- Construction changes

The article provides information about the causes of backdraft in a stove chimney, what to do about it, with video examples, as well as a guide to action. We will look at ways to stabilize the situation, ranging from making structural changes, continuing with the use of various devices, and ending with a review of ventilation. And, of course, we will share the secrets of prevention and inspection so that you are warned and armed, and your home is protected.

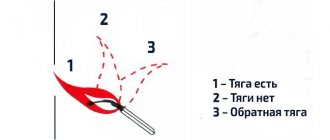

What is traction

Draft is the movement of flue gases up the chimney of a house, from an area of high pressure to an area of low pressure.

In a chimney (in a pipe) of a set diameter, with a height of at least 5 m, a vacuum is formed, this means that the required minimum pressure difference is formed between the lower part of the chimney and the upper, the air from the lower part, entering the pipe, goes up. This is called traction. The draft can be measured with special sensitive instruments, or you can take a piece of fluff and bring it to the pipe. Accordingly, if you take a pipe of sufficient diameter in which air has the opportunity to move, and stretch it high up, then air from the ground will begin to constantly flow upward. This happens because the pressure is lower at the top, and the vacuum is greater, and air tends there naturally. And in its place will come air from other sides. In the “firebox + chimney” system, the draft operates even if the stove in a private house is not working. When burning wood, increased pressure is formed in the internal combustion chamber and the flue gases generated during combustion require exit. All fireboxes and stoves are designed to exhaust flue gases into a chimney.

The height of each chimney is selected so that draft is created, an initial vacuum is created. When burning in the combustion chamber, heat and gases are released and excess pressure occurs. Gases move in the chimney under the influence of draft, tending to move from an area of high to an area of low pressure. The laws created by nature work.

More complex situations

Coping with the complex causes of air backflow in a furnace is much more difficult. It is possible to correct an incorrectly designed chimney, but only by rebuilding it completely, so it is very important to entrust the design to specialists. It is best that the chimney or pipe be installed strictly vertically.

Along a vertical straight pipe, without encountering any obstacles along the way, the smoke will move upward quite dynamically and escape into the atmosphere. Bends, corners, inclined or horizontal sections in the chimney will make it difficult and slow down the outflow. In addition, soot will accumulate in the corners much faster, and this will also contribute to the fact that traction may one day disappear.

The material from which the chimney is made is very important. It is best to use ceramics and bricks. The height of the pipe also matters, which cannot be less than 5 meters. Its inner surface should be smooth. Today there are various devices that can eliminate backdraft. These include :

- chimney deflectors;

- fans;

- smoke exhausters for chimneys;

- rotary turbines;

- chimney weather vanes.

The purpose of using these devices is to increase traction by creating additional air flows. The disadvantage is that in the absence of wind, all these devices are ineffective.

Why does backdraft occur in a stove or chimney?

Reverse draft is the movement of flue gases from an area of high pressure to an area of low pressure, but not upward (as described earlier), but downward. Reverse draft occurs when pressure is inverted - when the pressure at the top is higher than at the bottom.

The reasons are the most ordinary things: if a private house or room is sealed, there are double-glazed windows, and an exhaust hood works together with the chimney, drawing air out of the room. This is where low pressure is created relative to the surrounding area. Therefore, during kindling, when the chimney is still cold, the air in the upper part of the chimney has greater pressure than in the room. The smoke will of course go where it is easier for it. This phenomenon is called a “cold column”. When the chimney cools, a low-temperature air mass forms inside, which presses down, causing reverse draft. If the pressure in a private house is not reduced, then warm air will go up into the chimney.

Thus, if the house does not have a kitchen hood and it is not airtight, there will be no stagnation of cold air in the firebox.

Check: if in winter, before lighting the fireplace, you first set fire to a newspaper and put it into the chimney (bypassing the combustion part), then the fire will not go into the room, no matter what the column of cold air is. The fire will burn and come out only into the chimney. This indicates that the pressure in the room is not low and warm air normally tends to rise.

When lighting a stove or fireplace in a private home, sometimes smoke comes into the room. This is due to the fact that the flue gases formed during the initial kindling have not yet had time to heat up, and, when rising upward, coming into contact with the cold walls, they immediately cool down. After that, they will naturally rush down. Again, reverse draft occurs in the chimney ventilation. To normalize the draft in the stove, it is important to melt correctly, understanding the processes occurring there.

Cleanliness check

To prevent backdrafts from occurring during the heating season, chimneys should be regularly checked for cleanliness even before the need to regularly use heating appliances. Blockages can be caused by birds flying into the chimney, large accumulations of soot, or peeling of plaster from the inner surface of the chimney ducts. You can check the cleanliness by looking into the pipe from the roof or through the cleaning hatch, but using a mirror.

If there are contaminants in the pipe, they can be cleaned using special brushes and even chemicals that are sold everywhere today. To put off chimney cleaning as long as possible, it is recommended to use one of the preventive tips that have been passed down through generations.

The first states that aluminum cans should be burned in the stove every 10-12 fires. It is important that the combustion temperature is such that the cans burn completely in 5 minutes. It is also recommended that if there is a large amount of soot in the chimney, throw approximately half a bucket of peeled and chopped potatoes into the firebox while it is burning. The starch released during the combustion of the product can soften the plaque, and the soot itself will fall off the surface of the chimney. You can periodically burn rock salt in the firebox, this will also delay cleaning.

Rollover traction

Another issue that arises is the tipping of the draft. In what cases does this happen?

If the chimney is long and cold (often brick), and the pressure is reduced. If the ratio of the dimensions of the firebox and the cross-section of the chimney correspond, if there is normal pressure in the house, a situation still arises when, when lighting the flame, there is not enough strength and the exhaust flue gases manage to cool in the chimney and collapse down. Why is there no draft in the chimney? This happens in cloudy weather and wind. It happens that the fire flares up normally, but then smoke pours into the house. Why is there no draft in the furnace? Why does back draft form in the chimney? Air is taken from the house and the pressure decreases, there is no air flow. As the flue gases rise, they cool and fall down. What do you need to know in such situations? Open the window slightly if the room has double-glazed windows and is sealed. The preparation of firewood and its quality are important.

Reasons for blowing

Before you ask what to do if the wind blows out your gas boiler, you need to determine the cause of the problem. According to experts, the boiler blows out for several reasons. One of them is the appearance of an ice build-up on the installation head.

With this phenomenon, there is no need to rush to knock off the ice, as this can lead to damage to important elements of the heating system. If an ice edge appears on the head and inside the boiler, and the oxygen flow no longer enters the installation, it means that it will stop working. In this case, you should slowly defrost the head by removing it and moving it into the house.

While the tip is thawing, it is necessary to stop the gas supply, and after igniting the igniter, slowly open the tap. After waiting for flames to appear in the main burner, you need to warm up the device. This will allow the structure to operate at minimal gas pressure. With a stable temperature increase, the pressure can be increased.

When trying to understand why a gas boiler blows out in the wind, it is important to know about all the design aspects and structure of the system. Correct and timely measures will avoid many troubles and protect the installation from damage.

How to assemble a chimney correctly?

Sandwich chimneys (prefabricated), collected by smoke and condensate.

There is an opinion that it is more correct to collect by smoke. The explanation is that there are gaps at the pipe joints where the flue gases escaping into the pipe get clogged. In contrast, it is believed that if you collect the smoke, the smoke will stop coming out.

Such a dispute can be resolved if you drill a hole in the existing stove at home anywhere in the chimney and see what happens. It's most interesting to do this at the bottom. Drill any hole, at least a centimeter in diameter. What will you see? No smoke will come out of this hole (unless you close the chimney tightly from above).

Repair of wall-mounted and turbocharged units

Wall-mounted gas boilers with open and closed combustion chambers are more complex devices equipped with modern electronics and safety elements. But here, too, some problems can be solved on your own. All the manipulations described above with checking traction, fuel supply and sensors are just as relevant for wall-mounted atmospheric heat generators.

To find faults in a wall-mounted electric gas boiler, you need to arm yourself with the product’s operating instructions and a Phillips screwdriver; you are unlikely to need other tools. The technical data sheet contains the fault codes displayed on the heater display, and a screwdriver is needed to remove the front panel.

There are 3 non-working states of the heat generator:

- The boiler is completely turned off, not a single indicator lights up.

- The unit is turned on, the display and power indicator are on, but automatic ignition does not occur.

- There are attempts to start the main burner, but after ignition it immediately goes out.

The fuse box is located on the electronic board of the boiler.

Having made sure that voltage is supplied to the heater, we can begin to repair condition No. 1. To do this, unscrew the front panel of the gas boiler with a screwdriver or an asterisk wrench and remove it or fold down the front cover (depending on the model). Then the algorithm is as follows:

- Locate the fuse box and check each one with a multimeter or visually. Surely there will be one that is burned out.

- As a rule, the spare fuse is glued to the inside of the front panel. Put it in place of the burnt one or buy a new one (exactly the same value!).

- Try starting the heating unit. If it works, then the repair is complete, put the cover back in place.

- Did the device turn on and “die” again? All that remains is to call a technician, since the problem is more serious.

In the other two non-working states, the display shows an error code, by which you can determine the problem by looking at the product data sheet. The expert recommends the following: when the documentation says “contact service” next to the error code, then that’s what you need to do; you won’t be able to handle the breakdown yourself. You can resolve the following errors yourself:

- The sump filter that filters the coolant from the heating system is clogged. Disconnect the heat generator from the house electrical network, turn off the taps and clean the element mesh.

- The built-in circulation pump does not work. The reasons are jammed rotor or air lock. In both cases, unscrew the large screw (located in the center of the pump) and release the air or turn the rotor with a screwdriver. Be careful, some water will flow out of the hole.

- When the boiler pressure gauge shows low pressure and there are no leaks in the heating system, you need to pump air into the expansion tank mounted inside the heating unit. The pressure on the air side of the membrane should be 0.2 bar less than in the system. Read more about pumping up the tank here.

- If a leak is detected at low pressure, it must be repaired and then added to the water system.

Ways to normalize cravings

The main thing is to take into account that condensation may occur in every chimney of a house, especially when it is still cold and warm flue gases are greatly cooled as they rise. Condensation may settle on the walls and flow down the pipe.

If the chimney is assembled according to smoke, then condensation easily penetrates into the cracks and moistens the insulation, completely depriving it of its heat-insulating properties. It's not far from the fire here. Therefore, the assembly of modular chimneys is carried out only using condensate. The chimneys are assembled at a clear joint, with sealant along the inner pipe. However, the chimneys themselves must be of high quality so that no extraneous cracks remain. If the gaps remain, air will enter through them, and it turns out that there will be no draft anyway.

But the chimney is big and tall! Not understanding the reason, they call the experts. Craftsmen use a simple method: they cover the top of the chimney and watch where the smoke comes from. Here all sorts of inconsistencies in the chimney are discovered, which lead to air being sucked into the chimney. Remember? The air tends upward, to where the pressure is lower. Therefore, the more cracks, the worse the traction below. The smoke assembly, unfortunately, does not take into account the very essence of draft. As a result, the fire burns and smoke rushes in all directions. Although the logic here is not complicated - smoke goes from an area of high pressure to an area of low pressure, where it is easier for it.

Stabilizer installation

The chimney draft stabilizer involves the installation of an additional structure in which a gas boiler draft sensor is built-in. To install the system, a so-called umbrella is installed on the chimney pipe. Between the open part of the hood and the smoke outlet pipe there is free space through which air flows freely pass.

The stabilizer is endowed with a specific design, which acts as a chimney draft regulator.

With its help, the stability of the air flow is monitored to determine the desired level of traction force in the chimney pipe. If necessary, a special gas boiler draft sensor is installed in the cap on the chimney pipe. He monitors the temperature inside the chimney. The sensor is triggered when the temperature of the gases rising through the pipe decreases.

What else affects the amount of thrust?

First of all, the height of the chimney. The minimum required height is 5 meters. This is enough for a natural vacuum to occur and the upward movement to begin. The higher the chimney, the stronger the draft. However, in a brick chimney with an average cross-section of 140x140mm, at a height of over 10-12 meters, the draft no longer increases. This is because the wall roughness value increases with increasing height. Therefore, excess height does not affect traction. A similar question arises among those who want to use ducts for chimneys in their homes. They come in large heights and narrow cross-sections, so a serious fireplace is rarely connected to such a chimney.

Reasons affecting cravings:

- Flue gas temperature. The higher the temperature, the faster the flue gases rush upward, creating a greater draft.

- Chimney heating. The faster the chimney warms up, the faster the poor draft normalizes.

- The degree of roughness of the chimney and internal walls. Rough walls reduce traction, while smooth walls have better traction.

- The cross-sectional shape of the chimney. The circular section is a sample; oval, rectangular and so on. The more intricate the shape, the more strongly it affects traction, reducing it.

- It is important to note that the ratio of the size of the firebox, the diameter of the outlet pipe and the diameter of the chimney pipe also influences. If the height of the designed chimney is excessive, you should consider reducing the cross-section of the chimney by an average of 10%. Install an adapter on the firebox, on the smoke pipe (for example, from a 200-diameter to a 180-diameter) and take the 180-diameter pipe itself. This is allowed by the manufacturers. If we talk about “EdilKamin” as an example, you can see that in the instructions for the fireboxes he describes what diameter the chimney should be depending on the height.

For example:

- height up to 3 m – diameter 250,

- height from 3 m to 5 m – 200,

- height from 5 m and above – 180 or 160. Strict recommendations.

Other manufacturers (such as Supra) admit that changes are possible. Some don't allow it at all. Therefore, following the instructions, you should not forget about the processes occurring in the chimney.

Increasing the height of the smoke channel

This is the easiest option to increase the traction force in the smoke exhaust duct. Light doesn't mean cheap. It all depends on the high cost of the materials used in the construction of the chimney. The addition of pipe height must be calculated from the existing limits. The maximum permissible extension of the chimney is 4-5 m to the grate.

It is important to note that it is not recommended to deviate the direction of the enlarged section of the pipe, since in this case the traction force will decrease even more.

For this reason, the smoke channel is enlarged in a strictly vertical position.

Rose of Wind

A situation when the prevailing winds blow directly into the chimney and reduce the draft or reverse it. The chimney is installed on the windward side, of course, if the wind directions are determined. If the chimney is located far from the ridge and below, the leeward side cannot be used. Multi-storey buildings and trees also affect traction. To compensate for gusts of wind and poor placement of the chimney, anti-wind deflectors are used. According to the standards, the chimney is installed half a meter above the ridge. If the distance from the ridge is 1.5 m - 3 m, then it is brought to the same level as the ridge. If the distance is more than 3 meters, then proceed according to the formula: from the horizontal drawn from the ridge, 10 degrees down. In practice, the chimney is made higher than the ridge, or at the same level as the ridge. It is important to use one chimney for one stove in the house.

General characteristics of the problem

A modern gas boiler is a very complex device. When a gas boiler blows out, various abnormalities in operation can be observed, ranging from startup failure to unexpected stoppage of the burner. For example, the unit may start, and then extinguish the flame a minute later.

In addition to wind, there may be several reasons:

- malfunctions or insufficient pressure in the supply system, poor quality gas;

- The smoke removal system does not work well;

- electrical network leads to diagnostic errors.

Poor operation of the supply system, as well as low-quality gas, lead to failures of the ignition control system; in some boiler models, two factors - wind and poor fuel - work together.

Naturally, the most common reason why a gas boiler blows out is reverse draft, that is, the action of the wind. This factor manifests itself differently for atmospheric and turbocharged boilers. Therefore, if the boiler starts to blow out, you need to act based on its operating principles.