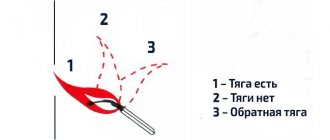

Backdraft in the combustion chamber, which occurs during gusts of wind, is a fairly common problem. A gas boiler constantly goes out during strong gusts of wind, which impairs its efficiency; due to frequent clocking, it reduces its service life, and models with manual ignition have to be constantly ignited even in the middle of the night.

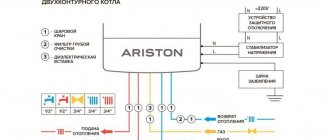

The problem can arise both in floor-mounted atmospheric boilers with an open combustion chamber and a vertical chimney, and in boilers with a closed combustion chamber and a coaxial chimney. However, correcting the situation in more than 90% of cases is not difficult.

Reasons for the boiler being blown out by the wind

If in apartment buildings the heating system is mounted in a coaxial air duct, which prevents wind from entering it, in private houses the problem of attenuation during strong gusts occurs quite often.

This is due to the design features of the chimney, as well as predisposing factors:

- There are trees near the air duct - with strong gusts of wind, vortex gusts are created that change the draft in the chimney, which leads to vibrations of the burner wick and, accordingly, the flame disappears.

- The predominance of downward wind flows, as well as the incorrect level and height of the chimney - this is especially true for lonely private houses (dachas, cottages), next to which there are no other buildings.

- Insufficient chimney height , at which a gusty wind easily extinguishes the burner flame.

- Malfunction of the draft sensor , which gives false readings, triggering the operation of the automation, blocking the supply of gas to the combustion chamber.

- Depressurization of the chimney , in particular an open inspection hole, which forms a reverse draft and triggers draft control sensors, which signal the need for an emergency shutdown of the gas supply to the system.

- Incorrect chimney design , when the required number of turns is missing and the wind from outside easily enters the boiler.

Also, the cause of boiler extinguishing in strong winds can be reverse draft. If the boiler is installed near a balcony door, in a gusty wind, when the door is open, a strong draft will be created, which will lead to vibration and extinguishing of the wick.

What type of gas boiler to choose so that the flame does not blow out

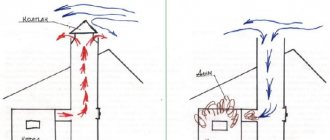

The minimum speed of flue gases at which the flame will not be blown out is 6-8 m/s. Flows of heated air entering the chimney move in a spiral. The vortices gradually increase in speed, which reaches maximum intensity at the exit from the chimney.

There are boilers in which the natural movement of flue gases is replaced by forced one. The design of turbocharged models with a closed combustion chamber includes two blower fans. The first one supplies air to the firebox, the second one removes combustion products. It is impossible to blow out a turbocharged unit with wind. Attenuation indicates that one of the failed fans needs to be replaced.

How to identify the problem?

Since the boiler can go out due to all sorts of malfunctions, you can understand that the wind was the cause by the following signs:

- The boiler stops working only in strong winds, but on other days it works properly.

- Oscillation of the burner flame towards the exit, change in its height in the presence of strong wind outside. Normally, external factors do not a priori affect the operation of the boiler and burner in particular.

- A pronounced whistling sound in the combustion chamber, which changes its intensity and severity with different gusts of wind and completely disappears in calm, windless weather.

Expert opinion

Filimonov Sergey Vinokurovich

Heating equipment repairman

I also recommend monitoring such a parameter as gas pressure in the system. If the boiler is set to minimum values, then it is more susceptible to being blown out by the wind than a boiler set to medium values. Often the problem can be solved simply by adding power to the heating system. If this does not help, then you need to consider the situation from all possible sides.

The wick burns weakly

Gas boiler wick

The wick burns weakly for two reasons: either it is clogged and needs to be cleaned, or you have weak inlet pressure. If you have a home controller, be sure to check its settings. You may need to increase the inlet pressure, as it constantly fluctuates due to the fact that gas consumption is different in different periods.

Accordingly, during the heating season, when gas boilers are operating, gas consumption is higher and the inlet pressure also drops. And the regulator, as far as you know, maintains a certain differential between the inlet pressure and the outlet pressure. Accordingly, this differential also drops, because of this your wick may burn weaker. Check the regulator setting and also clean the wick.

Boilers with coaxial chimney

If a gas boiler has a side chimney (usually in apartments) and goes out due to strong gusts of wind, the main reason lies in the formation of condensation and ice. In practice, the situation is as follows: when exhaust gas exits into the pipe, it cools very quickly and settles on the internal walls in the form of an ice crust, which rapidly increases in thickness.

Outwardly, this does not manifest itself in any way, with the exception of a few icicles hanging outward from the pipe, but in reality the natural removal of waste products is disrupted, which negatively affects the operation of the boiler itself. Whirls are created that lead to oxygen starvation of the gas chamber, and accordingly the gas combustion process is disrupted or completely stopped.

The problem often occurs in regions where winter temperatures are more than -30°C. Experts recommend installing insulation on the outside of pipes to minimize condensate icing. In case of significant ice accumulations, mechanical defrosting using special devices is required, so it is better to call the gas service to solve this problem.

If the design features of a boiler with a side chimney do not require a deflector, then you should install it yourself. This is necessary in cases where the number of windy days per year is more than 200. A device that cuts off vortex air flows. Installed on the air intake pipe.

Tags

yourself Ferrum chimneys.installation of a Ferrum chimney.these are chimneys from Ferrum chimneys with a cold chimney.the height of the chimney is selected.extension of the chimney is the length of the chimney.chimney project with rebuilding the chimney or preventing blowing out preventing blowing out the problem of blowing out so prevents blowing out.the reason for the boiler blowing out of the usual back blowing by the wind. causing the burner to blow out. and blowing out cause blowing out the wind of gas boilers quite reaches the boiler. These boilers are built in

Grigorovichaspecial

Increasing the length of the chimney

Increasing the height of the chimney is appropriate when there are other buildings or tall trees near the house that affect the draft in the chimney. The procedure involves putting several pipes with a cross-section 0.5 larger than the chimney itself onto the existing chimney pipe. It is important to remember that the height of the chimney depends entirely on the roof structure and the power of the boiler.

The average height of the chimney from the boiler grate is 5-6 m. This value can be increased taking into account the roof surface.

Only professionals should carry out work to increase height, as there is a risk of getting the opposite effect:

- A high chimney provokes increased draft, so most of the heat will literally “fly out into the chimney.”

- The amount of condensate increases, which at subzero temperatures will freeze on the inner wall of the chimney. This is fraught with disruption of natural air exchange and automatic shutdown of the gas supply.

Expert opinion

Filimonov Sergey Vinokurovich

Heating equipment repairman

I recommend installing traction stabilizers or dampers, with which you can manually adjust the traction and increase it in especially windy weather.

Influence of equipment parameters on the possibility of flame extinction

Among the most common causes of failures are:

- An incorrectly calculated ventilation system is a distance of less than 50 cm above a flat roof, 500 mm above a ridge (or parapet), etc. The errors are detailed in the image below.

- Violation of construction and technical requirements during installation - low-quality materials, non-compliance with SNiP.

To make adjustments, it is recommended to ask a professional if you have any questions.

There are often times when the reverse action valve comes into operation. This is caused by gusty winds that exert too much pressure from the street. Sensitive automation reacts quickly and the valve closes. Next, the fuel supply to the boiler is stopped and its operation stops completely. Regular repetitions force us to think through possible options for reconstruction. First, it is recommended to check whether the correct chimney height is selected. The difference between the highest point of the house and the canal should be at least 0.5 m. The diameter is calculated based on the parameters of the installed unit.

You can also improve draft by regularly cleaning the ventilation. This is explained by the need for a constant flow of air into the installation. If a small amount of oxygen enters it, then the intensity of gas combustion becomes weaker. As a result, the flame may go out completely.

Deflector installation

The deflector is an aerodynamically shaped nozzle that fits onto the chimney. Made from stainless or galvanized steel.

Performs several functions simultaneously:

- Protects against debris, precipitation and dust getting into the chimney - it has a cone-shaped top.

- Blocks gusts of wind, cutting them off - preventing the vortex from entering the chimney.

- Increases draft by 10-20%, which allows you to solve the problem without increasing the height of the chimney pipe.

The process of installing the deflector will not cause any difficulties, and the effectiveness can be assessed almost immediately. In regions where winds prevail, this design is necessary and is included in the gas heating system.

There are several types of deflectors, each of which has its own characteristics, advantages and disadvantages.

TsAGI

TsAGI

Metal pipe with a shielding cylinder. It has a protective cone inside that prevents blowing from the top and sides.

Advantages:

- Protects from precipitation

- Prevents debris from entering the pipe

- Easy installation

Flaws:

- In severe frosts it provokes the formation of heavy ice

Grigorovich deflector

Grigorovich deflector

A truncated cone with a widening at the base and a mushroom-shaped lid at the top. The air flow enters under the top cover, discharging the air and increasing traction.

Advantages:

- Protects against debris and precipitation

- Relatively low cost

Flaws:

- Not effective in low winds

Vane deflector

Vane deflector

Contains a weather vane and several metal canopies that rotate in the direction of the wind.

Advantages:

- Enhances natural cravings

- Protects against blowing from all sides

- Blocks sediment from entering

Flaws:

- Not found

Expert opinion

Filimonov Sergey Vinokurovich

Heating equipment repairman

The choice of deflector depends on the power of the gas boiler and the characteristics of the chimney. If it is selected incorrectly, the gas consumption will increase and the heat in the house will decrease. To eliminate this, you need to contact specialists and carry out work in compliance with the recommended standards.

How to deal with backdraft: main mistakes and misconceptions

Of course, extending the chimney is the simplest and most affordable option.

It is important to take into account that the method cannot guarantee a positive outcome. In this case, you can mount a deflector on the top

If this method is not effective, then the third option should be used. The pipe design needs to be reconsidered. The fewer angles and sharp turns there are, the higher the conductivity of heated air flows as they move through the pipes. This is a rather labor-intensive but effective technique.

Even significant extension and installation of the deflector does not fundamentally change the system. Strong and gusty air currents may cause the equipment to stop operating again.

Gradual heating of the boiler

If a gas heating system is used in country houses and has been inoperative for a long time, even weak gusts of wind can cause the flame to die out.

The problem is solved by gradually heating the boiler, namely, first after ignition, set the minimum temperature, after 5-10 minutes add gas, and after 20-30 minutes warm up the chimney at high settings. This will allow the chimney to fully warm up, which will make it easier for the exhaust gas to escape up the chimney.

Problems with closed-type turbocharged equipment

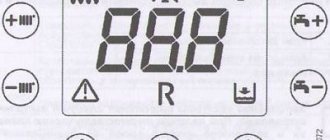

Sometimes when installing a new chimneyless apparatus, the flame periodically goes out. In this case, you need to check the components and parts. The problem is detected by the following factors:

ignition of the igniter is accompanied by periodic attenuation - this indicates a failure of the thermocouple, which affects the operation of the valve. It is produced in the form of a copper tube with a bimetallic piece at the end. When different metals come into contact, the voltage increases to 20-45 W. This problem keeps the gas valve open. The thermocouple must be replaced with a new one; it cannot be repaired;

- breakdown or clogging of the traction sensor - the flat part is combined with the fuel valve. When the leading contacts are closed and the burner is ignited, a fire occurs - this indicates the need to replace the sensor. Oxidized areas of contacts can be cleaned with sandpaper with fine abrasives;

- if the circulation pump malfunctions, it is necessary to carry out a complete diagnosis of the unit and replace it;

- A yellow flame is due to the fact that the jet is clogged. You can clean it if you have experience working with gas appliances.

Most of the reasons can be eliminated with your own hands, however, this will require some knowledge and a lot of time.

General tips and tricks

If the gas boiler is blown out by the wind, pay attention to the following nuances:

- Check to see if the boiler is operating at minimum temperatures. It makes sense to add gas by 20-30% to enhance natural traction.

- Be sure to call specialists who will not only find the problem, but also diagnose the entire heating system.

- Clean the chimney in a timely manner, as contaminants can form inside over time.

It is not recommended to independently inspect the combustion chamber, change burner parameters or adjust the operation of control sensors. This may lead to problems in the future. All work related to gas equipment must be carried out by qualified specialists.

Troubleshooting

It is very important to detect malfunctions in the operation of a gas boiler in time and eliminate them in time to avoid accidents. The main sign of a gas boiler malfunction is very weak combustion of the burner or its complete absence

There can be many reasons for this manifestation.

Malfunction of the internal mechanism of the gas boiler

Another sign is that the burner is difficult or impossible to light. This manifestation can occur due to filter clogging, broken electronic contacts, or violation of the electrode gap. If the filter can be cleaned yourself, then if other problems arise, a professional approach is required.

Other signs of a gas boiler breakdown include noise and spontaneous shutdown of the device, nozzle whistling, and others.

Frequently asked questions and answers

The boiler is blown out by the wind, and the smell of gas is felt in the room. What is this connected with?

There may be a problem with the backdraft valve, but to be sure, it is necessary to inspect the injector burner. Attention should also be paid to control sensors. Over time, they fail and are not able to timely generate a signal about the need for an emergency shutdown of gas supply to the system, which is where the characteristic odor appears.

The flame in the burner is unstable, fluctuates with any gust of wind, often goes out, the temperature in the system drops, what could be the problem?

This is characterized by an increase in natural cravings, for which there are many reasons. It is necessary to inspect the hood, as well as the burner itself, adjusting the gas supply and flame height. If there are strong gusts of wind outside and the problem with attenuation occurs very often, a deflector is installed on the hood (chimney) to cut off vortex air flows.

In conclusion, it is worth noting that the problem with the boiler blowing out periodically occurs among residents of apartment buildings. As for private mansions, attenuation is caused by improper chimney design or insufficient draft.

In resolving the issue, it is important to make sure that the burner and control sensors are in good working order, since they can indirectly contribute to stopping the combustion process. All work must be performed by qualified specialists.

Scale deposits inside the heat exchanger

The heat exchanger can be clogged not only with combustion products, but also with scale and limescale that forms with each portion of water entering the boiler. Scale is formed as a result of heating hard water.

Inside the heat exchanger, solid deposits of salts turn into a kind of insulator, reducing heat transfer from heating. The larger the scale layer in the heat exchanger, the worse the heat transfer from fire to water will be, because heat will not be able to penetrate a thick layer of solid deposits. This significantly reduces the energy efficiency of the entire system and the boiler stops reaching the desired temperature.

To remove scale, the heat exchanger must be removed and descaled using a special acid. As a preventative measure, it is recommended to maintain the operating temperature in the boiler.

Traditional methods for descaling include the use of ordinary table vinegar (3-10% acetic acid solution). Table vinegar is poured in equal parts with water, the solution is left to interact with the scale overnight. Cationation and reverse osmosis methods are also used.