How to make a buleryan oven with your own hands?

Judging by the drawing, the following materials are used to assemble the structure:

- sections of pipe with thick walls, with a diameter of about 6 cm. A smaller diameter will contribute to poor air flow;

- metal sheet having a thickness of 4 mm;

- a small piece of thick-walled pipe used to cut rings for the door or a metal sheet from which curved strips are subsequently made;

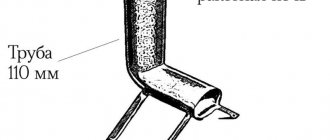

- a piece of pipe for a chimney with a diameter of 10−12 cm;

- door hinges;

- asbestos cord;

- lock for the door, lever for the throttle and damper.

The frame of the Buleryan stove is made of a wide metal pipe. The firebox is also made from it. The body can also be made from air ducts. The firebox in this case is made of separate steel sheets.

The pipes are bent 80 degrees, and for stability they are placed on a frame and welded with temporary transverse strips, thereby securing them. The blowers are then welded together with steel strips, creating a single body. The result is the following design: the pipes are arranged towards each other, creating a barrel-shaped body. All temporary strips are removed.

A firebox will be located inside the Buleryan structure. A steel plate 10 cm thick is welded for it, on which the logs will subsequently be laid. After this, a circle is cut out of steel 2 millimeters thick and welded to form the back wall. The chimney socket is welded to this circle in advance, inside of which the damper is located. It is held in place by a spring and a lever handle. At the top of the firebox, near the back wall, a plate is welded, which forms the 2nd tier, and above it are 2 tubes with a diameter of 12 mm. The result is a chamber for afterburning gases.

https://youtube.com/watch?v=0LEpgm9g2BQ

Making the front wall and oven door

These are the most difficult parts in the manufacture of this design. The front wall is cut out in the same way as the back. A hole should be made in it for the door. A narrow strip of metal is welded to its edge perpendicular to the area of the front wall. This will be a side that will help the door fit as tightly as possible.

Then the door itself is made. It should be larger in diameter than the cut hole. Stepping back a little from the edge of the disk, two metal strips are welded. They are positioned so that a welded strip on the front wall passes between them. An asbestos cord is placed in the gap between the strips.

Then they begin to make the throttle. A throttle body with a diameter of 25 mm and a length of 10 cm is made from a piece of pipe of a suitable size. Two holes are made 4 cm from the edge into which a metal rod is inserted. It is bent on one side, resulting in a throttle handle. The damper itself is cut out of metal in the form of a circle, smaller in diameter than the body pipe. The damper is inserted into the body and welded to the rod. The result is an adjustable damper.

The throttle is attached to the door. A hole is made in its upper part and welded. Then the hinges and lock are installed. Hang the finished door, checking the quality of the seams.

Making a chimney damper

The damper for the chimney is made in the same way. Only the dimensions will be slightly different, and a 90-degree sector will be cut out of the damper. A second section is welded to the horizontal section of the chimney pipe leaving the stove in such a way that a structure resembling the letter “T” is obtained. Then a damper adjacent to the body of the part is inserted. Two holes are made in the body into which a metal rod is inserted. A damper is welded to it, and to form a handle, one end of the rod is bent.

What you need to make a Breneran type convection oven

In order to get a truly reliable and durable heating unit, it is made of thick metal. The best material is considered to be heat-resistant boiler steel, which can be purchased at specialized offices. Before starting work, prepare:

- rolled steel sheets with a thickness of at least 5 mm, size 1000x2000 mm;

- sheet of heat-resistant steel 6 mm thick, 400 mm wide and 700 mm long;

- a small piece of steel sheet 3–4 mm thick for making valves;

- steel pipe Ø110 mm - 4 meters;

- round thick-walled pipe Ø57 mm or profile metal pipe with a thickness of 4 mm and dimensions of at least 60x60 mm - more than 10 m;

- steel tube Ø15 mm - 40 cm;

- rings for the door, cut from a pipe Ø350 mm;

- powerful loops for fastening the loading hatch;

- handle with a locking mechanism for the door;

- pieces of steel rod Ø8 mm for the manufacture of air and smoke damper levers;

- asbestos cord.

Often, zealous owners use cylinders or metal barrels to make furnace parts, but the materials from which they are made are not always suitable for the needs that they are going to satisfy with the help of such a homemade product.

Tools and devices that will be needed in the process of making a Canadian stove:

- powerful pipe bender;

- welding machine;

- angle grinder (grinder);

- cutting and cleaning discs;

- electric drill and set of drills for working on metal;

- hammer;

- roulette.

Precisely configured parts can be obtained by cutting a thick sheet of metal with a cutting torch

If possible, it is better to cut the metal sheet with a gas cutter or other special equipment. Firstly, this will save more than one cutting disc for an angle grinder, and secondly, after the gas cutter, the round body parts will only require a little grinding of the edges. If you use an angle grinder, you will need to put a lot of effort into turning the polygons cut out with it into circles.

Step-by-step instruction

Materials:

- Pipes;

- 4mm. 50x50 – 27 m;

- 2mm. 30x20 – 0.76m;

- 2mm. 40x25 – 2 m;

- Diameter 15mm – 0.6m;

- Diameter 95mm. (5mm.) – 1m;

- Steel – 5mm. – 3m2;

- Sheet metal – 100mm. – 0.1m2;

- Wire with a diameter of 10mm – 0.5m;

- Garage hinges – 2 pcs.

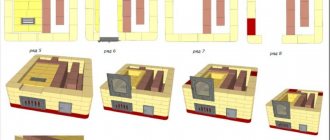

Step-by-step instructions for making Buleryan:

- We cut the pipe, which is 27 meters long, into 18 one and a half meter sections, from which we make pipes characteristic of Buleryan (two bends of 120 each).

- 15mm nozzles are welded into 4 of them. tubes (tube length – 15 cm).

- The pipes are folded together in the shape of the future Buleryan and secured by welding. Parts with nozzles are placed two on both sides (later they will act as a blower). Everything is finally boiled down.

- To make the gas afterburning chamber we use 5 mm. steel. We cut out 2 blanks (370x700 mm with a jagged edge 50x60mm to fit the pipe size).

- The parts are welded inside the contour formed by the pipes. Pipes with nozzles should be located in front of the partitions.

- Frame. From the same metal as for the afterburning chamber, we cut plates that will close the gaps between the pipes: 18 pieces for the middle part (400mm x 50mm). 36 pieces for all lower and upper spaces (350mm x 50mm).

- We cover the ends with two 6-carbon plates from the same 5 mm. metal (side 40cm). We make a hole in one of the plates for the chimney. It should be 85 mm in diameter. and located in the afterburning chamber.

- And a hole for the door is cut in the front plate. Approximately 25x25cm. We weld both plates into place.

- The chimney will be a 95 mm pipe, 50 cm long. A valve is installed in the pipe on a wire axis (similar to a throttle valve in a carburetor), with a quarter cut out.

- A pipe frame (40 x 25mm) is made around the perimeter of the door opening.

- We cut out two squares from 10mm metal. The first is 330mm, the second is 246mm. We weld the smaller square with a profiled pipe (40x25), so that it fits into the frame onto the hole for the door (see points 8, 10).

- The blower will be similar to the chimney, only the valve in it will not have a selected quarter. Pipe for 95, 140 m long.

- A 95 mm hole is made in the finished lid, and a blower is welded there.

- Canopies. The door is fixed (by welding) and at a distance of 40 mm from its top and bottom, 2 professional pipes with a length of 380 mm are welded horizontally. Where there will be awnings, the ends of the pipes should protrude 5 cm beyond the hatch. Garage hinges are welded to them.

- Constipation. You can make the lock yourself, or you can order it from a turner. After welding it to the door, the fixing welding is removed.

- All welds are ground.

- You can weld the legs.

Don't be tempted by narrow water pipes. For efficient operation of Buleryan, pipes of 50-70 cm are better suited.

Making a chimney

If you think that the chimney for the Buleryan stove, assembled with your own hands, is a piece of pipe, then you are completely wrong. We will make a T-shaped chimney with a slide damper for our stove.

Unlike a throttle, the gap here is not completely blocked, but only 3/4 of the maximum diameter of the chimney - this is exactly the damper that will need to be cut out and installed in the outlet (horizontal) pipe.

We weld a vertical section to the horizontal chimney pipe of the Buleryan stove. Smoke will escape through its upper part, and condensation will accumulate in the lower part (it will definitely happen). To make getting rid of it more convenient, weld a ball valve to the bottom. Just one movement of the hand - and all the accumulated condensate will drain into a previously placed container, as we promised earlier.

DIY Buleryan stove design

- First, firewood is placed in the firebox, ignited and the active combustion mode is set;

- after this the oven is put into smoldering mode;

- With the help of special blowers, hot air begins to spread throughout the room.

The first mode heats the firebox very quickly, providing an outlet temperature of more than 100 degrees. This takes about 30 minutes. After this, the firebox is completely filled with dry logs and the air supply is reduced using a special regulator located outside the housing. The oven goes into smoldering mode. Thanks to this, the temperature of 50 degrees lasts 10 hours. Therefore, if the Buleryan stove is filled with wood twice a day, then round-the-clock heating is provided.

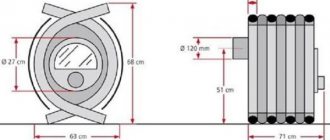

Determining the size of the buleryana stove

The size of the stove is of great importance. In the shortest, smallest buleryan (length - 455 mm, width - 620 mm, height - 555 mm), the firebox is correspondingly small, so not much firewood can be stored.

The fuel burns in such a miniature boiler from two to six hours. It depends on the type of wood, the quality of the firewood, and the thickness of the cutting. Accordingly, the area of the heated room will be small - this must be taken into account when choosing the size of the future buleryan.

Of course, for rooms with an area of more than twenty square meters, long-burning stoves with larger dimensions are designed. The average dimensions of a buleryan are: length – 835 mm, width – 436 mm, height – 640 mm. A large stove has the following parameters: 950 mm by 676 mm with a height of 1505 mm.

Frame of a homemade stove Buleryan

Customers' opinions

“I don’t go to the dacha very often, and therefore I didn’t pay for connecting to the gas pipeline, I decided to buy a Breneran wood stove, which I don’t regret. Inexpensive and powerful enough for a small area (I have about 60 m2). They delivered it and installed it quickly, although we had to tinker a little with the chimney. After turning on the stove for the first time, as was written in the reviews, an unpleasant smell appeared in the room, but later there were no such problems. Now, when I arrive in a cold house before the weekend, I fire it up and it takes less than an hour to warm up. Then I switch it to gasification mode and add firewood twice a day.”

Vladimir, Yaroslavl.

“It’s illogical to live in an eco-friendly wooden house and heat it with gas. My husband and I, after reading reviews about the Aqua Breneran stove, bought the AOT-16 model, for which we ordered a casing. It turned out quite stylish and original. Easily connected to water heating pipes, the fuel supply lasts for 6–7 hours. I’m happy that you can throw almost anything into the oven; my husband even used broken furniture. The main thing is that the wood is dry, otherwise condensation will flow straight down the chimney. I had to put in a jar. I consider it a disadvantage that Breneran’s design does not immediately provide a container for collecting moisture.”

Lyudmila, Smolensk.

“I like to steam, I built a sauna and installed a heater. According to reviews, it most closely matched my wishes, and the prices for Breneran sauna stoves turned out to be quite affordable. Compact dimensions made it possible to install it in a corner. For my 6.5 m2 area, one full bookmark is enough to steam without haste. The temperature rises to 100 ºС quite quickly - in a little more than an hour. I've been using it for almost 2 years. There were no problems the whole time."

Oleg Mikhailov, Belgorod.

“I set up a workshop in the shed, I got a lot of orders, so last summer I decided to install a stove so that it would be comfortable to work in the winter. I bought a compact Breneran for 9,000 rubles. I had to cover it with iron sheets on all sides, since I work with wood and am afraid of fire. At first, a lot of soot accumulated in the chimney; we had to clean the chimney almost every week. When I started throwing in dry wood, it got much better. I tried burning sawdust. They burn well, but they are used up too quickly.”

Alexander Belinsky, Saratov.

“I made the chimney for Breneran according to the instructions for the stove, fortunately, it details both the diameters of the pipes and the desired dimensions. I ran it in in the fall and it functioned without any problems. When installing it yourself, it is better to make the chimney a little higher: at a certain wind direction, the draft in the stove disappears and smoke appears. When it gets warmer, you'll have to lengthen it. In addition, black condensate with an unpleasant odor sometimes flows through the pipe; according to experts, this is due to insufficient thermal insulation of the pipes. But all the wooden waste from my production went into business. In general, I don’t know how to do it for the house, but for the utility room I need to bake a stove.”

Igor, Moscow.

“I purchased Breneran with a water circuit in 2013. In the third season of use, problems began, namely, it began to leak from the inside. At first one outlet had to be opened because there was a leak inside the firebox, then on the other side there was the same problem. It is not clear how the pipes could burn out if there is water in them. But has the metal become thinner in the same places on different pipes? the service life is very short.”

Alexander, St. Petersburg.

The lineup

The manufacturer offers equipment in several directions, differing in design features, but using the general principle of additional convection, which, according to reviews from owners, allows saving up to 50% of firewood:

1. Gas generator furnaces are the basic version of Breneran products. They are available both simple and with a hob, which additionally provides the ability to cook food.

2. Bath equipment can be used both in sauna mode and to create wet steam. It is distinguished by the presence of a compartment in which special stones weighing from 100 to 160 kg are placed, and the technical characteristics of Breneran sauna stoves provide for use in a steam room with a volume of 15 to 25 m3. Models are available both in a regular metal case and in a grille or cladding.

3. For water heating, Aqua or Aquaten stoves are offered, which provide heating due to the circulation of heated coolant. The Breneran is connected to the pipes containing it, the water is heated between the double walls of the furnace and fed into the radiators.

4. Fireplaces operate on solid dry fuel, have a stylish design and can be installed in cottages or apartments.

https://youtube.com/watch?v=CW3h3NpJwRk

Positive and negative aspects of the device

Breneran is a successful design that runs on solid fuel. It has many advantages:

- The housing serves as a forced convector through which all the oxygen in the room passes. In this case, air exchange is carried out naturally - due to the different densities of heated and cool air.

- You can burn peat briquettes, logs, waste from the paper and woodworking industries.

- High efficiency of the stove - it reaches 80%.

- Drawings of this heating device are widespread and can be found without much difficulty on the World Wide Web.

- The materials and equipment for installing the product are quite simple and are not very expensive. You will need a welding machine, a pipe bending device, metal sheets and stainless steel heat exchangers.

- The installation of the equipment itself, as well as the principle of its operation, is quite simple.

https://youtube.com/watch?v=CW3h3NpJwRk

Disadvantages of the design

Buleryan has no visible negative sides. These devices are called “furnaces without flaws.” But if you understand the design well, you can still find negative aspects:

- Burning coal in a stove may damage the device. The use of flammable liquids and gases is also prohibited.

- The operating principle is based on the combustion of wood and paper. In this case, reaction water is released, which is formed during the breakdown of molecules of living organisms.

Modern design

Sellers, when advertising breneran, say that when burning the tree does not form ash, but it is present in the wood initially. Therefore, ash particles fly into the chimney pipe.

When organic matter decomposes, hydrocarbon radicals are released, which reduce the efficiency of the stove by 6%. This is a small number, but radicals are quite dangerous for heating devices in everyday life.

The resulting water after the reaction precipitates as condensate. Moreover, this is not just a contaminated liquid, but a mixture of ash particles and a thin film rolled into a lump. The resulting toxins fall into the sump and have an unpleasant odor. This “water” always needs to be taken out somewhere, because it cannot be poured into the garden - otherwise the soil will be poisoned. In connection with this not very pleasant phenomenon, a heating device is often used in greenhouses, where the soil must be renewed annually.

Device diagram

The structure of a long-burning furnace Buleryan

In the barrel-shaped steel body of the Buleryan furnace there are two fireboxes (one above one). Vertical curved pipes (or their analogues in furnace modifications) pass through the firebox (recessed by 2/3 of the diameter). The number of pipes can be from 7 pcs.

To pump air into the furnace, a forced circulation device is not required - air is supplied to the pipes due to the temperature difference at the inlet and outlet of the pipes.

The blower in Buleryan has the form of a pipe with a throttle (damper) that regulates the power of the furnace. Some throttle handles have a graduated temperature scale and a stop limiter.

At the end of work, when the stove needs to be extinguished or the draft needs to be turned off so as not to cool the room, the throttle is closed tightly.

Buleryan transfers 70% of the heat to the air in the pipes. And another 10% is distributed throughout the stove body.

¼ of the size of the firebox is occupied by the afterburning chamber. The partition separating the two chambers does not reach the front wall of the stove by a fifth of the length of the firebox. From the afterburning chamber, combustion products enter a 1-meter horizontal section of the pipe. The combustion of gases stops here and the temperature drops slightly. Then turn up and economizer. If it is, the efficiency of the furnace becomes approximately 80%.

Principle of operation

The modern Buleryan potbelly stove is used in different areas - for heating a home, industrial or gardening buildings. Buleryan's thoughtful device makes it possible to obtain maximum thermal output from solid fuel. The Buleryan wood stove works according to the following principle:

- The required volume of firewood is loaded into the firebox (you can add a little paper or ignition mixture to facilitate the process of engulfing in flames).

- After the fire burns confidently, it is necessary to limit the air flow.

- The process of pyrolysis occurs - ignition under the influence of a secondary air flow.

Schematic representation of the operating principle

The heat generated during the active process of smoldering and residual combustion of wood fuel and pyrolysis products then enters the air heat exchanger. To ensure complete tightness of the combustion chamber, the pipes at the base of the heat exchanger, if the stove is assembled with your own hands, must be welded together with sheet iron.

Important! The amount of heat generated by the unit is sufficient to create a fully functioning distribution of pipes that heat other rooms or spaces.

Gases heated by fire release thermal energy (up to 90%) into the curved pipes of the structure. If you correctly calculate the power of the stove and the area of the room it heats, then you will need to add fuel 2-3 times a day.

Design features and principle of operation

During the development process, a convection-type oven was used, which ensures long-term combustion. The door is made quite large so that users can load large fuel, tree roots, and chopped logs.

The blower has the form of a pipe that cuts into the fuel loading hatch. That is why such a furnace does not use a two-door design. To regulate the amount of air that enters the room, a round damper is used. It has a movable design.

The throttle control lever is moved outwards. Users will be able to decrease or increase the amount of air to control the power level. The firebox has the shape of a cylinder. Heat exchangers made of metal are embedded on each side at the same distance. They have a curved shape.

The firebox space is divided into three parts. You can install a grate at the bottom. It is possible to make stoves without these parts. The upper chamber is used to collect gases. They arise during the combustion of fuel. This is where they are burned. In order for the draft to be good, you need to make a high-quality and high chimney. It must be insulated with thermal insulation materials. Otherwise, the temperature in the afterburning chamber will decrease, so a large amount of tar and other carbon compounds will remain in the flue gas.

Chimney diagram

Computer buleryan

The first buller was calculated almost on a slide rule. Oddly enough, they were the first to figure out how to properly simulate it on a computer and optimize it in Novosibirsk, at Termofor. Now their “Fire-battery” stoves of various sizes are one of the hits on the market. And it’s not surprising: having carefully calculated all the processes, it was possible to place a hot water circuit for DHW and a hob with a burner in the same tank, see fig.

Stove “Fire battery”

The “Fire-Battery” stoves immediately drew a volley of criticism. But here the complaints of the classics of literature come to mind: “All the same petty attacks on the font, vignettes, typos...”

“It doesn’t correspond to my idea of stoves...” Sorry, sir, there’s no arguing about tastes. “Metal stoves are harmful to health.” By whom, when and where was it proven or at least noticed? “Not a stove, but some kind of boiler for a destroyer.” Sir, you flatter the developers. The best minds in heating engineering worked on boilers for destroyers and cruisers. 70,000 kW in a volume of 8 cubic meters. m. with an efficiency of 97% - if this is not perfection, then what is perfection at all?

Instructions for making a stove

To make a heater you need to follow the instructions, do not follow the instructions. Below is the exact algorithm:

The pipe, which is prepared for the convection heat exchanger, is cut into small pieces. They must be the same size. The optimal length is 130 cm. To produce the stove, 8 blanks are taken. Pipe bender helps make a bend

It is important to take into account the radius of curvature. Holes are made in the workpieces. They install pipe sections (diameter 15 mm)

Their length is 20 cm. There should be at least 15 cm left on the outside. Each slot is carefully welded. During installation, two pipes are located next to the door. They will help ensure air injection into the inner chamber. You can make them yourself from a square or round pipe. Curved pipes are laid on top of each other. One by one, the landmark changes in the opposite direction. The structure must be stable, so it is recommended to use slats. Their thickness should be equal to the diameter of the pipe. All parts must be welded together. Additionally, a partition for the firebox is made. For these purposes, steel sheets are used. The partition is installed inside the chamber. The junctions with the main metal sheet are welded with a continuous seam. Gaps occur between the heat exchanger. They need to be sealed using steel strips. They are pre-adjusted to each detail. The furnace body and pipes are welded with a continuous seam. Next, the slag is removed. It is important to carefully check the quality of the weld. You need to take a steel sheet and cut out two shaped parts. They are necessary to form the back and front walls. A small hole with a diameter of 110 mm is cut out on the back wall. It will be used to connect the chimney. The opening in the front wall must have a diameter of 350 mm to create a loading door. You need to take two pieces of pipe and make a T-shaped structure. It will be used to remove combustion products. It is also used to drain condensate. The steel plate is used to make a round gate valve. A rectangle is cut out inside the structure. The rods bend at an angle of 90 degrees. They form a swing arm. Use an electric drill to help install the rod in the central part of the smoke channel. The T-shaped chimney assembly is mounted on the back of the stove using welding.

A blower is made using a similar principle. A spring is used to fix the throttle in the required position. A ring is welded into the front panel, which has a width of 40 mm. Next, sheet metal is taken from which the door is cut out. The optimal diameter is 370 mm.

Method of laying curved pipesPrinciple of air convection

Two hinges and a locking mechanism are welded onto the loading hatch. Next, all the parts, walls and panels, a hatch, and a fixing device bracket are assembled. To ensure air exchange, an injection device must be installed.

First steps

First, we need to make the frame of our entire Buleryan stove - it is an interweaving of curved pipes that form an air heater and the future firebox. Use a pipe bender and bend them to a radius of 225 mm. The length of each pipe is 120 cm - this is more than enough. The pipes are welded together with metal strips to create a stable base for our stove. There should be no holes on the sides, otherwise smoke will penetrate into the heated rooms.

Popular models of Buleryan stoves

Furnaces based on the use of air pipes are produced under two brands: Buleryan and Breneran. The first established production of stoves was organized, oddly enough, not in Canada, but in Germany. Since 1993, stoves began to be produced in Russia. It has become possible to purchase a Breneran stove since 2005. It was this year that the official Russian stove manufacturer decided to rename the Buleryan stoves. This was due to an improvement in the design of the furnaces and an increase in the warranty period to 2.5 years. At the moment, there are many popular stoves of famous brands.

Stove Buleryan

Breneran AOT-14

This model is one of the most bulky, but capable of heating a large room up to 400 m3. The Breneran AOT-14 model weighs 130 kg, respectively. Although it is worth noting that many stoves designed for smaller spaces weigh an order of magnitude more.

The furnace is made of structural steel. Burning time is up to 10 hours. The combustion chamber is designed for 100 liters of fuel. The length of firewood should not be more than 80 centimeters. The chimney is connected to the back of the stove.

This stove is suitable for heating an entire cottage.

Aqua-Breneran

The Aqua-Breneran model is an improved version of the stove, since heating occurs by heating the circulating liquid.

The stove is suitable not only for heating private houses and garages, but is also installed in workshops and workshops. Such a stove is capable of heating a room of 600 m3. True, a complete filling of flammable materials should be carried out every 6-8 hours.

The structure consists of steel and is coated with heat-resistant paint. Unlike classic stoves, it has an additional water tank. The stove has two regulators. One is located on the door and regulates the heat intensity. The second is on the chimney pipe. This is a gasifier regulator.

Aqua-Breneran is an excellent solution for heating the largest rooms.

Breneran AOT-08 type 005

Buleryan type stoves can be used not only for heating a home, but also for cooking. For these purposes, the company has released a line of stoves with a hob.

This is a gas generator stove, which will help out if there is no stove in the room. It is suitable for heating a room of 100 m3. At the same time, unfortunately, it is impossible to combine two functions - cooking and heating the room. In smoldering mode, Breneran AOT-08 will heat the room within half an hour. And during combustion it is worth using the hob. The hob consists of two burners. Food is prepared quite quickly on this device. For example, a 6-liter container of water will boil in 30 minutes.

Breneran-AQUATEN

The AQUATEN model is a unique stove, the analogues of which cannot be found. The stove is similar in its structure to other Buleryanov models, but still has important differences in its design.

The stove pipes are connected to heating radiators through which water flows. The structure of the pipes is the same as in the air versions of the Buleryan stove. Water rises through the drain to the pipes by gravity. The pressure manifold lifts the liquid up to 8 meters.

Just like other Breneran models, AQUATEN has several heat intensity regulators in the oven. The stove is made of high-strength steel, which is protected from corrosion by a layer of special paint.

In winter, if it is not possible to place solid combustible materials in the stove tank, you can use an electric heating element with a power of 1 kW for heating.

Refinement and modernization of the heating device

The design of the Canadian stove is designed to heat one room, since walls and partitions create a barrier to heated air flows. The installation of a metal unit in residential premises greatly affects the aesthetic value of the interior, and the need to throw firewood in the middle of the night so as not to freeze in the morning can hardly be called comfortable operation. Numerous owners of calorific furnaces are trying to solve these and other disadvantages of buleryan. And, I must say, not without success.

Distributing heat throughout the rooms of the house

In order to heat the whole house with buleryan, and not just one room, corrugated pipes are connected to the heat exchangers of the unit, which are led through the wall of the room, and the opening is ennobled with the help of a decorative grille. Of course, the ideal option is when this type of heating is considered at the building design stage. Then special channels are provided in the walls of all rooms to supply warm air. Nevertheless, even in a house built a long time ago, such a scheme can be implemented if you install a calorific furnace in the basement and run air ducts through the floor of each room on the floor. This fulfills the requirement for heat supply at the lower level and ensures ease of maintenance of the unit.

Buleryan, equipped with air ducts, will heat every room in the house

Air heating of every room in the building will require a slight improvement in the design of the buller. First of all, this concerns the air supply - natural inflow will not be enough, therefore, on the bottom side of the unit, collectors are installed on each row of heat exchangers, which will ensure the distribution of air coming from the duct fans. The same collectors are installed at the outlet of each group of air ducts. They will mix air masses coming from parts of the unit with different temperatures. Insulated corrugated pipes are connected to the output manifold, through which heat will be distributed to each room. Since the air temperature at the outlet of the heater reaches 120 °C, when laying pipes through ceilings and partitions, the conditions provided for the installation of chimneys must be observed.

Improving the appearance of the unit using brick or stone masonry

If you cover the Canadian unit with brick, you can simultaneously solve several problems:

- increase the aesthetic value of the stove in the interior;

- ensure safety during operation of the unit;

- increase the thermal capacity of the structure.

A buleryan stylized as a fireplace or Russian stove looks especially advantageous, and if in addition to this the front door is equipped with tempered heat-resistant glass, then such a unit can create a unique atmosphere of comfort and homely warmth, while also performing the main function of heating square meters.

The superstructure, stylized as a Russian stove, turns the potbelly stove into an exclusive heating device

Buleryan, completely hidden in stonework

If you decide to decorate the Buleryan yourself using bricks, for example, for a bath room, then keep in mind that if the height of the loading hatch is less than 40 cm from the floor, it will be inconvenient to heat the stove, and in addition, the design of the structure will suffer. The masonry should be as close as possible to the furnace body, and the gaps between the brick and the furnace must be filled with broken bricks, which are laid on the mortar. Remember - the masonry will act as a heat accumulator, so how long the stove will remain warm depends on its solidity. We remind you that during operation you must ensure that the inlet and outlet openings of the heat exchangers are outside the “fireplace” and that no construction waste gets into the pipes. It is best to cover the heat exchange channels with a rag at this time.

Converting a potbelly stove for liquid fuel

Despite the fact that the Breneran was originally designed as a wood-burning stove, it can be converted to run on diesel fuel or on cheaper fuel - waste motor oil. Of course, this heating method is not suitable for a living space, but it is suitable for long-term heating of a garage or utility room.

To transfer Buleryan for testing you will need:

- place an oil container on a slight elevation;

- extend the liquid fuel supply hose to the unit;

- cut a hole in the combustion door for the tube to which the fuel supply control valve is connected.

In order to convert a buleryan to function in mining, it is enough to install an oil container and a special burner

When using used oil, it is important to ensure good traction and correctly regulate the fuel supply. Sometimes, instead of a homemade dropper, a factory burner specially designed for this type of fuel is installed on the hatch. Unlike a home-made device, an industrial nozzle ensures more complete combustion of waste.

Water circuit installation

As noted earlier, inquisitive minds have more than once modified the classic Buleryan to work in a liquid heating system. At the early stages, DIYers tried to loop all the heat exchangers into one circuit. The result was a coil, through which water circulated thanks to the use of a centrifugal pump. Later, a scheme was proposed that was similar to the previously described design for upgrading the unit to distribute air flow throughout all rooms in the house. The upper and lower sections of the heat exchangers were welded into cylindrical collectors, connecting the lower element to the return line, and the upper element to the supply pipeline. Thus, it became possible to install the unit not only in heating systems with forced supply of coolant, but also when using natural circulation of liquid. By the way, the disadvantage of buleryan, associated with the impossibility of working on high-temperature fuel such as coal, is eliminated by itself - thanks to its high heat capacity, water does an excellent job of cooling the walls of the unit.

Buleryan with a continuous water jacket

As for making buleryan “from scratch,” the process is even simpler. Instead of making a frame from heat exchanger pipes, the body of the furnace is made entirely of sheet steel, resulting in a unit of the correct cylindrical shape. On top, the structure is wrapped in another cylinder, which serves as a water jacket. Since the lower part of the potbelly stove heats up weakly, the stove must be moved downwards relative to the casing. In order to make the most of all the heat, some craftsmen manage to install a water circuit at the exit of the smoke channel. In the photographs you can see all the nuances of the described metamorphoses.

Shifting the furnace body down relative to the water jacket allows water to be heated more efficiently

If we take into account that pyrolysis combustion of exhaust gases should occur in the vertical channel at the outlet of the buleryan, cooling this section of the chimney contradicts the very principle of operation of the stove, and therefore is hardly correct.

How to install correctly

To connect the stove with your own hands, you need to prepare a non-combustible base that will protrude 300 mm beyond the perimeter of the stove. A structure of four rows of bricks laid flat is suitable. A clay solution is used for the connection.

Sometimes a structure of metal pipes up to 300 mm high is made as a stand. A sheet of metal 500x700 mm must be placed in front of the stove.

You also need to maintain a distance from the walls. Its size depends on the material from which the wall is made. For example, when using unplastered wooden surfaces, a setback of at least 1000 mm is required, for single brick masonry - more than 500 mm, for double masonry - more than 300 mm.

For a concrete structure, the minimum requirement is 60 mm. A metal chimney is also possible. The pipe is installed with a height of at least 4 m and a cross-section of 120 mm.

The chimney can be vented through the roof or wall. The first option requires correctly guiding it through the ceiling and roof with a minimum height above the ridge of 500 mm.

The Buleryan stove is a fairly effective and safe way to heat residential and industrial premises. You can select the desired modification of the unit depending on the temperature requirements and taking into account the layout of the house.

And to heat several rooms, it is enough to build air ducts and a heat chamber or purchase a model with a water circuit.

Drawing

Now, apparently, it’s worth clarifying what this wonderful barrel, hugged by pipes, consists of. Buleryan, the drawing of which, nevertheless, folk craftsmen were able to recreate, is not so complicated. This technologically advanced “potbelly stove” has incorporated some elements of different stoves: The main firebox, additional space for afterburning gases formed during the primary combustion (or rather, combustion-smoldering) of fuel.

Next, the main elements include the main heat exchange elements - arc-curved pipe sections. The main process of convection occurs in them. Pipes, as a rule, are immersed in the firebox with two-thirds of their diameter. At the same time, they are part of the walls of the firebox and are in direct contact with the heat of the flame. There are options for fireboxes with a grate, when they want to add protection against burnout to the walls of the heat exchanger.

The upper part of the firebox, separated by a horizontal plate from the lower part, allows the gases to be burned when additional heated air enters there. It comes through injectors. The location and place of insertion into the furnace may vary slightly.

The classic version of the buller has a door with a blower, equipped with an air supply regulator, a throttle and an ash pan. Options can be with conditional graduation of air supply, fire-resistant glass, eyes for controlling gas afterburning and other differences. At the outlet, the chimney is necessarily equipped with a damper with a guaranteed open sector of a quarter section. This ensures reliable removal of carbon monoxide, except in cases of obvious emergency.

Buleryan in section

Chimney pipes must be equipped with thermal insulation, as this is decisively important for this type of stove. Original products, originally from Canada, are equipped with an economizer. It is mounted immediately after the first bend of the chimney, on its vertical part, and also participates in the afterburning of gas generation and oxidation products. Quite importantly, this increases efficiency and helps gases leave the chimney faster. Not to be confused with additional heat exchangers that are installed on the chimney to heat water or simply for additional heat-calories, in reserve. There are also so-called heat accumulators. The chimney, or rather its vertical part, must be of sufficient length, depending on your structure. On average it is about five meters. But you should not install the chimney lower; this length will not provide the required draft.

Advantages and disadvantages

Many homeowners sympathize with Breneran heaters and there are reasons for this:

- very fast heating of the room.

- burning duration is from 8 hours.

- practicality and safety, installing a Buleryan stove in a house or greenhouse is one of the best heating options.

- When installing, the unit only needs to be connected to a good chimney, and the installation of Buleryan consists of placing it on a level area.

As for the cost of such heating devices, their prices are somewhat higher than simple metal stoves, so Breneran cannot be called the most affordable option. There are other disadvantages:

- the design of the stove is quite simple, but difficult to manufacture; doing it yourself often does not make sense;

- You can’t burn any kind of fuel in it, you need large logs and only wood (not coal!);

- Due to the low temperature of the gases, condensate flows down the chimney, so the pipe will have to be calcined in maximum combustion mode.

Advantages

- Even the largest areas are heated quickly and evenly.

- Heat is easily transported throughout all floors of the building.

- The stove, despite its extensive properties and power, has quite compact dimensions.

- The stove is simple and convenient to use, and with careful and correct approach it can last for a very long time.

- Installs quickly.

- Breneran with a water circuit is fuel efficient. Firewood can be loaded once every 12 hours.

- Thanks to autonomous wood burning, no gas or electricity is consumed to heat the room.

- After burning, there is practically no ash left, so servicing the device itself does not take much time.

- The user controls the heating process independently.

Buleryan stove design options

- The usual type used for heating a room

. Its design includes a compartment for loading firewood, pellets or granulated fuel. After combustion of this material, the air heated inside it exits through the upper tubes to the outside. - Option with heated water

. The oven has a water circuit. To operate this type, it is necessary to install a special device that distributes heat. Buleryan of this type is mainly aimed at heating water, and only 10% of its power works for heating the room.

- garages;

- workshops and utility rooms;

- production workshops;

- saunas and baths;

- dachas and country cottages, even their wooden varieties;

- greenhouses;

- public institutions located outside the city.

Buleryan can provide rapid heating of the room due to convection heat exchange, economically using the supply of firewood.

Water circuit

To increase the efficiency of the furnace, many choose to add an aqua circulation system to it, through which the coolant moves. As a result, new devices appeared for organizing a water heating system - “Breneran-Aquaten”, “Aqua-Buleryan”.

Buleryan with a water circuit for heating also uses the convection principle of operation, however, instead of air, a liquid coolant is used, so it is easier for heat to penetrate through the partitions.

The peculiarities of this device are that inside the casing there is a combustion compartment, which is tightly fitted with pipes with liquid, due to this heat is transferred faster. The pressure in the system is provided by a special pressure manifold, capable of raising the coolant by 8 m. Due to its heating, natural circulation occurs, and due to the gas generation process, the Breneran-Aquaten furnace is more productive and consumes less fuel.

Scheme for using the oven

In other words, the furnace operates due to the fact that the coolant rises to the maximum height and is distributed through the pipes, then it returns again through the return line. On it, other circular equipment and a drain valve are installed. This entire design makes the system operate as efficiently as possible.

In the furnace structure itself, 70% of the entire combustion section is allocated to the water circuit; accordingly, the water is heated quickly and evenly without noticeable heat loss. There are no temperature or pressure differences.

Advantages and disadvantages of the Canadian stove

Essentially being the same “potbelly stove,” Buleryan has a special charm and charm, doesn’t it?

The specifics of using the Buleryan stove initially required compliance with several mandatory requirements, which subsequently made the unit famous throughout the world. The design of the heating device had to ensure:

- Mobility. Since cutting down trees involves constant movement through the forest, the logger’s stove is constantly transported from one place to another, and from transport to room is carried by hand.

- Compactness. The unit must have a configuration and dimensions that make it possible to install the device in small temporary buildings.

- Safety. Since the operation of a buleryan involves installing a heating device directly in a residential area, its design must exclude the possibility of carbon monoxide leakage. This was made possible due to the sealed working chamber and the decision in favor of a single-door design. Another important plus is that the configuration of the body prevents the body of the furnace from accidentally touching the hot metal.

- Performance. Using forced convection makes it possible to warm up a room in record time. This condition is met thanks to a system of channels that accelerate air exchange.

- Possibility of long-term work. The configuration of the working area and the design of the blower allows the Buleryan to work for several hours from one load of fuel, and firewood, bark, chips, shavings, etc. can be used as fuel. It is not recommended to heat the stove with coal, since due to the high combustion temperature of this fuel, metal the housing overheats and becomes deformed. As a result, the geometry of the device is distorted, the combustion door does not close, and cracks in the places of welded joints.

- Simplicity and reliability. When developing the design of the solid fuel unit, engineers took into account that it would be operated in places remote from civilization. To manufacture or repair a Canadian potbelly stove, no special equipment or expensive materials are required, and for a beginner to operate the stove, a little instruction is sufficient.

As you can see, the advantages of Buleryan were incorporated into the design at the design stage. Perhaps the developers had no idea that their brainchild would become so popular and would be used both in everyday life and in production. Of course, like any other design, a convection oven of this type is not without some disadvantages. First of all, the unit achieves its declared performance only when using absolutely dry firewood. When the fuel humidity is more than 10%, the released water vapor prevents the flow of air and reduces the combustion intensity, which leads to a decrease in efficiency. In addition, like any potbelly stove, the Buleryan does not retain heat at all - as soon as the fuel burns out, the temperature in the room begins to drop.

The model range of Buleryan type furnaces contains many types, differing in power and configuration

The disadvantages of the design include the fact that the operation of the stove assumes a gas-generating mode of operation, in which the wood smolders more than it burns. This process is accompanied by increased smoke formation, which leads to the release of harmful substances and tar deposits in the smoke channel. Often the outer part of the chimney and nearby areas of the roof are coated with an oily substance, which does not add any attractiveness to the picture at all.

It is also important that when installing a stove, additional requirements are put forward for thermal insulation and the height of the chimney, otherwise its efficiency will be reduced.

As you can see, the unit is not without its shortcomings, which both the developers and the owners honestly point out. Nevertheless, the numerous advantages of Buleryan have made this heater one of the most popular units on the market of compact solid fuel equipment.

Varieties with photos and geography of use of buleryan

In order to understand the difference between buleryan, breneran, buller, Butakov oven and other types of convection ovens, let’s take a closer look at all the nuances. First of all, o is a brand of the German company Bulerjan, which produces super-bourgeois stoves. Ovens of this type are often called the shorter word buller. “Breneran” are the same units, but produced by domestic factories under license. The furnace developed in Russia by Professor Butakov is very similar in operating principle to the original design, but has some differences:

- recessed convection heat exchangers;

- cubic body shape instead of cylindrical;

- the use of an ash pan and grate;

- flat platform at the top of the cabinet for heating food.

In fact, the use of a grate in a gas-generating unit is unnecessary, since intensive burning of wood is expected only in the first minutes after ignition. In addition, its purpose is unclear, given that it is located below the level of the blower. There are also doubts about the effectiveness of the platform for installing a pot or kettle. When entering operating mode, the temperature of the buleryan rarely reaches even 75 ° C, so it will take a lot of time to warm up the food.

Butakov's stove is a modernized Buleryan

Despite the fact that the heating device was originally designed as a stove with an air heat exchanger, some craftsmen loop convection channels by connecting them to a water heating system. The resulting aquabuller, of course, has the right to exist, but the feasibility of such a solution is questionable. Firstly, the heat capacity of air is 800 times less than that of water, so a furnace designed for convection will operate with reduced efficiency under liquid heat exchange conditions. Secondly, even if we take Breneran as a long-burning unit, this is also irrational, since there are more suitable specialized designs of solid fuel boilers that use pyrolysis. Despite this, aquabullers have found their place in the line of units, which are a modernized buleryan.

The water jacket turns the convection oven into a water heating boiler, which is called an aquabuller

To retain heat from a potbelly stove longer, owners use various heat-storing devices that are installed on convection pipes. In addition, buleryans are often wrapped in brickwork, creating a kind of fireplace with holes for warm air to escape on the sides. This option looks good in a country house. According to the owners, the symbiosis of the buller with a brick stove allows you to keep the room warm for up to 8 hours, which is quite enough for comfortable living in the winter.

Despite the fact that the calorific furnace was originally developed for domestic use, currently buleryan is widely used in all areas of economic activity:

- for heating dachas and country houses, including wooden ones;

- in production workshops;

- for heating utility rooms;

- in garages and workshops;

- in baths and saunas;

- to maintain the required temperature in greenhouses;

- as heating units for country cafes and restaurants;

- for heating administrative buildings in rural areas, etc.

The classic buleryan stove is not suitable for heating tents.

When installing a buleryan, be sure to take into account the power and dimensions of the heating unit, since this determines whether the device can evenly heat the entire room. It is equally important to choose the right place to install the Canadian stove, equip the chimney according to all the rules and ensure its regular maintenance.

Convection unit installation diagram

Advantages and disadvantages of the Buleryan stove

This design has certain advantages:

- the air in the water heats up very quickly;

- heated air can flow through metal air ducts to different rooms of the room;

- the design is easy to install and operate;

- with proper operation, the efficiency of the furnace reaches 80%;

- When fully loaded with fuel, it lasts for 10 hours of combustion.

Disadvantages of the Buleryan stove:

- Only wood is used as fuel;

- most of the generator gas goes into the pipe;

- the chimney must be insulated, regardless of the material;

- When installing a stove, a lot of free space is required: the distance from the wall to the stove should be at least a meter;

- dust constantly burns on the surface of the structure;

- the pipe is brought to a height of 3-5 meters from the surface so that the stove does not smoke due to incomplete combustion of the fuel;

- During operation of this structure, condensation often appears in the chimney, which, when heated, releases an unpleasant odor into the room.

https://youtube.com/watch?v=CW3h3NpJwRk

Helpful operating tips

“Incorrect” installation of chimney pipes is due to the need to protect the structure from resin, which is formed as a result of the combustion of wood. If this moment is not provided for, then the resin will flow out of the stove, and with such an installation it will remain in the chimney and gradually burn out.

Upon completion of assembly, the Buleryan stove is installed on a flat and fire-resistant base and connected to the chimney. In this case, it is necessary to comply with fire safety rules

Clogging with resin for the Buleryan stove is almost inevitable. Over time, resinous layers accumulate and clog the device. This is expressed in a noticeable reduction in the efficiency of its operation, a decrease in traction, and problems with the free movement of the gate. So it's time to start cleaning the oven.

A lightweight version of this cleaning is to heat the device with aspen firewood. Unfortunately, the practical benefits of such a measure are small and short-lived.

The best way to eliminate resin contamination is by burning. To do this, the stove is heated strongly with the ash pan open, essentially calcining all the channels. As a result, the resinous deposits burn out.

Based on the Buleryan stove, you can organize an autonomous heating system:

Image gallery

Photo from

Burelyan as the basis for autonomous heating

Air heating basis

Connecting their corrugated air ducts to the furnace pipes

Water heating device

Some craftsmen use oxygen to burn the furnace, bringing the nozzle of the cylinder to the opening of the ash pan. This is an extremely dangerous operation that violates fire safety regulations. Careless handling of an oxygen cylinder near an open flame may cause an explosion.

As fuel for the Buleryan stove, you can use not only firewood, but also wood waste (shavings) or special briquettes. An important condition is low fuel moisture. The less moisture, the less resin is formed inside the stove, and the less often it will have to be cleaned.

During operation of the furnace, you need to select an operating mode in order to obtain maximum heat with minimal resin formation. If the best option is found, cleaning will only need to be done a couple of times during the heating season.

Conclusion

The heating system of the building using a long-term combustion furnace, called Buleryan, involves saving fuel while providing high-quality heating of the air inside the building. Such stoves are very effective in country houses, garages, greenhouses and agricultural buildings. They are quite safe to use. But the main advantage of these heating systems can be considered that the manufacture of a Buleryan stove is possible at home, without the use of complex technologies and expensive materials.

What will you make buleryan from?

Profile pipeGas cylinder

Checking the welding machine

The main tool in the manufacture of a furnace is a welding machine. First you need to make sure it is working properly. If you have minimal experience in such work, we recommend that you first practice on training seams. At the final stage of assembling the stove, you will have to scald it around the entire perimeter. You need to be prepared for this. In addition, do not forget to check the metal and pipes for weldability. Materials may need to be replaced.