Home / Boilers

Back

Published: 12/03/2019

Reading time: 5 min

3

1448

Water heaters are used both in apartments and in private houses. Their use allows for uninterrupted supply of hot water regardless of the presence of a centralized network.

One type of water heater is an indirect heating boiler. The boiler device includes a heat exchanger that is connected to an external heat source. This allows you to heat a large volume of water in a short time.

- 1 Types of boilers for heating water

- 2 Design of water heaters 2.1 Electric storage

- 2.2 Electric flow

- 2.3 Gas water heaters

Boiler design

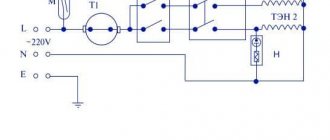

In this diagram you can see the main elements of the boiler design.

A boiler is a device that heats and stores hot water. Structurally, it is a container of one volume or another, equipped with thermal insulation and a heating element. The water supplied to the tank is heated to a predetermined temperature, after which it can be used by consumers. The heating temperature is adjusted and maintained using a built-in thermostat. The maximum temperature reaches +70-80 degrees. Most boilers have a pressure design. That is, the outlet water flows under the same pressure under which it is supplied to the unit’s tank. If the supply of cold water stops, then it will not be possible to get water from the storage water heater - it simply will not flow out of it. Thus, the water in the tank is under constant pressure (increasing with heating).

How does a boiler work and what components will we find in its interior?

- A tank with a protective coating is the basis of any storage water heater. Tanks are made of metal and coated with enamel or glass-ceramics to prevent corrosion. Tank capacity varies from 10 to 300 liters;

- Heating element – inside boilers we can find one or two heating elements. They are responsible for heating the water (in gas boilers this function is performed by the burner);

- Thermostat – provides support for the set temperature (mechanical or electronic adjustment is used);

- The control panel is hidden or open, it is used to set the temperature;

- Thermometer – provides control of the temperature of the water in the tank. The thermometer can be mechanical or electronic.

The design of boilers is extremely simple, and the main volume is occupied by massive tanks of varying capacities.

Where can I buy

You can purchase water heating equipment as quickly as possible at your nearest specialized store. The optimal option, in terms of price-quality ratio, remains purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| Photoelectric water heater, 220-240 V, 3000 W | TINTON LIFE multi-tap electric water heater with tap, LED display | Electric water heater, touch HYUNDAI |

| Instant water heater 3000W | 8L Stainless Steel Tankless Water Heater | FRUD Instant Heating Electric Faucet |

Pros and cons of boilers

Using a boiler, you can heat a large volume of water.

In the absence of a centralized hot water supply system, boilers are used. Their advantages include the following:

- Ease of use.

- Large volume can be heated.

- One device can be used to supply several rooms.

- The operation of the device does not depend on the pressure force.

- Possibility of heating to high temperatures.

- Maintaining high temperatures for a long time thanks to high-quality thermal insulation of the tank.

A large boiler requires a lot of space.

The disadvantages include the following:

- Long time for initial heating.

- If water flow is low, maintaining a constant temperature will incur energy costs.

- A large tank requires sufficient territory.

- The cost is higher than that of a flow-through product.

If there are problems with the water supply, you can install a boiler in an apartment building. The design and principle of operation will depend on the type of device, its functionality and additional functions.

Operating principle of instantaneous water heater

Installing a product of this type allows you to provide the room with hot water without preheating it. At the same time, instantaneous water heaters cannot produce a large volume of liquid in a short time. This is due to the low throughput of the boiler. The liquid passes through tubes in which a powerful electric heater is installed. A distinctive feature of a flow-through boiler is that it can supply hot water uninterruptedly for a long time.

Device depending on type

Direct heating

The energy that enters such devices is spent only on heating the water inside the device. This means that these types of devices themselves produce heat, which warms the water. They can be gas, when a gas burner is used for heating, as well as electric, that is, heated by a heating element.

By design, such boilers are a container (tank of water), around which there is thermal insulation and an outer casing with a control panel. In addition to the heating element (burner or heating element), such devices have a magnesium anode, a thermostat, a safety group and pipes (input and output).

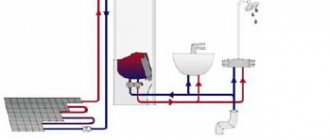

Indirect heating

This type of boiler is installed in houses or apartments with autonomous water heating, which includes a single-circuit boiler. The temperature of the water inside a boiler with an indirect heating type increases not due to the direct influence of the energy source, but as a result of heat exchange with the heating circuit.

The design of this type of boiler includes a housing, inside of which is placed an internal tank, separated from the outer casing by a layer of thermal insulation. Water from the cold water supply pipes enters the tank through the inlet pipe, and is discharged after opening the hot water tap through a pipe located at the top of the device.

Separately, the device has a heat exchanger, which in most models is represented by a coil. It can be evenly spaced inside the tank or located in its lower part. Both pipes of such a heat exchanger are connected to the heating boiler.

The coolant from the boiler moves through the heat exchanger, heating the water in the tank through heat transfer, and then is discharged through a separate pipe, returning to the boiler. There is usually only one such heat exchanger, but there are models with several heat exchangers that can be connected not only to a gas boiler, but also to another source.

There are also indirect heating boilers without a coil, the design of which is called “tank in tank” due to the presence of another tank inside the tank of such a boiler. Sanitary water in such a device is heated in an internal tank, and the coolant moves between the walls of the internal tank and the outer walls.

Some models of boilers of this type may have a recirculation pipe. Mandatory elements of all such devices are a magnesium anode and a safety group, as well as a temperature sensor. Large boilers with a capacity of over 150 liters often have an inspection window.

Combined

Such boilers combine the two previous types of heating devices. By their design, they are represented by devices with indirect heating, but differ in the additional installation of a heating element, which allows the device to be used as a directly heated storage electric boiler. This is especially in demand in the summer, when the single-circuit boiler is turned off.

4b1fd3f2b51f6fc7e5262e23a4c4c72b.jpe

Operating principle

The working circuit of the heating boiler is formed by the following elements:

- its own water heater (heat exchanger), located in the combustion chamber and heated by hot gas combustion products, which enters the furnace through the burner;

- a return pipeline supplying the boiler heat exchanger with cooled coolant (water) from the heating network;

- a direct pipeline of heated water leading from the heat exchanger to the heating system;

- a circulation pump that drives the coolant in a circle.

That's the whole concept diagram of the working cycle of a single-circuit boiler. Make-up (compensation for inevitable water losses) of the heating system of small boiler houses is usually carried out from the city water supply, which has a pressure in its pipelines higher than the pressure in the heating system.

The functional limitations of a single-circuit boiler, expressed in its use only for heating, is a significant disadvantage compared to its double-circuit “brother”.

But if the boiler is combined with an indirect heating boiler and thereby provides the consumer with hot water for domestic needs, then the capabilities of the boilers are equalized.

Almost like a thermos

In a thermos, the flask has a double glass flask with a vacuum - a heat insulator. In a boiler, the water tank is made to withstand metal corrosion and work under pressure. The best material is stainless steel. But such a tank turns out to be the most expensive, even in comparison with a structure made of ordinary steel coated with a super-anti-corrosion compound. The heat insulator is any modern material with the necessary properties, placed between the internal and external parts. If water flows from the inner tank through its corroded wall, the outer part will not save you from the flood.

Corrosion as it is

Therefore, for storage water heaters, corrosion protection is the most important task. It is solved by placing a special rod with a layer of magnesium inside near the heating element. It is called a magnesium anode and is designed to protect the housing from corrosion. Magnesium is chemically more active than iron in the body material. For this reason, negative ions in the water interact with this anode, and not with the wall, which may have a microcrack in the protective layer. The anode is a consumable item that is recommended to be replaced annually.

In a direct heating boiler, the heating element can heat water to temperatures even above 100 degrees Celsius. At the same time, due to the increase in pressure, it will not boil inside the tank. This is fundamentally dangerous for users. The water will boil immediately when it comes out of the tap, and splashes of boiling water will scatter in all directions. Therefore, a reliable automatic thermostat with a thermometer and thermostat is required in the boiler. The factory setting of the thermostat operation will eliminate the human factor, ensuring timely shutdown of the heating element in any case.

Flow or storage?

As mentioned above, of all the differences between water heaters, there are these two important parameters. Let's look at them. Storage devices have a number of advantages, as well as disadvantages. It all depends on the scope and possibilities of their use. The first advantage of such devices is volume. If a large consumption of H2O is envisaged, then the storage units have a reserve (certain models) of more than 200 liters. The second plus is the presence of an anode, which allows you to soften the water, and thereby extend the life of the equipment and individual modules. Another plus is that such devices operate under pressure, which allows you to power an entire system of branches and plumbing points.

Now to the cons. The biggest one is size. Although there are heaters of different shapes and mounting methods on sale, when choosing such an electric water heater, you need to take into account that it will take up a lot of space. Also, storage heaters (due to their volume) take longer to heat up compared to flow-through heaters.

In addition to traditional, round or square vertical units, there are also flat ones that can be mounted horizontally. These devices are more compact due to their shape. This was achieved by reducing the diameter of the container, but adding another one. That is, inside such a device there are two cylinders connected to each other. There are also flat water heaters that support two mounting methods, vertical and horizontal. This greatly facilitates their location, but one detail should be taken into account: such a device can be rotated 90% only in a certain direction. This is due to the difference in the location of the heating element and the outlet pipe. Therefore, when purchasing such a device, you should accurately calculate in which direction it will be turned, and be sure to check with your sales representative about the mounting features.

Gas heaters

- A storage gas boiler uses a gas burner as a heating element. The power and heating speed of a gas water heater are higher. But to install a gas storage boiler, you need equipment for exhaust gas removal.

The design of the gas storage water heater also includes a control device. The photo shows that in appearance, only the presence of forced gas removal distinguishes electric and gas storage boilers.

Storage-type boilers also require the installation of special safety fittings, which include a check valve, a safety valve and a reducer.

The video below shows different types of storage boilers and examples of their installation.

- Flow-through gas boilers are also called geysers. The principle of operation is the same, the difference is in the design and method of ignition. In appearance, a gas water heater is a metal box, to which two pipes fit, one with water, the other with gas. Main parts of the structure:

- heat exchanger;

- main burner;

- pilot burner.

The gas released during combustion of the main burner is sufficient to heat water in a heat exchanger made in the form of a spiral. Modern models of geysers use electronic ignition.

Forced or natural exhaust gas removal is also necessary

When using geysers as hot water equipment, special attention must be paid to good ventilation of the room

Indirect heater

An indirect water heating boiler uses heat generated, for example, by a home heating system. The main convenience is the use of water from the heater at several points in the house, since the device has a supply of hot water in the tank. Externally, the indirect water heater is also cylindrical in shape, but rectangular options are also possible.

The design consists of a tank, inside of which a heat exchanger is placed with coolant circulating through it. Inside there is a magnesium anode designed to prevent corrosion of the internal surface of the boiler. The anode is part of a safety system group that also includes a check valve, an overpressure valve and a temperature sensor.

It is advantageous to purchase an indirect heating water heater together with a single-circuit heating boiler. Although together this unit costs more than a double-circuit boiler and is a more bulky structure, it provides an almost uninterrupted supply of hot water to several points, with a uniform temperature of the supplied water.

Models of vertical and horizontal installation boilers are available, which are installed depending on the area of the room; vertical ones are attached to the wall and take up less space. Models without heat exchangers consist of containers inserted into one another, with coolant circulating between them. A combination boiler option is possible, in which water is heated both from an external source and from a heating element.

Modern water heaters are equipped with thermostats that ensure safe operation of the device. Replenishment of water used from the water heater occurs automatically. The reliability and durability of the boiler also depends on the internal coating of the tank, which today is mainly made of glass porcelain and enamel. The heating time of water in a water heater depends on the power of the heating element. The power of gas boilers is twice that of electric ones.

There are also non-pressure open boilers, although they provide hot water to one point, they are applicable in systems with little or no water pressure.

Summarizing all of the above, it should be noted that the operating principle of all modern boilers is simple, which makes them indispensable for rooms in which there is no centralized supply of hot water.

Extending the life of an electric boiler

Corrosion is the interaction of water with metal. The higher the temperature of the heated water, the higher the intensity of corrosion, so it is recommended not to increase the water temperature above 600C;

Another destructive factor for electric boilers is the formation of scale. To prevent its formation, it is necessary to install a water softener. The most common, reliable and convenient is the electromagnetic filter.

To ensure autonomous heating, it is best to purchase an electric or gas boiler, because this is its intended purpose, which means the heating efficiency will be much higher. An electric boiler can provide a reliable and constant supply of hot water.

How to save energy?

You can save a little on the electricity that the boiler consumes during operation. For this it is recommended:

- Set the heating temperature not to the maximum (75-85 degrees), but to 55-60. When cold water enters the tank and combines with the liquid that is already there, less energy will be needed to heat the mixed mass. In addition, a temperature regime of 55-60 degrees will help to significantly reduce the process of scale formation on the heater.

- It is necessary to choose the correct location of the boiler so that the pipeline from it to the sink or shower is not too long. Due to this, the heat from hot water will dissipate less.

- Periodically it is necessary to carry out preventive cleaning of the heating element from scale. Due to this procedure, its operating efficiency increases - the energy costs for heat generation will be less.

22e65a3b7f400f308f4218b9c699320a.html

Video description

Connecting the boiler in the video:

When installing a water heater, you must first choose the correct location in accordance with the requirements:

- Quick access to water supply connections for quick repair work.

- Proximity of communications.

- Availability of a strong load-bearing wall for mounting wall-mounted models. In this case, the distance from the fasteners to the ceiling should be 15–20 cm.

Options for placing a water heater Source legkovmeste.ru

Top 5 popular models

| Model name | Volume of the tank | Price | Power | type of instalation | Peculiarities |

| BOSCH Tronic 1000 T ES 050-5 N 0 WIV-B | 50 l | 125 USD e. | 1.5 kW | vertical, wall | magnesium anode, thermal insulation – 32 mm |

| Ariston ABS VLS PW 80V | 80 l | 270 USD e. | 2.5 kW | vertical, wall | Frost protection, thermal insulation – 32 mm |

| GORENJE GBF 80 | 80 l | 190 USD e. | 2.0 kW | vertical, wall | magnesium anode, thermal insulation – 17 mm |

| THERMEX IF 100 V | 100 l | 245 USD e. | 2.0 kW | vertical, wall | magnesium anode, thermal insulation – 17 mm |

| THERMEX ER 80 V SilverHeat | 80 l | 100 USD e. | 1.5 kW | vertical, wall | magnesium anode, thermal insulation – 17 mm |

Factors on which the heating rate depends

In any storage water heaters operating using electrical energy, the water heating process is carried out by one or two heating elements, which may have different power ratings.

The complete set of small-volume tanks (no more than 15 l) is usually represented by one heating element with a power of 1.0 kW. In storage electric water heaters with a useful volume of 50 liters, a 1.5 kW heating element is most often installed. High-power water heating structures with a reservoir of 100 liters are equipped with a heating element with a power of 2.0-2.5 kW.

Connection diagram and installation

The storage water heater should be installed in strict accordance with the installation instructions, which you will definitely find in the user manual.

We want to give you several recommendations that will allow you to connect the device to communications as efficiently and safely as possible.

- The boiler should be installed against a wall; at the same time, make sure that the pipes for hot and cold water are strictly parallel to it. There should be a small distance between the water heater and the wall, allowing for preventive inspection and maintenance of node connections.

- It is recommended to use a ¾-inch diameter pipe to connect to the water supply. Stand facing the appliance: the hot water pipe should be located on your left hand, and the cold water pipe should be on your right hand.

- Using a safety valve for storage water heaters will help avoid overheating of the device and associated unpleasant consequences.

- Before you start connecting the boiler to the water pipes, open the cold water tap. Make sure it is clean enough to be free of sand, rust particles and other small debris. If necessary, cut a special water filter into the pipe (in the section of the network before the water heater).

- It is also recommended to check the pressure in the water pipes before starting installation. Its level should not be higher than 8 bar. If this figure is exceeded, a pressure reducer should be installed.

- Drops of water falling from the hydraulic valve are a sign of normal operation of the device and the water supply network. But it is necessary to ensure that water from the valve does not fall on the body of the water heater. To do this, you need to attach a special drain funnel to the valve with an outlet into the sewer.

- If the boiler is installed in a country house that does not have constant heating, you need to make sure that there is no water left in the tank when the outside temperature drops below zero. Therefore, when leaving the house in the cold season, always drain the remaining liquid from the tank, otherwise the device may fail.

Advantages

Modern models of gas boilers with one circuit for heating the heating fluid could be called primitive water heating devices if they were not equipped with high-precision control and monitoring equipment to ensure the reliability and safety of all operating cycles. To solve the problems of regulation and safety of boilers, an automatic boiler protection system with gas flow and pressure regulators, fittings that regulate the flow, temperature and pressure of heated water, all kinds of sensors, instruments and safety devices is aimed. This is the main advantage of gas boilers.

Other important benefits:

- simplicity of design and installation of the boiler, which includes a combustion chamber with a gas burner, a loop heat exchanger in the firebox, a system of manifolds and pipelines, and pumping equipment;

- efficiency achieved by automation and adjustment work for optimal and efficient combustion of fuel, mixing processes and regulation of coolant parameters in accordance with standards;

- the ability to connect boilers to cascade heating systems within cities and large towns, which allows not only to centrally control the system, but also to ensure reliable and high-quality heat supply to consumers in residential areas, neighborhoods, microdistricts, as well as enterprises whose boiler houses are included in the cascade;

- more environmentally friendly emissions of gas combustion products into the atmosphere compared to similar boiler houses using liquid and solid fuels.

Tips for choosing a boiler

Like any household appliance, a boiler has its positive and negative sides.

The most important advantage of this technique is that under any external circumstances there will always be hot water in the house. For small towns and villages where there are problems with hot water supply (or it is completely absent), this is the only way out.

When choosing a water heater, you need to consider the advantages and disadvantages of each of them. For example, by installing a flow-through boiler, you will not have to wait for the hot water to warm up; its quantity will not depend on the volume of the tank. But you will need a powerful hotel machine and a power cable to connect the device, and electricity consumption will also increase significantly.

A storage boiler consumes less electricity, but only produces a certain amount of hot water. And its main drawback is that it takes up a lot of space.

When choosing a boiler, you must adhere to certain criteria.

Purpose of installation

The main criterion when purchasing a water heater is the purpose of its acquisition:

- have a reserve in case of shutdown of hot water supply;

- instant heating of water for washing dishes or taking a shower;

- constant supply of apartments (houses, cottages) with hot water.

External dimensions and volume

You must immediately decide on the installation location of the water heater. The equipment is large and cannot be placed or hung anywhere.

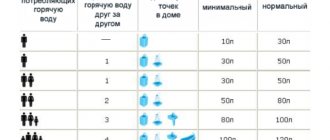

When selecting external parameters, we must not forget about such an important criterion as the volume of the boiler. This value depends on the number of people living in the house

The equipment of the bathroom also plays a certain role, that is, what is used for bathing - a shower or a bath. Using a shower is much more economical; this type of bathing consumes about 15-20 liters of water per person. In the bathroom, for such a procedure you will need 50 liters.

Water consumption table

If a boiler is needed only to provide hot water for washing dishes, and nothing else (without bathing), then a device of 15-20 liters will be sufficient. This type of water heater is usually installed in the kitchen directly under the sink.

Power

An important role in choosing. The more powerful the heating element (from 1 to 6 kW), the faster the water will heat up, but will the electrical wiring in the house withstand such a load? If it is new and capable of withstanding a load of 6 kW, then the power of the boiler can be easily selected based on the needs and number of residents. In apartments with old electrical wiring, the maximum you can count on is a 2.5 kW water heater.

Tank inner lining

In cheap boilers, the internal coating of the tank is made. Expensive models use titanium coating or stainless steel. When choosing, a person proceeds from his financial capabilities, but a high price, as a rule, guarantees quality and durability. In the case of household appliances, there is no need to skimp.

It is recommended to check the quality of the water heater by weight. The heavier it is, the better it will resist corrosion due to the greater wall thickness.

Internal coating of the tank (stainless steel)

What else should you pay attention to?

The degree of protection against moisture and dust of the boiler (IP) must be at least 23. If the water heater is installed in a bathroom, sauna, bathhouse, you will need a more protected model with IP 44. It is worth giving preference to models with a dry tubular electric heater (TEN). )

Lack of contact with water not only prevents the appearance of scale, but also reduces the risk of electric shock, since the heating element is placed in a sealed glass.

When purchasing a boiler, be sure to ensure that it contains a magnesium anode. Models with overheating protection, power-on indication, and accelerated heating function will be safer and more comfortable in terms of operation.

When choosing a boiler for a summer house where no one lives in winter, you should give preference to models with a freeze prevention mode.

When purchasing a water heater, be sure to inquire about its thermal insulation layer

The recommended thickness is at least 35 mm (the thicker, the longer the temperature will be maintained). The highest quality material is polyurethane foam (much better than foam rubber).

What to look for when choosing BKN

One of the main parameters that should be the decisive argument when buying a boiler is its capacity. To find out the required tank capacity, we advise you to focus on the number of people in your family.

Recommendations for displacement:

- 80-100 l - 2 consumers;

- 100-120 l - 3 people;

- 120-150 l - 4 users;

- 150-200 l - 5 consumers.

It is important to separate the concepts of “total tank capacity” and “working capacity”, because the spiral pipe located inside the boiler occupies a significant area. Therefore, be sure to check when purchasing how much water actually fits in the device. This nuance should be indicated in the technical specifications.

Also, in addition to the “universal” recalculation of potential consumers, it is necessary to take into account both the frequency and volumes of water use. For example, if your family likes to soak in a warm bath rather than take a quick shower, the working capacity of the tank should be appropriate - at least 120 liters.

It is beneficial to use BKN in conjunction with a solid fuel or single-circuit gas boiler, but if the water flow rate is less than 1 l/min, a double-circuit boiler will be cheaper, which will take up much less space than a system with indirect heating

Other important parameters:

- Power - the greater the water consumption, the higher the resource of the device should be. But at the same time, it is important that the power of the “indirect” does not exceed the capabilities of the heating system (or other external energy source). For example, if the volume of the storage tank varies between 120-150 liters, the boiler power should be at least 23 kW, and for 160-200 liters you will need 31-39 kW.

- Heating time is a parameter that depends on the volume of the tank and the number of turns on the coil (large or combined containers can be equipped with several spirals).

- Tank material – for long-term use, boilers made of stainless steel or medical steel are best suited.

- Thermal insulation - cheap models use foam rubber, which wears out quickly and allows heat to pass through, so it is better to purchase a more expensive device that uses polyurethane.

- Control - the device will be able to operate in automatic mode, turning off and starting the water flow as necessary, and control heating using a temperature sensor.

When choosing the shape and size of the tank, it is also necessary to take into account that although theoretically the boiler can be installed in any room where there is access to the heating main, its optimal location is next to the boiler. This is how heat transfer is most efficient.

You can make an indirect heating boiler yourself. Instructions for manufacturing the unit are described in this article.

Purpose and operating principle of an indirect heating boiler

Connecting an indirect heating boiler to the system allows you to avoid limiting the number of domestic hot water consumers. Correctly calculated heat exchanger power and its volume allow you to quickly and evenly heat the water in it to the desired temperature, which is the same throughout its entire volume.

For example, a 100 liter tank can provide about 500 liters of hot water per hour. An ordinary electric “apparatus” is not capable of this.

The operating principle of an indirect heating boiler necessarily involves a “tandem” with a heat source in the house heating circuit. The volume of the heater tank is consistent with the power of the heating boiler, which ensures an increase in water temperature by transferring coolant heat from one circuit (heating) to another (DHW circuit).

There can be several heat transfer “radiators” in a boiler.

For example, a solid fuel boiler, a solar collector, or a heat pump from a geothermal heating system can be used to heat water. Each of these “heat sources” has autonomous coolant flow lines connected by “heat transfer” in the heated medium.

Calculation of the volume of the storage tank and the power of the heating element

The main element of the boiler, which serves to heat water from the heating system, is volume. It can be calculated using the following formula: V=T*N/(t1-t2), where:

- V—volume;

- T is the time spent heating water;

- N is power measured in kilowatts per hour;

- t1, t2 — thermal regime of the mechanism.

The heating element is a tubular electric heater and the main component of the mechanism. It looks like a spiral wrapped in metal. The system must be filled with dielectric. For example, sand can be used as it. This indicator is subtracted using the following formula: P=0.0011*m*(tk-tн)/T, where

- P—power;

- m is the mass of water to be heated;

- tk is the initial temperature;

- tn — final temperature;

- T is the time spent heating the liquid.

Design and principle of operation

Storage water heaters, unlike instantaneous water heaters, heat the water in advance. Heating occurs in a metal tank, which is the main part of the design of any boiler. The size of the tank depends on the volume of water it is designed for. Domestic boilers with a capacity of 50 to 300 liters are available for sale.

The water in the tank is heated by a heat exchanger. Most often it is a steel or brass coil. It is located at the bottom of the tank or distributed over almost the entire surface of the device. The coil receives heat from a gas burner, which is located at the base of the water heater in a special combustion chamber equipped with a flame pipe.

In addition to all of the above, the design of a gas boiler contains heat-insulating elements, pipes for supplying and discharging water, as well as various sensors.

The tank is replenished with water automatically. When a fresh portion of water enters the tank, the gas burner is turned on, the heat from which exits through the flame tube and heats the tank. As soon as the water in the tank heats up to the desired temperature, the sensor is triggered and the gas supply stops.

You can get even more information about gas boilers from the following video.

Connecting a storage boiler to a gas boiler

You can heat water in the unit in question using a gas or solid fuel boiler, solar water heater or heat pump. Moreover, its operation is possible in conjunction with two types of heating equipment: single- and double-circuit.

According to the standard wiring diagram for an indirect heating boiler, it is connected to the heating system, as well as to the hot and cold water supply branches. In this case, cold water comes from below, hot water is removed from the container located on top of the tank, but the recirculation point is located in the middle of the boiler. The direction of movement of the heated coolant is the opposite - from top to bottom. That is, from the gas boiler it enters the water heater pipe located at the top, and returns to the heating pipeline through the lower pipe of the unit.

The principle of operation and connection of an indirect heating boiler to the boiler

Thanks to this connection scheme for an indirect heating boiler, the efficiency of this device increases. After all, heat is first transferred to the heated layers of water.

Features of connecting an indirect heating boiler to a double-circuit boiler

In order for the boiler to work successfully in tandem with a heating unit that has a hot water supply circuit, a three-way valve is used. It distributes the coolant flow between the additional water supply circuit and the main heating circuit.

A thermostat is installed in the indirect heating storage boiler. It is he who generates control signals for the three-way valve. When the temperature of the water in the tank drops below a certain level, the valve, upon command from the thermostat, will turn on and redirect the flow to the hot water supply branch from the heating pipeline. Signals from the thermostat will return the valve to its original state if the water temperature in the heater exceeds a preset point. The coolant flow is directed into the heating pipeline.

When connecting an indirect heating boiler, you must make sure that all communications are possible and also purchase the necessary pressure sensors

During the warm season, the unit works differently: the flow is not redirected, but the combustion modes of the gas boiler are controlled. When the temperature of the water in the boiler decreases, the thermostat transmits a corresponding signal to the three-way valve. Based on this “command,” the last device “ignites” the main burner of the heating unit. When the water temperature exceeds a certain value, the gas supply to the burner is stopped.

Important! When setting the maximum water temperature in the tank (also known as the temperature for automatic operation of the thermostat), the user should take into account that its value should be less than the value of this parameter set for the boiler automation.

The above scheme works most effectively when using gas boilers equipped with automation and a circulation pump. In this case, the heating unit itself can control the valve based on the signal received from the water heater thermostat. You should be aware that when operating a water heating system with a three-way valve, the priority of the heater circuit is higher than the heating circuit.

Connection diagram for an indirect heating boiler to a single-circuit boiler

To ensure effective joint operation of an indirect heating boiler with a single-circuit gas boiler, a circuit with two circulation pumps is used. A connection of this type can actually replace the above-described three-way valve circuit. Separation of coolant flows using pumps through different pipelines is the key feature of this type of connection. The distribution of circuit priorities is the same as in the previous case. However, higher priority of the water supply circuit over the heating circuit is ensured only through special settings of the pump activation algorithm.

Connection diagram for an indirect heating boiler to a single-circuit boiler

The alternating activation of the pumps is also controlled by signals from a thermostat installed in the tank. A check valve must be installed in front of each device. Creating such a piping for an indirect heating boiler prevents mixing of coolant flows.

This scheme works like this: turning on the DHW pump is accompanied by turning off the heating pump. That is, the heating system will begin to cool down. However, a noticeable decrease in the indoor temperature will not be observed for the reason that heating the water in an indirect heating boiler with a gas boiler will last a short period of time. The inhabitants of the house will feel this only during the initial start-up.

Sometimes, to create a large area of a building at a comfortable temperature, owners use several heating units. Then an additional pump is installed in the storage water heater piping.

Features of piping an indirect heating boiler with recirculation

If hot water is not drawn for a long period of time, it will begin to cool. It may take several minutes for the hot flow to reach the end consumer. Reducing the time for draining cooled water is ensured by using a piping scheme for an indirect heating boiler with recirculation. This is realized by organizing the forced movement of a heated flow through pipelines closed in a ring.

Connection diagram for a boiler with a recirculation system

Helpful advice! When choosing a piping scheme for heating and hot water circuits (with or without the possibility of recirculation), it is necessary to take into account the features of the heating system, as well as make accurate calculations of the equipment power and the level of demand for hot water.

The recirculation technical solution ensures almost instantaneous delivery of hot water to any connected plumbing fixture. It provides that another circuit, equipped with its own circulation pump, is installed in the indirect heating boiler piping, and additional structural components are installed:

- safety valve (designed to protect the water heating device from high pressure);

- automatic air vent (prevents the pump from airing);

- expansion tank (performs the function of compensating pressure in the DHW circuit when the taps are closed);

- check valve (prevents reverse water flow in the pipeline).

Related article:

Water boilers: review of the best offers on the modern market

Review of the best models and manufacturers. Types and rules for choosing a suitable water heater. Draining water from the boiler.

Main characteristics

The main technical characteristics of the boiler are:

- Case material (enamel, stainless steel, plastic).

- Type of placement (wall, floor, vertical, horizontal).

- Rated voltage of the electrical network (220 or 380 V).

- Water pressure (especially relevant for instantaneous water heaters). If the pressure in the water supply is low, the heating element may deteriorate.

Horizontal water heater model

- Volume of the tank.

- Weight.

- Overall dimensions (depth, width, height).

- Maximum power.

- Availability of water temperature regulator, magnesium anode.

- Thickness and material of the thermal insulation layer (the most highly effective is polyurethane foam).

- Heat losses (directly depend on the thermal insulation layer; the thicker it is, the lower the losses and the more economical the water heater).

- Type of control (hydraulic, electronic, LCD display).

How is such equipment connected?

Let's try to consider step by step how a water heater is installed.

| Photo example | Action to be performed |

| This is where we will place our boiler. | |

| If there are tiles on the wall, you need to drill it using a diamond drill like this. | |

| After the boiler is installed in place, we screw adapters for polypropylene pipes onto its inlet and outlet. Although, if desired, everything can be done with flexible hoses. It will turn out simpler, but not as aesthetically pleasing. | |

| We measure the distance to the input from the wall... | |

| ...and between I/O for neat design. | |

| We begin assembling the highways. | |

| Bends are useful for beautifully bringing out lines for connection points. | |

| Everything should fit perfectly here. | |

| We are installing an emergency valve... | |

| ...and there is a valve on it that comes with the boiler. | |

| Now all that remains is to finish assembling the inlet line. | |

| In the end it should look something like this. |

Important! In order to connect a storage water heater, you must be able to use an iron - a device for soldering polypropylene pipes. If you do not have such skills, it is better to use flexible hoses.

And one more important note! Before turning on the water heating boiler, it must be filled. To do this, open the supply and hot water tap. When water flows from it, it will mean that the boiler is full.

The boiler can also be connected using flexible hoses...

Pros and cons of the work scheme

The main advantages of an indirect heating boiler:

- the operation of such a water heater does not overload the electrical wiring during the heating season, since the boiler depends on central heating and does not consume electricity;

- with proper design, the boiler has very high performance indicators and an optimal cost ratio;

- the inner surface of the heater and the coolant do not interact with running water, which ensures safe and long service life of the unit;

- Due to recirculation, hot water flows immediately after opening the tap;

- An indirect heating boiler can always be switched to an alternative heat source or use several.

Unfortunately, each work scheme, in addition to positive ones, also has negative sides:

- to re-equip the system, additional costs will be required;

- the cost of a boiler with indirect heating is much higher than gas or electric heaters;

- the initial heating of water (volume more than 100 liters) lasts from 1 to 2 hours, this can negatively affect the quality of the heating system of the room;

- for a boiler with a volume of 100 liters or more, a separate room is required due to the impressive size of the device.

What to look for when choosing an indirect heating boiler?

The most important characteristic of a boiler is its volume. You need to roughly estimate how much water your family needs to live comfortably. Based on average indicators, a person spends 5−15 liters per day on personal hygiene, 15−25 liters/day on washing dishes, 50−100 liters/day on showering, and 150−200 liters/day on bathing.

It is believed that 80-100 liters of hot water are needed per resident; of course, this calculation is conditional, it all depends on the preferences and habits of the residents. For example, someone likes to shower twice a day, while others get by with a bath once a week. The larger the boiler volume, the higher its cost.

Preference should be given to boilers with a brass coil. It will heat water more efficiently than a steel coil, and it is much easier to clean a brass coil. The water heating container must be protected from corrosion. In cheaper models, the tanks are covered with a layer of enamel or glass ceramics. Expensive devices are protected from corrosion by stainless steel. In addition, do not forget about the thermal insulation of the unit; high-quality boilers are insulated with mineral wool or polyurethane foam. Models with foam insulation are best avoided.

Review of manufacturers

| Manufacturer (country) | Boiler models | Capacity of manufactured boilers, l | Average price, rub. |

| Protherm (Slovakia) | FE 120/6 BM; WH B60Z, FS B100S; FE 150/6 BM; FE 200/6 BM; FS B300S; FS B400S; FS B500S | 60-500 | 28 000-70 000 |

| Baxi (Baxi) (Italy) | Premier PLUS 100; Premier PLUS 1000; UB 80; UB 120; Premier PLUS 200; Premier PLUS 150; UB 120 INOX; Premier PLUS 300; Premier PLUS 400; Premier Plus 2500 | 80-2500 | 30 000-700 000 |

| Buderus (Buderus) (Germany) | Logalux L135; Logalux S120; Logalux SU400/ 5 W; Logalux L160; Logalux SU300/5 W; Logalux SU200/5E W; Logalux SU160/5 W | 120-1000 | 20 000-500 000 |

| Vaillant (Germany) | actoSTOR VIH QL 75 B; uniSTOR VIH R 120/6 V; uniSTOR VIH R 200/6 V; uniSTOR VIH R 150/6 V; uniSTOR VIH R 300; actoSTOR RL 400-60; actoSTOR RL 500-120 | 75-500 | 27 000-200 000 |

| Thermex (Termex) (Russia) | ER 100V (combi); ER 120V (combi); ER 150V (combi) | 100-150 | 20 000-30 000 |

| Bosch (Bosch) (Germany) | ST 120-2 E; ST 160-2 E; 160-5 C; WST 200-5 C EC; WST 300-5 C; WST 400-5 C; WST 500-5 C | 120-500 | 30 000-70 000 |

| Drazice (Drazice) (Czech Republic) | OKC 100; OKC 80; OKC 160; OKC 200 NTR; OKC 250 NTR; OKC 250 NTR/BP; OKC 400 NTRR/1 MPa; OKC 750 NTRR/1 MPa; OKC 1000 NTRR/1 MPa | 80-1000 | 20 000-170 000 |

Thus, an indirect heating boiler allows you to provide hot water to all consumption points at the same time. The main thing is to choose the right tank volume.

Device depending on energy type

Electrical

Such boilers are the most common and are available in a wide range. They use electricity to operate, so the main part of such devices is the heating element. It is this part that heats the water drawn into the tank of the device. The heating element can be located directly in the water or be placed in a capsule and not be in direct contact with water (such a heating element is called “dry”).

Next to the heating element there is a temperature sensor that controls its operation through an electromechanical or electronic thermostat. These parts ensure that the water temperature inside the tank is maintained at the desired level. As soon as the water cools down a little, the temperature sensor transmits a command via an electrical circuit to the thermostat, as a result of which the heating element begins to heat the water.

The electric boiler tank is surrounded on the outside by a layer of heat-insulating material, as well as a decorative casing made of plastic or steel. Cold water enters the device through a pipe located at the bottom of the boiler. As the liquid heats up, it rises to the top of the device, from where it is taken through the outlet pipe after turning on the hot water tap.

Most electric boilers have a magnesium anode inside. Due to its lower electrical potential, such an anode attracts free ions of those salts that are dissolved in tap water. As a result, scale is deposited on the anode instead of attacking the heating element and the walls of the tank. Over time, the anode deteriorates, so during regular maintenance of the electric boiler it is replaced with a new one.

A safety group with a safety valve must be installed at the inlet of the electric boiler

Its presence is important to protect the boiler from overpressure. If the pressure inside the tank increases, the valve relieves it and thereby prevents damage to the device

Gas

This type of storage heaters is not as common as electric boilers due to installation difficulties (needs approval, the presence of a chimney, good ventilation, registration).

Such heating devices operate on natural gas. Their design consists of a water tank, an incoming cold water supply pipe and a hot water outlet pipe. The body of the device is quite thick and is separated from the water tank by a layer of thermal insulation to maintain the temperature of the heated water for a long time.

b1378a3e665436a43ce29225054fe814.jpe

Heat exchange in gas boilers occurs through the lower wall of the water tank, since underneath it there is a combustion chamber with a gas burner located in it. Heat is also transferred to the water inside the tank from the central channel, through which combustion products from the burner chamber are discharged to the chimney.

Control in such a boiler occurs via a temperature sensor and thermostat. These elements record the water temperature and, if necessary, turn off the gas supply to the burner or turn it on. Also, gas boilers have a safety group, the main part of which is an emergency valve to relieve excess pressure.

To prevent scale from depositing inside the device on its walls, the design of the gas boiler includes a magnesium anode. Over time, it is “eaten up” and therefore requires replacement.

Nuances of the strapping device

It is easier to do the wiring and piping if the KN boiler is installed together with a boiler, pumps and other equipment involved in the assembly of the hot water supply system. It is much more difficult to insert an additional device into an existing network.

In any case, for normal operation of the devices you will have to follow a number of rules:

- choose the right installation location - as close to the boiler as possible;

- provide a flat surface for mounting the boiler;

- to protect against thermal expansion, install a membrane hydraulic accumulator (at the heated water outlet), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by installing filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to secure heavy devices to plasterboard or thin wood partitions. Walls made of concrete and brick are suitable. Brackets or other types of holders are secured with brackets, anchors, and dowels.

Regardless of the type of device - floor-mounted or wall-mounted - if possible, it should be mounted above the level at which the boiler is installed, or at the same level. For the floor, you can make a pedestal or a durable stand up to 1 m high

When installing, the pipes are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand pressure and water pressure.

For normal operation of an indirect heating storage water heater, the following functional devices must be included in the piping:

A complex technical system must be equipped with pumps that supply hot sanitary water to the taps and stimulate the movement of the coolant along the heating branch, as well as along the water heating circuit in the boiler. Cold water coming from a public or independent water supply must be cleaned through a mud trap or a filter system that destroys lime salts. Filtration will prevent the formation of mineral deposits. After the sump tank or water filtration system, there should be a pressure reducer. However, it is only needed if the pressure in the branch exceeds 6 bar

Before cold water enters the boiler, a check valve is required to prevent reverse flow. In order for the heating water to have a reserve for expansion during the period when it is not in use, an expansion tank and a safety valve to relieve pressure are included in the piping

To prevent excessively hot water from flowing into the taps, which can cause burns, a three-way mixing valve must be installed in the circuit. It will mix portions of cold water into the hot water, as a result, the water supply will have water at the temperature required by the user. In order for the coolant from the heating to flow into the “jacket” that heats the sanitary water only when it is needed, a two-way thermostat is installed. Its server connects to the water heater temperature sensor