Most autonomous heating systems in private houses or other premises are based on the use of gas boilers.

This is the best option for a source of thermal energy, capable of working independently and not requiring too much attention from the owner.

Most often, imported units are used to ensure stable and reliable operation of the heating system.

However, imported boilers have very serious disadvantages due to the manufacturers’ conceptual approach to the capabilities and specifics of the equipment.

Let's consider gas boilers from one of the domestic companies, which demonstrate a different approach to the operational capabilities of heating units.

Gas boilers from Conord

The Conord plant is located in Rostov-on-Don. It was founded in 1947, and since then has produced various types of heating equipment.

During its work, considerable technological experience was accumulated, the features and disadvantages of imported models of gas boilers were analyzed, and the necessary conclusions were drawn . Today Conord produces several series of gas boilers, which are the optimal solution for the Russian user.

Climatic features, the state of communications, and the possibility of interruptions in the supply of certain resources are taken into account.

The company relied on the production of units that were as independent as possible from external conditions, capable of performing assigned tasks despite the situation.

Non-volatile equipment in Russian conditions is a big plus; it guarantees the preservation of heating during a sudden power outage . This approach is reasonable and highly appreciated by specialists and ordinary users.

Secrets of High Performance

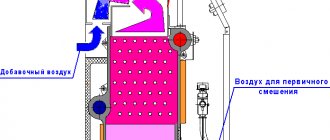

Modifications with thermohydraulics are non-volatile. The operating principle is based on the use of a thermostat. When the temperature reaches the declared value, the gas supply to the burner stops. This maintains the necessary heating of the coolant.

The devices are ideally adapted for harsh winters: they can stably maintain the required heating, the main thing is to correctly calculate the power. Efficiency increases due to:

- modulating burner;

- obtaining the optimal composition of the gas-air mixture;

- leaving the bulk of the heat for heating the coolant.

Kinds

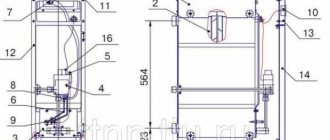

All Conord gas boilers have a floor-standing design. This feature allowed the manufacturer not to skimp too much on the dimensions and strength of components and parts.

There are different model lines:

- Single-circuit. Intended only for powering the heating system of the house.

- Dual-circuit. Capable of heating both coolant for heating and hot water for domestic needs (DHW systems).

Various types of automation are used in the design of boilers:

- Thermohydraulic (mechanical type).

- Automation SIT. Automatic operating mode control unit made in Italy. It has a thermostat, a piezo ignition system, an ignition burner with an electrode and a thermocouple.

There are also models with different types of heat exchanger:

- Steel.

- Cast iron.

IMPORTANT!

Cast iron heat exchangers have high heat transfer capacity and are effective in floor structures. Steel components show slightly reduced performance, but due to the large thickness - 3 mm steel walls - they are able to release a sufficient amount of thermal energy and remain operational for a long time.

Design Features

- Convenient adjustment. Heating is adjusted by a mechanical rotary regulator, which allows you to change the strength of the fire.

- Simple ignition - no complex automation, which in imported analogues often makes you nervous.

- Thanks to its special design, the cold-rolled steel heat exchanger is resistant to overheating, which significantly increases its service life.

- The burner is capable of operating even at the lowest gas pressure.

- Low heat loss - the body is thermally insulated.

- Dimensions are modest. Floor-standing units are always larger than wall-mounted units, but Conord’s dimensions are quite acceptable for small rooms. Stylish design - easily combined with modern interiors.

- The body is lined with steel sheets (3 mm thick): thanks to the powder coating, they are characterized by increased heat resistance.

- The burner flame is modulated automatically - the device is economical and efficient.

- A transition to another fuel is provided.

- The security system protects the device from emergency situations.

Series and model range

First of all, you should understand the markings of Conord boilers.

It is an abbreviation in which the first letters indicate the heat exchanger material:

- KSC is a steel boiler with a cylindrical heat exchanger.

- KCH - cast iron boiler.

The following letters indicate the feature set:

- G - single-circuit (gas).

- GW - double-circuit (gas with the possibility of hot water supply).

Then follow the numbers indicating the boiler power in kilowatts and the letter indicating the type of automation:

- N - thermohydraulic.

- S - Italian automatic SIT.

For example, a boiler marked KSts-GV-10N means a steel boiler with a cylindrical heat exchanger, double-circuit, 10 kW power with thermo-hydraulic automatic control.

Conord boilers are produced in the following series:

- KSC-G-S . A series of single-circuit units with Italian automatic equipment. They have a piezo ignition system, an additional ignition burner, and a special thermocouple is used for ignition. Designed for heating rooms from 80 to 500 m2, you just need to select a unit of appropriate power. The model range consists of units of 8, 10, 12, 16, 20, 25, 30, 40 and 50 kW.

- KSC-G-N . Single-circuit models with mechanical automation. A special feature of the series is the ability to work in systems with high pressure - up to 5 bar. The power of the models is 10, 12, 20, 25 and 30 kW, which allows you to heat rooms from 100 to 300 m2.

- KSts-GV-S . Double-circuit gas boilers with Italian automatic operating mode control. The power of the models is 8, 10, 12, 16, 20, 25 and 30 kW. This allows you to successfully operate the equipment in rooms from 80 to 300 m2. They have the ability to provide a home not only with heat, but also with hot water, which significantly increases their value for the user and allows them to solve two problems at once.

- KSts-GV-N . Double-circuit boilers with a capacity of 12, 20, 25 and 30 kW. They have a thermo-hydraulic type of automation. They provide heating and hot water supply, designed for use in rooms from 120 to 300 m2.

- KCH-G-S . Single-circuit boilers with a cast iron heat exchanger and Italian SIT automation. Three models are available with outputs of 16, 25 and 30 kW. These units are the most expensive, highly efficient and reliable. They weigh twice as much as steel boilers of the same power.

The model range is quite wide and allows the user to get the best option for the existing conditions.

Recommendations for users

For stable operation of such gas floor-standing boilers, it is necessary to follow all the manufacturer’s recommendations. Since heating systems that operate on fuel such as gas are objects of increased danger. But if you strictly follow all the developers’ instructions, then such a system will fill the house with heat without interruption.

The following conditions must also be met:

- build a boiler room that will meet the standards;

- consider the process of reloading a large and heavy boiler into the boiler room if a car cannot drive into it;

- ensure a flow of fresh air into the boiler room;

- be sure to consider the issue of laying non-combustible materials around the pipe that releases smoke;

- position the chimney on the house so that smoke does not enter the windows, that is, take into account the direction of the wind;

- ensure unobstructed access to the boiler in case of danger;

- do not allow small children and pets into the boiler room;

- If possible, do not plant the junction of the main pipe and the entrance to the house with heavily branching bushes.

Specifications

Let's look at the technical characteristics of Conord gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Feature Set | Heating and hot water supply |

| Efficiency | 90 % |

| Unit power range | 8-50 kW |

| Combustion chamber design | Open (atmospheric type) |

| Fuel type | Natural gas |

| Heat exchanger material | Stainless steel 3 mm, cast iron |

| Energy consumption | Absent |

| Service life declared by the manufacturer | At least 15 years |

| Guarantee period | 3 years |

Advantages and disadvantages

The advantages of Conord gas boilers include:

- High quality assembly and manufacturing of components and parts.

- Boiler efficiency exceeds 90%.

- The non-volatile design allows the units to be used in any room or area.

- The service life of boilers is at least 15 years.

- Capable of operating at low gas pressure.

- The manufacturer's warranty on Conord boilers is 3 years.

- The price of the units is noticeably lower than that of other manufacturers.

The disadvantages of the units should be considered:

- The dimensions of the boilers are quite large and require a certain amount of space for installation and maintenance.

- The use of natural draft places increased demands on the design of the chimney and the creation of conditions for high-quality smoke removal.

NOTE!

The specificity of floor-standing boilers is such that their dimensions are not a priority design condition. The use of natural draft is not an exclusive feature of Conord equipment; this method is widely used by all manufacturers, so the disadvantages of boilers are quite surmountable and are not too noticeable against the backdrop of undoubted advantages.

Advantages

After reading reviews about the products of the Rostov enterprise, it is easy to understand that they are in high demand. The Russian consumer is attracted to Conrod products by:

- Cost - prices for Russian products are much lower than for European ones. Sometimes the difference is 50%. The cheapest 8 kW models, used for heating a private home, cost only 15,000 rubles.

- Long warranty. The manufacturer guarantees uninterrupted operation for fifteen years.

- Does not depend on electricity. A blackout, especially in winter, due to lack of electricity, is almost a disaster. Therefore, for volatile equipment it is necessary to install backup power - a generator or battery. There are no such problems with Conord.

- Easy to use. The abundance of functions, electronics and automation from other brands often causes unnecessary trouble.

- Quiet operation.

- High quality build.

- Good technical characteristics: Rostov boilers are practically not inferior to foreign analogues in productivity, efficiency, and heating speed.

- High efficiency - about 90%.

Device (automation)

The main element is the gas burner. It heats the heat exchanger in which the coolant is located.

It is supplied by gravity or under the action of a circulation pump (purchased separately and connected as an external component of the system) into the heating circuit.

For double-circuit models, a coil is installed around the smoke pipe to heat the hot water of the DHW circuit.

Smoke is exhausted naturally, using the chimney draft, to which the boiler should be connected during installation.

The installation of the heating system must be carried out taking into account the placement levels of radiators that ensure natural circulation of the coolant.

If this is not possible, you have to use a circulation pump, which stabilizes the liquid movement mode, but makes the boiler energy-dependent.

Installation nuances

Reviews from owners confirm that Conord may go out. Provoking factors:

- The burner is dirty. Before turning on the device, you should clean the nozzles with a brush or vacuum cleaner.

- There is not enough oxygen to start the burner. The air nozzles should be cleaned and the room ventilated.

- Thermostat contacts have oxidized. Cleaning needs to be done.

- Automation sensors are broken.

If the coolant cools down too much, you need to switch the thermostat to maximum or increase the flow of gas to the burner, if the instructions allow such an action.

Features of summer use

In summer it is necessary to turn off the heating circuit. To do this, turn off the tap at the coolant inlet. When one pilot burner is running, the water will heat up to 60 °C in 60 minutes. If water is not consumed, it will retain heat for about two hours - it can be used for domestic needs. When the device heats up and there is no active consumption of water, it is turned off so that the water does not boil.

Briefly about the operating instructions and setup

The operation of Conord gas boilers is not particularly difficult, since the units have a durable and reliable design and are resistant to loads and external influences.

However, to improve working conditions, several simple procedures should be performed:

- Install a strainer in the gas line to prevent fine metal dust and scale from entering the burner.

- Use water softeners or filters. This is especially important for residents of regions with hard water.

- On the return line of the heating system, it is necessary to install a filter that retains scale, slag and other debris that is present in the system. This will protect the heat exchanger from clogging and increase the service life of the boiler.

Compliance with these simple requirements will save the user from having to clean and repair the boiler once again.

Setting up the unit is not difficult - all communications are connected, the strength and tightness of the connections are checked.

Then the operating mode is set and the burner is ignited using a piezo ignition system or a regular match.

Quality Policy:

The main goals of the team of LLC “Plant CONORD” in the field of quality:

|

The strategy for achieving the goals is:

|

| The management of Zavod CONORD LLC takes responsibility for the implementation of the declared quality policy, effectiveness and continuous improvement of the quality management system to demonstrate its commitment to the principles of total quality management in the production of heating equipment |

How to light it? Why does it go out? Why doesn't it turn off automatically?

Not all users experience problems with ignition of Conord boilers. The usual cause is contamination of the burner nozzles, which have not been cleaned for a long time. The same reason causes the boiler to suddenly go out.

In addition, external conditions can affect the flame attenuation - drafts, insufficient or reverse draft in the chimney caused by strong gusts of wind or improper placement of the pipe.

The absence of automatic shutdown of the boiler indicates an incorrect setting of the operating mode or a failure of the automatic control unit of the unit.

How to serve

Maintenance of Conord boilers consists of maintaining the cleanliness of the body, timely removal of soot or ash from the burner and performing other necessary procedures.

Most of the work is performed by the owner of the unit, but for some activities it is necessary to invite a specialist from a warranty or service organization. This must be done annually, or as urgently necessary - in case of problems or breakdown of the boiler.

Attempts at self-repair can cause permanent failure, so you should entrust complex operations to professionals.

Any attempt to independently interfere with the boiler design will be regarded as termination of the warranty agreement at the initiative of the owner.

Download instructions

Download instructions for Conord gas boilers.

Reviews

Judging by the reviews, they are mostly positive. There is a certain drawback, namely a slight deposition of soot, but this nuance can be easily removed during the next preventative examination by specialists. But you need to take into account that the gas is burned and, naturally, some sediment will still be present.

Some consumers say that they are not satisfied with the need to pay annually for preventive examination of the system, but this just applies to safety issues.

In fact, boilers from this company are a reliable and budget option for a private home and beyond.

Price range

The average cost of Conord gas boilers is in the range of 11.6-35 thousand rubles. Before purchasing, it is recommended to clarify the package contents, as well as find out the cost of the warranty agreement, so that you do not have to resolve these issues later, in a hurry.

At the same time, it is necessary to determine what the water quality is in the area where you live, whether it is necessary to install softening filters or other additional devices.

IMPORTANT!

Creating optimal operating conditions for a gas boiler will help to avoid unnecessary fuel consumption and get the expected effect from operating the unit.

comparison table

| vendor code | Power | Heated area | Average flow, m3/hour | Weight, kg | Dimensions, mm | Factory price including VAT, rub. |

| AOGV-11.6-3 | 11.60 | 116 | 0,74 | 41,1 | 411/304/936 | 17600 ₽ |

| AOGV-11.6-1 | 11.60 | 116 | 0,74 | 38,2 | 380/327/953 | 17600 ₽ |

| AOGVK-11.6-1 | 11.00 | 116 | 0,74 | 39,2 | 406/327/953 | 20100 ₽ |

| AKGV-11.6-3 | 11.60 | 116 | 0,74 | 42,1 | 413/304/936 | 20100 ₽ |

| AOGV-17.4-1 | 17.40 | 174 | 0,94 | 56 | 466/396/958 | 20900 ₽ |

| AOGV-17.4-3 | 17.40 | 174 | 2 | 56,2 | 495/368/936 | 20900 ₽ |

| AOGV-23.2-3-2 | 23.00 | 232 | 1,48 | 76 | 580/475/1120 | 24000 ₽ |

| AOGVK-17.4-1 | 17.40 | 174 | 0,94 | 60 | 495/396/958 | 25400 ₽ |

| AKGV-17.4-3 | 17.40 | 174 | 0,94 | 57,2 | 495/368/936 | 25400 ₽ |

| AOGV-29-3-2 | 29.00 | 290 | 1,48 | 76 | 580/475/1120 | 26400 ₽ |