Most modern gas boilers are energy dependent. Interruptions in the power supply completely stop their operation, which not only affects comfort, but also risks freezing of the coolant, and subsequently emergency depressurization of lines or heating devices. Fortunately, the solution is quite simple - installing a generator. Even the simplest models are often sufficient to ensure the operation of the automation of a boiler, circulation pump or turbine.

There are generators that run on gasoline, gas or diesel fuel, generators that are manually started or provide completely autonomous operation of the heating system, standard or inverter, synchronous or asynchronous - all these selection criteria are worth considering in more detail.

Rating of electric generators

The presence of an electric generator instantly solves the problem of blackout. Such products are in steadily growing demand, so more and more offers are appearing on the market. The VyborExpert project team compiled a list of determining factors by which the top rating was compiled:

- Type of fuel consumed;

- Fuel tank capacity;

- Power in minimum and maximum indicators;

- Quality of generated current;

- Intended use;

- Battery life;

- Two- or three-phase type;

- Additional options;

- Size, weight;

- Unpretentiousness in maintenance;

- Reliability of design and service life;

- Permissible temperature conditions for uninterrupted operation;

- Economical current consumption;

- Noisy when active;

- Protection from moisture, dust, interruptions, overheating.

The expert review included those models that demonstrate the best specified parameters, while their price corresponds to the build quality and functionality. The collection of information included the opinions of experts in this field, positive customer reviews, and test results.

The best heat pumps

Selection and calculation of the inverter

When calculating the required output power of the inverter, it must be taken into account that the presence of circulation pump electric motors in the load circuit will cause an increase in both constant current consumption, which determines the so-called power factor of the electric motor (cosine phi), and a significant current load at the time the pumps start. The maximum power consumption should not be more than 75% of the maximum power of the inverter output stage, especially for line-interactive devices in which the inverter operates constantly.

For an example of calculation, let's take a system consisting of a Baxi Fourtech gas boiler and two Oasis 25/2 pumps. Since the boiler electronics itself does not have an inductive load component, we will take its rated electrical power of 130 W into account without correction. The pumps have a rated power of 35 W. If the manufacturer did not also indicate the power consumption (in this case, 60 W), it could be defined as two times the nominal. Consequently, the consumption of two pumps will be 120 W in steady state, setting a double margin for the starting current and summing it up with the consumption of the boiler itself, we get a figure of 370 watts. Taking into account the power reserve for the inverter output stage, we will need a converter with a power of at least 0.5 kW.

If the inverter manufacturer indicates its power in kilovolt-amperes (kVA), you can convert it to kilowatts by knowing the power factor (cos φ) of the inverter itself. Thus, an uninterruptible power supply with cos φ=0.8 and a power of 1 kVA has a real power of 800 W.

The second parameter when choosing an uninterruptible power supply is the time during which it can supply power to the intended load. When calculating it, it must be taken into account that, on average, the functionality of the UPS output converter is maintained when no more than 75% of the battery capacity is exhausted. For example, if we use a battery with a capacity of 60 Ah, it can actually deliver no more than 45. Then, taking into account the average inverter efficiency of 80%, we get the following:

- The load from the previous example in steady state is 250 W, taking into account the losses in the inverter, we obtain the power taken from the battery at 312 W.

- At a nominal voltage of 12 V, this power means a current consumption of 26 A - a fully charged battery can supply the load for approximately 1.7 hours.

The type of uninterruptible power supply you choose determines both the budget and the features of the electrical network used. If the voltage in the network is relatively stable, it is enough to purchase an “offline” class UPS, but if the voltage fluctuates greatly, it would be more reasonable to either supplement it with an external stabilizer, or immediately buy an “online” or line-interactive class inverter. Since inverters of the required power usually use external batteries, it is worth checking what maximum charging current they can provide.

Considering that the optimal current for charging a battery is 10% of its nominal capacity, a device with a stated charging current of 6 A will work with batteries with a capacity of up to 60 ampere-hours.

Electric boiler design

In the most general case, the design of an electric boiler looks like this. There is a steel container with pipes for connecting the supply and return pipelines of the heating system. It has built-in devices of different designs for heating boiler water - induction coils, electrodes or heating elements.

Photo source: kit.byklimatkotlyelektricheskie

They determine the cost of the boiler unit (in descending order). In some cases, thermal insulation of parts of equipment in contact with heated water, a built-in circulation pump for it, and more are provided. There must be elements of automation (air vents, thermistors, pressure gauges, etc.), protection (against overheating, current leakage) and thermal power control.

Video description

How to choose a generator to start a boiler

When choosing the period of continuous operation of a generator, you need to take into account that no one is immune from such cases. You should adhere to the golden rule - the continuous operation of the generator should be at least 7 hours, which is enough for a person to get a good night’s sleep. The continuous operation of some compact and inexpensive models does not reach 3.5 hours. During severe frosts, the remaining 3-5 hours of sleep may be enough for the most remote areas of the heating system to freeze, since they will cool down very quickly when the circulation pump is turned off.

Part required for boilers with electric ignition

The generator is not mentioned by chance. If we talk about complete independence of the house from external networks, then this device is one of the elements to ensure it. Especially when we are talking about country houses located in areas where, for some reason, there may be a power outage. In this case, a gas generator will be necessary.

The fact is that all boilers, according to the connection method, are divided into:

- systems with piezo ignition;

- with electronic ignition.

In the first, the flame is ignited manually. But the second one needs electricity to start working. What to do if it is missing? Naturally, in such cases the generator comes to the rescue. It allows you to turn on light bulbs, keeps the refrigerator “alive”, and makes it possible to watch TV. He will also start the gas boiler, thereby preventing people from freezing.

The only question is which gas generator will be ideal for a particular heating system. There is a serious problem here due to the fact that many gasoline generators, regardless of what manufacturer they are, are not able to provide high-quality electric current at the output. As you know, automation suffers greatly from voltage surges.

What problems may occur after connecting?

Any gas boiler has a number of requirements for the quality of electrical energy, compliance with which guarantees stable and proper operation of gas equipment. The most frequently regulated limits are the voltage and frequency of the electrical network.

An example of a gas boiler error indication associated with low voltage in the network Source Teploburg.ru

Frequency fluctuations

Frequency fluctuations in the electrical network when using a gasoline electric generator are very rare, but possible. First of all, these fluctuations affect the operation of electric motors. With a change in frequency, the rotation speed of the circulation pump changes, and in pressurized gas boilers, the rotation speed of the air injection motor, due to which the burner burns unstably, because the gas-air mixture changes in composition over a wide range.

It is possible to avoid such a scenario by purchasing an inverter or gas generator with a synchronous actuator. They provide minimal fluctuations in output frequency.

Voltage fluctuations

Voltage fluctuations at the generator output most often result in inadequate operation of the gas boiler. Voltage dips and surges lead to periodic shutdowns of various automation elements and even the circulation pump. Specific faults depend on the boiler model. Most often the boiler shuts down completely.

Most modern boiler models are recommended to be connected via a voltage stabilizer. This will avoid possible problems in its operation associated with fluctuations and surges in voltage levels.

What is a gas burner

The gas burner is one of the most important components of any boiler. She is responsible for creating a stable flame. This is where the supplied fuel is burned. The resulting heat rises upward to the heat exchanger, where it is almost completely transferred into the coolant. Combustion products, along with residual heat, are removed into the atmosphere in one way or another.

The design of a gas burner for a boiler is extremely simple - it includes several main components:

The low emission of nitrogen oxides and carbon monoxide during combustion makes the boiler almost flawless in environmental terms.

- Nozzle - gas is released from here;

- Ignition system – provides gas ignition;

- Automation system – controls the temperature;

- Flame sensor – monitors the presence of fire.

To put it simply, this is exactly what it looks like. You will find out a little later how these or other types of gas burners differ from each other in different boiler models.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, quiet operation is important. I immediately remember some models of Soviet instantaneous water heaters, where the flame roared with the force of a hurricane

Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops or explosions). The design of the combustion chambers has an additional influence on the noise level. Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was made to last)

Today, such technologies no longer exist, so burners in boilers often break down. There is only one way out - to buy units from trusted brands that use components of normal quality. As for any Chinese junk from unknown manufacturers, everything is obvious here - you shouldn’t take it

Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was made to last). Today, such technologies no longer exist, so burners in boilers often break down. There is only one way out - to buy units from trusted brands that use components of normal quality. As for any Chinese junk from unknown manufacturers, everything is obvious here - it’s not worth taking.

The same applies to cheap Russian-made boilers - they often have short-lived burners installed.

Complete combustion of gas is another important requirement. A burner for a gas boiler must burn fuel completely, with minimal release of carbon monoxide and other related components. However, everything here depends not only on it - the quality of combustion is also influenced by other components

We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal. As for the operating principle of the gas burner, it is simple:

However, everything here depends not only on it - the quality of combustion is also influenced by other components. We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal. As for the operating principle of the gas burner, it is simple:

In the burner, the burned gas is combined with air. At high temperatures, a chemical reaction occurs to form carbon dioxide and water.

- The boiler detects a discrepancy between the temperature in the heating circuit and the parameters specified by the users;

- The gas valve opens and gas begins to flow into the burner;

- At the same time, the ignition system is activated;

- The gas is ignited and a flame is formed.

At the same time, the flame presence control begins to work - if the fire suddenly goes out, the automation will shut off the supply of blue fuel. As soon as the temperature in the heating system reaches the specified limit, the gas supply will be shut off.

The implementation of flame presence control is implemented in gas burners in different ways. Somewhere there is a simple thermoelement, and advanced boilers with electronic-based automation are equipped with ionization control systems.

Types of generators for heating boilers

The advantages of using a generator are obvious. Such a unit is economical to use, characterized by a reliable design, and most importantly, with such a device your boiler will operate without failures or malfunctions.

Based on what type of fuel is used, electricity generating devices are of the following types:

- Gas is an excellent option for premises that are gasified. You can use natural and liquid gas as fuel. The advantages of such a system: environmental friendliness, no additional costs, no need for refueling.

- Diesel generators for heating boilers - such devices are in great demand among users. They are characterized by durability, since the service life is almost twice as high as that of analogues operating on other types of fuel. During operation, such units are characterized by good profitability, since fuel is consumed three times less than that of a gasoline device.

- Gasoline generators for gas boilers - these models are the most popular. They are inexpensive, and their distinctive feature is their compact size. The structure is easy to transport from one place to another.

Gas generator Honda SH7500

Design features

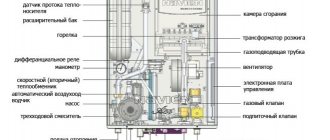

A double-circuit heating boiler has a simple design, although it performs the function of a mini-boiler room. Both of its circuits can work either individually or in pairs, heating the house and providing hot water at the same time. The equipment in question consists of the following components:

- heat exchanger;

- boiler;

- heating elements;

- expansion tank;

- circulation pump;

- air vent;

- safety valve;

- automation;

- control unit.

Electric double-circuit models differ from single-circuit models by the presence of a built-in boiler in the design.

In appearance and main design features, electric boiler models can be:

- wall-mounted – compact and relatively light;

- floor-mounted – massive, with a high power rating (more than 60 kW).

As the name implies, heating equipment of the first group is mounted on walls or on specially installed metal frames. The second group of boilers is placed directly on the floor in a specially designated area. It should be noted that modern electric boilers are quite aesthetic and in no way can spoil the interior of the room.

According to the heating method, they can be divided into three groups:

- Heating elements - highly reliable, having one or more heating elements in the form of a metal tube inside the container;

- electrode (or ionic) – heating the coolant as it passes through a liquid alternating current medium. They have the ability to switch off independently in the event of a short circuit, a maximum increase in temperature and a decrease in the volume of water to a critical value;

- induction - operating thanks to inductance coils. Refers to energy-saving devices.

The first option refers to indirect heating of the coolant, and the second is considered as direct heating.

In terms of power, electric boilers intended for heating needs can be:

- single-phase (up to 12 kW);

- three-phase (more than 12 kW).

It is recommended to select power with the help of specialists, since only they can make a competent calculation. The method of selecting a boiler based on the area of the house is incorrect, since in addition to this parameter, a number of others are also taken into account (wall thickness, number of openings, orientation to the cardinal points, etc.).

As a rule, household heating units operate from a 220V network.

A number of models of Visman boilers with a Stirling engine

The Visman company produces two basic models of boilers, with a built-in Stirling engine. The models are distinguished by their design features and the presence of additional features. functions.

Regardless of the selected series, all boilers are distinguished by their energy independence, high thermal efficiency and efficiency of at least 96%. During the operating period, the burner and motor make almost no noise, which makes it possible to install gas-powered equipment in a bathroom or kitchen.

Boiler Viessmann Vitotwin 300W

The Viessmann Vitotwin 300W mini thermal power plant with a Stirling engine is small in size and at the same time highly productive, making it possible to cover the basic costs of electrical energy. An external battery storage tank provides the required amount of hot water.

The motor is connected to a timer, a remote control unit, and controlled using a remote control or smartphone. The Vitotwin 300W model has the following advantages:

- At the same time, it generates electricity and heat energy.

- Provides DHW needs.

- Quiet operation.

- Normal connection to the heating system and existing electrical network.

Boiler Viessmann Vitotwin 350F

The Vitotwin 350F gas floor-standing boiler with a built-in buffer tank has a rather more complex design than the previous model. The basic configuration includes the following in the housing:

Built-in expansion tank.

The highest productivity of the Vitotwin 350F model is 26 kW. The boiler simultaneously does not stop working to heat the heating medium and produce electrical energy.

Connecting a gasoline generator

In this process, first of all, you need to take into account that the device runs on fuel. And after burning it should come out. For this purpose, an exhaust hood is created.

There should be free space around the device itself: 1-2 m. This provides access to the device for various purposes: refueling, manual starting or repair.

Before connecting the unit to the boiler, read the instructions. To connect to the network, a distribution panel is used, in which an automatic fuse is installed.

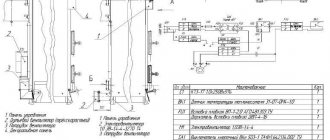

Both devices must be grounded. You can proceed according to the standard scheme:

This way you guarantee safety and the appearance of zero. These are mandatory conditions, without which the system will not be able to identify the flame and the boiler will not start.

If the generator is installed for the entire house, then a common network is used to ground it.

For both units to function correctly, the output must have a 50 Hz sine wave. If the indicators are different, it will be difficult to start the boiler. IHD can correct the situation.

In general, the algorithm for connecting a generator to a boiler has the following steps:

- Finding the necessary contacts in both devices (the diagram in the instructions helps with this).

- Connection and insulation of wires.

- Grounding of devices.

These operations look simple, but it’s better to trust them to professionals.

Scope and capabilities of Vitotwin boilers

Vitotwin boilers are an autonomous micro-CHP designed to heat rooms from 40 to 260 m². The equipment is optimally suited for heating 1-2 room apartments, but can, with equal efficiency, be used for private houses.

Technical characteristics of the equipment significantly expand its capabilities:

- Visman models are suitable for upgrading an existing home heating system or producing a new one.

Thermal energy and electricity are generated at the same time. The power of the generated voltage is from 0.6 to 1 kW.

A condensing boiler, with a Stirling engine, with low power, can be used exclusively for peak loads, covering the heat deficit for a certain period of time.

The equipment is connected as a backup power source to a solid fuel unit.

There is only one heating circuit in the boiler body. To meet the needs of hot water supply, a connection to an external storage boiler is provided.

Method number 3 - Homemade stations

Also, many craftsmen create homemade stations (usually based on a gas generator), which they then sell.

All this indicates that you can independently make a power plant from available materials and use it for your own purposes.

Next, let's look at how you can make the device yourself.

We recommend: Cooling towers of open and closed types: their design, operating modes, photos

Based on a thermoelectric generator.

The first option is a power plant based on a Peltier plate. Let us immediately note that a device made at home is only suitable for charging a phone, a flashlight, or for lighting using LED lamps.

For production you will need:

- A metal body that will play the role of a furnace;

- Peltier plate (purchased separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make a stove. We take a metal box (for example, a computer case) and unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top you can install a grate on which you can place a kettle, etc.

- We mount the plate on the back wall;

- We mount the cooler on top of the plate;

- We connect a voltage regulator to the terminals from the plate, from which we power the cooler, and also draw terminals for connecting consumers.

POPULAR WITH READERS: What are smart sockets, their types, design and operating principle

It works simply: we light the wood, and as the plate heats up, electricity will begin to be generated at its terminals, which will be supplied to the voltage regulator. The cooler will start working from it, providing cooling of the plate.

All that remains is to connect the consumers and monitor the combustion process in the stove (add firewood in a timely manner).

Based on a gas generator.

The second way to make a power plant is to make a gas generator. Such a device is much more difficult to manufacture, but the energy output is much greater.

To make it you will need:

- Cylindrical container (for example, a disassembled gas cylinder). It will play the role of a stove, so hatches should be provided for loading fuel and cleaning solid combustion products, as well as an air supply (a fan will be required for forced supply to ensure a better combustion process) and an outlet for gas;

- A cooling radiator (can be made in the form of a coil) in which the gas will be cooled;

- Container for creating a “Cyclone” type filter;

- Container for creating a fine gas filter;

- Gasoline generator set (but you can just take any gasoline engine, as well as a regular 220 V asynchronous electric motor).

After this, everything must be connected into a single structure. From the boiler, gas should flow to the cooling radiator, and then to the “Cyclone” and a fine filter. And only after that the resulting gas is supplied to the engine.

This is a schematic diagram of the manufacture of a gas generator. Execution can be very different.

For example, it is possible to install a mechanism for forced supply of solid fuel from a bunker, which, by the way, will also be powered by a generator, as well as all kinds of control devices.

When creating a power plant based on the Peltier effect, no special problems will arise, since the circuit is simple. The only thing is that you should take some safety measures, since the fire in such a stove is almost open.

But when creating a gas generator, many nuances should be taken into account, among them is ensuring tightness at all connections of the system through which gas passes.

In order for the internal combustion engine to operate normally, you should take care of high-quality gas purification (the presence of impurities in it is unacceptable).

The gas generator is a bulky design, so it is necessary to choose the right place for it, as well as ensure normal ventilation if it is installed indoors.

Since such power plants are not new, and they have been manufactured by amateurs for a relatively long time, a lot of reviews have accumulated about them.

Basically, they are all positive. Even a homemade stove with a Peltier element is noted to completely cope with the task. As for gas generators, a clear example here is the installation of such devices even on modern cars, which indicates their effectiveness.

Efficient energy consumption

Even the average person who has a gas boiler installed for heating their home may wonder about the rational use of thermal energy. Indeed, when gas is burned in a boiler, not all of the heat generated is used.

When a heating system operates, some part of the heat is always lost irretrievably. This usually happens when combustion products are released from the boiler into the atmosphere. In fact, this is wasted energy that could have been used.

What exactly are we talking about? On the possibility of using wasted “wasted” heat in the production of electrical energy.

If we assume that the heating boiler system is already optimized in order to maximize efficiency, then the “discarded” energy still constitutes a significant proportion of the energy that is released during fuel combustion

The types of fuel can be different, starting with banal firewood and all kinds of briquettes, ending with the most economical options: main gas with a predominance of methane in its composition, artificial blue fuel and liquefied propane-butane mixtures.

It may seem that this is far from the “discovery of America,” but in fact, the technology, or rather, the installation, developed back in 1943 by Robert Stirling, exists. Its design features and basic operating principle make it possible to classify this system as an internal combustion engine.

Why then was this installation not used for such a significant time? The answer is simple - the theoretical development of technology in the forties of the last century turned out to be very cumbersome in practice.

The technologies and materials that existed at the time of development did not allow reducing the size of the installation, and the existing methods of producing electrical energy were more cost-effective.

Including a device in the gas boiler circuit that converts wasted heat into electricity can significantly increase the efficiency of the gas processing plant.

What can make us today think about a more careful attitude towards resources that are not classified as renewable? Nowadays there is a common problem all over the world - the development of technology inevitably leads to an increase in the consumption of electrical energy.

The increase in consumption is happening at such a rapid pace that network companies do not have time to modernize electrical energy transmission systems, not to mention production. This situation inevitably leads to the fact that elements of power supply systems fail, and in some cases this can happen with enviable regularity.

Modern heating boilers are equipped with control systems that are also energy-dependent. The circulation pump, sensors, automation, and the panel itself need power. The entire set of devices cannot but cause concern for maintaining functionality during a power outage.

It is not possible to run forced heating systems without electricity. A power outage during the heating season is almost catastrophic for them. Not only will this inevitably lead to rapid cooling of the room, but if the heating is not operating for a long time, the circuit may freeze.

A prolonged absence of operation of the heating system during the cold season leads to freezing of the heating system, the appearance of ice plugs in it and, ultimately, damage to equipment and heating pipes due to rupture

The standard existing options for solving the issue are the installation of uninterruptible power supplies, generators of various modifications (gas, petrol, diesel generators or unconventional sources - wind generators or mini thermal power plants, hydroelectric power stations).

But this solution is not acceptable to everyone, since many find it difficult to allocate space for installing an autonomous electricity supplier.

While residents of individual houses can still allocate space for a generator, this is almost impossible for installation in a multi-storey building. Thus, it turns out that residents of apartment buildings with individual heating systems are the first to suffer when the power goes out.

That is why, first of all, companies that produce components for assembling heating systems have asked themselves the question of making full use of the heat that is “thrown away” by the heating system. We thought about how to use this wasted substance to generate electricity.

Of the well-known technologies, the developers chose the “well-forgotten” Stirling installation; modern technologies make it possible to increase its efficiency while maintaining a compact size.

The principle of operation of the Stirling engine is the movement of the engine piston down and up. The engine operates almost silently and does not cause equipment vibrations

The operating principle of the Stirling installation is based on the use of heating and cooling of the working fluid, which in turn activates a mechanism that generates electrical energy.

Inside the piston (closed) there is a pumped gas; when heated, the gaseous medium expands and moves the piston in one direction; after cooling in the cooler, it contracts and moves the piston in the other direction.

Installation Features

The liquefied gas generator is connected to the cylinder through a special reducer - this task is not difficult and is performed by the owners regularly. Connecting a stationary unit to the network is more difficult - only professionals have the right to do this and only based on the results of officially obtained permits. In addition to the presence of a gas pipe, there are several other important requirements for the room chosen for installing the electric generator.

- Mandatory and good flowing air ventilation. Promotes better combustion and helps replenish oxygen losses in the home atmosphere.

- The generator should not be located close to the walls. The room should be spacious enough so that the device can be walked around from different sides and examined for damage. The owner must be able to approach the unit from any side - this is a matter of operational safety.

- The room with the gas generator must be equipped with fire extinguishing equipment. With an immediate reaction and a successful combination of circumstances, they will help you quickly avoid huge problems.

The following video provides a detailed overview of the Gazlux CC 5000 D gas generator.

Synchronous and asynchronous system

To make the right choice, you should know their distinctive characteristics. They are set out in the following table:

Characteristics Synchronous Asynchronous Voltage and frequency Stable and high-precision retention Variation in a significant spectrum Electrical overloads High vulnerability to them when starting in standard mode. Resistance to them when starting in a similar mode. Cost Higher Lower Design Complex Simple Maintenance criteria Requires frequent and serious service and inspection Less demanding and unpretentious

Synchronous models are purchased when a scrupulously precise amount of current is required, and the voltage in the network often changes over a wide range.

Devices of the second category are a good budget option and protect the heating network from power surges. This is especially true in domestic conditions. But for this it is recommended to supplement the devices with uninterruptible power supplies (UPS).

Minimum power values

This is the second criterion that deserves close attention (after choosing a standard or inverter version) when you need to buy a generator.

It is not difficult to determine its power. To do this, the starting and functional power of all connected devices is added up. A reserve of 20-30% is added to the result.

The minimum power for boiler operation is reflected in its documents. The indicators of electricity consumption and power consumption are also indicated there. As a rule, these parameters are in the range of 120-180 W. Approximately 150 W is required for the circulation pump and turbine, if it is installed in the boiler.

Calculation example:

One boiler is connected to the generator. Then for full operation a minimum of 0.5 - 0.62 W is required. This is the result of this arithmetic: 120-180 + 150 + 150 + 20-30%. It turns out 504-624 W.

Today, buyers have the opportunity to purchase devices with parameters of 0.6 - 7 kW. In 90% of situations, this is enough for devices producing 0.8 - 1 kW. In other cases, the total power of all equipment connected to the generator is calculated.

Connection instructions

Scheme of combining a gas boiler and a generator with grounding.

Connecting a gas boiler to a generator is quite simple; it is only important to ground the “zero”. But if the generator does not have a clearly defined “zero” and “phase”, there are 2 methods of grounding:

- Use a 220/220 separation transformer corresponding to the power of the gas boiler. Consider one of the terminals of its secondary winding as “zero” and ground it.

- Take the phase with a higher potential to ground as “zero” and ground it.

Without grounding, the gas boiler will not operate from the generator, since the ionization flame sensor will not function. If the generator is connected to the electrical network at home, grounding is not required, since it is already carried out in the electrical network.

Instructions for grounding a gas boiler in a private house

It is important to understand that the generator, like the internal combustion engine of a car, during its operation emits a sufficient amount of combustion products in the form of exhaust gases. Therefore, you need to take care of the ventilation system, preferably forced. To do this, you need to install ventilation to the generator itself; an excellent solution is to completely divert all exhaust gases to the street by connecting a corrugation to the exhaust pipe.

Compliance with all safety rules: exhaust to the street through a corrugated hose, additional forced ventilation of the room, fire protection of floor and wall coverings.

To start the generator, follow the instructions in the instructions; as a rule, it contains schematic images that describe a simple algorithm.

The most worthy models of gasoline current generators by nomination: Tehno.guru editorial version

It is clear that one generator cannot be the best in everything, so we will take one of the best in the following categories: “best frame gasoline generator”, “quietest gasoline generator”, “smallest gasoline generator”. Let's also consider the opinion of the owners of the models we have chosen. Let's start analyzing our small rating of gasoline generators presented on Russian shelves.

The best frame gasoline electric generator for a summer residence according to Tehno.guru

"CHAMPION GG6500" is a good model with a rated power of 5 kW (maximum - 5.5 kW). Four-stroke internal combustion engine, 390 cm³, air-cooled. Tank volume – 25 l. The case has a voltmeter, 2 sockets for 220 V and one for 12 V. There is overload protection.

The weight of the device is 85 kg. Users note ease of use and reliability (with proper care and compliance with operating rules established by the manufacturer). Here is one of the reviews of the CHAMPION GG6500.

CHAMPION GG6500

The smallest of the compact gasoline generators – “Kipor IG2000”

A very worthy device, despite its small size and weight. The power, of course, is small, only 1.6k W, but for such a baby this is decent. This is quite enough to illuminate a small country house and watch TV. Of course, he will not be able to run an electric stove, but this is not required of him if the electric generator is used only for emergency purposes.

The background noise from the operating device is quite low - only 61 dB. And this despite the fact that according to standards, 40 dB is allowed inside an apartment! This inverter model consumes only 0.6 l/h at 75% load. Weight – 22 kg, dimensions – 515 × 300 × 430 mm. We invite you to read the opinion of one of the owners about this model.

Gasoline generator Kipor IG1000

The quietest gasoline generator: one of the best models - “Caiman Tristar 8510MTXL27”

As surprising as it may sound, the quietest model today is a three-phase current generator with a power of 6 kW. Such a device is quite enough to continuously supply a two-story cottage and a home workshop with electricity in sufficient quantities for 13 hours. In this case, the noise level during operation of the device will be only 45 dB. This means that even if the device is placed under a window, the neighbors will not be disturbed by the noise of the motor.

The weight of the electric generator is 99 kg, which is quite a lot. A Robin Subaru EH 41 DH engine with a volume of 404 cm3 and a flow rate of 2.1 l/hour is installed. Tank volume – 27 l. In addition to the standard overload protection, two sockets (220V and 380V), you can optionally add a transport cart, an electric starter, and a voltage regulator.

Caiman Tristar 8510MTXL27

The best known manufacturers and models: characteristics and prices

Denzel GT-950i

One of the best inverter gasoline generators for a gas boiler with a power of 0.9 kW and economical fuel consumption of 0.5 l/hour. Designed for continuous operation for 4.5 hours, it has compact dimensions, a more stable and quiet 4-stroke internal combustion engine, a body in the form of a soundproof casing, which makes its operation quite quiet.

According to reviews from the owners, the mobility of the generator allows it to be used not only to power the boiler, but also other equipment in the house, and to take the generator to the garage or fishing at any time.

Daewoo Power Products GDA 1500I

An excellent, more powerful 1.4 kW inverter synchronous gas generator, which is enough to provide electricity to the most complex heating systems. The four-stroke engine is housed in a soundproof casing, making its operation virtually silent. However, the model has higher fuel consumption - 1.25 l/h, which is still compensated by the presence of an inverter and the ability to adjust the speed. With a sufficiently high power, it has only one outlet.

Through practice, the generator has proven itself to be optimal in performance, reliable and durable.

Cost : 17,000 rub.

Huter DY5000L

Powerful 4.5 kW dual-fuel (gas/petrol) synchronous generator. Designed to power not only the boiler, but also the full-fledged electrical network of an average country house. Designed for continuous operation for 9-9.5 hours, the generator automatically turns off when overheated, overloaded or low oil level. No obvious shortcomings were observed due to the practice of use.

CHAMPION IGG980

An excellent inverter gasoline generator with a power of 1.1 kW and economical fuel consumption of 0.6 l/h. It is distinguished by an extremely affordable price, small size, greater power than stated by the manufacturer, and the ability to adjust it. But, like other inexpensive models, it has characteristic disadvantages in the form of a low-quality sinusoid at the output, noisy operation, poor assembly, which causes oil and gasoline leaks.

Most popular models

An efficient floor-standing unit is the energy-independent boiler Protherm Volk 16 KSO, which belongs to the category of budget equipment. Power is 16 kW. That is, if there is high-quality insulation and energy-efficient windows, the device provides heating for a house with an area of up to 150 m². At the same time, it has a high efficiency of 92.5% - boilers with a higher figure are rarely found.

Gas consumption is 1.9 m³/h, which is considered an acceptable level for equipment of this type. The model is equipped with a traction stabilizer. It operates almost silently, is easy to install and control, despite the fact that the simplest standard mechanical elements are installed.

The device has a high efficiency of 88%, consumes little fuel and operates with the maximum level of safety. The unit is equipped with modern automation that protects against overheating and gas leaks. Characterized by a durable and strong cast iron heat exchanger.

How long is uninterrupted power supply required?

According to current legislation, all residential private households belong to category 3 of uninterrupted power supply, which allows the energy supply organization to legally suspend power supply for up to 3 days.

As a rule, all emergency situations are resolved within 1 business day, but the most severe and prolonged accidents occur during periods of heavy snowfall. So in 2022, heavy snowfall led to a break in a high-voltage power line in the Pskov region. The accident took more than 3 days to resolve. 20,000 people were left without electricity in sub-zero outside temperatures.

Appearance of various designs of gasoline generator housings Source Pk-asia.kz

Design and manufacture of a gas generator

Let's take a closer look at the device of the gas generator. In addition to the housing, inside which the main part of the elements is located, the design includes

:

- bunker (chamber for loading fuel);

- combustion chamber (this is where the wood smoldering process occurs at high temperatures and with minimal air supply);

- the neck of the combustion chamber (resin cracking occurs here);

- an air distribution box equipped with a check valve;

- tuyeres (calibration holes through which the distribution box communicates with the middle part of the combustion chamber);

- grate (serves as a support for smoldering fuel);

- loading hatches equipped with sealed covers (hatches in the upper part are required for loading fuel, in the lower part - for cleaning the unit from accumulated ash);

- outlet pipe (flammable gas escapes through it and enters the welded gas pipeline pipe);

- air cooler (in the form of a coil);

- filters for purifying gas mixtures from unnecessary impurities.

The gas generator circuit may include a fuel drying system. For pyrolysis to be effective, the firewood must be dry. If part of the gas pipeline runs in a ring around the fuel loading chamber (in the space between the walls of this chamber and the housing), the raw firewood will have time to dry before entering the combustion chamber. This will significantly increase the efficiency of the installation.

The body of the gas generator is made of a metal barrel, on top of which a pipe is attached with corners and bolts to a seal, and a propane cylinder is attached to the inside with bolts

Before making a gas generator, you need to find information about a suitable device model and detailed drawings indicating the dimensions of all elements.

Particular attention is paid to the choice of materials for each of the structural elements. The gas generator can have a rectangular or cylindrical shape - the body is usually welded from sheet metal or a metal barrel is used

The bottom and lid must be made of steel sheet with a thickness of 5 mm.

The hopper, which is bolted inside the housing, should be made of mild steel. The combustion chamber is made of heat-resistant steel; you can use an empty liquefied propane cylinder.

The gas cylinder is installed inside the barrel and bolted to its top

The hopper lid should be equipped with a reliable seal made of heat-resistant material (asbestos cord with graphite lubricant). A fire-resistant insulator (asbestos cord or material with similar properties) is laid between the neck of the combustion chamber and the body. It is more convenient to make the metal grate of the grate removable, from reinforcing bars, to make it more convenient to clean the combustion chamber.

The pipe is attached to the bolts on top of the barrel

An air distribution box with a check valve at the outlet is installed outside the housing; a fan can be mounted in front of it to pump air to increase the efficiency of the unit when working on freshly cut wood.

Blower fan to help improve efficiency

Some craftsmen use a steel or bimetallic radiator as an air cooling coil. The mixer, through which purified flammable gas is mixed with air, is equipped with a fan.

When selecting materials for a permanent installation intended to generate electricity for home use, the emphasis is on reliability and affordability. If you need to make a gas generator for a car, preference should be given to stainless steel - this will make the unit lighter and more compact. But the use of stainless steel significantly increases the cost of the design.

Conclusion

The compact wood-burning gas generator is suitable for installation on a truck or car. The unit for a local power plant can be installed in the basement of a house, in an outbuilding, or, if necessary, installed on the street or under a canopy (when it is necessary to provide electricity to any stationary electrical equipment).

The fundamental issue is the correct operation of the gas generator. In order for the unit to operate with high efficiency, it is necessary to carefully adjust the level of air supply (taking into account the moisture content of the fuel), the intensity of gas removal, etc. It is advisable to manufacture a gas generator according to professional drawings, observing all dimensions and proportions.

Video on the topic:

https://youtube.com/watch?v=MF_ABzCPJ80

Choosing a heating boiler for your home

Today, the modern market offers a wide variety of boilers from foreign and domestic manufacturers. How to make the right choice and not make a mistake? Can't figure out the cost of a heating boiler for your home? You can, of course, entrust the choice of a boiler for heating your home to a qualified specialist if he will design a hot water supply and heating system. He will be able to ensure the best combination of system elements, tell you which boiler to choose and how to obtain the permits required for its installation. But it’s quite possible to figure out the priorities yourself when choosing a boiler that can economically heat your house.

For any home, the most important communications are: plumbing, energy, heating and sewerage. The quality of heating has a direct impact on the degree of comfort of the house and on how expensive its maintenance will be, especially during the heating period.

Which electric generator is better

Each nominee presented in the review demonstrates high build quality, decent technical characteristics, and performance. But to decide which electric generator to buy for your home, they rely on personal needs, conditions for further operation, and financial capabilities. A comparative analysis of parameters, test results, and owner reviews showed:

- Hyundai HHY 7020FE ATS (5000 W) – long continuous operation, high reliability;

- Denzel GE8900 (7000 W) – the best balance between compactness and performance;

- Bison ZIG-3500 (3000 W) – best price, compatible with gas boilers;

- Patriot GP 1000i (700 W) – ultra compact, quiet model with minimal weight;

- Hyundai DHY-6000 SE (5000 W) - a professional device with a total control system;

- Daewoo Power Products DDAE 10000SE (7200 W) - highest performance;

- Generac 6520 (5000 W) - an original station with an informative display and light indication.

In addition to functional, quality characteristics, the Vyborexperta.ru portal advises not to forget about the need for regular maintenance. We are talking about changing the oil, cleaning the air filter, and regularly replenishing fuel. If you neglect such requirements, the service life of any device will be shortened.

Prices: summary table

| Model | Type of fuel | power, kWt | Fuel consumption, l/h | Operating time, h | Cost, rub. |

| Denzel GT-950i | petrol | 0,9 | 0,5 | 4,5 | 19 800 |

| Daewoo Power Products GDA 1500I | petrol | 1,4 | 1,25 | 4 | 17 000 |

| Huter DY5000L | petrol/gas | 4,5 | 2,3 | 9 | 34 000 |

| CHAMPION IGG980 | petrol | 1,1 | 0,6 | 4 | 9 800 |

FAQ

Some manufacturers have generator power in kVA, others in kW. What does this mean and how to correctly compare these characteristics when choosing a generator?

Kilovolt-amperes (kVA) indicate the total power of the generator. Apparent power consists of active (kilowatts - kW) and reactive power (kilovolt-amperes reactive-kVar). Active power matters to the consumer. The power ratio depends on the load. For household calculations, we can assume that the active power of the generator is 0.8 part of the total power. As a rule, you can take for translation: “kW=0.8*kVA”

And also, do not forget that the power of the generator should exceed 20-30% of the total power of consumers. Firstly, this will increase the service life of the generator. Secondly, you will be able to avoid generator shutdowns when turning on consumers with a power comparable to the generator.

What to look for when choosing a low-power gas generator?

Make sure that the engine is at least 40% more powerful than the alternator. For a 3 kVA alternator, you need a motor with a nameplate rating of at least 4.5 kW (6.2 hp). Otherwise, already at the rated load on the network, the engine will work for wear; In this case, large starting currents (grinder without soft start) and sudden load shutdowns (electric kettle) will have an even stronger effect.

I don’t overload the generator, I don’t violate maintenance deadlines. What else can be done to keep the generator running as long as possible?

It is extremely important to compare the power of the generator with the power of the load being switched off. Example: by abruptly disconnecting a 2 kW stove from the network, which is powered by a 3 kVA generator, you provoke a power surge

Which will affect both the gadgets being charged along the way and the “filling” of the alternator.

Comparison table of models to choose from

For a gas boiler with an electronic control unit, it is preferable to purchase an inverter gas generator. Its price is noticeably higher than a simple one: 20-40 thousand rubles. versus 5-7 thousand, but it provides a sinusoidal voltage waveform and a stable frequency and voltage. In an inverter generator, an unpretentious input rectifier and a filter feed the inverter - a DC-to-AC voltage converter with excellent quality.

Before buying a generator, you need to find out what kind of power the boiler and pumps, if any, require. In the simplest case, it is enough to connect the terminals of the gas generator to the boiler power plug and start the generator engine. You can then light the boiler in the usual way.

When electricity becomes available, the generator can be turned off and switched to the power grid.

If the pumps in the system have three-phase motors, then the generator inverter must also be three-phase, and the boiler automation will be powered from one of the inverter phases. This applies to fairly powerful heating systems that heat medium-sized buildings and large cottages. Such a system must provide uninterrupted power supply to the boiler automation and pumps from an inverter operating together with the electrical network, through a bypass or even online. The generator is started in such systems to avoid draining the batteries for too long.

The power of the purchased generator should be selected with a 30-50% margin of the power consumed by the boiler together with the pumps. This will reduce the load on the generator engine and ensure its longevity.

If the boiler can operate from a gas generator, but has a separate neutral and phase, that is, it is not connected with a plug into a socket, but is mounted with a cable in the electrical panel, then a special generator connection diagram will be required, which prevents the simultaneous operation of the network and the generator. A single-phase inverter generator can be connected to such a boiler in any way, i.e. both of its terminals are equal in this case. The RCD should work with this connection.

The table shows examples of some 220 V gas generators. ModelPowerReliabilityNoisePriceWeightStartingFuel consumptionOperating timeServiceReviews

| DDE GG950DC | 625 W | 4 | 65 dB | 4400 rub. | 18.5 kg | manual | 0.72 l | 5.8 h | — | good |

| DENZEL DB950 | 650 W | 5 | 62 dB | 4800 rub. | 17 kg | manual | 0.7 l | 5 hours | — | great |

| FAVORITE PG950 | 950 W | 4 | — | 4990 rub. | 16 kg | manual | — | — | — | — |

| Most Power G800L | 650 W | 4 | quiet | 5027 rub. | 17 kg | manual | 0.69 l | 4 hours | There is | good |

| CHAMPION GG951DC | 650 W, inverter | 4 | very quiet | 5250 rub. | 19 kg | manual | 0.65 l | 4.6 h | There is | great |

| Hammer GNR800B | 600 W | 5 | quiet | 5990 rub. | 18 kg | manual | — | 8 hours | There is | great reviews |

| DDE DPG1201i | 1 kW, inverter | 4 | 58 dB | 6490 rub. | 12 kg | manual | — | 4.5 h | — | good |

| DDE DPG1201i | 1 kW, inverter | 4 | 65 dB | 6610 rub. | 13 kg | manual | — | 5 hours | — | normal |

| Eurolux G1200A | 1 kW | 4 | 75 dB | 6680 rub. | — | manual | 0.58 l | 9 hours | There is | very stable |

| Caliber BEG-900I | 900 W, inverter | 4 | 70 dB | 6590 rub. | 12 kg | manual | 0.52 l | 8 hours | There is | works well, lightweight |

| Redbo PT2500 | 2.2 kW | 5 | — | 6990 rub. | 38 kg | manual | — | 14 h | — | — |

| Eurolux G3600A | 2.5 kW | 5 | 77 dB | 9002 rub. | — | manual | 0.8 l | 18 h | There is | great |

| FAVORITE PG3000 | 2.5 kW, inverter | 5 | — | 9620 rub. | 36 kg | manual | — | 13:00 | There is | great |

| Kölner KGEG 5500 | 5.5 kW, inverter | 4 | 72 dB | 20493 rub. | 78 kg | manual | 1.6 l | 12 h | There is | good |

| CHAMPION GG650 | 5 kW | 5 | — | 22100 rub. | 77 kg | manual, starter | — | 13:00 | There is | very reliable |

| Bort BBG-6500 | 5.5 kW, inverter | 5 | 75 dB | 20750 rub. | 77 kg | manual, starter | 1.8 l | 12 h | There is | good |

| Daewoo Power Products GDA 12500E-3 | 10 kW, inverter, 220/380 V, 3 phases | 4 | — | 159,000 rub. | 165 kg | manual, starter, autostart | 4.2 l | 5 hours | There is | good |

| ENERGO EB 15.0/400-SLE | 12.6 kW, 220/380 V, 3 phases | 4 | 75 dB | 227700 rub. | 135 kg | starter, autostart (AVR) | 4 l | 6.2 h | There is | — |

| EUROPOWER EP16000TE (Honda) | 13 kW | 5 | 77 dB | RUR 293,791 | 152 kg | starter, autostart | 5.1 l | 4 hours | There is | good power plant |

| ENERGO EB 14.0/230-SLE | 11 kW, 220 V, 1 phase | 4 | 74 dB, with soundproof casing | RUB 554,480 | 930 kg | starter, autostart | 3.9 l | 6 hours | There is | — |

They are sorted by price/power and additional features in ascending order.

How does a gas generator for a gas boiler work?

In the event of a power failure, the boiler automation switches off the burner. The gas valve is designed in such a way that it is pressed due to the current passing through the coil. If there is no current, the valve closes.

In our country, power outages are not uncommon, so even if there is gas in the mains, owners of gas boilers have to sit in a cold house. A gas generator that transforms thermal energy into electricity will help solve the problem.

The undeniable advantage of a gas generator is its economical fuel consumption, due to which it is much more often chosen as a backup energy source for autonomous heating circuits

The equipment runs on liquid fuel (gasoline). The generator supports the uninterrupted operation of electrical appliances, in particular the electronics of a gas boiler. Its power is enough to provide electricity to a small one-story house.

The unit can be equipped with an automatic start system. Since a domestic gas boiler consumes a small amount of electricity, there is no need to purchase a powerful generator.

Such equipment is small in size and weighs up to 50 kg. Depending on the design, in emergency situations the device can generate energy for up to 4-8 hours.

Why does the boiler go out when the power goes out?

All models of automatic gas boilers are equipped with a protective function to shut off the gas supply in the event of a malfunction, which includes a power outage.

This happens thanks to the shut-off valve. When there is no power supply, the valve is always closed and can only be opened using an electrically powered inductive coil. In addition, the electronic control unit is also de-energized, making it simply impossible to issue a command to open the shut-off valve.

Gas regulator for a non-volatile gas boiler that does not turn off when the power supply is interrupted Source Santechbomba.ru

In modern models, the burner ignition process is fully automated, so immediately after the power supply is restored, the gas boiler will conduct self-diagnosis and resume gas supply by sending a command to open the shut-off valve.

Advantages

It should be noted that the operation of these units is fully automated and does not require constant user participation. In particular, regular refueling of fuel is not necessary; it comes from the main line (cylinder) as needed. In addition, gas generators use the cheapest fuel - natural or liquefied gas (LPG). At the same time, they use it very economically, even in long-term battery mode. If we talk about the cost of these units, then it is not much higher than the prices of similar devices that consume gasoline or diesel.

Considering the fact that the engine of a gas generator will last many times longer, since gas does not cause corrosion of metal elements. Also, parts in the cylinder-piston group are subject to less wear, and the oil needs to be changed much less frequently, due to the reduced exposure to gas. What gas you use can be determined by knowing what gas supply source your gas stove is connected to. If the gas stove is connected to a gas cylinder, then you are using liquefied propane-butane gas.

If the gas stove is connected to the in-house gas pipeline (which in turn is connected to the street gas pipeline), then you are using natural gas, which is called methane. Gas power plants are considered comfortable and easy-to-use equipment, since they are equipped with special casings to protect them from moisture, precipitation and corrosion. They are also equipped with a specific protective base, which allows the units to be installed on any surface.

Gas generators are in no way inferior to diesel and gasoline ones, but, on the contrary, have a number of advantages, such as:

- Greater fuel economy. The use of LPG significantly reduces costs. Savings of up to 40% compared to gasoline. From calculations we found that due to savings on fuel, gas equipment pays for itself within a year. Gas consumption is indicated in the description.

- Fuel efficiency. LPG engines have greater performance and require less maintenance compared to traditional gasoline engines.

- Increasing the service life. Using LPG places less stress on the engine, which prevents excessive wear and mechanical problems.

- Low emissions into the atmosphere. LPG produces fewer exhaust emissions than gasoline, including CO², NO and SO, making it virtually environmentally friendly and a better choice for you.

- Reduced noise level. You will not only breathe clean air, but also experience less discomfort due to the low noise level.

Criterias of choice

When deciding to buy a gas electric generator, be sure to pay attention to the following factors

Variability of fuel. It has already been said above what types of fuel the gas generator operates on. Moreover, some models can run not only on different types of gas, but also on gasoline or diesel fuel. Versatility is a guarantee of trouble-free operation.

Technical specifications. The main thing is power, it should be enough for the normal operation of all equipment in the house

Also pay attention to the phase pattern and the level of noise produced, because not all models are silent. Type of cooling system.

Automatic protection system. Cheap generators may not have it at all, but for the safety of people and property, such an addition to the design will not hurt at all.

Startup type

It can be manual, semi-automatic or automatic. It all depends on the needs of the specific owner. Only manual start will mean that the cost of the unit will not be too high, while automation is needed to quickly respond to a power outage or turn on according to a schedule, in order, for example, to maintain a positive temperature in a dacha that is empty in winter.

Reliability. No one can be sure of it in advance, but if the gas generator is produced by a brand that has been collecting thousands of positive reviews for many years, then this increases the chances of not being disappointed with the purchase.

Product cost. For a private house in which only one family lives, the issue of price may be perhaps the most significant. A gas generator is a device that is better not to buy at all if you don’t have the money for a quality model.

Types of UPS

According to their design, uninterruptible power supplies are divided into three types:

Online inverters for boilers, unlike offline ones, have a built-in stabilizer at the input and, thanks to this, switch to backing up power from the battery only when the network power is turned off. When its voltage deviates from 220 V, the stabilizer operates. This scheme is more expensive, but also more effective when used in a network with strong daily voltage fluctuations (for example, a low-power substation in the private sector). An offline inverter under such conditions will go into standby mode too often, requiring the installation of a separate voltage stabilizer in front of it.

Line-interactive inverters are the most advanced class of devices. In them, the input voltage is immediately converted into direct current, supplied to the output inverter, and the battery is connected between the blocks. A conventional welding inverter is constructed in a similar way (if you do not take into account the battery). Thus, the supply voltage is always stabilized, and when it is turned off, there is no delay in switching the UPS output from the external network to the inverter.

REG (Russia)

The range, maintainability of “older” engines and the availability of original spare parts for them explain the popularity of REG products in the Russian Federation. Additional handles and wheels are offered for compact equipment; protective covers can be purchased for stationary ones - ease of use is ensured in any conditions.

About products

REG generators cope with the assigned tasks within the stated power without any problems. Some inconvenience is caused by noise - for everyone it is not lower than 75 dB. The casing (frame covered with sheets) does not always help - if you approach it from the side of the ventilation grilles, you will have to strain to talk. But you won’t be able to close them – all REG models are air-cooled.

The engines run without problems. The only downside is that it is not profitable to invest in the “younger” FH210 motors - they are unlined. Taking into account the promised 500 hours of service life, they are relevant for dachas, where the continuous operation time does not exceed 1-2 hours.

There is no own service network; the regions are serviced by dealer technicians, so service prices are different everywhere.

Technical characteristics of REG gas electric generators

| Characteristics | For the dacha | For a rural house permanent residence | For cottage, workshop |

| Model | E3 POWER GG3300-X | GG8000-A | GG14-230V |

| Power / voltage (current), kVA / V (A) | 2.4 / 12 (8.3), 220 (12.7) | 6 / 220 (29.5) | 14 / 220 (63) |

| Main gas consumption at 100% power, per 1 kVA, m3/h | 0.52 | 0.5 | 0.42 |

| Dimensions, (l/w/h), (weight, kg), mm | 680/535/550 | 740/550/620 | 690/590/810 (150) |

| Engine (revolutions, rpm; cooling) | FH210 (3,000; airborne) | FH420 (3,000, airborne) | REG803 (3,000, airborne) |

| price, rub. | 46 750 | 76 900 | 270 000 |

Manufacturer's Youtube channel→