lemax company produces only one line of prime-v wall heaters. Each device is equipped with SIT automation made in Italy. All models in this series are dual-circuit and can operate in heating systems with a pressure of up to 3 atmospheres.

Chimney of a parapet boiler.

The boilers are equipped with a closed combustion chamber, so they require the installation of a coaxial chimney. A fan is located above the combustion chamber. Turbocharging is needed to pump in air from the street and at the same time remove smoke outside. The maximum length of a coaxial chimney can be up to 5.5 m.

How to flush heating

You can purchase various reagents in the retail chain, offered in 3 types:

The concentrate and powder must be diluted with water, following the manufacturer's instructions. As a rule, before cooking, the water is heated to 40...60 °C. The finished liquid for flushing the heating system is poured into a barrel and disposed of after use.

We will give a number of recommendations on the best way to flush heating pipes:

We do not recommend using various folk remedies for washing, in particular citric acid. Firstly, it is only effective against scale, which is found only in boiler heat exchangers. Secondly, a high concentration of the acid solution is required; with a large amount of water it cannot be achieved.

Solid fuel boiler Lemax

Solid fuel heaters are available in two configurations:

- solid fuel boiler – forward series;

- potbelly stove – series heat house and heat house-S.

According to reviews, the Lemax solid fuel heating boiler is designed to operate on coal. In this case, it is possible to use firewood and even natural gas as an alternative. In the latter case, you need to order a special burner. The peculiarity of this unit is the vertical loading of fuel, the hatch is located on top. Coal can be poured directly from the bucket.

The most economical heaters for an apartment are those that are equipped with good automation and thermostats.

About kerosene heaters for summer cottages is written here.

The TT boiler is available in three capacities (13.17 and 21 kW). Heats water up to 95 degrees, works in autonomous heating systems with pressure up to 0.2 MPa. The efficiency is quite low - only 75-80% for coal and 72-77% for wood.

Potbelly stoves are made from 4 mm steel. They come with a flat top and a basket for stones. The last option is used in doubles. The thermal power of both stoves is 10 kW. Weight 65 and 80 kg. Logs up to 60 cm long can be placed in the firebox. A potbelly stove can only be heated with wood.

Autonomous heating systems based on gas boilers are widespread in European countries.

In our country they are less popular, however, the situation is changing every year. Users are actively switching to heating using imported and domestic heating installations.

The choice of boilers is very wide, which makes it possible to choose the appropriate installation for any conditions or room size.

Let's consider floor-standing gas boilers produced by the domestic company Lemax.

A little about the manufacturer

began its journey in 1992 on the shores of the Azov Sea, or more precisely in Taganrog. Against the background of a sharp change in the political situation and a real economic catastrophe, the founders of the organization managed to concentrate a close-knit group of performers capable of fulfilling any, even the most sophisticated order. As a result of many years of efforts, it was possible to ensure a stable position in the market, and in one of the most advantageous positions.

Lemax boilers are considered one of the best in terms of cost and quality. The company produces single-circuit and double-circuit systems, as well as water heating columns.

Lemax floor-standing gas boilers

The Lemax company was founded in 1992 in Taganrog. Gas boilers produced by this company are assembled from imported components from leading European manufacturers.

Floor-standing boilers are non-volatile, operate on natural draft and do not need to be connected to the power supply, however, they have the ability to connect water heating units and turbo nozzles to create forced draft.

Lemax floor-standing boilers are presented in a large assortment; the model range has samples with a power from 6 to 100 kW, which allows you to heat apartments or large houses.

Why does the device go out?

There may be several reasons for the burner to go out:

- Stopping the gas supply. Turn off the boiler and wait until the supply is restored.

- Unstable or absent voltage in the power supply network (for volatile Lemax boilers).

- Failure or activation of the traction sensor. We need to check whether it is there and whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts have oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive draft. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most common in non-volatile installations, where the stability of the unit’s operation depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of the flame on the burner exploding, which will provoke the supply of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency event, leading to the boiler stopping.

Advantages and disadvantages

The advantages of Lemax floor-standing gas boilers include:

- Simplicity, reliability and durability of the design.

- Non-volatility, increasing stability and reliability of operation.

- Ease of Management.

- Low fuel consumption.

- Relatively low price with high quality components.

- It is possible to only heat the home, or additionally prepare hot water.

There are also disadvantages:

- Ignition of Lemax boilers is quite difficult, especially if you lack the skill.

- Natural cravings are very unstable and depend on many external factors.

Disadvantages are common to all energy-independent models of gas boilers. However, they are many times compensated by undoubted advantages, so it is more correct to consider them design features.

What series and models are floor-standing

The Lemax group of floor-standing boilers includes the following series::

- Patriot . There are 6 models available with a power from 6 to 20 kW, which is optimal for apartments or small private houses. Parapet-type units are equipped with convection openings in the body, allowing the room to be heated. If such a boiler is in the kitchen, radiators will not be needed. A coaxial chimney eliminates the need for labor-intensive connections to a common house pipe.

- Premium . The series consists of single- and double-circuit models of floor-standing gas boilers with a power from 7.5 to 100 kW. There are 22 models in total. Double-circuit units have the letter B in their name. The most capacious series, allowing you to select the right boiler for any room or operating conditions. The simplicity of the design makes them very reliable and durable, and the low gas consumption contributes to the popularity of this equipment.

- Premium N. They differ from the basic Premium series by the presence of a gas valve 820 Nova Sit. The remaining features and parameters are the same as the main line models, but the power of the models is limited to 35 kW.

- Wise . These boilers are new, they appeared relatively recently. Made from ductile gray cast iron. They have 5 models with a power of 16, 25, 35, 40 and 50 kW. Single-circuit models with a sectional heat exchanger. They differ from conventional series in the need to connect to the power supply network.

- Leader . They are also a new product in the Lemax model range. Non-volatile single-circuit boilers with power from 16 to 50 kW. The cast iron sectional heat exchanger allows for high efficiency of thermal energy transfer.

Specifications

Let's look at the table of the main technical characteristics of Lemax floor-standing boilers:

| Characteristics | Values |

| Boiler type | Gas |

| type of instalation | Floor |

| Type of fuel | Natural, optionally liquefied gas |

| Thermal power | 6-100kW |

| Efficiency | 87 -93% |

| Gas consumption | 0.38 – 2.6 m 3 /h |

| Maximum coolant temperature | 90° |

| Diameter of coaxial chimney | 250-310 mm |

| Chimney length | 330-800 mm |

| Water pressure in the system nom/max | 1.5/2 Bar |

Device

Lemax floor-standing gas boilers have a heat exchanger in the form of a welded or cast iron container that forms a water jacket around the combustion chamber.

A gas burner is installed in its lower part, and under it there is a gas valve, control devices and connecting pipelines . The upper part of the heat exchanger has a passage for installing a chimney, which can be of a classic or coaxial design.

The connections for connecting the heating circuit for different models are located either on the sides or on the back of the boiler. There is also a hot water supply pipeline (for dual-circuit models).

The operation of the unit consists of the coolant entering the heat exchanger tank, heating and exiting independently under the influence of gravity - the density of the heated layers decreases somewhat, which helps to displace them by colder layers of liquid.

Self-circulation of the coolant is based on this effect. Hot water is heated in a copper coil installed inside the heat exchanger .

Smoke removal occurs under the influence of natural stove draft.

Procedure: how to clean the boiler from scale, soot and soot

If you decide to do the procedure for cleaning the structure yourself, before carrying out work at home, you need to turn off the electricity, turn off the gas, and close all valves of the heating system and boiler.

All actions should be carried out carefully; disassembly and assembly requires special care:

After completing all the necessary procedures, you can open the gas valve and turn on the electricity.

When the boiler operates for a long enough time, contaminants in the form of carbon deposits gradually form on the burner. Accumulating in large quantities, it can cause equipment malfunctions. Therefore, it must be removed periodically.

For mechanical cleaning with small accumulations of dirt you will need:

The gas duct must be wiped clean. The surface of the nozzles is cleaned with brushes or a brush. A needle is used for holes. Under no circumstances should the hole be widened, as the combustion process may be disrupted.

If there is a lot of carbon deposits, you can use acidic solvents.

User manual

Operation of Lemax floor-standing gas boilers comes down to igniting the burner as needed and setting the desired temperature. All other operations - replenishing the volume of water in the heating circuit, installing a chimney, connecting a boiler - are performed without interfering with the boiler design.

To ignite the burner, turn the regulator to position 1, which means switching on the operating mode. Then you need to push it all the way and hold it while pressing the piezo ignition button.

When the pilot burner lights up, the button is released, but the regulator is held for about a minute.

Periodically it is necessary to clean the internal components of the boiler from carbon deposits and soot . You also need to monitor the condition of the heat exchanger, gas valve and other components of the unit.

Periodic maintenance should be performed by specialists from the service center. It is not recommended to do this work yourself, especially if the warranty period has not yet expired.

Possible faults

No matter how hard the engineers try to prevent possible problems, no matter how attentive the owners themselves are, sooner or later everyone faces failures. If Lemax Premium, for example, goes out (the main burner stops arbitrarily), we can assume the following reasons:

- weak vacuum in the smoke passage;

- gas outlet overflow;

- Incorrect thermostat setting.

First, inspect the channel through which the smoke is removed. If any dirt or blockages are found, they are removed immediately. If this does not help or nothing interfering is detected, you need to configure the regulator.

If a gas leak is detected, you should give up the idea of fixing it yourself. All restoration work may only be carried out by authorized gas service specialists.

Please note: cleaning chimneys and burners can help with excessively elongated flames that take on an orange or even red hue.

If there is no movement of water in the system, it needs to be topped up. When this measure does not help, you will have to redo the entire heating circuit. If the boiler suddenly turns off due to a temporary failure in the gas supply, the inlet valve must be closed. Then very unpleasant consequences will be excluded. If you cannot light the boiler, the problem may be related to the igniter or thermocouple. It is necessary to clean the contacts and replace the thermocouple. You also sometimes need to work on the traction sensor, connecting it not “by crimping”, but according to a more practical scheme.

Important: ignition is strictly not allowed if the fire from the igniter rushes outward, which is almost always due to a lack of draft and poses a great danger