What is a long-burning stove, where is it used, its advantages and disadvantages

A long-burning furnace is a heating structure equipped with an additional chamber for combustion of the gas emitted by the fuel. In such a furnace, the combustion process of the combustion material slows down, as a result of which the room is heated in a period from several hours to a day and a half.

Under the influence of constant temperature, the fuel in the furnace breaks down into wood coke and pyrolysis gas. When interacting with oxygen, the gas begins to burn more intensely, releasing a large amount of thermal energy, sufficient not only for heating, but also for heating water.

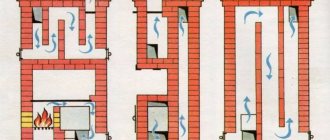

Long-burning stoves are equipped with an additional chamber for combustion of gases

Long-burning furnaces differ from traditional designs in that they require a dosed supply of oxygen not from the bottom, but from the top.

Long-burning stoves are used for heating country houses, private households, garages, workshops, basements, chicken coops, barns and other outbuildings and residential buildings. Depending on the size and modernization of the design, these heating structures are also used in industrial premises.

In common parlance, these heating structures are also called long-burning stoves.

These efficient heat sources have gained great popularity due to their functional qualities. However, such furnaces have a number of both positive and negative criteria.

Initial stage of furnace construction

It is necessary to understand what types of furnace drawings there are and how they are created. It is important to realize that we are talking about the design plan of the product. Without it, you cannot assemble, since you can miss an important part or assembly, which may later turn into, at best, an ineffective homemade product. And a waste of time.

It is important to decide for what purpose you plan to build a stove for your home. Some simple owners suggest that you can sleep on it, as they did in ancient times. But you will have to surprise this category of homeowners.

Types of long-burning stoves and their choice for self-production

These stoves are usually made of bricks, metal or stone. They can be round, cylindrical, square or irregular in shape. Depending on their design and method of burning fuel, long-burning furnaces differ in types.

Classic long burning stove

The design in which the flame spreads from bottom to top, pushing burning gases through layers of combustion material, is classic. This type of furnace is equipped with a heat exchanger and an afterburning chamber into which an additional portion of air is supplied. Prominent representatives of this type are long-burning furnaces: Buleryan (Breneran), Butakov furnace, as well as modified designs with different heat exchangers.

In Buleryan furnaces, the role of a heat exchanger is played by curved pipes located inside the furnace body

Long burning shaft furnace

Another type of such structures is a shaft furnace. In this design, the combustion zone is shifted to the grate part. The products of fuel combustion are discharged through the adjacent compartment, in which they burn out, creating heat exchange. This type is best built from brick, which has been confirmed over many centuries.

In shaft-type furnaces, the combustion zone is located directly above the grate

Hearth oven

This is a top-burning design in which the upper part of the combustion material is ignited, and the direction of fire is in the opposite direction. Such a device requires oxygen supply under the burnt layer, so the furnace must contain special air delivery channels. Simplicity of design combined with efficiency and functionality has led to the creation of many DIY options. In this case, the material for its manufacture will be used cylindrical containers. A striking example of this type of heating units is a stove called “bubafonya”.

You can use an old gas cylinder as a body for a homemade stove.

Gas generating furnaces

Gas-generating furnaces or structures with additional combustion of pyrolysis gases. In this design, the combustion material burns under the influence of two factors: high temperature and a small amount of oxygen. This leads to the release of flammable gases, which burn out in the additional chamber. The designs of this type of furnace are the most complex to manufacture, but their efficiency and ease of use are superior to previous options.

Pyrolysis gases burn out in an additional chamber above the firebox

The Burelyan stove is considered a hybrid of a potbelly stove and a long-burning wood stove. In our next material you will find a description of the operating principle of this unit, as well as step-by-step installation instructions:.

Features of operation

Wood-burning stoves are quite unpretentious in operation. Just know, add solid fuel and enjoy the warmth! The only thing you need to watch out for is that the stove doesn’t leak and starts leaking smoke into the room.

When lighting the fire, do not close the vent at first so that the fire can burn better. But when the flame is already actively playing in the firebox, you need to close all the oven doors tightly.

At the end of the installation, the damper is usually closed - this is done to prevent heat from leaving the stove through the chimney pipe.

Furnace design, its features and operating principle

Before you start making your own stove, you need to carefully study all the characteristics of the device.

If you plan to make a unit for heating a large room, then the stove must have high heat output. For example, for a house or room with an area of 150 m², you should choose a stove designed to heat up to 200 m². This “reserve” of power is necessary to be completely sure that every corner of the house will be warm.

It is also necessary to take into account that not every room is adjacent to a heat source, so heating it will require more time and power from the heating device.

If it is intended to heat a room with an area of 30–50 m², then the stove can be made without the specified “reserve”. In such a small room, heat loss will be minimal, so a unit with low power is sufficient. Automatic fuel refueling will greatly simplify its maintenance. When making such a stove, it is possible to provide hobs for cooking on its body. If the stove is not only a source of heat, but also an interior item, then its body can have windows made of fireproof glass.

Design features of long-burning furnaces

Long-burning heating devices have design features that distinguish them from other stoves:

- the combustion chamber has a volume for loading a large amount of combustible material;

- the body of long-burning stoves is equipped with a large door;

- the combustion compartment in the furnace body is divided into two chambers; one chamber is intended for smoldering flammable material, the second for gas combustion;

- the design of such a stove provides for the presence of a special bumper that prevents flame from entering the chimney;

- This element of the furnace frame is made of a metal plate, which is welded into the upper part of the combustion compartment.

Differences between a conventional and pyrolysis oven

To understand the operating principle of a long-burning stove, you need to compare it with the operation of a conventional stove.

The work of a conventional stove is to heat its surface and transfer heat to the room. The combustion material is ignited from below, causing the flame to spread to the sides, heading upward. This occurs due to the access of a large amount of air into the combustion chamber. The fuel in such a stove burns quickly, which is why the air temperature in the room is unstable - it either drops or rises.

The operating principle of a long-burning furnace is different. The firewood is ignited from above, and the fire spreads downward, while air is supplied only to the burning site. As a result, the material smolders, releasing heat evenly over a long time. In addition to the combustion material, pyrolysis gas is released, which also serves as fuel, additionally creating heat.

In a conventional furnace, fuel burns quickly, in a pyrolysis furnace it smolders slowly

To make stoves, you can use almost any available means. In our next article you will learn how to make a long-burning potbelly stove from a barrel: .

Making a furnace firebox for a bathhouse from metal

The installation of the firebox must be carried out in accordance with all standards. The foundation for the firebox is a very important element. The reliability of the base determines the duration of its use, which can range from several months to decades. The firebox itself does not look quite aesthetically pleasing, so it is decorated with fireplace tiles. There are a lot of variations on how to make a firebox for a bath.

For the frame you will need a sheet of steel with a thickness of at least two millimeters; you can also use a chylous barrel, but with additional fastening. The sheet is divided into several sections for the firebox, tank and heater.

The remainder will be needed to make the ash pan and door. Corners or plates will be welded along the length where the grate will rest. It is best to purchase it in a store.

Making a heater

This type of stove is called a heater because it consists of individual stones. When fuel burns, the stones heat up, and the water that ends up on them forms steam. First of all, you need to choose the design and dimensions of the mechanism for heating the water. For the heater, the rods are attached by welding. Since it is heavy, the rods or square must be at least 10 millimeters.

A door is cut into the heater to transfer water to the stones. In this case, the heater door must face into the steam room, and the firebox must be placed opposite the entrance. The stones are distributed into the heater with some clearance, not closely. It is a good idea to use stones with small crystals of small size. It can be diabase or just chlorite.

Stones containing mica are prohibited; it promotes the release of carbon monoxide, and this is harmful to life. You need to attach a metal chimney cover above the heater, and then install a water tank.

Creating a tank for heating water

The most practical method of heating water in a bathhouse is to use heat from the stove. There are several ways to install a tank for a sauna stove, the main thing is the location of the tank, it can be: internal, mounted or remote.

To design the tank, three versions of the material are used: cast iron, stainless steel containers or stainless steel. To make an iron barrel, you need to carry out a number of actions.

First you need to cut the desired piece of pipe. The cutting areas must be carefully processed. Then you need to start installing the bottom and top lid of the container. The next stage is soldering all the cut parts. Afterwards you need to install a tap and pipes, as well as a heat exchanger for the sauna stove. Then the installation of the module is carried out.

Assembling a sauna stove with your own hands from metal

They prefer to build the stove supply for the bath separately. This is due to the fact that it is possible to create exactly the model of the stove that you wanted. Then, to make a metal sauna stove with your own hands, you will need blueprint reading skills, construction tools and materials. First you need to draw up a project and determine the dimensions of the device.

There are 2 design options for homemade stoves, these are the horizontal and vertical versions. To make a stove you will need:

- a rod ten millimeters thick;

- sheet steel, 8 mm thick;

- iron pipe;

- latches;

- water tap;

- two meters of pipe.

We take a large piece of pipe and cut out an opening in it for the blower. In the middle of the pipe, on the side of the opening, we weld fastenings for the grate. Then we equip the firebox, for this we weld fastenings for the heater rods. On the back side of the heater we cut a hole through which steam will flow. We fill it with stones suitable for this type of unit.

We cut a hole in the roof for the stove for the chimney pipe and install it. And don’t forget to cover the sauna stove with useful material to create a classic stove. It’s not difficult to build the device; just follow the instructions.

Necessary equipment for work

Installing a sauna stove is an important matter, the correct operation of which depends on the correct organization of the installation. Initially, you should choose a place to place it. It is also necessary to adhere to fire safety rules.

According to standards, the distance between the stove and a flammable wall must be at least 25 centimeters. First you need to determine what kind of stove you decide to install. The next stage is drawing up a plan and counting the necessary material.

To assemble a homemade stove, you will need tools: a grinder, metal scissors, a welding machine, a variety of measuring and marking kits. You will also need material. The step-by-step manufacturing process can be seen in the video presented in this article.

Making a heater stove for a bath from a metal pipe

A do-it-yourself sauna stove made from a pipe is the easiest and most economical option for furnishing a room. A similar design will work well in every room. Thanks to the sealed housing, the stove made from 530 pipe will not emit carbon monoxide when active, so it is completely safe. A pipe bath can be made in two types: a horizontal and a vertical model.

This type of furnace significantly reduces the number of welding steps. In order to obtain an improved stove, only high-quality tubes are used, without corrosion. The workpiece should be cut into two parts, a longer section is needed for making a firebox and heater, and the remaining piece is suitable for constructing a tank. First you need to start making a pod.

A hole is cut at the bottom of the pipe, and a strong round-shaped plate is welded above it. Then we make a firebox and a door for it. We hang the door on a loop or hooks. A piece of pipe is welded above the firebox, which will be used as a heater.

Material for a metal stove in a bathhouse

Making stoves is an interesting and labor-intensive procedure. There are many types of metal stove models. The main task is to create a structure that is strong enough to prevent deformation and high thermal conductivity. For the manufacture of the mechanism, different materials are used: cast iron, steel and heat-resistant steel. The most common manufacture is steel.

This matter tolerates temperatures up to 400 degrees. The thickness of steel starts from 4 millimeters, but the disadvantage of the material is that it quickly burns out. The next material used is heat-resistant steel.

The minimum metal thickness is 3 millimeters. The stoves are made from the safest material, efficient and easy to install. Another material for forming metal sauna stoves is cast iron. It is not inferior in strength to steel, but at the same time its heat capacity and fragility are comparable to ceramics.

Installing a stove in a bathhouse

Precisely installing a stove in a bathhouse with your own hands is a responsible procedure, since the comfort and safety of its operation will depend on this.

In order for the steam room to warm up effectively, you need to select the location of the stove structure. By following all the rules and regulations for the placement of the heating medium, you will not have to worry about altering the bath unit for many years.

First of all, you need to calculate the dimensions of the device for the size of the high-temperature room, because the roof and interior decoration can burn, smolder, or melt; to prevent this, you need to choose the correct placement of the stove. You should also take care of installing a hood for a sauna stove, and do it yourself. It should be placed 50 centimeters from the wooden covering.

If it is protected by a metal screen, the distance can be reduced. The partitions opposite the firebox may not be insulated. The gap from the ceiling to the top cover should be 1.5 meters.

There must be unhindered access to the elements of the furnace structure in case of an emergency. You also need to plan in detail the ventilation system in the steam room, and think about the release of combustion products. When installing a brick kiln, you need to create a solid foundation, and place light metal structures on a non-combustible floor base.

Required materials and tools

To make a long-burning stove, you will need the following materials:

- metal barrel for fuel and lubricants with a capacity of 200 liters; as an alternative material, you can use a steel pipe with a diameter corresponding to the drawing or an empty gas cylinder with a capacity of 50 to 100 liters; You can also use sheet steel with a thickness of 3 mm or more;

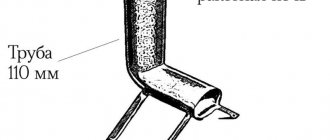

- to make an air supply channel you will need a pipe with a diameter of at least 50 mm;

- for the chimney a piece of pipe with a diameter of 100 mm is required;

- a steel channel or a section of an angle with a flange width of 55–65 mm;

- for the air distributor you will need a metal sheet of at least 3–5 mm, with a diameter slightly larger than the circumference of the housing;

- to make the lid you will need a steel sheet with a thickness of at least 3–5 mm;

- metal hinges for the door;

- if the furnace body is equipped with a water circuit, then sheet steel and two threaded pipes will be required.

The tools you cannot do without when making such a stove are:

- welding machine, electrodes;

- Bulgarian;

- file;

- electric drill;

- metal drills of various diameters (including core drills);

- hammer;

- an anvil or other stable hard surface;

- yardstick;

- building level;

- pencil.

How to fold a modern stove

It is not difficult to build a stove with your own hands, since its design is simple, but allows you to achieve the highest performance and efficiency. The body of the heating unit includes a firebox and a chimney. If it is planned to install a cooking stove, then it is necessary to have a stove, and sometimes an oven or a special tank for heating water. Main components:

- Firebox

. When you create a stove in your home with your own hands, this element is one of the main parts of the heating unit. It should accommodate the maximum volume of firewood or other fuel to ensure the greatest performance of the structure. The size of the firebox can be different, since this parameter depends on the type of solid fuel (for example, for firewood, the height of the chamber ranges from 40 to 100 centimeters), volume, and productivity. The firebox is laid out exclusively from refractory bricks, and the thickness of its walls should be at least half a brick. - Ash pit

. This chamber is equipped with a door and is located directly under the grate. It is designed to collect ash and supply air to the fuel. The height of the ash pit is equal to three bricks. - Chimney

. One of the main elements that are found in every modern brick oven. Outwardly, it is similar to a coil through which flue gases move, heating the air in the room. When creating a stove for heating a house, such as in the photo, when designing a chimney for a modern heating structure, experts do not recommend including a large number of turns and bends, since they create additional resistance to the movement of flue gases, resulting in a decrease in the efficiency of heating the room.

Calculation of basic parameters

A long-burning solid fuel stove can be made from available materials, such as a used gas cylinder, a piece of large steel pipe or a metal barrel. You should select a material with a wall thickness of at least 5 mm. This is due to the fact that a thinner casing will burn out after some time.

Option of the “Bubafonya” stove with a water jacket

Furnace size

In the absence of any drawings and diagrams for the manufacture of the furnace, you can make all the necessary calculations yourself.

Calculation of parameters in the Bubafonya furnace

In this case, it would be more accurate to talk about its diameter - D and height - H. These values should be proportional to each other, where a ratio in the range from 1:3 to 1:5 is considered optimal. The height of the stove is usually made at least 100 cm, since this parameter is directly related to the duration of operation of the unit. However, it is not worth making a structure that is too high, as it will be inconvenient to load it with firewood. It can also negatively affect traction. It can drop so much that the maintained flame inside the combustion chamber goes out.

As numerous thermal engineering studies have shown, you should not make a stove with a small diameter. From this narrow unit, the air will simply be drawn into the chimney pipe, causing the stove’s power to significantly decrease.

If you make the stove frame too wide, then there will be no uniform burning of the fuel near the inner walls of the chamber and in the middle of the hearth. In this case, only the central part of the combustion material will burn out. The metal circle of the piston will sag and clog the fireplace, causing the flame to go out. The optimal diameter of this design is from 300 to 900 mm.

Thickness of material used

This criterion must be taken into account, since the thin walls of the housing will burn out after some time. In this regard, it is necessary to select a material with a thickness of at least 5 mm. This is especially important if you plan to equip the frame with a water jacket, turning it into a boiler. In the image, the wall thickness is indicated by the symbol Δ.

If you use material with a wall thickness of up to 4–5 mm, this risks causing the oven to lose its power. Due to the thin walls of the housing, the temperature above the piston plate will drop. As a result, the afterburning of pyrolysis gases will be reduced, and therefore the heat generated will be reduced.

However, for heating small spaces such as a garage, shed or small workshop, the thickness of such material is quite acceptable.

Parameters of a metal pancake

For efficient operation of the furnace, not only the diameter of the round plate on the piston is important, but also its thickness. After all, the metal pancake is a partition and at the same time a heating surface for igniting pyrolysis gases.

When making a metal pancake, you should adhere to the optimal size. The distance from its outer edge to the inner wall of the oven should be 5%. In the image, this gap is indicated by the formula C=5%D.

The diameter of the metal pancake should be slightly smaller than the internal diameter of the oven body

Outlet pipe parameters

In the image, the diameter of the chimney pipe is indicated by the letter S. It is recommended that its diameter be at least 80 mm.

Air supply pipe dimensions

In the diagram, its diameter is indicated by the letter d. To design such a furnace, you can use a 75 or 80 mm pipe. The pipe must be welded to a metal circle (into its hole in the middle). The result is a part called a piston.

Another option for a long-burning stove is Bubofonya. Description of the operating principle, calculation of materials, as well as step-by-step installation instructions in our article:.

Types of stoves by shape

Do-it-yourself metal sauna stoves can be in the following shape:

- curly;

- rectangular;

- horizontal;

- cylindrical.

Rectangular installations are considered the most popular because their corner zones do not heat up to very high temperatures. The shape of the device is directly related to the uniform heating of both the installation itself and the room. Cylindrical and round shaped units have the lowest degree of heat transfer, so fairly thick iron is used for their production. Rectangular structures are distinguished by enviable stability, but have cold corners.

Preparatory work and choice of location for installing the furnace

If the furnace is made of sheet steel, then it is necessary to cut it into blanks in accordance with the drawing:

- cut identical fragments from the corners that will serve as a grate;

- you can also use metal corners to make stands and handles for the case;

- It is also necessary to cut the pipes in advance.

The location for installing the long-burning stove is selected with the condition that when assembled it is not installed closer than 100 cm to the wall.

Since the furnace body will be completely heated, it is necessary to take care of the insulating material in advance. To do this, you can build a stand from brick, which should be 30 cm larger than the base of the case. Alternatively, you can weld steel rods or angles to the stove frame.

At the installation site, from the side of the door into the combustion chamber, it is necessary to lay insulating material. As such, a basalt or asbestos layer is used, on top of which a steel sheet with an area of 100 cm is placed.

The walls next to the stove must be lined with insulating material

Drawings and diagrams

The undoubted advantage of the long-burning “potbelly stove” design presented above is its undemanding size. As a rule, for the stove to operate correctly, knowledge of the principles of its operation and compliance with the basic proportions is sufficient. However, we present to your attention drawings and diagrams of existing structures, manufactured and tested in real conditions.

Drawing of a vertical loading oven

Drawing of a long-burning boiler

Diagram of a long-burning furnace with an open air channel

Boiler drawing

Do-it-yourself long-burning stove: diagram and step-by-step instructions

The most common materials for making long-burning stoves are metal and brick.

Making a “bubafonya” stove from a gas cylinder

For making your own “bubafonya” stove, a used gas cylinder with a volume of 50 liters is best suited. The order of work is as follows:

- Cut off the top part of the cylinder at the place where the body is rounded using a grinder. This fragment will serve as a cover in the future design.

The top part of the cylinder can be conveniently used as a stove lid

- Weld a metal strip to the upper edge (at the cut point of the future lid). This side will prevent the lid from sliding off.

- Next, it is necessary to make a pressure piston, thanks to which the combustion material will be pressed during combustion. Cut a circle from a thick steel sheet with a diameter slightly smaller than the body. The circle should fall freely inside the cylinder. The gap between the housing wall and the circle should be 8–10 mm wide.

- Drill a hole with a diameter of 100 mm in the middle of the circle. It is convenient to do this using a core drill.

- Take a pipe with the same diameter and weld one end to the middle of the circle. The result is a part with a common hole.

- Then weld four sections of channel in a cross pattern to the back side of the circle. They form unique channels through which air will flow into the combustion chamber.

Instead of channels on the piston, you can use angles

- Weld the handles and stands.

- Clean sharp and protruding welding fragments with a file or grinder.

Video: how to make a “bubafonya” stove from a gas cylinder

Making a long-burning stove from brick

Of course, in comparison with a homemade metal structure, a brick oven looks more advantageous. However, making it yourself is a labor-intensive process that requires certain skills and time.

There is a hob above the combustion chamber for cooking

Foundation preparation

Since the brickwork is quite massive, the stove definitely needs a solid foundation. The depth of the foundation must ensure the stability of the structure. The foundation is prepared as follows:

- First you need to dig a small pit 30 cm deep. Its width and length should be 10 cm larger than the expected dimensions of the stove.

- Level the bottom of the pit and cover it with roofing felt or other insulating material.

- Pour a 10 cm thick layer of sand on top, which must be compacted.

- Place a layer of fine gravel of similar thickness on top of the sand cushion.

- To ensure the reliability of the base, it can be reinforced with a metal grid. To do this, use reinforcing bars connected to each other with wire. The width of the grid cells should be no more than 10 cm. The thickness of the rods is selected in the range from 8 to 12 mm.

- Place the grate in the pit so that it does not touch the bottom. To do this, place broken bricks under the metal frame.

- Pour concrete mixture grade M-200 or M-250. The concrete must completely cover the metal frame.

For reliability, the foundation can be reinforced with a metal grid

Order of brickwork

After a few days, when the base has hardened, you can begin laying brickwork for a long-burning furnace. Before starting construction work, it is necessary to soak the brick in water for a day. This must be done so that the bricks laid in rows do not draw moisture from the mixture. Bricks should be laid as follows:

- The first and second rows must be laid out in continuous layers.

- An ash pan will be installed on the second row, so you need to provide space for the door.

- On the fifth row, a ceiling is installed above the door. Subsequently, a drying chamber box will be installed in it.

- The sixth and seventh rows are designed to accommodate the grate and install the door into the combustion chamber.

- From the eighth to the tenth row the firebox will be placed. When laying the combustion chamber, it is necessary to use fire-resistant material - fireclay bricks. Use clay-based mixtures as an adhesive for masonry. Ready-made mixtures intended for laying stoves are available for sale.

- The eleventh row serves as the ceiling of the combustion chamber and forms the area for the chimney. On top of this row it is necessary to lay steel reinforcement and fill it with cement mixture.

- On the twelfth row, a place for the hob is formed.

- Starting from the thirteenth - fourteenth row, rows for the chimney are laid. Its height is made according to individual projects, so the number of rows can be increased several times.

The procedure for laying bricks for a long-burning stove with a hob

Video: long-burning brick stove modeled on a children's construction set

Combined oven model

Used for cooking food and heating the house. But it is a very complex project. Therefore, you should not rely on this model. It is suitable for a large house.

After choosing a project, you can start creating a drawing in order to clearly understand what and how to do.

How to upgrade a long-burning stove yourself

To make a homemade stove less of a hassle, it can be improved.

Modernization of the Bubafonya stove

The weight of the Bubafonya stove structure usually reaches 150–170 kg. This creates inconvenience, since it must be turned over to clean it from ash and other combustion residues. To avoid this, you can improve the design by making holes in it with doors. However, it should be taken into account that the peculiarity of such a stove is precisely the absence of extra cracks through which air can penetrate. Therefore, when manufacturing doors, they will need to be carefully sealed in the closed position. This can be achieved by welding metal sides and seals to the body.

Air draft in the combustion chamber will be improved if the number and shape of the ribs on the round piston plate of the structure are changed. To do this, instead of channel sections, you need to weld steel plates. At the same time, they should have a slight bend along the entire length of the part. This shape will allow the incoming air to swirl, which will be evenly distributed in the combustion chamber. To obtain the desired effect, 6 to 8 plates are enough.

Curved ribs on the piston help improve traction

Modernization of a brick kiln

A long-burning stove made of brick will take up much less space if its design resembles the shape of a triangle and is placed in the corner of the room. The construction of such a structure will require less building material and, accordingly, less financial investment.

The brick version of the long-burning stove can be upgraded with a separate damper to switch between winter and summer heating modes. In the autumn-spring period, when there is no frost, but the air is saturated with dampness, this damper will help prevent the heating from being too hot.

An additional damper will make heating more comfortable

Advantages of a homemade metal stove

A homemade metal stove has a number of advantages over brick heating units. Among the main advantages of the structures under consideration, it is necessary to highlight the simplicity of their design and the availability of raw materials.

DIY metal stove

Making a simple metal stove will not take much time - there are usually no difficulties in finding (purchasing) metal sheets or iron containers of a suitable size.

DIY metal stove

The installation of a metal furnace will require many times less financial investment compared to the construction of a brick heating unit. At the same time, a metal stove does not take up much space and heats up very quickly during operation.

Homemade metal stove

Metal stoves weigh much less than their brick counterparts, which eliminates the need for a strong foundation. To further increase heating efficiency, a screen made of heat-resistant brick can be laid around a metal heating unit.

Extraordinary handmade stove

Cleaning and repair

During intensive use, the wood-burning heat generator must be subjected to preventative cleaning approximately once a month. This is due to the fact that the stove gradually becomes clogged with wood combustion products - ash chips. The latter interferes with the normal functioning of the unit.

If there are any places where smoke breaks out of the stove not into the chimney, but directly into the room, it is necessary to identify these holes through an external inspection.

When they are detected in the welds, you can use the electrodes again. But there is another cardinal method for any defective places. It is enough to cover them with fireproof sealant or cement mixed with liquid glass.

However, usually a well-made stove lasts a long time and does not cause problems.