Self-installation of a boiler is considered a responsible undertaking that requires maximum compliance with the rules and regulations of connection. A safety group must be involved in piping the water heater, which includes a safety valve for the boiler - a small but functionally important device.

In this article we will consider the types of safety valves and their design features. After all, in order to install the heater without errors, you need to understand the structure and operating principle of the valve.

We will also provide instructions for piping the boiler and tips for installing a safety valve, and give useful recommendations on choosing suitable equipment.

What is it needed for

Installing a safety valve prevents the pressure inside the device from increasing above the standard value. What causes blood pressure to rise? As you know, when heated, water expands, increasing in volume. Since the boiler is a sealed device, there is nowhere for the excess to go - the taps are closed, and there is usually a check valve at the supply. Therefore, heating the water leads to an increase in pressure. It may well happen that it exceeds the tensile strength of the device. Then the tank will explode. To prevent this from happening, they install a safety valve for the water heater.

This is what an installed pressure relief valve looks like in a water heater

Maybe there is no need to install a safety valve, but simply remove the non-return valve? At a sufficiently high and stable pressure in the water supply, such a system will work for some time. But the solution is fundamentally wrong, and here’s why: the pressure in the water supply is rarely stable. There are often situations when water barely flows from the tap. Then the hot water from the boiler is forced out into the water supply system. In this case, the heating elements will be exposed. They will heat the air for some time and then burn out.

But burnt-out heating elements are not the worst thing. It’s much worse if they get hot, and at this time the pressure in the water supply rises sharply. The water that gets on the hot heaters evaporates, a sharp increase in pressure occurs - with a jerk - which leads to a guaranteed rupture of the boiler flask. At the same time, a decent volume of scalding water and steam escapes into the room under high pressure. What this could mean is clear.

With release handle

One of the most common types of check valves that are equipped with water heaters is a valve with a release handle. Let's talk briefly about its structure and principle of operation.

The design of a check valve with a release handle has the following elements: a body, a water release fitting, a forced pressure release handle, a safety valve spring and a check valve spring.

Under the influence of water pressure, the spring of the check valve is compressed, as a result of which the poppet valve rotates and allows water access to the tank. Once enough water has been collected, the check valve returns to its original position.

The release handle is needed to, if necessary, forcefully relieve pressure inside the system. As soon as the pressure exceeds the permissible maximum, a safety valve is activated, through which excess water is discharged, thereby normalizing the pressure.

How does it work

It would be more correct to call a safety valve for a water heater a valve system, since there are two of them in the device.

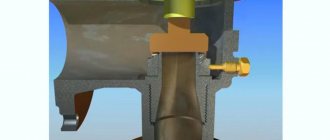

They are located in a brass or nickel-plated case, which looks like an inverted letter “T” (see photo). At the bottom of the housing there is a check valve that prevents the outflow of water from the water heater when the pressure in the system decreases. In the perpendicular branch there is another valve, which, if the pressure is exceeded, allows some of the water to be released through the fitting.

Safety valve device for boiler

The working mechanism is as follows:

- While the pressure in the boiler is less than that in the water supply (when filling or when the tap is open), the check valve plate is pressed out by the flow of water. As soon as the pressure is equalized, the spring presses the plate against the protrusions of the body, blocking the flow of water.

- When the heating is turned on, the water temperature gradually increases, and with it the pressure also increases. As long as it does not exceed the limit, nothing happens.

- When the threshold level is reached, the pressure compresses the safety valve spring, and the outlet to the fitting opens. Some of the water from the boiler is released through the fitting. When the pressure drops to normal, the spring closes the passage and the water stops flowing.

Based on the principle of operation, it is clear that water will constantly drip from the fitting. This happens when the water heats up and the pressure in the water supply decreases. If you periodically see water on the fitting, then everything is working normally. But the draining liquid must be drained. To do this, put a tube of a suitable diameter on the pipe and secure it with a clamp. The normal operating pressure of the boiler is from 6 Bar to 10 Bar. Without mechanical fastening, the tube will be torn off in no time, so we select a high-quality clamp and tighten it well. Place the tube into the nearest sewer drain.

One more point: the tube for the fitting needs to be transparent and preferably reinforced (the so-called “herringbone”). Why reinforced is understandable - because of pressure, and transparent - to be able to monitor the performance of the device.

Service

During use, depending on the intensity of hot water consumption, it is necessary to flush the safety valve for the boiler from scale, rust fragments from pipes and other foreign matter in the water. To do this, you just need to sometimes open the emergency discharge channel of excess liquid using a lever.

This mechanism should not be used to empty the water heater. Particles settling at the bottom of the tank passing through the bleed spring will get stuck and interfere with its further normal operation.

By following all the rules for using the water heater and ensuring that the safety valve is working properly, you will confidently and safely use hot water.

Types and varieties

If we are talking about conventional safety valves for a water heater, then they look almost the same, only the nuances differ. But it is these small details that are responsible for the convenience and safety of operation.

Safety valve for boiler with forced pressure release option

The photo above shows two safety valves with release levers. They are needed for periodic performance checks. The lever flag is lifted up. It pulls the spring behind it, freeing it to release water. This check should be carried out approximately once a month. You can also empty the boiler tank by raising the flag and waiting for everything to drain.

Design Features

The difference in the presented models is that the model in the photo on the left has a lever secured with a screw. This eliminates the possibility of accidental opening and complete discharge of water.

Two more differences are striking. This is an arrow on the body indicating the direction of water movement, and an inscription showing what pressure the device is designed for. Seemingly minor details. But if you can figure out the direction of water movement (look in which direction the poppet valve is turned), then the nominal value is more difficult. How to distinguish, for example, whether it is 6 Bar or 10 Bar? Only checks. How will sellers differentiate them? No way. By boxes. What if they put it in the wrong box? In general, it is better not to take a valve without markings on the body. These are usually the cheapest of the Chinese designs, but the difference in price is not so great that it is worth the risk.

Safety valves - serviceable and not

Also pay attention to the shape of the water discharge fitting. The model on the left has a long fitting and has a non-linear shape. The hose fits on it quite easily and is long enough to install a clamp. The shape of the fitting on the model on the right is different - with an extension towards the end, but more importantly, the fitting is short. You can still pull the hose onto it, but the clamp is questionable. Unless you crimp it with wire...

The following photo shows the safety valves without a forced pressure release flag. The one on the left has a threaded cap at the top. This is a serviceable model. If necessary, you can unscrew the lid to remove clogs, scale and other contaminants.

The model on the right is the worst option. No markings, forced resets or maintenance. These are usually the cheapest available, but this is their only advantage.

For large volume boilers

All of the above models are suitable for water heaters with a volume of up to 50-60 liters. Larger boilers come with other models, many of which have built-in additional devices. Typically this is a ball valve and/or pressure gauge to control pressure.

For boilers up to 200 liters

The water drain fitting here has a standard thread, so there will be no problems with fastening reliability. Such devices already have a fairly high price, but their quality and reliability are much higher.

With pressure gauge and original

Not everyone likes the appearance of these devices. For those who attach great importance to aesthetics, very attractive devices are produced. Their price, however, is comparable to the price of an expensive water heater, but it’s beautiful.

Installation

We have compiled short instructions for you that will help you install a safety valve for a domestic water heater yourself.

- Disconnect the boiler from the electrical network and drain all the water from the tank.

- We find a material that we will use as a sealant for joints (for example, ordinary tow or FUM tape).

- Armed with a wrench, screw the valve into the junction of the water pipe and the boiler.

- Make sure the valve is installed in the correct position. The direction of water movement must coincide with the arrow-shaped markings on the device.

This is interesting: How to choose a water heater for a bathroom

Is it possible to install other valves?

Sometimes, instead of a special safety valve for a boiler, a blast valve is installed, which is intended for the emergency release of heating water. Although their functions are similar, the main mode of operation is fundamentally different. The demolition device should only be used in emergency situations. It is designed for volley discharge of a large volume of liquid. It is not suitable for constantly bleeding small portions of water. Accordingly, it will not work correctly.

Another case is to install only a check valve. It will not allow water to drain when the pressure in the water supply decreases, but it will not save you from increasing pressure in the boiler. So this option doesn't work either.

Checking for serviceability

At home, you can quite easily find out whether the safety valve installed on the water heater is working properly. To do this, you just need to set the temperature regulator to the maximum value and open the hot water tap. If, after the water in the boiler has heated to the required temperature, excess liquid begins to flow out through the safety valve, then it is quite suitable for operation. If water does not flow through the valve, it is most likely faulty.

How to choose and install

Select a safety valve for a water heater based on the pressure for which the unit is designed. This number is in the passport. The volume of the tank also influences the choice. They produce devices with operating limits of 6, 7, 8, 10 Bar. Basically, all units are designed for this pressure. So everything is simple here.

Installation is simple: flax tow or fum tape is wound onto the threads, after which the valve is screwed onto the pipe. Twist it all the way by hand, then another one or two turns using keys. It is much more important to choose the right place to install it. When installing a water heater, this valve is installed directly on the cold water inlet pipe.

Installation example

Next there may be a check valve, which is also called a shut-off valve. But this is already reinsurance - the same device is available in the safety device, and often after the water meter at the inlet. The installation diagram is shown below. This is one of the normal options.

Installation diagram of a safety valve for a boiler

The diagram shows a ball valve. It is necessary to empty the tank before storing it for the winter (at dachas) or before dismantling it for prevention and repair. But more often they put it on a tee, which is screwed directly onto the inlet pipe of the water heater. A safety valve is screwed onto the tee from below, and a ball valve is placed in the side outlet.

Installing a safety valve after a tee

Actually, these are all normal options.

Tips for choosing

When choosing a safety valve for a household water heater, use the recommendations that experts have compiled for you.

- Among the variety of designs, the spring mechanism is the most reliable, as it is able to withstand water pressure well.

- We must not forget about such a factor as valve capacity. We advise you to choose a low or full lift device.

- Consider the water supply and sewer systems in your home. If excess liquid will be discharged into the atmosphere, choose an open safety valve, and if into a specially equipped pipeline, then choose a closed one.

- When choosing a safety valve, you should remember the maximum allowable pressure in the water heater system. If it is higher than indicated in the technical data sheet of the device, the valve will not be able to function normally.

Breakdowns, causes, elimination

In principle, the safety valve for a water heater has only two failures: water either often flows from it or does not flow at all.

First of all, it must be said that bleeding of water when heating is the norm. This is how the system is supposed to work. Water may also be released when the boiler is turned off, if the pressure in the cold water supply pipes is higher than the valve response limit. For example, the valve is 6 bar, and the water supply is 7 bar. Until the pressure drops, the water will be released. If this situation repeats often, it is necessary to install a reducer, and it is best to use water in an apartment or house, but there are compact models of reducers that can be installed at the entrance to the boiler.

Boiler piping with safety valve and reducer

How to check the serviceability of the valve? If there is an emergency reset lever, this is easy to do. With the boiler turned off, you need to lift the lever several times to release excess pressure. After this, the dripping stops and does not resume until heating begins.

If water continues to drain, the spring may be clogged. If the model is serviceable, the device is disassembled, cleaned, and then put back in place. If the model is not collapsible, you just need to buy a new valve and install it.

This is what the reducer looks like - to stabilize the pressure on the boiler

Constantly dripping water is unpleasant and hurts your wallet, but not dangerous. It is much worse if, when heating the water, you never see water in the pipe. The reason is that the valve is clogged or the outlet fitting is clogged. Check both options. If it doesn’t help, change the valve.

For indirect heating boiler

Many apartments have indirect water heaters. Indirect heating does not occur in the boiler itself, but in another device, most often in a heating boiler. Thus, the operation of the indirect boiler and the boiler is closely interrelated. For this type of water heater, it is necessary to select a suitable safety valve.

All the characteristics we need are indicated in the technical data sheet of the device, so be sure to study this document before purchasing. It is important to know the permissible operating pressure of the device - you need to focus on it, and not on the pressure in the water pipes.

Operating rules

- It is not allowed to install shut-off mechanisms in the area between the safety valve and the entrance to the boiler.

- The safety valve must be fixed at a distance of no more than 2 meters from the entrance to the water heater.

- Using a flexible drain tube made of clear material will allow you to check the operation of the safety valve by visual inspection alone.

The procedure for connecting a water heater

After installing the water heater, begin connecting it. To do this, take a tee, try it on, screw it onto the cold water inlet pipe, marked in blue. If there are not enough threads, then several turns are added with a special device so that the tee is installed correctly.

Then they wrap the thread with tow, coat it with paste to ensure a tight connection, and screw on the tee, tightening it with an adjustable wrench. Next, a tap is screwed onto the side outlet of the tee to ensure quick drainage of water from the boiler in case of replacing a burnt-out heating element or cleaning the tank from scale.

The connection is also sealed with tow or tape for threaded connections. A safety valve is connected to the bottom of the tee, focusing on the arrow showing the direction of cold water entering the water heater. The arrow is located on the valve body.

Next, one part of the American one is screwed onto the safety valve. The second part of the American connection is screwed onto the tap and a connection is made to the first part. Then a transition coupling is screwed into the tap for connection to the water supply with propylene pipes.

Next, connect to hot water. To do this, screw the first part of the American onto the boiler outlet pipe, marked in red. The second part of the American is screwed onto the shut-off valve. Make a connection.

Then an adapter coupling is also screwed onto the tap to solder the propylene pipe. All that remains is to connect the boiler to the cold and hot water supply system. Propylene pipes can be replaced with flexible pipes.

The diagram for connecting a water heater (boiler) to hot and cold water supply systems shows the sequence in which the device is installed

Alternative way to install a check valve

This method was invented by a craftsman who was faced with the problem of contamination of a safety valve with sediment from a tank of hot water under pressure. If a piece of rust gets under the piston plate onto the seat, the valve will no longer work correctly. It remains open all the time.

To prevent such a development of the situation, it is necessary to install the valve at the level of the middle of the tank. That is, in the same way as described above, a tee is connected to the inlet pipe of the boiler, and then the connection is made a little differently.

The drain valve is screwed on from below, a pipe is pulled to the side, corners are placed, a pipe is placed again, and a safety valve is installed somewhere at the level of the middle of the tank. After it comes a shut-off valve and fitting, through which the device is directly connected to the water supply.

With this method, the valve always remains clean and the poppet piston does not “hang” above the seat. In addition, in the absence of water in the system, such a flexible connection serves as a kind of water seal.

You can learn more about this editing method from the video.

Tips for using a water heater

When using the boiler, make sure that the drain hole on the safety valve is not clogged or blocked. The drain can become clogged with rust, small solids, and other impurities found in tap water.

To check its working condition, a small amount of water is periodically discharged by pressing a special lever or turning the handle. The instructions included with the water heater safety valve indicate how the valve's forced opening mechanism operates.

Installing a filter to purify tap water partially solves the problem. It is not advisable to change the factory settings of the spring stiffness in valve models equipped with such adjustment.

Such intervention may lead to destruction of the water heater tank due to exceeding the permissible pressure values inside the household appliance.

Forced discharge of water from the boiler in order to reduce the pressure in the tank is carried out by pressing the lever

Water is constantly dripping - what to do and how to fix it?

Some boiler owners are faced with the problem of constant water seeping through the drainage hole. Water may drip from a drain for two reasons:

- incorrect valve setting;

- too high pressure in the cold water supply system.

The first problem can be resolved by replacing or adjusting the device, which must be done with a hex key. At the same time, slightly tighten the clamping nut located at the entrance to the valve.

You can get to this nut by partially disassembling the device, during which you remove the lever, nut and sealing washer. In general, you can solve the problem faster by purchasing a new valve.

The second problem associated with high pressure in the system disappears when installing a pressure relief valve.

A tube with transparent walls is connected to the drainage hole without leading it into the sewerage system

Connecting the outlet in the form of a transparent tube from the drainage hole of the safety valve to the sewerage system through a pipe with an oblique inlet