The uninterrupted operation of any heating device depends on the correct selection of components, and water heated floors are no exception. In this design, an important point is given to maintaining the temperature level and intensity of coolant supply - this function is assigned to shut-off valves: a two-way or three-way valve.

In our article we will tell you what a three-way valve is, the principle of its operation, and what types there are. You will also learn which valve to choose for a heated floor, as well as how to install it yourself.

Application area

Underfloor heating systems are increasingly popular in residential buildings today, but without a control valve it is impossible to ensure proper heating. A three-way tap is an element designed to adjust the heating level in a water floor that is filled with screed.

The valve is installed both as a complete set with a mixing and distribution unit, and as an independent device. In small rooms (bathtub, toilet, kitchen), there is no point in installing a multifunctional collector - it is expensive and not justified.

A three-way thermomixing valve can control the temperature and regulate the volume of liquid for such rooms.

Main areas of use:

- In a radiator heating system.

- In the DHW system.

- In warm floors.

Large areas

Installing heated floors as the main type of heating involves installing full-fledged mixing equipment that is capable of dividing the flows into two - heated floors and central heating. Here, three-way thermostatic valves with full flow into the system are required.

Experts recommend installing one common circuit where the working fluid is pumped by a pump. At the entrance to the heated floor there is a mixing valve. It is controlled by a special temperature regulator. The mixing valve is installed between the bypass and return. A sensor at the top of the valve regulates the set temperature.

If the temperature rises, the mixing valve closes the return flow. Further circulation of the working fluid occurs in the coolants of the heated floor.

Sources

- https://ProUteplenie.com/otoplenie/termostaticheskiy-klapan-dlya-teplogo-pola-vidy-i-kak-vybrat-shemy-montazha

- https://bph-saratov.ru/otoplenie/termostaticheskij-ventil.html

- https://OtoplenieBlog.ru/oborudovanie/teplyj-pol/kak-vybrat-termostaticheskij-klapan-dlya-tyoplogo-pola.html

- https://seti.guru/termogolovka-dlya-teplogo-pola-vodyanogo

What do you think of this article?

Functions

Water heated floors have significant differences from standard radiator heating. The floor pipeline, which lies in a cement screed, requires water at a certain temperature level, much lower than that circulating in the radiators. Therefore, it is necessary to install a three-mix running unit, in which the coolant will be brought to the required degree.

Bringing the liquid to the required degree of heating that meets the standards for underfloor heating (which ranges from +35 to 55 degrees) is the main function of a three-way thermomixing valve.

Main varieties

Three-way valves come in three types:

- Hydraulic.

- Electrically driven.

- Pneumatic.

Electrically driven devices (for example, the ESBE model) differ slightly in their operating principle. The electrical appendage acts here like a regular thermostat: thanks to it, the flows are not only mixed, but also maintained at the desired temperature. During a decrease or increase in temperature, the position of the shut-off valves is automatically changed. As a result, the flow cross-section increases or decreases. At the same time, the cross-section at the inlet of the cold flow changes, which makes it possible to impart a stable temperature to the outlet water. In this case, the three-way valve is completely dispensed with without human control: the control of the equipment falls on automation.

The ESBE valve with electric drive and thermostat can be successfully used in heating systems and hot water supply. Strictly speaking, such a valve can be equipped with any type of pipeline where it is necessary to mix two liquid streams and maintain a stable temperature. Even the highest quality and reliable models of a three-way valve with a thermostat have one common drawback for products of this type: the inlet points through which liquid flows are greatly narrowed. As a consequence, this provokes an increase in hydraulic resistance.

These types of taps are great for water pipes. ESBE valves are often equipped with heated floors, although a special connection diagram is used. Along with the modifications mentioned above, three-way thermostatic valves can be found on sale. Despite the apparent similarity of these devices, their functions differ in many ways. Thermostatic varieties use thermostats with a remote-type sensor. In addition, the operating principle here is also different.

Unlike standard models, thermostatic valves control flow at only one point. The other two inlets are in a permanently open position, with a stable cross-section

When purchasing such a design, it is important to test the second point for narrowness, otherwise difficulties in the operation of the device may arise due to high hydraulic resistance. If such a defect is detected, the problem can be solved by installing a mixing valve in an additional circuit

Design and principle of operation

A mixing valve is a device for mixing and regulating water flows; it has three openings: two inlet and one outlet. In the space between the inlet holes there is a heat-sensitive damper; it is responsible for regulating the movement of liquid - cooled and heated. Modern devices are equipped with a thermal head or control valve.

The heating floor valve operates continuously. The step-by-step process is as follows:

- heated water is supplied to the first inlet - its temperature is determined in the valve;

- if the heating degree of the water exceeds that required for heated floors, then the supply of cooled liquid from the return line opens through the second hole;

- inside the valve, heated liquid is mixed with cooled liquid;

- after obtaining the desired temperature, the return flow is closed;

- The coolant is supplied through the outlet to the underfloor heating pipes.

For the thermal valve to work effectively, it is necessary to maintain constant pressure in the line.

When operating an automatic thermo-mixing tap equipped with a servo drive, heating is carried out in 3 minutes ; if there is a thermal head, the liquid is heated in 15 minutes .

Characteristics of two way valve

The two-way valve is an upgrade to the valve. Built into the collector, it operates automatically and maintains the set temperature level. Unlike a traditional valve, this model is focused on passing liquid flow in one direction. If you install it back, the entire process of functioning of the heated floor will be disrupted. To extend the service life, a filter is installed in front of the valve to retain mechanical impurities.

Thermal mixing unit for heated floors

[ads-mob-1][ads-pc-1] Such a thermo-mixing tap is made of brass, steel, and cast iron. Includes a thermostatic head with a liquid sensor, the purpose of which is to control the temperature of the coolant. During its operation, cool water coming from the “return” is constantly supplied, while hot coolant is supplied only when necessary. Two way valve diagram

Thanks to this scheme, the heated floor does not overheat, therefore, its service life is extended. Since the throughput of a two-way valve is relatively low, temperature control is smooth, without jumps. Experts recommend using this device when installing heated floors over a large area exceeding 200 m2.

Kinds

Esbe three-way for heated floors, why is it needed.

Three-way thermal valves come in separate and mixing types. For underfloor heating, mixing valves are used.

In addition, they have different implementation methods; they can be manual or automatic. They also differ in their design - the location of the holes (inlet and outlet).

Manual

The price of a manual device is not high, but it is rarely used because it is not convenient. Suitable only for small rooms - bath, kitchen. The temperature level and volume of supplied coolant are adjusted manually using a handle.

Automatic

Automatic valves have a thermal head or an electric drive, which can be controlled by a sensor.

Types of mixing units:

- Simple - if the temperature rises, the liquid expands, the damper opens, cold and hot water mix.

- Three-way valves with a thermal head with a remote thermostat for heated floors are more advanced models. They are widely used because they are accurate and do not require electricity to operate. Average price from 500 rubles to 2500 rubles.

- Three-way valves for heating with a thermostat - they regulate the flow of heated and cooled water, and also control the temperature with a built-in thermostat. The expansion and contraction of the holes occurs automatically, depending on the temperature of the liquid.

- With an electric drive (drive with a magnet or servo drive) - the damper in the valve is activated under the influence of an electric motor, it is controlled by a controller, and a signal is received from a temperature sensor. They are easy to connect, so they are widely used. But unreliability is their main drawback, since they depend on electricity. Their cost is higher than with a thermal head, approximately 4 - 5 thousand rubles.

- With pneumatic or hydraulic drive - used more often in production, for devices with high pressure. They have a high cost, but their service life is longer.

- Electronic - adjustment is carried out by a built-in electric motor or a control element with a thermometer.

Design

A three-way mixing valve has a control element, which is a rod or ball. The rod moves vertically, the ball moves around its axis. Since the movement of the control element does not completely block the flow of the working fluid, it is mixed and redistributed. The simplest models are a regular faucet. Their main advantage is low cost and design simplicity. The disadvantage is the impossibility of stabilizing the outlet temperature. Despite the disadvantages, the faucet can be installed in underfloor heating systems. Now let's imagine a faucet with an electric drive. This design is already more functional, since it is able to regulate the temperature automatically. A simple valve is a balancing valve. Its main function is to adjust the cross section for the passage of the work flow. Conventionally, the principle of its operation can be described as follows:

- The handle is turned 50% - uniform mixing of the two flows, since the inlet valves will be equal.

- The handle is turned 100% - the first valve is fully pressed and blocks the movement of liquid flow.

Modifications on the market may have different handle rotations, but the principle of their operation remains the same. The tap and its position are manually adjusted, thereby ensuring a balance between the two flows.

Manufacturing materials

Three-way thermomixing valves are made from the following materials:

- Brass is a copper alloy with zinc additives. The product is not subject to corrosive destruction, it is strong and durable. Sometimes these thermomixers have a chrome or nickel coating, which protects against darkening. This option is most often used in residential areas.

- Bronze is a copper alloy with tin additives. It is rare, although the quality is no worse than brass.

- Stainless steel is an excellent metal for making control products. It is characterized by durability, strength, and corrosion resistance. But the cost of appliances made from it is high, so they are not suitable for a private home.

There are titanium and carbon steel regulators, but they are recommended for industrial use. Valves are produced from silumin (an alloy of aluminum and silicon), their disadvantage is low strength.

Valve operation procedure

The mixing process occurs according to the following scheme:

- The heated water enters the collector, an integral part of this type of heating system.

- When liquid passes into the valve, the temperature is automatically detected.

- If it is higher than necessary, then the passage opens for the return, which is cooler.

- The flows are mixed inside the three-way valve.

- As soon as the temperature enters the parameters, the flow of cold water is blocked.

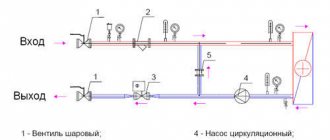

Valve kit with coarse filters and pump

It would seem that everything is ideal, but there is a drawback - with strong temperature fluctuations, it is not able to convert it into one suitable for a heated floor. This has a negative impact on the condition of the pipeline, and ruptures may even occur.

Advantages and disadvantages

Three-way thermostatic mixing valves are simple in design, yet reliable and durable. Their use allows for high-quality and precise control of the floor heating level.

Thermostatic valve for heated floors: types and their design, how to choose, installation diagrams and alternative connection methods

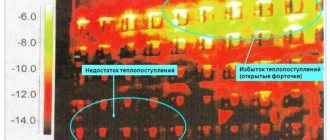

The devices are sealed and compact. Plus - they do not allow the pipes and screed to overheat, which extends the life of the system.

The benefits of control valves are irrefutable, but they have a number of disadvantages:

- They increase hydraulic resistance - this negatively affects the functioning of a unit that has more than one collector.

- There is a risk of a large volume of hot coolant entering the floor pipes. And this can lead to leakage and airing of the system. Such problems most often occur when the device is starting up.

Disadvantages of mixing units

Despite the obvious benefits, three-way valves are not without some disadvantages:

- Increasing the hydraulic resistance of the system. This can be especially noticeable in complex networks that have multiple collectors, pumps and mixing units.

- The likelihood of a sudden surge of large volumes of hot water into the heating circuits. This risks airing the system and can even lead to leaks. This problem most often manifests itself at the stage of system startup, so this stage of work should be treated very responsibly.

Manufacturers

Preference should be given to mixing valves from manufacturers that have proven themselves well in the market. Such companies include:

- Esbe (Sweden) - occupies a leading position in the quality of products of this type. The valves are reliable, with a warranty period of more than 5 years.

- Valtec is a Russian-Italian company; its mixing taps have good characteristics at an affordable price. Warranty - 7 years.

- Honeywell (America) - the priority of mixers from this company is considered to be convenient and uncomplicated installation. They are reliable, but expensive.

However, it should be remembered that even high-quality products if installed incorrectly will not ensure correct operation of the system.

conclusions

Installing a three-way valve is not a difficult task, but requires compliance with technical rules. Typically, mixing valves are placed in front of the mixer on the supply pipe, at the points where the bypass and return pipes are connected. The pump in the system is located next to the three-way valve.

After assembling the entire mixing unit, the reliability of the connections and the functionality of the valve is checked by a test run, based on the results of which commissioning is carried out, if necessary.

A correctly installed valve maintains a given temperature in a heated room and ensures rational coolant flow, and therefore heating efficiency.

How to choose?

It is recommended to select a three-way valve in specialized stores. When choosing a model, you need to take into account its characteristics. When purchasing a device you need:

- study all documentation - warranty, manufacturer’s certificate, installation and operating instructions;

- give preference to bronze or brass devices - they will not expand when heated;

- based on the valve capacity - this parameter must correspond to the boiler performance;

- select a valve with a cross-section that exactly matches the size of the floor pipes; if there is a mismatch, you will have to buy adapters.

An important point is that even the apparent coincidence of the diameters of the valve inlet and outlet does not indicate the throughput level. This is affected by the size of the internal cross-section of the holes. This parameter is specified in the accompanying documents.

You need to choose a device based on the size of the heated room - for large areas an automatic device is recommended; it is able to maintain heating at the proper level. For small rooms, a simple one with a thermal head will do the job, so there is no point in overpaying for a more complex model.

When purchasing, you must visually inspect the device for chips and cracks. If the device is brass, then the inside should be golden.

Purchasing automatic devices will facilitate the adjustment process. And the presence of software will allow you to adjust the temperature taking into account the time and day of the week.

Selection criteria

When choosing a mixing valve, it is advisable to focus on several indicators.

- Room area. For small rooms - bathroom, toilet, it is not always recommended to purchase a more expensive thermo-mixing valve, since it is enough to install a familiar valve. Large rooms with warm water floors will require mixers that automatically regulate the temperature of the heating fluid.

Esbe three-way valves model VTA320 - Cross-sectional dimensions. This indicator must be taken into account when selecting a thermostatic valve, ensuring precise connection to the heating system. If there is no device with the required diameter in the assortment offered in the store, then special adapters are purchased.

- Possibility of obtaining an automatic operating mode.

- Bandwidth. This parameter is calculated at the design stage of the heated floor. Based on the obtained values, a mixing valve is selected that can withstand the required load.

Heated floor diagram with a three-way valve

A three-way valve can be installed together with a mixing and distribution unit, or as a separate device.

Three-way valve. We install it correctly.

Scheme with separately installed valve

If the valve is mounted separately, it takes over all the functions of the manifold. This scheme is intended for small rooms, no more than 25 m2. The temperature level is adjusted using a special device and a thermostat, they are located in the valve.

The disadvantage of using a valve according to this scheme is that there is no way to dose the flows.

The system looks like this:

- a three-way valve is installed on the hot coolant supply pipe;

- a temperature sensor is attached behind it;

- Next, a circulation pump is installed; it will deliver water with the required heating degree to the sex pipeline.

Scheme without mixing unit

Valve with mixing unit

If the area is large, then it is necessary to use a scheme where the valve is part of the distribution unit.

It will ensure uninterrupted operation of the floor heating device, and the water entering the floor line will be at the required temperature and volume.

The connection diagram is as follows:

- a pump is installed on the supply pipe; it will pump the heated coolant from the source;

- then a temperature sensor is installed, it will control the degree of heating;

- at the next stage, a three-way valve is attached - it mixes the coolant to a given degree;

- a tap is placed on the return circuit through which cooled water will flow into the three-way device.

Scheme with a mixing unit

That is, coolant heated to the required temperature will be supplied to the underfloor heating pipes.

Connection diagrams depending on design

In addition, the connection diagrams differ in the design and direction of the coolant in the device, there are:

- L-shaped - the product is equipped with two holes on the side and one round hole on the bottom of the body. The heated liquid is supplied to the side inlet, and the cooled liquid is supplied to the bottom. After mixing, the water moves into the floor branches through another side hole.

- T-shaped - both flows, cold and hot, enter the mixer through the side inlets. The mixed coolant is sent to the floor through the central lower outlet.

When deciding on a diagram for installing a three-position valve, you should consider how it will fit into the pipeline piping.

Application of valves for heating boilers

Three-way valves for heating boilers deserve special attention. They perform the task of preventing the cooled coolant from entering the pipeline entering the boiler. If this is not done, the pipes will begin to become covered with condensation, and a dangerous temperature difference will arise in the system. This is fraught with deformation of the connecting areas, the most harmless consequence of which will be the appearance of small leaks. If you do not react in time, the system may completely fail.

Particular responsibility should be taken when installing shut-off valves in the piping of a solid fuel boiler, during the operation of which significant temperature changes occur (pro

Installation and connection of a three-way valve to a warm floor

Connecting a three-way valve to a warm floor is not difficult; you can do it yourself. The main thing is to follow the steps according to the attached instructions.

All inputs and outputs are indicated by letters:

- A - input for heated coolant;

- C - inlet for chilled water;

- AB is the outlet.

Before connecting the device, it should be taken into account that it may need to be dismantled, so it is necessary to have an unobstructed approach to the unit.

Materials and tools

Before installing the valve, you need to stock up on the necessary tools. You will need wrenches (2 pcs), pliers, American nuts with union-type gaskets, FUM tape.

Work progress

Connecting a heated floor to the heating system. Three-way mixing valve.

First of all, the three-way valve must be checked for functionality.

To do this, the minimum value is set on the regulator, then hot water is released through the valve. If the device is functioning correctly, the damper should close immediately.

Installation of the tap must be done together with the installation of the manifold group and before pouring the screed.

When using any scheme, the valve is installed using American union nuts.

The work looks like this:

- The fittings located at the ends of the pipes are cleaned of dirt and burrs.

- The same procedure is done with the valve pipes.

- The nut is checked for gaskets.

- Then screw the nuts onto the pipes and tighten them - but not too much. This procedure involves two wrenches - one for tightening the nut, the second for holding the valve.

- A mechanical filter is installed in front of the valve.

It is necessary to monitor the correct connection of the valve outputs: to A - hot water, to B the bypass coming from the return line, to AB the manifold with floor outlets.

To ensure the tightness of the joints, it is recommended to screw plumber's tape or FUM tape.

System check

In addition to the correct installation of the mixing tap, its operation must be checked. System testing is carried out with the coolant heated to 25 degrees. The time for crimping is 24 hours.

After checking, you can proceed to pouring the screed.

Direct connection diagram

You have a boiler, after which all safety fittings + a circulation pump are installed. In some wall-mounted boiler versions, the pump is initially built into its body.

For floor-standing units you will have to install it separately. From this boiler, the water is first directed to the distribution manifold, and then disperses through the loops. After which, having completed the passage, it returns through the return line to the heat generator.

Specification of materials and equipment using the example of Valtec

With this scheme, the boiler is directly adjusted to the desired temperature of the TPs themselves. You don't have any additional radiators or radiators here.

What are the main features worth paying attention to here? Firstly, with such a direct connection, it is advisable to install a condensing boiler.

In such schemes, operation at relatively low temperatures is quite optimal for the condenser. In this mode it will achieve its highest efficiency.

If you use a regular gas boiler, you will soon say goodbye to your heat exchanger.

The second nuance concerns solid fuel boilers. When you have it installed, for direct connection to heated floors, you will also need a buffer tank.

It is needed to limit the temperature. It is very difficult to directly regulate the temperature with solid fuel boilers.

Common installation mistakes

The most common mistake when installing a three-way valve is that the supply and return floor circuits are incorrectly connected. For example, when floor contour pipes are connected to the inlet.

Therefore, care is required; for this, there are letter designations at the mixer outputs. If you mix up the holes, the device will not function.

In addition, it is necessary to strictly follow the manufacturer's instructions regarding the distance between straight sections before and after the screw. If this rule is violated, the functioning of the regulator will be disrupted.

Installation of the mixing unit. Installation Features

*

With the correct selection of components and compliance with all necessary technical conditions, installing the mixer should not cause difficulties. Having determined the location of the mixing unit and modeled the design of the manifold cabinet, begin assembly.

For the future. The heated floor control unit must be freely accessible. Otherwise, you will have to face difficulties during operation.

First, the pipelines coming from the heating device are connected. Next the collector is installed. Finally, the system can be equipped with sensors for adjusting pressure, pressure and thermometers. It is important to determine how the collector combs are positioned. The way you connect the distribution combs depends on what heating source your system is connected to. This can be an end connection or a regular one, top and bottom.

For the hot water supply line, it is better to use metal-plastic pipes or polymer materials. These components are able to cope with pressure surges in the system and can withstand high temperatures perfectly.

Connecting equipment to water circuits is carried out in a clear sequence using fittings. Pipes through which cooled water flows in the opposite direction are connected to the blue inlet pipes. A water loop is connected to the red pipes, providing floor heating in a heated room.

If you are planning to make a heated floor to heat large areas, you will definitely need a circulation pump. The large length of the water circuit, a large number of bends and the small diameter of the heating pipe lead to the fact that the coolant circulation in the system is noticeably weakened. By installing a circulation pump, you will ensure a normal supply of prepared water to the heating circuits. It is recommended to install the pump at the beginning of the mixing unit, where the supply pipe fits and the return pipe is connected.

The pump is installed in a strictly horizontal position. It is recommended to install pumps with several speed settings. Such models allow you to manually determine the required feed speed and flow intensity.

Features of operation

When operating a heated floor mixing valve, there are special points. The main one is the mandatory installation of a filter. In addition, it is not recommended to place a mixer with a thermal head in a manifold group that serves more than one room or is located in an adjacent room. A device with a remote temperature sensor placed in a heated room is suitable.

The mixing valve is the main element in the water heated floor system. The quality of room heating depends on how correctly it works. Therefore, its selection and installation must be approached responsibly. If you are not confident in your abilities, then it is better to invite a professional.

Purpose of using the collector

A collector is a device with which the coolant flow is distributed over individual circuits of the water floor and then returned back for heating. The collector unit looks like two pipes with holes to which the system circuits are connected.

The presence of a distribution manifold in the heated floor arrangement makes it possible to control the volume of coolant flow. One of the collector pipes is the supply pipe; hot water flows to it and the inputs of the water floor circuits are connected to it.

The return circuits are connected to the return pipe of the collector. The openings to which this connection is made are usually equipped with threaded, fitting or other connections.

The collector consists of a number of elements such as the collector itself (1 and 2), an adapter for the Mayevsky tap (3); drain valve (4); air vent (5); valve (6); bracket (7); Eurocone (8)

Various devices are also installed here with which you can regulate the coolant flow rates. The simplest version of an industrial manifold is a pipe with a connector called a Eurocone. This is a completely convenient and reliable unit, but it does not allow you to control the flow of water.

To effectively use such a device, you will have to additionally purchase and install a number of elements.

The manifold made in the DPRK is a little more complicated. In addition to the connections at the outlets, valves are installed here; no automatic means of regulating the flow are provided. This is an excellent and inexpensive option for a water floor in a small area with two or three contours of the same length.

Such a system does not require complex management. But on large areas, this type of collector will have to be supplemented with automation.

In addition, the center-to-center distance between the feed and return sections of Chinese devices does not meet the standards adopted in Europe, which can cause problems when connecting it to European-made devices.

Ball valves in such devices are sensitive to low-quality water, and over time they begin to leak. To fix the problem, it is enough to replace the O-rings, but you must take into account the fact that the need for such repairs will arise periodically.

If the operation of the water floor system is intended to be automated, it makes sense to purchase at least a manifold with control valves.

Servo drives can be installed on such valves, connected to thermostats in the rooms. This will ensure automatic control of the coolant flow in accordance with data on the air temperature in a particular room.

To automate the operation of a water heated floor system, flow meters are installed on the collector supply (indicated by a frame), and connectors for servo drives are installed on the return (blue caps at the bottom)

It is most difficult to control a water floor system in which the individual circuits vary markedly in length, but in complex systems this is usually the case. In such a situation, the optimal choice would be a manifold with flow meters installed on the supply side, and sockets intended for mounting servos on the return side.

Using flow meters, it will be possible to adjust the intensity of the coolant flow, and servo drives in conjunction with thermostats allow you to set the appropriate temperature on each circuit.

If there is no need for automatic control, you can purchase a supply manifold with flow meters, and a return manifold with conventional valve taps.

It happens that it is not possible to choose a collector with the number of connection sockets that corresponds to the project. Then you can take the device “with a reserve”. And the extra holes are simply closed with plugs.

This solution may be useful if you later need to add a couple more loops to the water floor system.