How to insulate a wall inside an apartment?

As a rule, insulation of internal walls in an apartment is carried out first , since it is the most affordable and can be done independently, but even such measures will help reduce heat leakage through the walls and especially all the benefits of insulation will be appreciated during the winter cold.

Most often, the following types of insulation :

The most optimal combination option is when the base is covered with polyethylene, followed by a main layer of mineral wool - this is for residential premises, and polystyrene foam can be used on loggias, balconies and rooms with intermittent occupancy.

Before insulation, the wall surface is cleaned of poorly adhering coatings, and it also needs to be primed .

The heat insulator layer will be covered with a decorative coating , so you should make a sheathing around the perimeter of the walls from wooden beams, since wood is a good heat insulator, which cannot be said about a metal profile.

If it is decided to make insulation with polyethylene, then it is mounted first on the wall , and pressed on top with a wooden beam.

Mineral wool is placed in the walls between the ribs , sheets of plasterboard are fixed with glue, after which the entire structure is “sewn up” with plasterboard or other decorative material.

Mistake 8: Improper floor design

Do not try to make the floor perfectly flat using a thick sand-concrete screed, which will subsequently be covered with a solid layer of tile adhesive and then ceramic cladding. It is dangerous to overload the ceiling. It’s better to insulate the floor using ultra-light materials (let’s immediately agree that in this example we are not talking about a heated floor system).

InMyRoom tip:

There are many recipes for insulating a loggia floor, but they all essentially boil down to using soft insulation directly on top of concrete slabs (you can use penoplex or mineral wool). Then it is recommended to put a second layer of insulation - and be sure to apply waterproofing (lay hydroglass insulation with an overlap of more than 15 centimeters). You can make a thin screed on top - and many craftsmen simply lay plywood if there is no significant slope on the balcony: the plywood is thin, light, smooth, and on top of it, in a warm and moisture-protected loggia, you can lay both carpet and laminate.

vote

Article rating

How to insulate the wall behind the battery?

Insulation must be done first of all behind the heating device located under the window.

Its placement in this particular zone was not chosen by chance, since the greatest heat losses , even if the window belongs to the energy-saving class, because in addition to the walls, heat comes out in the form of radiant energy through transparent glass.

In the area where the radiator is located, the largest temperature imbalance , especially at the peak of low temperatures, which negatively affects the condition of the decorative coating and the concrete base.

During severe frosts moisture may condense , leading to peeling of the wallpaper and the appearance of mold.

Insulation behind the radiator is best done in the summer and is very good if new removable batteries are installed.

In this case, it is enough to turn off the valves and remove the device from the brackets, and apply a piece of polyethylene foam ; the covering should be directed with foil into the room, after which the radiator is installed back.

It will be a little more difficult if the radiators are old and cannot be removed, in which case the polyethylene is carefully cut into as many strips as the number of brackets the device is attached to, after which each strip is passed between it and the wall, using double-sided tape for gluing.

How to make a reflective surface with your own hands?

It was decided to attach the reflective material to “liquid nails”. Having purchased a roll of penofol, a bottle of glue and a gun for work, I got to work. Installation didn't take long.

All operations can be described by the following algorithm:

- First I removed the radiators from the walls. This work is best done with an assistant (I worked with my nephew).

- Before installing the screen, we were able to carefully inspect the walls. Several small chips and cracks were found, which my nephew covered with putty.

- While my nephew was putting putty on the walls, I was cutting out penofol. The material can be easily cut with a construction knife.

- On the putty and cleaned wall, we glued penofol with “liquid nails”. It’s convenient for two people to work: one applies the glue, the other sticks the reflectors.

When the composition has dried, having firmly glued the screen to the walls, all that remains is to replace the brackets and hang the batteries back.

Is there an effect from the reflector? I measured the effectiveness of the screens with a room thermometer. With the same gas boiler settings, the temperature in rooms equipped with reflectors increased by 1 degree. Not much, but given the low installation costs, I think there is an effect.

What care does the reflector need? No maintenance is required - just periodically wipe off dust from the foil so that the reflection efficiency does not decrease.

What gap should be between the screen and the battery? According to Russian standards - no less than 2 cm. Foreign sources recommend making a gap of 40–60 mm.

What to do if the radiator is in a niche? Choose a thicker material (from 1 cm to 1.5 cm) and glue it to the back, top and side surfaces of the niche.

I hope that my experience will be useful to you in your struggle to save on heating. Good luck with your work!

How to insulate walls on a balcony?

Who among the apartment owners has not dreamed of adding at least a few square meters to the existing space with a balcony, which can be used not only in the summer, but also to fully spend winter days?

To do this, you will need to insulate it , and since the balcony area is small, it will not take a lot of money and effort.

To insulate the room, it will be enough to use foamed polyethylene with polystyrene foam ; this is quite enough to bring the temperature closer to the most comfortable and not close the door from the apartment here even in frosty weather.

Only the outer walls bordering the street are insulated

Only wooden beams should , since the metal profile conducts heat well and will create a massive cold bridge on the already thin wall of the balcony.

Mineral wool or polystyrene foam is placed in the space between the ribs of the sheathing , after which plastic, plasterboard, plywood or clapboard is sheathed over the sheathing.

You will also be interested in the following video with practical tips on wall insulation

Source

Placing radiators too close to the wall often leads to the fact that part of the heat goes to nowhere - to the street. Many people advise insulating this part of the wall to avoid heat loss, since a considerable part of the energy is spent on heating this part, and not for its intended purpose - maintaining a comfortable temperature in the entire room.

Most often, such recommendations are given in cases where the radiator is recessed into a niche. This is a common occurrence in newly built houses, where the external part of the house is made of aerated concrete. Since the wall thickness decreases due to the niche, experts advise using insulation in this place to compensate for the difference.

We believe that this is an absolutely wrong decision. The insulation, usually consisting of polyethylene foam covered with foil, will become an obstacle to balancing the temperature inside the wall. The cold outside will begin to penetrate deeper, so the dew point will move deeper into the room. This will cause regular dew on the wall under the insulation, and then the development of mold. In addition, this insulation option has many other disadvantages:

And, although the material itself is declared to be biologically inert and safe, there is a danger of the proliferation of harmful microorganisms on the wall underneath it, since its air permeability is low and the insulation is not intended for independent use, but as an auxiliary additional layer.

Therefore, when arranging a niche, you should first carry out plastering work. Then finish it using a sheet of moisture-resistant material - plasterboard. Its advantages:

install a gas tank in a private house

GKL sheets have good moisture and fire resistance, are easy to install and safe for health. The special structure allows the material to be flexible and durable at the same time, and not crumble when cut. Gypsum fiber retains heat well, but at the same time allows some of it to pass through - this allows you to maintain a balance of temperature conditions inside the walls and avoid the accumulation of moisture inside the room. Therefore, the walls do not freeze, and the humidity in the apartment remains within normal limits.

Source

Scope of application

Reflective thermal insulation is applicable to all surfaces without dirt and dust, suitable for complex structures with corners, bends and differences. Insulating walls from the outside can achieve maximum effect by creating an air gap of 20 mm on the foil side.

The material is effective for multi-story and single-story frame houses, and it will increase the resistance of the walls without increasing their volume. Installation is carried out end-to-end without overlaps, and the seams are taped with foil tape.

Application from inside

If you want to insulate the room from the inside, then there are two options. The first option is to make 2 air gaps between the external wall and the material, between the insulation and the cladding (for example, drywall). In this case, TIM with double foil is used.

The second option is to create one gap between the external wall and the insulation, for which material foiled on one side is used. The foil is turned indoors.

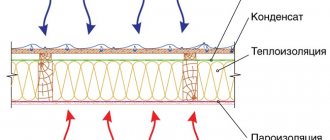

Roof insulation

Reflective TIMs mounted on the roof provide not only thermal but also vapor insulation. The under-roof space is also protected from moisture.

Reflective film is especially effective when insulating the ceiling of a bathhouse.

Piping and ventilation

Pipes require insulation with double-sided foil. If the pipes have a diameter less than 159 mm, then there is no need to create an air gap between the TIM and the pipe. If the pipes have a larger diameter, then a gap is required. The air gap is arranged as follows:

The joints must be sealed with aluminum tape. Insulating ventilation ducts will eliminate heat loss and provide sound insulation.

Installing a heat-reflecting screen behind the battery

In the context of constantly rising prices for energy sources, the issue of saving is especially relevant. Heating pipes are usually mounted on walls under windows. In these places, heat loss increases. If the radiator is installed in a niche, the power required for heating is even higher due to the reduced wall thickness. The best solution in this case would be a heat-reflecting screen behind the radiator. It isolates the wall area from the heating device and keeps the house warm.

Operating principle and design features

Various materials are used in the production of heat-reflecting screens. Their main property is a low level of thermal conductivity. First of all, these include:

Porilex can be used for thermal insulation

Also, all screens have a layer of insulation. Sealing is achieved using metallized tape. The thermal conductivity coefficient should not exceed 0.05 W/m*°C. There should be a layer between the foil and the wall that will retain heat. When creating heat-reflecting screens, rolled foam can be used.

Due to its low cost, polyethylene foam is most often used. It is installed with the foil facing the pipes and the insulated side facing the walls. It is best if there is a layer of air under the screen, which will increase heating in the room.

Screens can be used not only as an energy-saving mechanism, but also for thermal protection of furnaces

This is especially important for finishing steam rooms and saunas. The stove is a source of increased fire hazard, so it is important to insulate the walls from excessive overheating

Basalt cardboard is used for thermal protection of furnaces

For such screens, stainless steel and mineralite are used. In accordance with the standards, they are manufactured in several sizes, the edges must be curved at a certain degree, and there must be a natural non-flammable material inside. Usually basalt cardboard is used for this purpose. The heat-reflecting screen is attached behind the stove and on the ceiling. Minerite is installed in two layers. This reduces the distance from the protected surface to the oven.

Front screens in bathhouses began to successfully replace brickwork. In addition, with their help, the temperature rises and adjacent rooms are heated. The thickness of the steel sheet must be at least 0.8mm. A special silicone paint can be used to cover the screens. They are usually assembled from hollow box-shaped elements. There must be a thermal gap between the oven and the screen. Ceramic bushings can be used for fixation.

Aluminum foil is installed under the wooden covering on the walls in the steam room for thermal insulation and increased safety in the room. Next, the lining is installed. The joints between the layers are taped. Aluminum-bitumen tape is used to seal the seams. Convection screens can be used if the temperature of the outer walls of the oven does not exceed 400 o C.

Screens also reduce the effect of wood decomposition in baths and saunas, thanks to protection from wet steam and intense heat. The installation must be carried out strictly opposite the radiation from the stove stones.

Installation features

The screen allows you to retain heat behind the cast iron radiator and pipes. This is where the greatest losses occur. The use of energy-saving installations makes it possible to save up to 10% of heat when heating a room. Thermal resistance increases, the heat from the radiator and pipes remains in the room. During installation, it should be taken into account that the size of the material used must be larger than the radiator.

It is important to pay attention to the location of the battery. If the pipe is in a niche, the thermal insulation layer needs to be thicker

You should also not forget about the type of radiator connection during installation. It can be produced in a one-sided pattern or diagonally. In order to check the material, it is enough to set it on fire - the foil will not melt.

Heat shields for batteries can be attached using a staple gun. In addition to retaining heat, they also protect the walls from moisture penetration. You can install it yourself; you don’t need specialized knowledge; the manufacturer’s instructions are sufficient.

facade of a house with a gable roof

Heat-reflecting screens behind radiators and pipes can be used in residential buildings, country cottages, office and industrial buildings, children's institutions and hospitals. Technically simple installation makes it possible to save energy on heating pipes, protect walls from intense heat in saunas and avoid mold.

Foil insulation: types and technical characteristics

We recommend that you pay attention specifically to isolon. There are also penofol, foil plastic and other reflective insulation materials. But they have significant disadvantages when used for mounting behind a radiator. Therefore, we will focus on isolon as a progressive material. It comes in two types - NPE (non-crosslinked gas-filled) and PPE (crosslinked with closed cells). Both have decent parameters, but PPE is still better. Technical characteristics of these insulation materials (in NPE brackets):

- thickness: 1-50 mm (1-16 mm);

- density: 30-200 kg/m3 (19-35 kg/m3);

- thermal conductivity: 0.031-0.041 W/m K (0.036 W/ m K);

- sound absorption: up to 68% (3-13%);

- temperature range: −60…+100°С (-80…+80°С);

- water absorption: up to 1% (up to 0.2%);

- steam absorption: up to 0.001 mg/(m h Pa) (same value);

- shelf life: approximately 90 years (the same);

- heat reflectivity: reflects 95-97%, emits 3-5% (similar to NPE).

Both materials are used for home use.

Principle of operation

To understand the principle of operation of such insulation, consider the main methods of transferring heat from one coating to another:

Thus, heat loss is inevitable. It turns out that to create the effect of thermal insulation, it is necessary to minimize heat loss from radiation. But traditional TIMs are not able to protect a building from this type of heat transfer. And the optimal material was found - foil insulation, known for its reflective and low-emissivity properties.

Reflective thermal insulation works across all heat transfer processes: radiation, convection and conduction, inhibiting heat loss.

Installation of films behind radiators is a simple sequence of actions

From a technological point of view, the foil behind the heating battery is installed without any difficulties. You will complete all the work efficiently and quickly if you listen to some advice.

First, don't buy matte metallic material. Use only polished foil.

Second, don't buy double-sided films. One air gap is quite enough to ensure high-quality heat reflection.

Thirdly, leave a gap of about 1.5–2 cm on both sides of the insulator layer. It is necessary to obtain the optimal thermal resistance of the reflector (1.15 sq.m*°C/W).

Prepare liquid nails or standard adhesive used for installing wallpaper, as well as directly reflective foil, and proceed to install it. The procedure is as follows. First, carefully measure the dimensions of the wall areas where you plan to install the screen or niches.

The parameters of the film must correspond to the projection of the heating radiator onto the wall. Add about 10% to the result obtained. In this case, the heat-reflecting potential of the foil will be slightly greater. Some masters say that extra centimeters are not needed.

The effect from them will be insignificant, but the edges of the screen sticking out from behind the radiator will greatly spoil the aesthetics of the room. See for yourself, choose the option that suits you personally.

Then make sure that there is a gap of at least 1.5 cm between the heating device and the film that you will mount. When there is not enough free space, you will have to adjust the radiator suspension to provide the missing centimeters.

Next, remove the radiator. Mark the places where its mounting brackets are located. Dismantle them. Inspect the brick or concrete masonry of the wall surface.

If there are gaps, cracks, or other defects, plaster them (or putty). Level the wall, glue the screen (coat its back side with wallpaper or polymer composition).

Instead of glue, as noted, it is allowed to use liquid nails. In some cases, it is permissible to use staples or small nails to secure the foil (if they fit into the wall material without any problems and are firmly held in it). Carefully return the pendants to their place and install the battery.

Additionally, we will give some useful recommendations to home craftsmen who are installing heat-reflecting products for the first time. If during installation of the screen you damage its outer covering, the cut site can be masked with LAMS or LAS films.

They are made of foil and do not reduce the efficiency of heat reflection. Don't try to find screens that are too thick. Practice shows that five centimeters is enough to effectively save heat in the house.

Recommendations for the installation process

Why do you need foil?

The coefficient of reflection of thermal radiation of polished aluminum is higher than that of other metals.

This means that maximum heat will return inside the room.

You should not use screens with a double-sided metal backing.

The layer of foil on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in construction markets deceive customers by talking about new metallized coatings with fantastic characteristics.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermal reflective screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a heat reflective screen

Reflectors for radiators Heating system

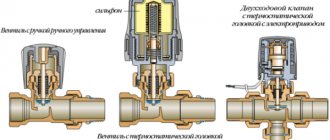

The heating system includes fasteners, thermostat pipes, an expansion tank, air vents, batteries, collectors, a boiler connection system, and pressure-increasing pumps.

On this page we will try to find and select certain installation components for the desired dacha. Installation of heating a dacha has different elements. All installation elements are very important.

Therefore, the choice of parts of the structure must be done technically correctly.

Reflectors for radiators

Battery reflectors are an energy-saving technology available to any resident of a city apartment. Already now, such brilliant battery reflectors can be seen in Kyiv hospitals, schools and kindergartens.

They return heat from the radiators to the apartments, which is uselessly lost into the wall closest to them.

The foil installed under the battery acts like a thermos - heat is reflected from such surfaces like the sun's rays from a mirror.

The Russian-made material is called “Penofol”, the Ukrainian one is called “Aluf”, there are also a lot of imported reflectors. The basis of the material is aluminum foil, which is attached to a soft foam material with a thickness of 2 to 10 mm.

Head Department of Building Physics and Resource Saving of the Research Institute of Building Structures Gennady Farenyuk told how to best choose a reflector:

— Thanks to Penofol or Alufom, it is possible to save about 5% of room heat (about 1 “extra” degree). Believe me, this is a lot! In 1993, I received a patent specifically for the idea of preserving heat in apartments using this foil material, and now it is installed in several hundred schools as part of an energy saving program.

Ready-made reflectors are not sold in stores, but they are easy to make yourself - you need to buy special material at the market or in a store and cut pieces of suitable size.

“It must be metal foil,” the physicist advised, “it reflects heat better.” Aluminum coating on a lavsan base works much worse. Checking whether it is foil or not is very simple - you need to set the edge of the material on fire with a lighter. If it doesn't melt, it's foil.

The price of a heat reflector depends on the thickness. The material is sold at construction markets and supermarkets.

Removing and preventing the formation of air pockets in the heating system.

One of the main reasons for the deterioration of heating, and sometimes its absence, is the formation of air jams in the heating system of buildings. This causes consumer indignation towards heat supply organizations, sometimes groundless, because At that time, the source of thermal energy was the boiler room, operating in normal mode.

The first reason is that water itself contains dissolved air. If the water heats up, air begins to be released in the form of bubbles that rise to the uppermost sections of the pipelines. It is there that, accumulating, they create air jams.

laying porcelain tiles in the hallway of an apartment

The second reason is that when the pressure in the heating system decreases or changes, it is partially emptied, and all the resulting voids represent air pockets.

The third reason is that leaks from pipelines also contribute to the “airing” of the system as a whole.

The fourth reason is the repair of the piping system and subsequent assembly. There is no way to avoid the possibility of “airing”.

Practice shows that air most often collects in heating devices installed on the upper floors.

In such cases, at the upper points of the heating system, air is removed through special devices - Mayevsky taps.

When searching for the location of an air lock, tap the pipes and heating devices with a light hammer. Where air pockets are located, the sound becomes stronger and louder.

Air locks can form in places where pipelines are kinked. Therefore, when installing the system, it is necessary to observe the magnitude and direction of the slopes of the distribution pipelines.

Air locks are eliminated by opening the air bleed valves until all air is removed from the system. This method of removing air is repeated several times, especially on contaminated systems.

The news uses materials from the magazine “Miske Gospodarstvo of Ukraine”

Sergei Stefanchikov:

Installing a thermal insulator behind a radiator causes difficulties even for experienced workers with experience. That is why the problem area is sometimes left completely unattended, but heat loss in this place is maximum. Nobody wants to heat the street, so it’s important to be careful about the process.

A proven method of insulation placed behind the battery is a reflective screen . The operating principle is simple. A thin plate with a reflective surface is placed behind the heating system, reflecting radiated heat away from the wall. Thus, heat loss is minimized.

Material selection

A material with a low degree of thermal conductivity is selected from the following options:

- penofol;

- foil plastic;

- isospan (different types: polypropylene woven or non-woven fabric, coated polyethylene foam);

- Porilex with foil;

- other aluminum coated materials.

For complete sealing, the joints between the layers are covered with metallic tape.

Products containing metalized aluminum foil have similar properties. She is a reflector. If you are dealing with a thermally coated metal product, the thickness of the reflective layer will not be sufficient to serve as a heat reflection shield. Please take this into account when purchasing materials. To check whether this is really foil and not metal coating, a cut piece of insulation is set on fire. If it doesn't melt, then you're dealing with foil. It is used to reflect heat.

You can also make a screen yourself using a layer of plywood and a sheet of aluminum foil. Instead, a structure made of galvanized sheet is sometimes used.

For high-quality operation of the insulating screen, an empty distance of at least 3 cm thick is left between it and the heating device to ensure convection of air flows. Otherwise, the circulation of flows is disrupted, and the work will not help, but will only create other problems.

The effectiveness of insulation behind the battery

To verify the effectiveness of the insulation procedure, studies were carried out on the change in temperature inside the room after installing an insulator behind the radiator between the radiator and the external wall. The increase in temperature indicators is about 2 degrees. In addition to the heat-reflecting effect, a vapor barrier effect can be observed. Thus, the wall is protected from absorbing moisture formed when drying washed items on the radiator.

To obtain a similar effect, observe the conditions for installing reflective screens:

- The thickness of the insulation with foil is at least 5 mm.

- Low thermal conductivity coefficient of the material, no more than 0.05 W/m*°C.

- The reflective surface faces the room.

- The joints are taped with metallic tape.

- The size of the insulating screen is larger than the vertical area of the heating system.

Typically, foil heat insulators have a self-adhesive layer, using which the insulation is attached to the wall. Otherwise, the insulator is installed using a construction stapler. It's easy to install the screen yourself.

Using regular glue is not a good idea. For the reflector to function optimally, there must be an air gap between it and the wall, so a stapler would be the best option. You can also use a special grille to which a layer of heat insulation is attached.

Application nuances

When choosing thermal insulation, it is worth remembering that not everyone can reflect heat. In order for the indicator to be maximum, the foil must be thick enough. Most often, the insulation, its basis, is extruded polyethylene with a thick aluminum layer that retains maximum thermal energy. These include insulation materials Teplofol, Penofol, Alufol, and others.

Teplofol

Sheathing that can reflect is available in the form of mats, rolls, and pipe cylinders. If it is manufactured using testing technology, the thermal resistance characteristics must be indicated in the accompanying documents. If you foil the material, its range of applications will expand indefinitely. It's ideal for

For interior work, metallized polyethylene material, which is capable of reflecting heat, is ideal. When installing, you will need to leave a distance between the sheathing and the wall for ventilation. This will preserve the material and prevent moisture accumulation and mold growth. If this is external thermal insulation, you should choose mineral wool or polyethylene with metal

When laying, it is important that the material is joined, the cracks are taped with special tape. When the ceiling is insulated, mineral wool is used, a layer of air between it and the finish. To create such a structure, a sheathing of wooden blocks is installed, and a metal profile is also used.

For heating networks and small-diameter water mains, insulation without an air gap will be indispensable. If the pipe is large in diameter, a cushion between it and the casing is required; an exception to the rule is foiled mineral wool. When pipeline insulation is made of polyethylene, it is desirable that it be foil-coated on both sides. In order for heating radiators to operate at full capacity, they use a material that can effectively reflect heat. Cut the sheet to the size of the battery, place it between the wall and the heating device, the foil should be directed towards the room. Insulation is easy to install, but guarantees high efficiency of heaters, batteries, air heaters, increasing it by 30-35%.

battery thermal insulation

What does this threaten?

As a result, mold may appear on the walls. But such a problem does not always arise. Probably, when arranging the load-bearing walls, the builders did not comply with legal norms and rules.

Screens can only be installed for the winter and removed for the summer. Thus, the beneficial properties of the thermal insulator will only work at a certain time.

But the result from using insulation becomes noticeable immediately. The house will be warmer due to reduced temperature losses. Without shielding, the wall behind the battery sometimes heats up to 40 degrees. And the absorbed heat is wasted on heating the external walls.

Correct installation of a heat-reflecting screen involves placing it on the back side of the radiator and then mounting it on the wall with a gap of at least 4 mm.

This distance is considered the optimal value for high-quality heating of the air and performing a reflective function.

Installing a heat shield involves several steps.

These include:

- At the first stage, the necessary tools and materials are prepared. These include: foil insulation, cassette knife, tape measure, ruler, building mixtures for leveling walls, spatula, materials or elements for attaching a heat-reflecting screen to the wall behind the radiator, and an adjustable wrench.

- At the second stage, the heating radiator is removed and the surface of the wall on which the foil insulation sheet will be installed is leveled.

- Taking measurements of the niche under the window and cutting out the heat-reflecting screen, taking into account small allowances. Its size should be larger than the radiator area. The best option is considered to be simultaneous insulation of the lower part of the window sill. When making such a decision, the size of the screen should correspond to the total area of the niche and the surface under the window.

- Making markings and cross-shaped cuts with a cassette knife at the locations of the holes for the radiator mounts.

- The next stage involves placing the insulation on the wall surface in a niche, leveling it and ensuring a tight fit over the entire surface of the wall. At the same time, it should be remembered that the foil layer of polymer material should be directed towards the radiator.

- The heat-reflecting screen is attached in the absence of a self-adhesive base using a special adhesive composition, liquid nails, a stapler, and double-sided tape. The use of screws with dowels is considered the most reliable way of fixing insulation to the wall behind the radiator. Their placement around the perimeter and across the entire area of the canvas in a checkerboard pattern eliminates the appearance of wavy sections of the screen. When insulation comes out at the corners of the window sill, it is recommended to trim the material in accordance with the required dimensions.

- Installing the heating device in place is considered the final stage of installing the heat-reflecting screen behind the radiator.

Performing such simple steps and the affordable cost of foil insulation allows you to reduce heat loss, prevent moisture and steam from entering the inner surface of the wall behind the radiator, increase the temperature in the room and save on heating bills. Installing a heat-reflecting screen is a rational, cost-effective solution that is rightfully worthy of the attention of the country’s population.

This is interesting! Convector heating batteries: detailed classification, advantages and disadvantages of different models

Watch the video in which a specialist gives advice on how to install a heat-reflecting screen behind a radiator and how effective it is: