Heating systems for country houses differ in operating principles and, accordingly, in the selection of equipment. Among gas, electric and solid fuel heat generators, a condensing gas boiler stands out due to its energy-saving effect and other characteristics. Let's figure out what features it has, what models are on the market, and what properties you should pay attention to.

Condensing gas boiler in the kitchen interior Source amazon.com

Operating principle of a condensing boiler

In a traditional boiler, gases pass through a heat exchanger and give up most of the energy to the coolant, being released into the atmosphere along with the heat. Water vapor also escapes outside the room and carries away hidden energy. And to achieve a comfortable temperature, you have to spend a lot of fuel. A condensing boiler stores energy in the heating system.

During cooling, the steam becomes liquid and releases heat. In a modern model of heating equipment, condensation occurs in a heat exchanger that removes heat.

Fuel savings when used in low temperature systems

The main advantage is efficiency, approximately 20-35% compared to traditional equipment. Fuel consumption is determined by the power of the unit and the area of the room. If you have a country cottage of 200-250 m2, then a 28 kW boiler is sufficient for heating, which will consume a maximum of 2.85 m3/h. A regular boiler will consume 3.25 m3/h.

If we take into account that a person uses heating appliances for 6 months a year, the approximate savings per year will be 3,000 rubles. But if we talk about regions where the average temperature in winter is -30 degrees, then these savings will be several times greater, because there the heating works constantly. And if we take into account that the cost of gas increases every year, then the savings will increase when using a condensing boiler.

Liquefied gas consumption

The amount of fuel spent on heating depends on the operating conditions of the device and its technical characteristics, usually power and efficiency. So, for example, according to the passport data, for the boiler JSC Zhukovsky AOGV-17.4-3 with a power of 17 kW with an efficiency of 90%, the consumption of liquefied gas is 0.7 kg/h or 1.3 l/h.

Knowing that the cost of refueling in 2022 is 12-23 rubles/l, taking the average value, you can roughly calculate the cost of heating a house over a certain period of time:

- per day (24 hours) – 1.3 × 24 = 31 l × 17 ≈ 527–558 rubles;

- per month (30 days) – 31 × 30 = 930 l × 17 ≈ 15810–16740 rubles;

- for a season (six months) – 930 × 6 = 5580 l × 17 ≈ 94860–100440 rubles.

It must be taken into account that a 50 liter cylinder actually contains 40–42 liters of propane-butane mixture: about 15–20% of the free volume is used to increase the area of gas evaporation, and overfilling leads to a decrease in its production. This means that with a flow rate of 1.3 l/h, one cylinder is enough for approximately 1.5 days.

But not everything is so bad: the numbers in the passport are given on the basis that the unit will always operate at maximum power 24/7, but in reality this only happens in severe frost. In warm weather, the boiler is active only 10–14 hours daily, i.e. the result obtained can be safely reduced by 30–50%.

How to choose a room thermostat and save up to 30% per month on heating

Price

Technically improved boilers are more complex, and it becomes clear why their cost is higher. But most of all, the surcharge is provided for the additional percentage of thermal energy. Keep in mind that the equipment will last for several decades, so you can overpay to get a high-quality heating device, on which you will be able to save money when using it.

All condensing boilers can be divided into 3 categories according to prices:

- Premium class. This category has the fewest buyers, because boilers are more expensive. This includes models of the German brand, which are distinguished by high quality, attractive appearance, due to durable materials. Such boiler models meet European quality standards and therefore can last for several decades. Due to the high price, the equipment is equipped with many useful functions that make use as comfortable as possible. They can be used to program operating modes even when the owners are absent from the house, or reduce the temperature level at night, and adapt to weather changes.

- Middle class. This class of heating equipment includes boilers with a modest set of functions. The boilers provide high performance and, like premium equipment, can adjust the temperature to weather changes. These are the most popular models that people choose for their home.

- Economy class. Such boilers also save fuel, but they are not equipped with the functions described above. Budget models are produced by Korean companies. The cost of such heating elements is half that of a premium product. But such devices are maximally adapted to the climatic conditions in Russia.

When choosing a boiler for your home, you need to consider the cost of installation and further maintenance of the equipment. Before purchasing, keep in mind that modern equipment saves gas. Such boilers are only suitable for places with permanent residence. The more cold days there are in the region where you live, the more advisable it is to install such equipment in your home.

High cost of the heat exchanger used

The heat exchanger itself is complex and expensive equipment, and if it breaks, the owner will have to spend a lot of money to restore it. Sometimes purchasing a new heat exchanger and installing it is more expensive than purchasing a new boiler.

But to prevent such situations from happening, it is necessary to constantly maintain the heat exchanger and monitor its condition. Do not allow it to become clogged, as it is extremely difficult to flush the equipment. Also, before installing a condensing boiler, it is necessary to update all pipes and get rid of rusty elements.

The durability of the heat exchanger depends on the quality of the coolant. The water must be soft so that scale does not form inside the pipes, which will be difficult to get rid of. It is unacceptable to use water containing impurities of rust, salts, suspended matter and iron.

Due to the acids in the composition, the heat exchanger must be susceptible to such compositions. It is worth choosing designs made of stainless steel and silumin. The second material is cheaper, but it is less resistant to aggressive environments than steel. If you want the equipment to last for several years, you need to purchase heat exchangers made of more durable material, despite their cost.

Kinds

The design of condensing boilers was created on the basis of conventional models.

There are different species that have typical characteristics:

- single-circuit. They only heat the coolant for the heating circuit;

- double-circuit. Together with the preparation of the heating agent, they are capable of heating water for domestic needs.

By installation type:

- floor Installed on the floor or a special non-flammable stand. They have no restrictions on weight and power;

- wall-mounted For installation, strong load-bearing walls are used. This imposes restrictions on the weight and power of the boiler. The limit is usually 45-50 kW.

All condensing boilers have a closed burner, since the operation requires strict regulation at all stages and does not allow the use of natural processes.

They are unstable and cannot be the basis for fine tuning.

Inappropriate for use in high temperature systems

An efficiency of 108-110%, as the manufacturer claims, is not always achieved. Its value depends on the type of heating - it can be high-temperature and low-temperature. The difference lies in the temperature range at the coolant inlet and outlet.

In high-temperature systems, the ratio of water to liquid temperature in the return circuit is 75-80 degrees to 55-60. Condensing boilers can be used in high-temperature systems, but this will be irrational. It is effective to use such equipment if the temperature ratio is 50-55 degrees to 30-35. This value is optimal if heating occurs using a heated floor. Otherwise, you will need to install additional radiators.

Main components of the system and their features

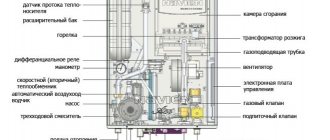

The operating principle of condensing gas boilers looks quite simple, but its implementation requires a structurally complicated system. It includes the following elements:

- The combustion chamber. Its working parts are a burner, a gas supply system and a fan.

- Primary heat exchanger. The coolant is heated in the chamber. As a rule, it is made cast to avoid corrosive destruction of the metal (the weak point is the seams).

- After-cooling chamber. In it, exhaust gases containing water vapor are cooled to 50-60°C.

- Condensation heat exchanger. Water vapor gives off energy to the opposite will of the heating system and condenses on the walls of the chamber. Water enters the primary heat exchanger, is heated to operating temperature and distributed throughout the premises.

- Condensate collection tank. The accumulated condensate is subsequently disposed of.

- A chimney through which cooled combustion products leave the system.

- A pump that maintains forced circulation of coolant in the system.

Design features of a condensing boiler Source twimg.com

The condensate that accumulates in the heat exchanger contains a mixture of acids and is a fairly aggressive liquid. Therefore, for the manufacture of such containers, materials with corrosion resistance are chosen: acid-resistant stainless steel or silumin (an alloy of aluminum with silicon).

Particular attention is paid to the design of the chimney. It is also made of acid-resistant alloys or plastic, and the horizontal fragments are placed at an angle. This is necessary so that condensate, which partially forms in the chimney, does not accumulate in it, but returns back to the chamber.

For efficient and economical operation of the system, the ability to adjust it throughout the day is important. The adjustment is carried out using a gas burner, the operation of which is organized in the following modes:

- Single stage burner. It maintains one set water temperature; With the help of automation you can only turn it on and off.

- Two-stage. It works in two modes; one maintains the boiler power at 40%, the second at 100%. Switching between modes is also automated.

Condensing boiler and piping Source domkotlov.by

- Modulated. It heats the boiler continuously, but at the same time gradually increases or decreases the combustion power. A modulating burner will cost more than a stepped model, but you can set the operating mode in the range from 10 to 100% of the rated power. Most boilers intended for private homes are equipped with a modulating burner.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Difficulty in disposing of condensate

The resulting condensate must be properly disposed of. After all, it contains acids that are hazardous to the environment. On average, about 70 liters of condensate are formed per day.

If your home is connected to a central sewer system, then you do not have to decide on disposal yourself. Following European standards, boilers up to 28 kW do not require condensate disposal. This amount can be diluted with household wastewater without harm to the pipes.

But if you have an autonomous sewer system, you need to decide how to dispose of waste. Never pour liquid into a septic tank; this method will instantly kill beneficial bacteria. You also can’t pour acids into the soil, so as not to salt the soil, on which nothing will grow later.

It will be difficult to remove 70 liters of condensate every day. Therefore, the best option is to use a separate system for neutralizing acids. If we talk about Western countries, people there automatically buy neutralizers when buying heating appliances.

Where to buy a gas boiler using liquefied gas

In Moscow and Moscow Region

- MirCli (mircli.ru/kotly-otopleniya/nastennye-gazovye-kotly/odnokoturnye-kotly) – Leningradsky Ave., 80, building G, tel. +7 (863) 303–35–06, +7 (800) 775–29–90.

- IM “Gas Boilers” (https://msk.kotel-gazoviy.ru/na-szhizhennom-gaze/) – Moscow, st. Podolskikh Kursantov, 22, tel..

In St. Petersburg

- ProTeplo (https://www.proteplo-spb.ru/products/kotly-na-szhizhennom-gaze) – st. Chugunnaya, 14, lit. K (entrance from Mendeleevskaya 5), tel. +7 (812) 241–12–06.

- TechnoDOM (https://www.teh-dom.ru/gazovye_kotly_na_sgigennom_gaze#0) – Marshal Govorova Ave., 35, BC Yellow Corner, p. 119, tel. +7 (812) 671–00–88.

In conclusion, I would like to remind you that, despite all its advantages, liquefied fuel is not a competitor to natural gas. However, if connection to the pipeline is not available, then it can be argued that an LPG boiler is the most profitable and convenient option for organizing heating of a country house.

Gas boilersBoilers

Sensitivity to intake air quality

In order for the boiler to operate without complaints, it is necessary to pay attention to the access of combustion air and the removal of combustion products. Condensing boilers take air from the street, and so that the fan does not become unusable in the shortest possible time, the quality of the air taken in must be high. It is also important to maintain the optimal temperature of the intake air so that the air duct does not freeze. To avoid problems with servicing the boiler, its connection and configuration should be done by professionals. A trained person with a license and permission must set the parameter responsible for the incoming air.

Gas analyzers are most often used for this purpose. In the absence of equipment and incorrect settings, it is not possible to achieve the maximum efficiency value, and can also damage the boiler.

Reviews of domestic boilers: advantages and disadvantages

Having studied the reviews of owners of LPG boilers, you can understand that such devices are quite ambiguous - they have both strengths and obvious weaknesses.

Advantages and disadvantages of operating on reduced gas :

| pros | Minuses |

| autonomy - such devices do not depend on either the increase in utility tariffs or the stability of the gas main | refueling price - if you do not bring gas yourself, the price includes the amount spent on its transportation |

| versatility - reverse adjustment (for natural gas combustion) is possible at any time with minimal cost | regular maintenance – small jets become clogged with sulfurous substances, so they need to be cleaned frequently |

| maintaining cleanliness - bottled fuel, unlike solid fuel, does not form ash, dust, burning, smoke, etc. when burned. | high fire hazard - storing fuel reserves on site requires strict adherence to safety measures |

| environmental friendliness - the majority (91–95%) of LPG waste is carbon dioxide, which is then absorbed by plants | weather dependent - in winter there is a problem of snowdrifts that impede refueling and gearbox icing |

| simplicity of the system - the absence of complex parts ensures protection against accidents and breakdowns, as well as ease of maintenance | additional costs - the final price depends on the excavation estimate, the length of the gas pipeline, the volume of the vessel, etc. |

Users of a heating system powered by LPG are required to constantly check the remaining fuel in the connected tank. This creates certain inconveniences because it is necessary to frequently renew the contents of gas cylinders or immediately pump a sufficient amount of gas into storage.

Despite its simplicity, the refueling process requires care: the slightest carelessness when connecting the gas pipeline line can lead to a leak.

Myths about condensing boilers

Air conditioning equipment has recently appeared on the market. Many buyers have already appreciated their advantages and have replaced conventional equipment in the house. But there are people who are satisfied with traditional boilers and see only disadvantages in condensing heating devices. Let's dispel myths about modern equipment.

Myth 1. The cost of improved boilers is much higher than conventional ones.

The devices are floor-mounted and wall-mounted, and buyers most often compare them on this basis. But do not forget that the power of different designs is very different, for example, floor-standing household models usually do not exceed 60 kW, and wall-mounted ones 50 kW. When comparing units, it is necessary that they be of similar power. Yes, the cost of updated units is higher, but this difference is not several times, if we talk about equipment of the same power.

Pros and cons of equipment

Knowledge of the structure and principle of operation helps to gain an understanding of the condensing gas boiler; the advantages and disadvantages will help you understand whether you need such a unit. Strengths include the following:

- Saving on fuel. When compared with traditional models, it reaches 15-20%.

- Saving on the chimney. The gases leaving the system have a low temperature, so a steel chimney can be safely replaced with a cheaper plastic analogue.

- Environmental friendliness of the system. When operating a condensing boiler (with a closed combustion chamber), the amount of harmful emissions is reduced by 60-70%.

Environmental friendliness makes installation possible in the kitchen or bathroom Source oteple.com

- Increased service life. This occurs due to a reduction in the load on the main equipment components. If the necessary conditions for starting the condensing heat exchanger are not met, the boiler continues to operate as a convection type model.

- Low noise level. The operation of the boiler does not affect the comfort of life in the house.

The following features of the device are called weaknesses:

- The need for condensate disposal. Condensate has a high pH and must not be discharged into the public sewer system. There are no restrictions in the local sewerage system (septic tank), but high acidity can destroy beneficial microorganisms. Condensate is neutralized in special installations (containers with limestone or marble chips).

- Work specifics. The difference between the temperature in the house and outside its walls should not exceed 20°C, so it is possible to really reduce costs in many regions only during the off-season.

- The price for condensing models is higher than for classic ones, and repairs will cost more.

Comparison of efficiency of different systems Source warmex.com.ua

Myth 2. Problems with condensation

Yes, condensation forms during boiler operation, but there are several ways to eliminate it. If it is produced in small quantities, you can use the services of local services or install neutralizers.

Few people know that when a conventional unit operates, condensate also forms, which needs to be disposed of. When the chimney is stopped, condensate flows to the boiler and is later drained into the sewer pipe through a condensate drain. But to minimize the impact on the environment, the condensate must first be neutralized.

Myth 3. Complex chimney

A feature of the equipment is that during operation of the boiler a large volume of condensate accumulates. And many people think that the chimney must be made of lead or a more durable material. But chimneys are practically no different. Combustion products are removed forcibly, so the boiler can be connected to different smoke removal systems. Chimneys must be airtight, and to connect the boiler it is not necessary to build a chimney.

Converting the boiler unit to bottled gas

Theoretically, converting the boiler to liquefied gas is not difficult: the most important thing is to replace the nozzles responsible for fuel consumption, or the entire burner. This is followed by alteration of the gas valve (in accordance with the attached operating instructions) and reconfiguration of the electronic board if the unit is automated.

But you shouldn’t interfere with the internal structure of the boiler yourself; it’s better to contact a licensed gas company. Specially trained personnel will complete the task in half an hour - maximum, while the cost of work with the purchase of all consumables will cost approximately 2.5-3.5 thousand rubles.