With the rapid rise in energy prices, many began to seriously plan to purchase alternative heat sources. The most economical of them is the Buleryan stove. This is a development by Canadian scientists that allows you to save money spent on purchasing fuel.

This stove runs on wood, a fuel that is always available. In addition, its consumption is minimized due to the unique design of the furnace. Other stoves are designed in such a way that they heat the room by releasing heat from their surface. Buleryans work differently, namely by heating the room with the air that comes out of them. This operating principle gives a higher efficiency compared to conventional boilers.

The second name for such a stove that can be found on the Internet is Breneran. A lot of positive reviews from customers force us to study the principles and features of the operation of such a stove in more detail.

Universal Soldier

Autonomous heating of your premises with wood with minimal costs and maximum output - this is Buleryan or Breneran. Cottage, garage, construction site, workshop, service station, warehouse, greenhouses, workshops, retail and public premises, and most importantly, the properties of Buleryan allow it to be installed even in residential buildings as a constant heating system.

The only nuance that needs to be taken into account is choosing the appropriate size and type of stove so that the room is evenly heated. It is also important to choose the right place for the stove, and to install the chimney responsibly and not forget about cleaning it. Then you can avoid the main problems that Bullerian users face.

Carpentry shops are simply an ideal place for Buleryan - there is plenty of fuel in the form of scraps of wood, which are also perfectly dried.

Conclusion

Canadian technology, which is used to manufacture heating boilers and their analogues in other countries, is an effective source of heat with low consumption of solid fuel. Correctly configured system will allow you to maintain optimal temperature in rooms of any size. It is important to adhere to the rule: the ratio of the power of the unit and the size of the premises so that the efficiency is optimal. To heat several rooms and/or water for domestic needs at once, it is recommended to choose special systems that use a liquid heat exchanger and gas generation process for their operation. Additionally, the Buleryan stove for a greenhouse or house with a water heating circuit uses the principle of pyrolysis in its operation.

Briefly about the main advantages

A small stove of this type can easily heat 100 m2, and a little larger in power and 200–400 m2, while the period between fillings can be about 8–12 hours. You only need to add firewood several times a day and the stove will maintain a constant comfortable temperature .

The rate of firewood combustion depends on the set power, and in many ways also on the type of wood. The room heats up very quickly - in 3 hours the air will be heated to an acceptable temperature. For large areas, several Buleryans are installed or a larger unit is purchased.

This stove is truly very convenient and versatile; it pleases the new owners with big dividends:

- heats a large area;

- uniform heating;

- absence of soot and smoke in the room;

- compact size;

- quick heating of the living area;

- saving firewood;

- easy-to-use door for storing firewood.

Popular manufacturers

Buleryan stoves are produced by various factories in many countries, Russia and neighboring countries are no exception. 3 manufacturers have gained the most popularity:

Kyiv Novaslav

A company from Ukraine that specializes in the production of stove equipment for saunas, baths, and heating of various rooms. Novaslav equipment operates according to the basic design of the original models, but is better adapted for heating compared to standard stoves of this type. Available in a number of series:

- Vancouver 01 type up to 200 m3, maximum power 11 kW. Weight 97 kg. Upon request, it can be equipped with a thermal glass door. Area of use: premises with a volume of up to 200 m3. The cost ranges from 16,000 to 20,000 rubles.

- Montreal, 02 type up to 400 m3 - this model range stands out for its increased power of up to 18 kW, in comparison with Vancouver, with a low weight of 127 kg and small dimensions, it is capable of heating a room with a volume of up to 400 m3. The cost ranges from 26,000 to 30,000 rubles.

- Quebec, 03 type up to 600 m3 - this type is best suited for production needs. Upon request, the door can be equipped with a glass thermal insert. The maximum heating area is 260 m2. The cost ranges from 30,000 to 40,000 rubles.

- Toronto, 04 type up to 1000 m3 – high power heat generator. The power is sufficient to heat an area of up to 350 m2. The cost starts from 43,000 rubles.

- Ontario, 05 type up to 1300 m3 - a convection oven of the highest power, which is sold by the company. The power of the equipment reaches 45 kW; it is easy for them to heat a volume of up to 1300 m³. The cost starts from 44,000 rubles.

The stoves look aesthetically pleasing and can serve as an element of a design solution. The company also produces a variety of Buleryan fireplace stoves.

A metalworking company from Novosibirsk produces furnace equipment and accessories. NMK produces ovens using convection, Siberia BV Buleryan. The equipment of this company is ideal for heating any premises. The following equipment can be purchased:

- Siberia BV 120 is best suited for industrial premises: greenhouses, dryers, etc. The highest temperature of heated air is 80 °C. At a single load, in gas-generating mode it will work for up to 10 hours. The largest heating volume is 120 m³. Cost 11,500–13,000 rubles.

- Siberia BV 180 – works on any solid fuel mass: wooden logs, coal, cardboard packaging or briquettes. A thermometer is installed to regulate the temperature of the exhaust gases. The stove is undemanding to the quality of the fuel mass. Cost 14,000–15,000 rubles.

- Siberia BV 480 - is distinguished by a modified design of convection pipes; the standard circular cross-section is replaced with a rectangular one. It is distinguished by optimal dimensions of the firebox door and an eccentric type lock, which ensures tight contact with the body. Heats up to 480 m³. Cost 17,000–19,000 rubles.

- Siberia BV 720 - with a mass of 157 kg, this equipment is a powerful heat generator producing energy of 49 kW. Suitable for heating large warehouse areas and premises with a large number of living rooms. Cost 23,500–26,000 rubles.

Models "Sibir BV"

Eurosib

A company from Russia that specializes in the manufacture of structures entirely made of metal. A distinctive feature is the presence of a cooking surface in some models. The company sells a few modifications:

- Klondike NV Buleryan stove - their capacity ranges from 100 to 1200 m3. They were developed for effective heating with buleryan in harsh winter conditions. At a single load, the operating mode is about 10 hours; they are not too demanding on the quality of the fuel mass. Cost from 12,000 to 46,000 rubles.

Conclusion

Owners of individual buildings or houses should pay close attention to the Buleryan stove. Using a Buleryan stove for your dacha is the optimal solution

After all, it has high efficiency, is capable of operating on a single load for up to 12 hours (this eliminates the need to add fuel late at night), does not require conservation, and is easy to operate and maintain.

The principle of operation of the Buleryan furnace

In fact, the operating principle of such a stove is similar to a potbelly stove, but with high efficiency. The firewood that is placed inside does not burn in the full sense of the word, but slowly smolders. Due to this fact and the large heat transfer area, Buleryan is economical.

But let's not forget that everywhere there are pitfalls. Having studied them, you will be armed and ready to begin a fruitful collaboration with this unit. The Bullers' two main problems are:

- wet firewood - does not burn well, produces soot (you need to use dry firewood);

- clogging of the chimney with dense soot, lack of draft (need to clean the smoker).

Let's look at these questions in more detail.

Using wet firewood. When the stove is lit, the wood flares up and heats up, thereby heating the chimney pipe and starting the draft. When burned, wood releases volatile gases, which ensure a constant combustion temperature of the wood in the firebox. Next, heavier gas fractions are released, intended for combustion in the afterburner. Practice shows that when laying wet firewood, such gases are released more than normal, and they do not burn due to lack of air. Therefore, it is advisable to put only dry firewood in Buleryan.

Afterburning tubes, offered by some craftsmen, do not solve the problem, since they change the very essence of the furnace - fuel economy. And when using such pipes, the firewood will burn quickly, then the stove simply will not fulfill its intended purpose.

Clogged chimney pipe. If you still use damp wood, then unburned heavy oily gas fractions rise into the chimney and stick to the inner surface of the pipe. Drops of condensate flowing down form resin build-ups and subsequently clog the entire pipe . Sometimes the satisfied owners of a new stove, not knowing this nuance, discover that the chimney is completely clogged and does not allow rising gases to escape. The downside of clogging is a common concern for Breneran users.

The instructions, which few people are able to read, contain valuable tips for using Buleryan. The problem for users is that they, without thinking, start using new stoves without studying their features.

The instructions say that you can only use well-dried firewood , the humidity of which is not higher than 30%. Of course, such drying cannot be achieved under normal conditions - special dryers are needed. However, most manufacturers require precisely such raw materials for the stoves they sell.

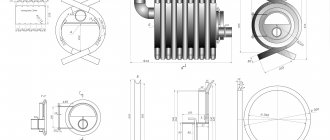

Description of design and operating principle

Initially, in essence, it is an ordinary metal stove, whose task is to heat the room by directly heating the air. Another thing is how this heating is implemented. The heater does not heat the air in the room with its hot walls, as is the case with a conventional stove, but passes it through a kind of heat exchanger - a heater, this is the principle of operation of the Breneran stove.

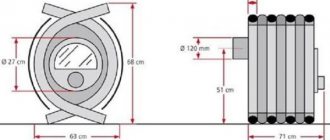

The heat exchanger is the heater body itself in the form of curved pipes that form the walls of the cylindrical firebox. The pipes do not fit closely to each other; there are certain gaps between them, in which the wall of the combustion chamber is made of thick sheet metal. This is done to more intensively heat the air in the pipes. When the heater is heated, convective draft appears in them, causing air masses to heat up and circulate from bottom to top until all the air in the room passes through such a heater.

A correctly selected stove can heat a heated room within 20-30 minutes, since the design of the Buleryan stove allows it to operate in two modes.

- Kindling and warming up, when intensive combustion of wood occurs in order to quickly heat the building and switch to a more economical and long-lasting mode.

- Long burning.

Air is supplied to the heat generator through a round damper built into the loading door of the firebox. During the ignition process, the damper opens completely, allowing the wood to ignite and quickly heat the stove body. The photo below shows the internal structure of Buleryan.

You can immediately notice the complete absence of an ash chamber; a thick metal sheet is simply laid underneath. A second sheet is installed on top at approximately the same distance from the walls of the firebox as the hearth sheet. Above it there is a chimney pipe, that is, there is no direct exit from the combustion chamber for gases; they must go around the upper partition, due to which an efficiency of about 65-70% is achieved. In order to fully understand how Breneran heating units work, we will follow the process from the ignition itself, which is carried out according to its own rules.

Purge of Buleryan

No matter how wonderful this heating unit is, the time for preventative maintenance comes. Any Buleryan eventually shows signs of contamination, which are expressed:

- Deterioration of melting.

- Lack of traction.

- Difficulty closing the gate.

To do this, there are several options from which you need to choose the most effective and safe.

- Cleaning burns. A dangerous method, but some daredevils use such an extreme move. Its essence is to heat the pipe to a very high temperature, when the metal turns red. In this case, the resin simply burns out and the chimney is cleaned. Here it must be repeated that this is a risk both for yourself and for the stove itself.

- Mechanical cleaning. You can take a special rod and clean the pipe directly on the roof. But given that the length of the pipe above the roof surface is about 3 meters, this task is no less dangerous. Needless to say, it is not worth doing such experiments in winter, however, if such an opportunity exists, the effect is obvious.

- Cleaning through a “glass”. What to do if the smoker is thoroughly clogged, and the chances of cleaning it from above are zero. Theoretically, you can knock the pipe hard, realizing that most of the resin will still remain in place.

The option of cleaning the smoker from the inside only seems complicated, but in reality everything is simple. You need to make something like a folding meter with a ruff at the end from scrap materials. It can be a pipe or an angle made of aluminum, the main thing is that the structure is light. The height of the chimney pipe is decent and with a heavy cleaning device this will be difficult to achieve .

It will be much simpler and more economical to use a long, rigid but flexible rod or wire. Roll its end into a ring along the diameter of the pipe in several layers and clean the chimney through a condensate glass. One disadvantage of the procedure is dirt, but you will need no more than an hour for the cleaning itself. And you can use your favorite stove again without any problems.

Buleryan in a residential building

For a summer cottage and temporary heating for an unfinished house, this type of heating is simply ideal. But many doubt whether Buleryan can be installed in a residential area. Here opinions differ, so you need to carefully study the opinions of those who already have experience using it in their home.

There is a minimal possibility of harmful effects on the healthy atmosphere of Buleryan’s home. Ordinary dust, sucked in with a portion of air, can heat up and burn, and its thermal decomposition does not require too high a temperature. Combustion products of dust particles can live in the air and have a negative impact . For a large house, an excellent solution could be to install both a Buleryan and a stove at the same time. The first one will quickly heat the house, and the stove will perfectly maintain the temperature.

However, if you position Buleryan correctly and follow the basic rules and frequency of prevention, then its use in a residential building is quite acceptable.

How to remove condensation ↑

There is another known problem that is associated with the operation of Breneran. Its smoke pipe, as you know, is located on the wall of the stove at the back. A tee is mounted here - a chimney pipe is connected to it. At the bottom there is a glass plug for condensate. This design does not have the required tightness. And this is a problem, because condensation inevitably and steadily enters the air, which is not good. Some craftsmen adapt their own solutions, making sealed containers to collect condensate, while others remove it from the room using pipe devices. In short, we have to innovate as best we can, because the market, alas, does not offer ready-made solutions.

Tips for use

You will be satisfied with the purchased buleryan if you are careful when using it.

Although sellers in advertising talk about this stove as a universal solid fuel boiler, this is not entirely true. The best fuel in this case is wood. It is best to heat it with non-resinous woods such as acacia, poplar or birch. Briquettes and pellets that you can buy also work well. However, it is better to melt with logs, using briquettes during the combustion process. Never use flammable substances to light the stove.

Before stacking, it is best to dry the firewood on top of the stove, then it will burn more efficiently. A burning period of 8–12 hours is possible only when the firebox is fully loaded.

Never make the chimney pipe shorter than recommended. For successful combustion you need good draft, which is possible with a total chimney height of 5 meters . It is also recommended to assemble the chimney pipe not in the direction of gas movement, but against the movement. This will rid your flooring of resins that leak from the stove openings. If you install the chimney wisely, these resins will return and burn again.

The smoker needs to be checked and cleaned 2 times a year, then you will not have any problems with Buleryan.

Installation

Such a stove must be installed no closer than 1 meter from flammable materials or 75 cm if these materials are plastered with a 25 cm layer, and no more than 50 cm with walls with special insulation.

Buleryan can be installed on a kind of pedestal, which serves as both a decoration and a functional element. You can make a niche in it for firewood, and also fit it into the interior in a special way. This foundation is made on the basis of piles.

With the growing popularity of this stove, the market was flooded with numerous fakes similar in appearance to Buleryan. To buy a quality product, it is advisable to read reviews from customers of the specific company you are interested in.

Varieties of execution

Professor Butakov's stove

Let's figure out the difference between Buleryan, Breneran, Professor Butakov's oven and what other types of Buleryan there are.

Buleryan is a brand from Germany. Under license, identical stoves are produced in Russia and they are called “Breneran”. There is no significant difference between these two ovens.

Professor Butakov’s stove has features and differences:

- Convection pipes are completely recessed into the body;

- The body is not barrel-shaped, but in the shape of a parallelepiped;

- There is an ash pan;

- There is a grate;

- The flat top surface allows you to heat food on it (although this will take a lot of time, because the body does not warm up very much).

The disadvantage of the design is the rotary valve. It is made in such a way that when adjusting its position you can burn your hands on the body.

Many people believe that the grate in convection ovens is an unnecessary part. Storing firewood needs to be done more often, although in Buleryany it burns almost without a trace.

Inquisitive minds invented aquabuleryan. However, Buleryan was originally developed as an air heating stove. It is not designed to heat water, which has a heat capacity 800 times greater than air.

Heat accumulators are used for greenhouses - this is a tuning designed to accumulate heat that is usually accumulated by walls. Curtain panels filled with gravel, pebbles, broken bricks, etc. They fit onto Buleryan convection pipes and follow the shape of the furnace walls.

Buleryan stove user reviews

5 years of experience using a Buleryan 00 type stove in our 42 m2 showed it as an economical source of heat. In severe frosts, we could not even use up a carload of firewood, let alone during warm winters. It heats the house quickly, however, in severe frosts one stack of firewood lasts not for 8 hours, but for 6 hours at most. The chimney often cokes, however, we are thinking of solving this problem with insulation. Overall the unit is great!

Svetlana, Kostroma

For three years we have been heating two garages with a small Buleryan. The main garage is 60 m2, in which a stove is installed, the second is heated through the wall. Maintains an ideal temperature of 25 degrees in the main garage, while in the second garage the temperature is maintained above zero even in severe frosts. One “but” - firewood quickly disappears in cold weather, but at 0 degrees one stack is enough for 8 hours. The unpleasant fact is that tar goes onto the roof and the chimney becomes clogged. With all the nuances, there is simply no better alternative to gas.

Nikolay, Volgograd

I bought Buleryan for my dacha and for a whole season I couldn’t figure out what the problem was - condensation was coming out of all the cracks. A kind person at the market helped me understand my mistakes. The first - the horizontal section of the chimney should not be more than 1 meter, the second - the street part of the pipe should be in a “sandwich”, the third - the chimney should be assembled not along the path of the smoke, but along the path of the condensate. Now we are working normally.

Andrey, Penza

The modern design of the stove is slightly different from what it was originally. The bent pipes through which air moves were about 80 mm in diameter. But in order to save money, they began to be reduced to 40 mm, and in some cases to 30 mm.

About water bullers

Buleryan can also carry out heating and water heating at the same time. Boilers equipped with a water circuit are used in homes and factories. Buleryan - a stove with combined functions in design and design is similar to the conventional modification, which uses air convection for full heating.

Example of water buleryan

Device Features:

- There are pipes around the combustion chamber.

- The basic principle of operation is chemical processes: pyrolysis or gas generation.

- The pipes are filled not with hot air, but with heated coolant liquid.

The Buleryan system furnace with a water circuit operates as follows:

- Pipes (convection) in the lower part have a collector (lower and upper).

- An outlet is specially mounted on the lower of the collectors, which is necessary to return the liquid to the system.

- The upper element has a pipe that is required to supply coolant liquid to the system.

- The water or other liquid heat carrier used in the system gradually heats up. This happens during the process of firing the furnace.

- The desired pressure is created (selected by setting).

- Liquid circulation occurs under the influence of physicochemical factors and its rise to a height of 7-8 meters.

- The coolant fluid moves through pipes and is supplied to heating devices (batteries, convectors), which are located in rooms (living rooms, production workshops or greenhouses).

The cooled liquid heat source is returned back to the system using an outlet on the lower collector.

In this case, the gas formed during the combustion of solid fuel takes part in the heating process. For this purpose, the design of the furnace provides two, rather than one, combustion chambers - in one, the main fuel is burned (firewood, pressed sawdust or coal briquettes), in the second, the process of afterburning of gases occurs.

Water buller connection diagram

After heating the firewood combustion compartment, it is recommended to switch the boiler to gas generation mode. In this phase of operation, the fuel does not burn, but smolders. This allows you to increase the heat transfer time, but the system will function autonomously. Feature - the efficiency remains the same as when burning wood or other solid fuel. A Buleryan home stove with a water heating system allows you to obtain hot water for domestic needs if the pipes are connected to a special container. Water heats up to 100 degrees in 30-40 minutes, depending on the model chosen for use, which requires about 2.5 kW of energy.