The most popular method of heating a private home today is gas heating. But not all areas have been gasified yet; not every country house or private house has a gas pipeline.

You can try electric heating, but it is expensive. Heating with wood or coal makes the residents of the house regular stokers for the boiler or stove. Diesel fuel permeates the house with a specific smell. In this case, heating with a gas boiler from a gas holder .

How safe is a gas tank?

- In the gas tank, increased pressure and access to oxygen are excluded, so a gas explosion is excluded.

- The gas tank is grounded, so in the event of a lightning strike, an explosion or other negative consequences are also excluded.

- The gas tank is equipped with a whole system of sensors, so a gas leak is immediately registered, the automation is triggered and an alarm signal is sent to the house.

By following safety precautions and operating rules for gas heating from a gas tank, you can provide your home with warmth and comfort for many years.

What is the mini gas holder made of?

It is made of high-strength steel grade 09 G 2S. The thickness of the steel here is 4 millimeters. If we take a regular 50 liter cylinder, its wall thickness is somewhere around 3 millimeters. Here goes 4. This is more reliable and more durable equipment that will last a long time. The gas holder is also covered with a special two-component coating so that it also lasts a long time and does not rust. When we wrap the thermal cable and wrap the mini-gas holder with insulation, the container underneath will also serve for a very long time and will not rust.

Next comes its insulation. We wrap the barrel with insulation to keep it warm when there is severe frost in the winter. The thermal cable is plugged into the outlet. It has insulation on top, and it turns out that the container is warm. The gas is heated and, accordingly, evaporates well. And the boiler works well and stably. A turbocharged chimney emerges from the wall above. There is a boiler on the other side of the wall. We will run the line through this wall to the boiler and, in principle, that’s all. That is, the facility will be gasified.

Advantages of autonomous gasification of private houses

For dacha or permanent residence in distant areas of the Moscow region, independent turnkey gasification is convenient:

- efficiency, optimization of heating costs, household needs;

- energy independence;

- short construction periods;

- environmental friendliness (during combustion there are no harmful substances, soot, or unpleasant odors).

When operating an independent gas supply, uninterrupted delivery of liquefied gas by special gas tank trucks becomes crucial. Regular maintenance includes leak testing, identification and replacement of worn components and devices, chemical and mechanical cleaning of the tank and pipes.

To draw up a contract and call an engineer, call our contact numbers.

Ease of use

The operation of modern boilers, regardless of the type of fuel, is not difficult.

Ease of maintenance and use is an important characteristic. The consumer pays extra for convenience.

Electric boiler

The device is equipped with a control module and multi-stage automatic safety system. The setup is extremely simple and is carried out by the consumer himself. If the device is equipped with a programmer, you can also set the operating mode - for example, reducing power at night, on and off times, etc.

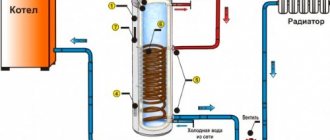

Gas holder

Operating the gas tank itself is also not difficult. The tank operates in automatic mode. The owner periodically checks the fuel level using the sensor and, if necessary, buys a gas mixture. The download is performed by the supplier.

To make the right decision, you need to evaluate all factors. For example, if elderly people live in a private house, electricity is preferable - it is safer. If there are interruptions in the supply of electricity, it is better to install a gas holder.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

More information about refueling

Next, we begin to fill the mini-gas tank. There is a hose through which gas will flow from the car. The car is parked about 20 meters on the road. She doesn't come to the site. Doesn't spoil the lawn, the appearance, or anything. The driver connects the refueling nozzle. Or it is also called a clamp. It is screwed to the gas tank, the driver opens the tap and turns on the pump, refueling will go directly through this hose. The gas will go into the gas tank. At this stage, you need to pay attention to the percentage that is installed on the gas tank. The arrow will begin to rise when gas begins to fill. And if you multiply these percentages that are indicated here by the volume of this container, you will get how many liters you were filled with. It will be enough to go to the car and look at the meter in order to verify this data. The data on the meter and the data on your gas tanks must match.

Now the pressure has increased to five. It will rise a little because the gas is under pressure. He fills the container. Do not forget that the working pressure is about 5 atmospheres when the gas tank is full. There is a counter here that reports how many liters of gas you have received in the gas tank. How many liters the meter will pour for you is how much this meter will show.

Now we are preparing the pipeline through which the steam phase will flow from the gas tank to the boiler. We drill a hole in the wall and install a corrugated line. It is necessarily certified for gas. It has a certificate that it is intended for gas. It must be made of stainless steel. Accordingly, it will not rust and will serve for a very long time.

Gas tank filling is complete. The driver disconnects the hose. That's it, he filled the barrel. Let's look at the percentage. Capacity shows 80 percent. Why 80 and not 85? Because 5 percent is allocated for purging the gas tank. This is the gas that escapes along with the air during purging. Refueling is complete. The meter shows 680 liters. The gas holder has a volume of 800 liters and is 85 percent full. Multiply and get 680 liters. We check, the meter shows 680 liters. And on my gas holder the percentage indicator also shows 80 percent.

Cost of installing boiler equipment

Installation

| Solid fuel boiler (15% of the boiler cost) no less | PC | from 10 000 ₽ |

| Floor-standing gas/diesel boiler (15% of the cost of the boiler) no less | PC | from 10 000 ₽ |

| Pellet boiler (10% of the cost of the boiler) no less | PC | from 15,000 ₽ |

| Wall-mounted single-circuit boiler up to 30 kW | PC | from 9 000 ₽ |

| Wall-mounted 2-circuit boiler up to 30 kW | PC | from 10 000 ₽ |

| Pump (D, up to DN 32) | PC | from 3 150 ₽ |

| Pump group (pump, shut-off valve assembly) | PC | from 2 500 ₽ |

| Expansion tank for heating system (up to 100 l.) | PC | from 2 500 ₽ |

| 3-way valve (D, up to 1 1/4″) | PC | from 2500 ₽ |

| 3-way valve mixer servo drive (D, up to 1 1/4″) | PC | from 3 150 ₽ |

| Chimney (D, up to 250 mm.) | m/linear | from 2,500 ₽ |

| Boiler (water heater, up to 200 l.) | PC | from 8 500 ₽ |

| Boiler (water heater, up to 500 l.) | PC | from 10,000 ₽ |

| Boiler safety groups | PC | from 2 250 ₽ |

| Water Heater Safety Groups | PC | from 2 250 ₽ |

| Boiler manifold | PC | from 5,500 ₽ |

| Hydraulic separator | PC | from 2,500 ₽ |

| Heated floor temperature control groups (thermostatic valve, thermostat with clamp-on sensor, bypass valve, starter) | PC | 3 750 ₽ |

| Fuel tank connection | PC | 5 000 ₽ |

| Fuel filter installation | PC | 2 000 ₽ |

| Air vent, thermometer, pressure gauge per unit | PC | 650 ₽ |

| Ball valve, mud filter, check valve | PC | 500 ₽ |

| Check the cost by phone: | 84957446774 |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Commissioning works

| Commissioning of a wall-mounted gas boiler | PC | from 10 000 ₽ |

| Commissioning of boiler house up to 60 kW (protherm, ferroli, baxi, dakon) | PC | from 14,000 ₽ |

| Commissioning of boiler house up to 60 kW (Vaillant, Viessmann, Buderus) | PC | from 18,000 ₽ |

| Commissioning of boiler house from 70 to 120 kW (protherm, ferroli, baxi, dakon) | PC | from 20,000 ₽ |

| Commissioning of a boiler house from 70 to 170 kW (Vaillant, Viessmann, Buderus) | PC | from 25,000 ₽ |

| Commissioning of a cascade boiler house (2 boilers or more) | PC | from 30,000 ₽ |

| Commissioning of electric boiler up to 6 kW | PC | from 7 000 ₽ |

| Commissioning of electric boilers from 8 to 30 kW | PC | from 8 500 ₽ |

| Commissioning of a pellet boiler up to 50 kW | PC | from 14 000 ₽ |

| Commissioning of pellet boiler from 60 kW to 100 kW | PC | from 18,000 ₽ |

| Commissioning of a boiler room with a pellet boiler up to 60 kW | PC | from 20,000 ₽ |

| Check the cost by phone: 8 495 744 67 74 | _____________ | |

| The exact cost is calculated after receiving the technical | _tasks_ |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Types of tanks

The ground type of device is located in a designated area. With this arrangement, you don’t have to worry about problems related to maintenance, because you can approach the tank at any time. Corrosion and other excesses harmful to metal are also quite easy to detect; the only nuance will be weak evaporation in winter.

Underground types of construction will lead to additional costs for site preparation; it may be necessary to call in special equipment, it all depends on the size of the equipment. Protection against cold in this situation remains at a high level, which will affect the practicality of the device.

Experts advise burying the tank to a depth of at least 60 cm. Vertical models are very similar to ordinary cans; they are installed to save free space on the building site. For large quantities of consumption, such containers will not be practical. Horizontal types of structures are considered the most common, but they occupy a large area.

Sale and installation of copper pipes

| Name and technical characteristics | Qty | Unit. | Materials and equipment, ₽ |

| Copper pipe ⌀ 35 | 1,00 | m/linear | 1 408,80 ₽ |

| Copper pipe ⌀ 28 | 1,00 | m/linear | 634,80 ₽ |

| Copper pipe ⌀ 22 | 1,00 | m/linear | 570,80 ₽ |

| Copper pipe ⌀ 15 | 1,00 | m/linear | 348,56 ₽ |

| Copper angle 45° ⌀ 35 | 1,00 | PC. | 614,00 ₽ |

| Copper angle 45° ⌀ 28 | 1,00 | PC. | 112,00 ₽ |

| Copper angle 45° ⌀ 22 | 1,00 | PC. | 86,00 ₽ |

| Copper angle 45° ⌀ 15 | 1,00 | PC. | 62,10 ₽ |

| Copper angle 90° ⌀ 35 | 1,00 | PC. | 627,00 ₽ |

| Copper angle 90° ⌀ 28 | 1,00 | PC. | 112,00 ₽ |

| Copper angle 90° ⌀ 22 | 1,00 | PC. | 86,00 ₽ |

| Copper angle 90° ⌀ 15 | 1,00 | PC. | 62,10 ₽ |

| Copper tee ⌀ 35 | 1,00 | PC. | 680,00 ₽ |

| Copper tee ⌀ 35*28*35 | 1,00 | PC. | 714,00 ₽ |

| Copper tee ⌀ 35*22*35 | 1,00 | PC. | 714,00 ₽ |

| Copper tee ⌀ 35*15*35 | 1,00 | PC. | 714,00 ₽ |

| Copper tee ⌀ 28 | 1,00 | PC. | 156,00 ₽ |

| Copper tee ⌀ 28*22*28 | 1,00 | PC. | 156,00 ₽ |

| Copper tee ⌀ 28*15*28 | 1,00 | PC. | 156,00 ₽ |

| Copper tee ⌀ 22 | 1,00 | PC. | 127,50 ₽ |

| Copper tee ⌀ 22*15*22 | 1,00 | PC. | 127,50 ₽ |

| Copper tee ⌀ 15 | 1,00 | PC. | 82,00 ₽ |

| Copper coupling ⌀ 35 | 1,00 | PC. | 214,00 ₽ |

| Copper coupling ⌀ 35*28 | 1,00 | PC. | 317,00 ₽ |

| Copper coupling ⌀ 35*22 | 1,00 | PC. | 317,00 ₽ |

| Copper coupling ⌀ 35*15 | 1,00 | PC. | 317,00 ₽ |

| Copper coupling ⌀ 28 | 1,00 | PC. | 63,00 ₽ |

| Copper coupling ⌀ 28*22 | 1,00 | PC. | 63,00 ₽ |

| Copper coupling ⌀ 28*15 | 1,00 | PC. | 63,00 ₽ |

| Copper coupling ⌀ 22 | 1,00 | PC. | 56,00 ₽ |

| Copper coupling ⌀ 22*15 | 1,00 | PC. | 56,00 ₽ |

| Copper coupling ⌀ 15 | 1,00 | PC. | 34,00 ₽ |

| Brass end cap ⌀ 35*40 bunks | 1,00 | PC. | 1 420,00 ₽ |

| Brass end cap ⌀ 35*40 in. | 1,00 | PC. | 1 456,00 ₽ |

| Brass end cap ⌀ 35*32 bunks | 1,00 | PC. | 1 420,00 ₽ |

| Brass end cap ⌀ 35*32 bunks | 1,00 | PC. | 1 420,00 ₽ |

| Brass end cap ⌀ 35*32 int | 1,00 | PC. | 1 560,00 ₽ |

| Brass end cap ⌀ 28*25 Amer. | 1,00 | PC. | 720,00 ₽ |

| Brass end cap ⌀ 28*25 ext. | 1,00 | PC. | 720,00 ₽ |

| Brass end cap ⌀ 28*25 bunks | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 28*25 in. | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 22*20 Amer. | 1,00 | PC. | 620,00 ₽ |

| Brass end cap ⌀ 22*20 ext. | 1,00 | PC. | 620,00 ₽ |

| Brass end cap ⌀ 22*20 bunks | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 22*20 in. | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 15*15 Amer. | 1,00 | PC. | 396,00 ₽ |

| Brass end cap ⌀ 15*15 ext. | 1,00 | PC. | 396,00 ₽ |

| Brass end cap ⌀ 15*15 bunks | 1,00 | PC. | 130,00 ₽ |

| Brass end cap ⌀ 15*15 in. | 1,00 | PC. | 130,00 ₽ |

| Water socket ⌀ 15*15 in | 1,00 | PC. | 189,00 ₽ |

Gas consumption per house 200 m2

Gas consumption for heating a house of 200 m2 is determined using similar methods. Autonomous gas heating of such an area with a long heating season will ultimately be characterized by the following production values of liquefied propane-butane:

- Hourly - 1.56 l;

- Daily – 37.4 l;

- Monthly (30 days) – 1222 l.

Taking into account the fact that the calculation of the minimum required level of “blue fuel” consumption for heating housing of a given area was given above, the optimal indicators of its required reserves and, accordingly, the costs of its acquisition are somewhat higher. They are determined from the indicators calculated with a reserve capacity of the heating boiler.

The gas tank is frozen: common causes and ways to quickly fix the problem

Melt water floods the gas tank reducer.

It is necessary to raise the gearbox and equip it with a tube leading to the top for air access.

Raise the gas tank reducer

COST IN RUBLES

The gearbox was raised above groundwater using thick-walled STAINLESS material on a rigid rod. This is the most common solution

Work performed: lifting the gearbox, draining condensate from the gearbox and drying, replacing the old hose with a longer one, fully checking the tightness.

Lifting the gearbox above groundwater was done using a material based on flexible copper liner. This solution is not the most common since you have to get creative and come up with fasteners for the gearbox. Produced work: raising the gearbox, draining condensate from the gearbox and drying, replacing the old hose with a longer one, full leak check. Lifting the gearbox above groundwater was done using thick-walled STAINLESS material on a rigid rod. The gearbox was raised very high. This decision was made by the customer due to the fact that he will build up the casing (cover) in the summer. Work performed: lifting the gearbox, draining the condensate from the gearbox and drying it, replacing the old hose with a longer one, full tightness check. Raising the gearbox above groundwater was done using thick-walled STAINLESS material on a rigid rod. Work performed: raising the gearbox, replacing the old hose with a longer one, full leak check

The gas tank reducer freezes: how to fix the problem?

A gas holder is a special tank designed to store liquefied fuel. It is capable of providing autonomous gasification, which will be absolutely indifferent to the vagaries of the weather and will eliminate conflicts with utility services.

However, in order for the gas tank to operate continuously, and for such an important component as the gearbox not to freeze, it is necessary to pay special attention to installation and operating requirements. Digging a pit for a gas tank should be carried out on the basis of technical specifications and drawings.

The depth of the trench should not be less than 1.7-1.8 meters, and the angle of inclination of the pipes should be within five degrees. The hole must be dug no lower than the freezing depth of the soil. Its walls should be flat. Sand is used as drainage and the bottom is covered with it.

If there is a high groundwater level, it is recommended to additionally use a layer of crushed stone. After that, a concrete slab with a thickness of at least 16-17 cm and a rubber flooring that is resistant to freezing is installed. Next, the gas tank is fixed to the concrete pipe.

After the gas holder is installed, it is backfilled with sand. This is necessary so that when the snow melts, the water goes into the ground. What to do if the gas tank reducer freezes?

Gas tank reducer. Why does it freeze?

A reducer is a device necessary to increase or maintain the required level of pressure in the system. Many owners of liquefied gas storage tanks are faced with the problem of freezing of the reducer.

In this regard, the question arises: “What to do in such situations and is it possible to prevent such a problem on your own? The problem lies in the design data of the gearbox. This part of the gas tank consists of two parts, which are separated from each other by a flexible membrane that acts as a regulator.

The lower section of the gearbox carries out gas flow, and the upper section communicates with the environment. If flooding occurs, water accumulates on the gearbox membrane. Under the influence of low temperatures it freezes and makes further work impossible. Water can appear for a variety of reasons.

As a rule, the appearance of water is due to the presence of condensation, since the gas evaporates and is absorbed under the influence of thermal energy. In order to eliminate this problem, it is necessary to try to prevent flooding of the gearbox. That is, this issue must be resolved at the installation stage - raise the gas tank reducer, apply drainage.

This is especially true for situations where there is an accumulation of large amounts of groundwater. If the gas tank reducer is flooded with water, it needs to be dried. Before the start of the heating season, the gearbox is serviced, that is, it is dismantled and thoroughly dried to avoid freezing of the gearbox membrane.

In case of emergency situations, the gearbox is heated using boiling water. It is not recommended to use fire or other heating devices for heating, as this is dangerous. It is allowed to use a heating cable with a thermally insulated structure.

The main signs of a problem that may indicate freezing

As a rule, when the reducer freezes, the operation of the autonomous gasification system is blocked and the gas pressure decreases. In such situations, it is recommended to use the services of professionals. They will conduct a comprehensive diagnostic of the operation of the boiler equipment in order to determine the cause of the breakdown.

If problems are found in dynamic pressure fluctuations, a specialist will inspect the gas tank. Often, even with high-quality installation of the gas tank, ice can form on the membrane. In this case, the gearbox is removed, dried and reinstalled.

It is important to raise the gas tank reducer above ground level.

5 problems and solutions for gas tanks: owners’ experience and engineer’s comments

We have selected five situations with containers that were described by users of the ForumHouse forum. All cases were analyzed by our engineer Evgeniy Kalinin. He has been installing since 2013 and has completed over 1,800 installations.

The whole article in 3 paragraphs

2 out of 5 problems arose due to operational errors: excess liquefied petroleum gas (LPG) in the tank and three years of heating at one gas station.

3 out of 5 problems are related to the incorrect selection or installation of a gas tank: low pipes and too/insufficiently deep installation.

https://www.youtube.com/watch?v=tEwRX17Mhb4u0026list=PLisenTcyE06KTLIpoMIV2DHKvboPVAx77

If you choose the right tank and reducer, carry out high-quality installation and refuel with good gas, there will be no problems.

The gearbox freezes

Operating principle of the gearbox

To supply gas to private houses, gas tanks are often used, the pressure inside of which is quite high, but it is not suitable for supplying gas to the house. Therefore, to reduce it, a gearbox is used. It has a special design that reduces the LPG pressure to controlled values.

The reducer works as follows: a special valve, which is connected to a flexible membrane, periodically opens and closes. Due to the difference in pressure between the lower and upper chambers, the membrane comes into action and passes gas at the desired speed.

Residents of country houses often encounter a problem when the gas tank reducer freezes, and this happens quite often, especially in winter. How efficient will the system be in this case and how can it be repaired?

The problem is that the gearbox is installed openly, so it is often flooded with water, covered with snow, dirt, which causes the device to freeze when frost sets in.

It is important to install a protective cover over the gearbox or cover it with moisture-resistant materials to prevent moisture accumulation and avoid the problem of freezing of the device.