A standard heating system cannot be called flexible. To adjust the operating parameters of batteries, various devices have been invented.

One such device is a thermostatic valve for heating radiators. It is used to regulate the heat transfer of the system depending on weather conditions. In this article, we will analyze the design and operating principle of a thermal valve, and get acquainted with the existing varieties and main manufacturers.

We will also provide installation recommendations, providing the material with visual photos and video reviews on the installation and response speed of devices of various brands.

Using valves with thermal heads

These are the best taps that can be installed on radiators in the heating system of a private home. Tuned to a certain air temperature, the thermal head acts on the valve stem, forcing it to open or close its flow area. In this way, automatic quantitative regulation of the coolant passing through the heating device occurs.

The thermostatic valve is installed on the supply line to the battery, and a balancing valve is installed on the return line. It is a mistake to assume that the system will be automatically balanced by thermal heads; valves are needed in any case. Installation of conventional ball valves instead of them is allowed for centralized heating or in systems with associated coolant movement (Tichelman loop). But it is unacceptable to regulate the coolant flow using a ball valve, and it will not work.

Advice. Most models of thermal valves have a mechanical blocking mode for the flow area. If you received products without such a mode, then to service the battery you will have to install an additional cut-off device, as shown in the diagram:

Why do you need shut-off and control valves when installing a battery?

In general, this category of devices includes not only faucets of various types, but also various dampers and valves. And the shut-off valves for heating radiators also include plugs that are installed on the holes in the side of the battery.

When installing the battery, it is advisable to use:

- a couple of ball valves - they will be useful to quickly stop the flow of coolant into the battery. For this purpose, a bypass is installed, and shut-off valves are installed on the supply and return pipes;

Bypass will increase the reliability of the heating system

- when connecting the radiator to the system, a special shut-off valve can be used, which provides the ability to quickly drain water.

Among the regulating devices, an automatic thermostat will be useful; it will allow you to change the heat transfer of each battery individually. Thanks to this, you can save on heating costs, and the house will be more comfortable.

Note!. The thermostat is connected to the radiator itself, followed by a shut-off valve, then a bypass tube. Only with this sequence will the system work normally.

Purpose. Characteristic

Taps ensure efficient operation of water pipes. The heating system cannot operate without these devices, and in some situations, using it without them becomes downright dangerous.

When the riser leaks, it is the shut-off valves that shut off the water, which makes it possible to make repairs without stopping the entire system

An important function will also be managing the heat dissipation of the battery.

The minimum set for the normal functioning of a conventional heating system consists of several types of shut-off and control valves. When connecting to the radiator, shut-off ball valves are mounted on the supply pipes, on the outlet and on the bypass. A mechanism is installed on the supply to adjust the coolant pressure. The radiator itself must be equipped with a Mayevsky tap. to bleed air. As you can see, the number of such products is significant and this is by no means an excessive option.

Taken together, this system allows:

- turn off the radiator without shutting off the entire circuit for repair, replacement, or maintenance;

- direct all coolant through the heater with the bypass turned off;

- control the pressure power through the radiator to reduce or increase the temperature;

- drain water, bleed air;

- protect the system from hydraulic shocks and breakdowns;

- regulate the efficiency and level of heat supply, which saves heating costs.

Requirements

The criteria for the variety of types of taps placed on heating radiators are: design, principle of operation and material

It is important to know that mechanisms of this type are divided into shut-off and control valves. What are the best taps to install? It must be taken into account that they have a rather complex structure and must meet a number of requirements in order to function in difficult conditions

- coolant temperature up to 200°C;

- must withstand pressure of 16–40 bar;

- high corrosion resistance;

- resistance to mechanical loads.

For heating systems, such mechanisms are made more stable. Conventional taps and valves for cold water cannot be installed in heating radiators.

Each connection has its own characteristics: there are regular and corner (for the bottom connection) taps. This division allows you to maximize the distribution of pipes when installing a heating system. The design features of the valves allow you to hide the pipes behind the decor, in a screed, or to mount radiators in a small space under a window opening.

In everyday life, the general name is used - “faucets”. But from a technical point of view it is correct to distinguish:

Heating systems also use thermostats; it is not recommended to use dampers or valves in radiators - they quickly become inoperable. If shut-off valves are needed, then ball valves are the best for this. They have only two positions - closed/open. Valves with a cone are designed to control the pressure manually. There are also mechanisms for automatic adjustment - these are thermostats with valves or cones.

Purpose and range of shut-off valves

For heat supply systems, this fitting is used to control the supply of hot coolant and open the heating circuit.

As a rule, a shut-off valve on a heating device is mounted in areas where radiators are piped. In addition to functional advantages, such a solution has practical benefits. After closing the shut-off valve of the battery, the home craftsman will have the opportunity to repair it without stopping the functioning of the entire heating structure.

Today, shut-off valves for heating are offered in a wide range on the domestic market, and among the most commonly used products are the following devices:

- shut-off valves;

- valves;

- needle valves;

- Ball Valves.

Control valves

Operating principle

A control valve for a heating radiator is a device that allows you to automatically control the movement of the coolant.

The design of such products is quite complex, but they also work much more efficiently than valves for manual adjustment:

The bellows, a container filled with liquid or gas, is responsible for sensing the outside temperature. As the temperature rises, the bellows expands, affecting the control unit.

Please note! The price of liquid and gas-filled devices is approximately the same, but the operating features are different. Thus, gas models react faster to temperature changes, while liquid models more accurately convey the effect on the coolant flow

- The expanded bellows presses on the valve stem, which lowers and gradually closes the valve saddle, through which hot water enters the battery.

- When cooling, the opposite situation is observed: the rod rises and the lumen of the saddle expands.

We set the degree of initial compression of the bellows ourselves, either by setting the temperature value we need on the digital display, or by rotating the mechanical adjustment knob. It is also possible to connect the thermal valve with external sensors - in this case, the movement of the rod is controlled not by a bellows, but by a servo drive under the influence of an electrical or hydraulic system.

Installation of thermostatic tap

Among specialists, the question of whether it is necessary to install taps on heating radiators is practically not discussed. Even installing a simple ball valve provides a number of advantages, and the presence of a high-quality thermostat is even more so. However, the instructions advise following a number of rules when installing such devices:

Example of correct installation of the product

- First, you need to select a suitable valve modification. For systems with one pipe we use products of type RTD-G, for two-pipe systems - RTD-N.

- Secondly, before installing taps on heating radiators, we check the direction of movement of the coolant (indicated by an arrow on the body). If we mix it up, the device will work any way, just not the way we need it.

- Thirdly, we place the thermoregulation head perpendicular to the plane of the battery. so that the heat flow does not affect its operation.

How to regulate heating radiators using taps is also a fairly simple question:

- Having installed the valve on the radiator, we check the tightness and supply coolant to the system.

- Using the handle or dial, set the average temperature.

- After about an hour, we adjust the valve setting according to our feelings and checking the thermometer in the room.

- If necessary, repeat the adjustment again. however, this is usually not required.

The system is adjusted by rotating the handle

After this, it is usually necessary to interfere with the operation of the device no more than once a month - in case of sudden changes in external temperature.

Why do you need to make adjustments?

Setting the optimal temperature of the heating radiators allows you to create the most comfortable living conditions indoors. In addition, adjustment allows:

- Remove the effect of air in the batteries, allow the coolant to move freely through the pipeline of the heating system, effectively transferring its heat to the interior of the room.

- Reduce heat consumption costs by up to 25%.

- Do not keep windows constantly open if the air in the room is excessively overheated.

It is advisable to set up heating and adjust batteries before the start of the heating season. This is necessary so that later you do not experience discomfort in the apartment and do not adjust the heating temperature of the batteries in emergency mode. Before setting up and adjusting the radiators, initially in the summer you need to thermally insulate all windows. In addition, you need to take into account the specific location of the apartment:

- In the middle or corner of the house.

- Lower or upper floor.

After analyzing the situation, it is advisable to use energy-saving technologies to maximize heat conservation inside the apartment:

- Insulate walls, corners, floors.

- Carry out hydro and thermal insulation of the seams between the concrete joints of the panel house.

Without this work, it will be useless to regulate the temperature of the radiators, since the lion's share of the heat will heat the street.

Criterias of choice

A radiator valve is, as a rule, a ball-type device that regulates water flow and connects pipes to the radiator. Installed on the bypass, risers, at the top of the battery, in places where air accumulates to bleed it.

Choosing a suitable faucet is not difficult, just know a few nuances:

- the diameter of the pipes to which it will be connected (DN, in millimeters or inches);

- working pressure (PN, in the range of 15–40 and above);

- type of connection, presence of thread inside or outside, American.

The choice should take into account the purpose of the reinforcement, its location, and the properties of the environment

The ratio of the input and output of the valve in the radiator, their relative position is also important

When choosing, you should consider the characteristics of the cranes:

- Ball valves, although the most common and affordable, are not very effective. It has only two modes: closing/opening;

- a cone valve is a more acceptable option due to the possibility of an intermediate position. Disadvantage: the tap must be returned to its original position and constantly monitored;

- An automatic thermostat is the most efficient, reliable, but also much more expensive than others. When installing it on a one-pipe system, a bypass must be present.

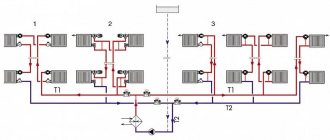

Strapping scheme

As a rule, in modern heating systems, the battery connection diagram (piping) looks like this:

- A control valve is installed between the inlet pipe and the battery - this can be a manual valve or a valve with a thermostat.

- A ball valve is installed between the outlet pipe and the radiator.

- A bypass (jumper) is installed in front of the input and output shut-off valves , which allows the coolant to bypass the battery if necessary. The jumper is installed when connecting radiators in series.

As a rule, a ball valve is embedded in the middle of the jumper.

At the outlet, it is better to install shut-off valves with a drain fitting.

This will make draining the battery easier.

Here, in fact, are all the instructions for connecting a heating battery.

For heating radiators, different types of shut-off valves can be used. Moreover, each type has different functions. Therefore, different types of taps are most often installed at the input and output of the battery.

You can find additional useful information on the topic discussed in the video in this article.

Balancing valve for heating system

Existing heat supply systems are conventionally divided into two types:

- Dynamic. They have conditionally constant or variable hydraulic characteristics, these include heating lines with two-way control valves. These systems are equipped with automatic balancing differential regulators.

- Static. They have constant hydraulic parameters, include lines with or without three-way adjustment valves, the system is equipped with static manual balancing valves.

Rice. 7 Balancing valve in the line - installation diagram of automatic fittings

In a private house

In a private house, a balance valve is installed on each radiator; the outlet pipes of each of them must have union nuts or another type of threaded connection. The use of automatic systems does not require adjustment - when using a two-valve design, the supply of coolant to radiators installed at a large distance from the boiler is automatically increased.

This occurs due to the transfer of water to the actuators through a pulse tube under lower pressure than that of the first batteries from the boiler. The use of another type of combined valves also does not require calculating heat transfer using special tables and measurements; the devices have built-in control elements, the movement of which occurs using an electric drive.

If a manual balancer is used, it must be adjusted using measuring equipment.

Rice. 8 Automatic balancing valve in the heating system - connection diagram

To determine the volume of water supplied to each radiator and, accordingly, balancing, an electronic contact thermometer is used, with which the temperature of all heating radiators is measured. The average supply volume per heater is determined by dividing the total value by the number of heating elements. The greatest flow of hot water should flow to the furthest radiator, a smaller amount to the element closest to the boiler. When carrying out adjustment work using a manual mechanical device, proceed as follows:

- Open all control valves all the way and turn on the water, the maximum surface temperature of the radiators is 70 - 80 degrees.

- Using a contact thermometer, measure the temperature of all batteries and record the readings.

- Since the furthest elements must be supplied with the maximum amount of coolant, they are not subject to further regulation. Each valve has a different number of revolutions and its own individual settings, so the easiest way is to calculate the required number of revolutions using the simplest school rules based on the linear dependence of the radiator temperature on the volume of passing coolant.

Rice. 9 Balancing fittings - installation examples

For example, if the operating temperature of the first radiator from the boiler is +80 C., and the last +70 C. with the same supply volumes of 0.5 m3/h, on the first heater this indicator is reduced by a ratio of 80 to 70, consumption will go less, and the resulting volume will be 0.435 m3/h. If all the valves are not set to the maximum flow, but set to the average value, then you can take the heaters located in the middle of the line as a guide and similarly reduce the throughput closer to the boiler and increase it at the farthest points.

In a multi-storey building or building

The installation of valves in a multi-storey building is carried out in the return line of each riser; if the electric pump is far away, the pressure in each of them should be approximately the same - in this case, the flow rate for each riser is considered equal.

To set up in an apartment building with a large number of risers, it uses data on the volume of water supplied by an electric pump, which is divided by the number of risers. The resulting value in cubic meters per hour (for the Danfoss LENO MSV-B valve) is set on the digital scale of the device by rotating the handle.

Features of installation and maintenance of regulators

Thermostat installation diagram

After choosing the optimal model of thermostat or tap for regulating the heating temperature, you should install them correctly. The location of the fittings directly depends on its function and design.

Most often, the adjustment components are mounted in the trim of a specific heating radiator. They are installed on the supply pipe or on the bypass. In order to comfortably adjust the temperature of the radiators, it is recommended to adhere to the following rules:

- The device should not be covered with decorative panels or other interior items;

- The service life of thermostats largely depends on the quality of the coolant. Therefore, a mesh filter should be installed in front of it, which will protect the valve seat from limescale;

- When installing the heating temperature control valve, you must follow the installation diagram. On the body of the device, arrows indicate the direction of movement of the coolant;

- Many thermostats and servos are connected to the electrical network. Therefore, it is necessary to provide power supply to them.

Before installing and further adjusting heating batteries in an apartment, you must read the manufacturer's instructions. It specifies the installation conditions for the operation of a specific adjusting element.

One of the important indicators of apartment heating control valves is the maximum and minimum throughput. They must match the current system parameters.

Maintenance of regulators and valves

Pressure testing is carried out only after installing the control valves

After installation, preliminary adjustment of the taps on the heating radiators should be carried out. To do this, the operating temperature and pressure in the system must be normal. Then, by changing the degree of heating of the coolant, the operation of the control valves is checked. The system is tested in several modes. Alas, it will not be possible to independently adjust the heating in an apartment building using this scheme, since consumers do not have the opportunity to change the degree of heating of the coolant.

In fact, it is possible to check the performance of a specific element only when starting up the central heating supply. Those. Correct adjustment of heating radiators in the apartment is carried out during the heating season.

During the startup of the heating system, the heating system of a private house must be fully adjusted. It should include the following steps:

- Checking the functionality of taps and thermostats;

- Compliance of their actual parameters with passport data;

- If, during the control adjustment of the degree of heating of the heating batteries, a faulty element is detected, it must be replaced.

In addition, you need to remember that the operation of the system is influenced by a number of external factors: the degree of thermal insulation of the house, the climatic features of a particular region. This should also be taken into account when adjusting the temperature of the heating radiator.

The video shows an example of organizing the adjustment of heating radiators in a house:

Advantages and disadvantages

Advantages of using thermal valves for heating radiators:

- The ability to automatically regulate the heating of the room and create comfortable conditions for the residents of the house.

- Ability to adjust the heating level of the radiator.

- Reducing the temperature in unused rooms to minimum positive values.

The most significant advantages of thermal cranes are the ability to save fuel. They limit the heating of rooms and make it possible to minimally heat unused rooms. The use of heating control in a private house saves approximately 20% of fuel; when preserving the second floor or part of the rooms, even more (for example, bedrooms, guest rooms, saunas, cinema rooms, billiard rooms, gyms, etc.). Even turning off the heating in one room for five days a week (in the “student bedroom”) produces noticeable savings. But you shouldn’t think that one unheated room will freeze the whole house - with the doors closed, the temperature in one room does not drop below +10 °C.

Any heating system, even designed by an experienced plumber, is not ideal. The possibility of not entirely uniform heating of rooms is possible - thermal valves are also used to compensate for uneven heating. They are also used to lower the temperature in buffer zones that do not require constant heating at 20 °C (in storerooms, boiler rooms, vestibules, hallways, verandas). Often, prudent owners increase the heating of the bathrooms only before the evening bathing of the family and especially children, and the rest of the time they maintain an acceptable 20...21 ° C.

In fairly complex and expensive “smart home” systems, the heating is generally programmed in such a way that the temperature in the house decreases during the day, when the family runs off to work, school, or kindergarten, and increases in the evening, when everyone is gathered. In such a system, the advantages of using thermal valves increase to the maximum, and the disadvantages are almost unnoticeable.

The disadvantages of using regulators are some complication of installation, a slight increase in hydraulic resistance. Additional thread resistance increases the possibility of leakage. In addition, thermal valves require maintenance - they become clogged, and sometimes (in a private house once every few years, in an apartment - annually) they need to be removed and cleaned.

Design and operating principle

The principle of operation of balancing valves is to block the flow of liquid with a retractable valve or rod, causing a reduction in the cross-section of the passage channel. The devices have different designs and connection technologies; in a heating system they can additionally:

- Maintain the pressure drop at the same level.

- Limit coolant consumption.

- Shut off the pipeline.

- Perform drain functions for working fluid.

Structurally, balancing valves resemble conventional valves; their main elements are:

- Brass body with two through pipes with internal or external threads designed to connect to a line with standard pipe diameters. The connection in the pipeline, in the absence of a threaded fitting with a movable threaded nut (American), is made through its analogues - additional adapter couplings with different union nuts.

- A locking mechanism, the movement of which regulates the degree of blocking of the coolant passage channel.

Rice. 4 Danfoss LENO MSV-B manual balancing valve

- Adjustment handle with scale and setting indicators, allowing you to adjust the flow inside the device.

- Modern models are equipped with additional elements in the form of two measuring fittings, with the help of which the flow volumes (throughput) are measured at the inlet and outlet of the device.

- Some models are equipped with a shut-off ball mechanism that allows you to completely shut off the flow, or have the function of draining liquid from the water supply.

- High-tech modern types can be controlled automatically; for this, instead of a rotating head, a servo drive is installed, which, when power is supplied, pushes the locking mechanism, and the degree of channel closure depends on the amount of voltage applied.

Rice. 5 Danfos AB-QM automatic balancers - design

What is an Angle Stop Valve

They differ from each other, first of all, in their operating principle. Now we are interested in the principle of operation of the corner valve. The valve shut-off element rotates on a spindle. When the spindle rotates, a forward-return movement of the lock occurs, which simply blocks the flow.

The angle valve blocks the flow gradually, that is, it is a smooth adjustment device. When using a valve, the flow can be opened as much as necessary in a particular case.

The corner valve is a valve that is familiar to each of us since childhood. They are mainly installed in apartments on water faucets. Angle valves are also used in heating systems.

They are often used on pipe bends when heating pipes transition to a heating device. In this case, you can also connect a temperature control sensor to the valve. In this case, the valve is driven electronically.

When the required temperature level changes, the sensor sends a signal to the valve to change the level of water flow into the device and thereby change the temperature. They can be of various types: with a built-in or remote sensor, with remote control and other functions.

As the pressure increases and the pipe turns sharply, the valve can simply be knocked out by the pressure. In addition, angle valves are available in small diameters.

Thus, the angle valve has the following characteristics:

- features smooth adjustment;

- used at low blood pressure;

- differs in a variety of areas of application.

An angle valve is a durable part of the fittings if properly maintained. Since the flow shutoff is sealed when the shut-off element enters the pipe, the seals or O-rings wear out quite quickly.

Therefore, to maintain the operating condition of the valve, it is necessary to periodically change these rings. This ensures high quality of operation and smooth operation of the valve.

Use only the highest quality materials to create a sewage system in your apartment. This will save you a lot of time, money and nerves. You can, of course, not listen to this, then, most likely, you will have to listen to the “singing” at night. your pipes.

Locking devices

The taps used for installation in the room heating system should be divided into two groups - shut-off and control. This division is largely arbitrary, since shut-off valves also allow you to regulate the movement of the coolant. Naturally, in this case the adjustment accuracy is quite low, but it is possible to cut off the battery from the water source.

Ball design diagram

The simplest and most commonly used type of valves are ball valves:

The ball valve is designed to shut off the radiator. Its design allows the device to be installed in either an open or closed position, so that the adjustment is carried out quite according to the principle “there is heat - there is no heat.”

Ball valves for heating radiators provide two-position adjustment

Please note! In principle, you can fix the valve in an intermediate position, but then the rate of its wear will increase many times due to the friction of particles suspended in water against the shut-off element. So it is better not to do this unless absolutely necessary

- The coolant flow is blocked by the movement of a metal ball with a hole coaxial with the pipe clearance. When you turn the faucet handle, the rod comes into action, which rotates the sphere inside the body, aligning the hole in it with the lumen of the pipe.

- As a rule, faucet parts are made of steel, bronze or brass. PTFE gaskets are responsible for sealing the connections and the locking part, which, if necessary, can be replaced with your own hands.

- Connection to the radiator is carried out either using a regular nut or using an “American” one.

Ball design with American

Unlike ball valves, cone valves make it possible to regulate the coolant flow more smoothly. This is ensured by the features of their design:

Sectional view of the device

- The locking element is a conical rod, on the surface of which a thread is applied.

- When we rotate the flywheel, the rod moves along the thread, moving in a vertical plane.

- In the lowest position, the pipe lumen is completely blocked. The tightness of the overlap is ensured by elastic gaskets that fit onto the annular grooves of the rod.

- By lifting the locking part, we open the gap slightly, and the coolant begins to flow into the radiator.

Please note! The indoor microclimate can only be adjusted approximately by decreasing or increasing the amount of hot water in each battery

Model in polypropylene case

In practice, bronze or brass cone valves for heating radiators are most often used: only systems are equipped with polypropylene, some of the pipes in which are also made of plastic. This is explained by the relatively low strength and wear resistance of polymers compared to sanitary alloys.

On the other hand, polypropylene taps for heating radiators are somewhat cheaper, so in conditions of budget deficit they can be used.

Mayevsky crane

When you pour coolant into the heating system, air gets inside along with water or antifreeze.

To remove it, special devices are used - the so-called Mayevsky taps:

Air release device

- The design of such a product is quite simple: it is based on a shut-off rod installed in a housing with a thread for the radiator plug.

- The rod is driven either by a screwdriver or a special wrench, opening the lumen of the pipe in the saddle.

Please note! If possible, buy valves for a screwdriver, since you will regularly lose the key, which is not surprising - you will have to use it once or twice a year. You need to keep in mind that the throughput of such a faucet is small, so, for example, you shouldn’t install it on an expansion tank: it will take about an hour to bleed off excess air

In such a situation, a regular valve or a water tap installed with the spout facing up is more suitable.

You need to keep in mind that the throughput of such a faucet is small, so, for example, you shouldn’t install it on an expansion tank: it will take about an hour to bleed off excess air. In such a situation, a regular valve or a water tap installed with the spout facing up is more suitable.

Photo of the installed valve

Types of pipeline fittings

Reinforcement products are classified according to method of application, purpose, design. The types of fittings on pipelines are as follows:

- flanged;

- connecting;

- for pipes made of different materials;

- for nuclear power plants.

Let's take a closer look at these types.

Flanged

A flange is a flat disk with a certain number of mounting holes. The flanges of adjacent elements fit tightly to each other. The connection is made by tightening the fastening bolts with nuts. Gaskets ensure tightness. Flange fittings are installed in systems operating at different pressures and temperatures. The flange is welded to the pipe.

The flange connection is dismountable, which simplifies repair work, inspection and replacement of elements. It is made of cast iron or steel, is used for pipelines from 50 mm in diameter, can withstand temperatures up to 400 C, and can be placed in horizontal and vertical positions.

Connective

Pipeline connecting fittings are used when connecting elements made of different materials and diameters. At the point of joining of pipes made of steel and plastic, where the diameters of the elements being connected are different, connecting fittings are used.

Couplings, plugs and other fittings are installed as additional parts, the design of which does not have a locking and adjusting mechanism. Such elements ensure quick installation and replacement of pipeline parts. Connecting elements are produced with a cross section of 25-2020 mm, for pressure from 1 to 4 MPa, from cast iron, steel, and plastic.

Stainless

Stainless steel pipe fittings form a connection that does not react chemically with the working environment, which ensures the longevity of the system. Elements such as valves, taps, adapters, gate valves are used for stainless pipelines when transporting food liquids, alcoholic and non-alcoholic drinks.

Stainless steel elements form a strong connection that is resistant to corrosion and aggressive environments, which ensures its use in the petrochemical and gas industries, pharmacology, and nuclear power plants. The parts do not interact with the transported products and do not change its structure.

Valves for nuclear power plants

A nuclear power plant is a high-risk energy facility. Its design includes a large number of pipelines, and industrial pipeline fittings are installed. The following requirements apply to the elements:

- The direction of movement of the working fluid must coincide with the arrow on the body.

- Do not use parts that are not suitable for their intended purpose.

- Access to all types of fittings must be free.

- Cover the connecting elements of the pipeline that are heated during operation with a removable structure with thermal insulation, secured with threads.

Separate parts of a pipeline under high or medium pressure are connected by welding or flange fittings, which reduces the possibility of leaks. The material for the products must be high-quality metals.

Important: to ensure the safe operation of steam generators, safety valves are installed - main and auxiliary. To remove drainage from the station circuit, first install a shut-off valve, then an adjustment valve.

Metal-plastic pipe fittings

Metal-plastic pipes are used for installation indoors. This is internal plumbing and heating. The sections are connected by valves, shut-off and transition valves and other elements. They are used at coolant temperatures up to 95 C and pressure 16 atm.

Pipelines made of metal-plastic are used in everyday life, have a neat appearance, and have a threaded or pressed connection. The fittings are made of nickel-plated brass. The products have standard sizes and are marked on their surfaces.

Fittings for polyethylene and polypropylene pipes

Fittings for plastic pipes are distinguished for pressure and non-pressure systems. For polyethylene pipes, a welded connection is considered the most reliable. As a result, we get a single cast sealed pipe.

American: what is it, a fitting for connecting pipes A device used to combine individual elements of pipelines into a single circuit, consisting of a union nut and threaded bushings, is called an American fitting among plumbers. Used in…

To regulate the flow and divide it into separate parts, taps, dampers and valves are used that can withstand pressures of up to 16 atm and temperatures from 45 to 80 C. Brass, bronze, and steel fittings are used.

For water supply, it is permissible to install polyethylene taps with a metal insert. Date: September 25, 2022

Balancing valve manufacturers

Models from foreign and domestic manufacturers are widely represented on the construction market; some companies are leading suppliers of energy-saving equipment.

Danfoss, a Danish company founded in Norborg in 1933, is one of the world's leading manufacturers and suppliers of energy-saving systems. The concern produces refrigeration equipment, power electronics, heat pumps, thermal and industrial automation, cable heating systems (warm floors). The product line is represented by shut-off, automatic and manual balance valves of the ASV and MSV series, combined models AB-QM, AB-PM.

Broen is a Danish company founded in 1948 by Swedish engineer Paul Broen and appeared on the Russian market in 1996. The company's plant has been operating in the Kolomensky district since 2010. The concern produces a wide range of pipeline fittings, which include: ball valves, gate valves, check valves and balancing valves (Broen Ballorex), safety valves, cast iron filters. The line of balancing fittings is represented by the Broen series: Venturi Fodrv, DRV, Dynamic, Venturi DRV.

Rice. 13 Balancing fittings from Danfoss and Broen

Giacomini is an Italian supplier of pipeline fittings. The concern was founded in 1951, has a turnover of 170 million euros per year, 3 factories in Italy and 18 branches around the world, employing about 1000 employees. The concern produces control and shut-off valves for radiators, thermostats, manifolds for heating and water supply, pipes and fittings for energy metering equipment, and solar panels. Balance valves are represented by modifications R206 A, R206 B.

ADL is a Russian manufacturer of engineering equipment for the housing and communal services sector and various industries. The company was founded in 1994, and since 2002 it has had its first plant in the village of Raduzhny, Kolomna district, Moscow region.

The company produces a wide range of plumbing equipment: control check valves, pumping units, gate valves, valves and ball valves, circulation and steam-condenser pumps, heating units, separators. The line of balancing valve devices is called Granbalance and consists of models of the DN series.

Fig. 14 Automatic balancing valve Giacomini and ADL

A balancing valve for a heating system is an essential device for maintaining a constant temperature in risers or heating radiators. Their use in everyday life is not entirely justified. The cost of one device from a well-known manufacturer reaches 100 USD; domestic devices are also not cheap. It is more rational to use the devices to maintain the temperature in the risers of apartment buildings with a large number of radiators.

Any heating system must be configured properly. The main goal of this setup is to ensure the same performance in all parts of the network. For example, if this is the heating system of a multi-storey building, then there should be heat on both the top and bottom floors. These indicators should not only be equivalent, but also close to the normative ones. One of the most effective ways of setting is to use a balancing valve, the installation of which should ideally be thought out at the stage of creating a heating system project.

Radiator shut-off valve. Features of ball and valve valves with thermostat

In modern heating systems, when connecting radiators, shut-off and control valves must be installed. As a rule, they perform several functions simultaneously. In this article we will look at what shut-off valves for heating radiators are usually used, and also get acquainted with its functions.

Valve for radiator

Why are there taps on radiators?

Each heating device is a separate element of the system that requires adjustment and periodic maintenance. If you control the coolant flow through the batteries depending on the heat demand, you can achieve good results in terms of energy savings. That is, radiator valves and heating taps are designed to solve the following problems:

- Complete isolation of the heating device from the system.

- Restriction of coolant flow through the battery.

- Change in coolant flow depending on external conditions.

- Bleeding air from the radiator and piping network.

There are many situations in which it is difficult to do without disconnecting the battery. For example, properly working central heating in the middle of spring, when it’s already warm outside, but it’s just hot in the apartment. Another case is the need to remove a heating device for the purpose of replacement, flushing or repair. In the absence of shut-off valves, carrying out any action with the radiator becomes problematic.

Valves are also installed on batteries in retro style

Restriction of the flowing coolant is carried out in order to balance individual heating in a private house or apartment

No matter what type of heating system you have, without balancing with valves, the first radiators will always receive more water than the last ones. Limiting the coolant flow at the beginning of the network and thereby balancing all devices with each other is the task of the control radiator fittings

Automatic control of the flow of incoming coolant is a way to save energy used to heat the house. If each tap on the heating radiator maintains the set air temperature in the room by controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And this is a considerable saving.

Well, the problem of air release when filling the system or during operation is also solved by special air valves installed on all modern radiators. Below is a list of types of shut-off and control valves, listed in the same order as the tasks they solve:

- Half-turn ball valves in straight and angle versions. Made from brass, bronze or polypropylene with a metal insert.

- Balancing valves for radiators – straight and angular.

- Regulating valves with thermal heads (thermostatic valves).

- Air drain valves – automatic and manual.

For reference. Some home craftsmen use three-way mixing valves to connect heating appliances. But such a solution is unreasonably expensive and is rarely used in practice.

Now we should consider in detail which taps are best installed on radiators in various conditions and circumstances. Some options are clearly shown in the video:

Why is a thermostatic valve needed?

The valve solves two problems: maintains the room temperature at a comfortable level and saves energy.

But in order for it to really cope with such functions, you need to understand in what cases the device is appropriate and how to install it correctly.

If in the middle of winter there is a need to open the windows so that the temperature in the room drops to an acceptable level, a thermostat is definitely needed. But it won’t help when the radiators are barely warm—it will probably make it even colder.

In the second case, it is better to try to regulate the temperature in the room differently: change the volume of coolant in each radiator, adjust the operation of the boiler (for a large area), select the optimal circulation pump or adjust the operation of the existing one.

The price of a thermostat ranges from several hundred rubles (200-600), so re-equipment of the heating system will not be expensive. But there are also expensive models

As a temporary measure, control valves can be used. But it is not recommended to use ball valves for these purposes.

Balancing valve

The design of a valve for regulating heating differs from a conventional ball valve in that it can smoothly close the flow area in a few turns. Moreover, after balancing, the position of the valve can be fixed so that no one accidentally violates the settings. This type of control valves is installed at the outlet of the radiator, as shown in the diagram:

Shown here is the connection to a two-pipe horizontal system, most common in private houses and apartments with individual heating. By the way, the principle of installing fittings with a single-pipe scheme remains the same. A regular ball valve is installed on the supply line, and an adjustment valve is installed on the return line. In the case when a two-story house has a system with vertical risers, the installation diagram of the accompanying fittings looks like this:

The principle of product selection is the same as in the previous section

Straight or angular design is accepted depending on the layout of equipment and pipelines; it is also important to use American designs during assembly

Pay special attention to the quality of casting and the thickness of the brass walls of the fittings. If you have networks made of polypropylene pipes, do not rush to buy PPR taps; it is better to install adapters and reliable metal products

Advice. Balancing valves are installed on all radiators, except for the very last one, located at the dead end of the branch. It is enough to install simple ball valves on the connections to it.

Radiator valve equipped with thermostat

Thanks to the radiator shut-off valve with a thermostat, it is possible to switch the adjustment of the coolant flow rate to automatic mode. Another name for this device is a thermal valve or thermal valve. The shut-off valve for a heating radiator is quite simple to install.

The locking mechanism includes the following parts:

- Metal body. It has a passage hole and a seat.

- Elastic cone.

The degree of permeability of the coolant is regulated by lowering and raising the cone. How it is located depends on the thermal head (thermoelement), which consists of the following elements:

- Cylinder (bellows).

- Thermal agent. Liquid or gaseous bellows medium. The volume of the thermal agent largely depends on fluctuations in ambient temperature.

- Piston. On one side it is connected to a cylinder, on the other - to a cone.

A change in temperature provokes compression or expansion of the thermal agent. This activates the piston, which changes the position of the cone through the rod. Thanks to the thermal head, the temperature is adjusted, resulting in complete blocking of the liquid flow.

- Mechanical.

- Electronic. They have a display and a sensor that displays the air temperature. This makes it possible to plan the operating modes of the shut-off valve for different times of the day or days of the week.

For example, during the daytime work or study of family members, it is logical to set a lower temperature value. Upon the return of household members, the batteries will heat up to higher values, effectively heating the home. The cost of electronic thermostats is noticeably higher than mechanical ones. To save a little money, not all radiators in one room are usually equipped with a thermostat. It is enough to have a control device on one or more heaters, which together provide at least half of the total heat.

Modern heating systems are equipped with the following battery connection diagram:

- The supply pipe and the battery are separated by a control valve. We are talking about a manual valve or a valve with a thermostat.

- The return pipe and radiator are separated by a ball valve.

- The inlet and outlet shut-off pipes are additionally equipped with a bypass (jumper). Thanks to it, the coolant in the right situations has the ability to bypass the battery. Jumpers are used in serial radiator connection diagrams.

There is usually a ball valve in the center of the bypass. It is recommended to equip the outlet with shut-off valves with a drain fitting. This makes draining the battery much easier.

To make the operation of heating radiators more efficient, they are equipped with different types of shut-off valves, depending on the technological requirements of the system. It is for this reason that different types of taps and valves are installed on the supply and return pipes.

Step-by-step instructions for adjusting temperature

To ensure comfortable living conditions in the room, you need to perform some basic steps.

- Initially, it is necessary to bleed the air on each battery until water flows from the tap in a trickle.

- Then you need to adjust the pressure in the batteries.

- To do this, in the first battery from the boiler you need to open the valve by two turns, on the second - by three, and then according to the same scheme, increasing the number of turns of the valve being opened on each radiator. Thus, the coolant pressure will be evenly distributed over all radiators. This will ensure its normal passage through the pipes and better heating of the batteries.

- In a forced heating system, control valves will help to pump the coolant and control rational heat consumption.

- In a flow-through system, the temperature is well regulated by thermostats built into each battery.

- In a two-pipe heating system, you can control not only the temperature of the coolant, but also its quantity in the batteries using both manual and automatic control systems.