A homemade metal stove is perfect for heating a greenhouse, garage, work space, and even a living room. To assemble the unit in question, you can use sheets of metal, barrels, pipes and even fire extinguishers of a suitable size. The procedure for making the stove remains the same. Differences are present only in the initial stages of corps preparation.

DIY metal stove

Tips for use

- The denser the wood is placed in the stove (this increases the smoldering time), the greater the fuel savings.

- Constant cleaning of the chimney is an indispensable safety measure.

- To ensure that no one touches the stove or gets burned on the structure, you can install screens or cover the metal body with bricks.

- If the stove door is glass, it will regularly turn black from soot. It's best to clean it before the glass cools down, otherwise you'll have to deal with resin. Cleaning can be done with a simple glass cleaner and a sponge or newspaper. You should not use iron scrapers as they will cause scratches.

- You need to make sure that the metal parts (especially the grate) do not burn out. They need to be changed on time.

- The ash pan must be constantly inspected and cleaned.

A metal stove for a wood-burning home is an excellent solution to the problem of heat supply, which is popular due to its intuitively understandable operating principle and simple maintenance. When choosing from the options provided, it is necessary to take into account not only the cost, but also the technical characteristics and reviews of owners who are already owners of one or another model.

Home stove models

This is a Canadian designed and built oven. It is very easy to use and has a simple design. The main part of the furnace (combustion chamber) is created in the shape of a steel cylinder, its thickness is 5-6 mm. The hole for coal supply (door) is created in the cut of the furnace. Adjacent to the main part are round (or with right angles) pipes, empty from the inside. After heating, these pipes form the necessary transfer of warm air in the required direction.

A grate for supporting coal (grid) is created at the bottom of the combustion chamber. At the top of the combustion chamber there is a barrier that divides the weighty part of the furnace into two halves. This is done so that it can be heated with both coal and gas. The smoke outlet is located on the other side of the door and is connected to the combustion chamber, due to which the smoke is safely released into the street.

Butakov stove

It was tested in difficult conditions of a cold climate, not meeting the expectations of the owners of the patent for this discovery. This brand has several options. Models that are supposed to be used around the clock are improved with glass barriers. The stove consumes 12 times less fuel than a potbelly stove, and almost half as much as ordinary brickwork.

Model "Student"

This is done due to the fact that in such a furnace the fuel does not burn, but smolders (pyrolysis process). One drawback is that the section of the chimney pipe is not sealed enough and water may drip from there during the transition of steam into liquid. There are 6 varieties of similar stoves. “Gymnasium student” is the most functional in size.

Domestic model of the Buleryan stove. The oven is light and miniature. It is suitable for both a living room and a garage. Testing of such a stove was carried out in the mountains of Tajikistan, where border premises for official needs are equipped with stoves of a similar type. Breneran stoves come in 5 sizes, with a power of up to 35 kilowatts.

Teplodar-Matrix

It is a successful combination of design and practicality. Furnaces of this type have the possibility of continuous 8-hour combustion (with one fuel supply). The housing of the convector compartment provides equal heating and protects against negative radiation. The depth of the smoke exhaust compartment and the compactness of the stove design save space and provide additional advantages during installation - the chimney can be created in the direction in which it is necessary or comfortable. This manufacturer has a fairly wide selection of models, so you can choose the appropriate option based on your needs and desires.

Teplodar-Matrix 100

Teplodar-Matrix 200

Suitable if you need to heat a room up to 200 square meters. For garage spaces, a good option is the Teplodar T series. For kitchen areas, a Vertical fireplace stove is perfect. If uniform heating of the living space is important, it is better to choose the Vesuvius model.

High-quality domestic stoves for heating areas with an air volume of 50 to 250 cubic meters. The power of similar furnaces reaches 13 kilowatts. Suitable for heating both residential and non-residential premises. Some models have added fans for very high-quality acceleration of warm air. A lot of different models were demonstrated - Ermak, Normal, Indigirka, Cinderella, etc. These stoves are compact and have an efficiency of up to 90%. Individual models have glass shutters.

We select bricks and prepare mortar

In order for the stove to serve for a long time, you should choose all materials wisely. There are three types of brick products:

- Ceramic - they are used to build a stove.

- Silicate - absolutely not suitable for this.

- Fireproof - used for laying out fireboxes and fireplaces.

When choosing a certain type of brick for a stove, it is recommended to completely abandon its hollow varieties.

Mix the solution from clay. Red would be a good option if the stove is made of bricks of a similar color. When using fireclay, you will need a specific fireclay clay. Some stove makers still, as in the old days, prepare a solution with their own hands, which contains river sand with a diameter of about 1.5 mm, clay and water. It is better to use quarry sand without foreign substances and fatty clay. But it’s still easier and more reliable to purchase a ready-made baking composition in the store, preparing it according to the instructions.

Selecting a heating device

To choose the right heating device, you need to take a couple of points into account. This will help avoid unnecessary misunderstandings, re-planning and save you from unnecessary nerves:

The place where the stove will be placed. A good place to install a boiler or furnace would be a separate room with an external entrance

This is comfortable, first of all, due to the fact that there will be less garbage in the house, there will be no burning smell and the possibility of poisoning with fumes is reduced to zero. But if this does not work out, do not be upset. The kitchen or living room is a great option for installing a stove, the main thing must not be forgotten about precautions. It is especially important when choosing a location for a future stove to take into account how the chimney will be installed. If there is an attic floor in the house, then the main thing is to calculate all the details of the passage of the chimney through this room. And it is equally important that there are no beams or rafter systems in the path of the chimney. Heating device power When choosing a stove, you first need to calculate how much area it should heat

If you don’t take into account the square footage and take a stove for a small area, then it will be impossible to warm up the house. If you overdo it, there will be an extra high fuel consumption. Radiator size and shape. The main thing is to decide for what purpose the stove is needed: only as a decorative interior addition in the role of a fireplace or for continuous use. Additional functions. Currently, there are thousands of stove options. Therefore, the main thing is to take into account what functions are needed so as not to be surprised when ordering. There are options with and without an electric stove. Available with heating tank for water or hydraulic circuit. Naturally, with the addition of additional elements, the cost of the heating device also changes. In this regard, it is necessary to think through all the little things before making a choice. Decor elements. The latest technologies make it possible to beautifully decorate an everyday thing, such as a stove, with a variety of decorative components. This could be a glass door that will allow a simple stove to transform into a fireplace. There may be forging elements that can make it a sophisticated interior detail.

Preparation for work

For laying a stove with a stove, different types of brick are used. Usually they take red solid one for external masonry and fireclay - to make the internal lining of the firebox, as well as the smoke well.

The foundation is poured with concrete mortar. To prepare it you will need cement of at least M400, preferably M500. The sand can be river or from a quarry, but it must first be sifted to prevent the ingress of impurities. Clean water should also be used. For the solution, you should also take granite crushed stone about 30 mm.

The foundation is backfilled using rubble granite, a suitable fraction is approximately 300 mm. In addition, you will need to prepare a solution of red clay and sand.

Instead of clay, you can purchase clay powder; the instructions for using it are indicated on the package. All components must be of good quality; the integrity and service life of the future stove depends on this. To seal the joints, you need to prepare a high-temperature sealant.

The work is carried out using ordinary construction tools.

You may need:

- containers for mixing the solution;

- Master OK;

- Bulgarian;

- plumb line;

- level;

- roulette;

- rule;

- mallet;

- furnace hammer;

- other devices for processing and laying bricks.

To make a high-quality solution, it is better to use a hammer drill or drill with the appropriate characteristics, as well as an attachment designed for these purposes. A shovel and a sieve will come in handy.

How to choose

When choosing a wood-burning stove for a country house, you should choose long-burning heating structures, since they do not require constant fuel supply. A cast iron body will take longer to warm up and cool down more slowly. Some stove manufacturers equip their designs with cooking surfaces. This technology increases the versatility of the units.

It should be noted that today, summer residents can choose almost any design: from heating devices with a strict design to fireplace stoves with decorative glass inserts, which allows you to admire the fire blazing in the fireplace.

One load of fuel provides the room with heat for approximately 6-10 hours, provided that a long-burning design is used.

The use of firewood allows you to save some of the thermal energy, because according to this indicator, it takes second place immediately after natural gas. It is for this reason that stoves for summer cottages can be used as sources of main heating, as well as in case of accidents and the need for additional heat.

As a rule, when choosing a stove for a wood-burning cottage, users are guided by the design of the structure, its power and dimensions, as well as fire-fighting qualities. Some models allow the chimney to be diverted to the side, but it should be understood that this option significantly complicates installation, but at the same time improves the aesthetics of perception. It is impossible not to note the so-called rotary models: their firebox is capable of rotating 360 degrees.

What it is

A metal furnace is a separate group of heating devices made from various types of metal. Unlike stationary brick ovens, metal structures are compact and do not take away volume from the room.

They have high performance qualities, thanks to which the demand for metal furnaces is consistently high and constantly increasing. The main reason for this is the ability to heat the room to the desired temperature very quickly.

The metal has high thermal conductivity, and the surface of the furnace is capable of actively releasing thermal energy.

For a small private bathhouse, metal stoves are considered the best choice, much superior to the usual properties of brick stoves.

Pros and cons of iron stoves

An iron stove can be a small potbelly stove in the garage or a powerful long-burning stove that will heat rooms with an increased area. It can also be made entirely of metal or just have a steel combustion chamber.

The iron heating device has many good qualities. Having dealt with them, you can see why this method of heating is popular:

- Compactness. Each iron or cast iron stove will take up significantly less space compared to a brick one.

- Strength. When compared with other materials, the iron version of the heating device will last longer.

- Price. Prices for this type of combustion chamber are quite affordable. The savings also lie in the fact that you do not need to pay for the services of a specialist for installation and extraordinary costs for materials, as is necessary for bricklaying.

- Resistant to temperature changes. This point is so important for heating in a house outside the city, where time is rarely spent. He arrived, lit the fire, and after a short period of time the house was warm without any hot spots.

- Simplicity of the installation process. Anyone can install such a heating device. Installation does not require any special tools or devices, or much knowledge.

- Mobility. You can install it in any place without thinking about how to install a chimney. There is also no need for foundation equipment. In iron stoves, it is possible to remove the chimney through the wall, and this solves a lot of problems: you do not need to take into account the location of beams and rafter systems, or make fire-resistant insulation.

There are no beautiful things in the world. And iron heating systems have their own disadvantages. There are only a few of them, but they are present:

- Low heat capacity. After heating, home heat is not retained for a long time, so you have to keep the fire going all the time. Actually, due to the large use of firewood, such heating devices received the name “potbelly stove”. However, thanks to new technologies, this figure has decreased slightly, and long-burning furnaces have emerged. They are filled with wood once every 6–8 hours.

- Burnout of the bottom of the combustion chamber. As a result of operation, the metal bottom burns out. But this problem can easily be corrected by replacing or welding on a new bottom.

- Drying the air. This is also easy to remove, you just need to humidify the air. To do this, do not purchase specialized humidifiers; just place a cup of water on the stove.

When installing the stove, you must remember to take safety precautions. Because the heat radiation of such devices is too strong, fire safety rules must be followed.

Special requirements

We repeat: the advantages are simple - compactness and the ability to build in an existing house without major construction work. But it is not so easy to place a more powerful firebox in a furnace structure of generally the same dimensions; from excessive heat load it will quickly become unusable. If special requirements are not met:

- Furnace foundation.

- Masonry mortars.

- Methods of laying the structure of the furnace.

- The choice and methods of installing stove fittings.

The design of the foundation for the rough is shown in Fig. The crushed stone cushion without sand bedding is leveled to the horizon before pouring. Pouring mortar M150 – cement M300 and sand 1:2. The gap between the rubble foundation and the flooring is 30-40 mm. Don't forget to support the cut joists! Leaving their ends hanging is a common but serious mistake. The dimensions of the foundation in plan should protrude onto the contour of the furnace by at least 100-150 mm.

Construction of the furnace foundation - rough

Note: the brick bed on the foundation under the furnace is laid out with bandaging in the rows and between the rows in the same way as the first 2 rows of masonry for the furnace structure, see below.

To fold the rough, 3 types of solutions are used, see fig. below. The bed on the foundation and the chimney are laid out on lime mortar as it combines sufficient heat and moisture resistance, but the rubble must be laid only on a completely moisture-resistant cement-sand mortar. It is highly advisable to use mountain or ravine sand with rough grains for clay mortar. Ordinary clay - purchased from the oven, guaranteed fat content and, most importantly, purity. Self-excavated clay, brought to the required fat content with sand, is of little use for coarse masonry.

Compositions of masonry mortars for coarse stoves

For rough masonry, stove bricks and, if the order (see below) is provided for, fireclay bricks are used; red worker is of the highest quality - light red in color (fully annealed), without burn marks, distortion and swelling. Dry molded brick is absolutely unsuitable. The masonry of the structure is roughly carried out following the trail. rules:

- If you are an inexperienced stove maker, each row of masonry is first laid out dry; detected defects in cutting/chipping bricks are eliminated.

- Before laying on the mortar, each brick is soaked until the release of air bubbles stops. You can’t dump all the bricks into a barrel indiscriminately!

- A 5 mm layer of mortar is applied to the bed and the base of the brick being laid.

- The brick being laid is laid with a smooth movement, slightly tilted, and moved towards the previous one so that there are no air bubbles left in the seam.

- The brick is pressed until the seam comes together to 3 mm; You can't knock!

- Between fireclay and ordinary masonry, the initial seam is 8-10 mm; after pressing – 6 mm.

- The seam between bricks and metal embedded parts (see below) is 10 mm.

- Excess mortar squeezed out of the seam is removed with a trowel (trowel).

- The recesses in the seams found after removing excess mortar are filled with mortar by pressing without transverse movements, but not by rubbing!

Those who prefer to learn visually can watch a video tutorial on laying heating and cooking stoves below:

Video: laying a heating and cooking stove

Incorrect oven door installation

Fittings and grates for roughing require cast iron; doors and latches - with an installation skirt and holes in it for diagonal wire whiskers. Welded steel or cast iron fittings with eyes for straight lugs (laid along the corresponding furnace wall) are unsuitable in this case. However, install the doors/latches as in Fig. on the right, in the rough it is impossible; This is not according to stove rules at all. For a Dutch country house with 2.5 bricks in plan, which is heated once or twice a season, it may be fine, but not for a rough one.

It is necessary, firstly, to crimp the mustache (galvanized wire 2-3 mm) with a twist so that it does not move. Press not too tightly at first, place it at the desired angle (at least 12 mm should remain from the far end of the mustache to the inside of the masonry). Then tighten carefully and shake the door/latch slightly. Didn't leave? Good. Then, secondly, you need to tightly wrap the skirt with asbestos cord (or basalt fiber), and only now put it in place. You can also watch the following videos about installing accessories into the oven.

Cons of iron stoves

No matter which stove model is good and suitable in size and practicality, you must not forget that any stove, no matter how well it fits, always has drawbacks.

Metal stoves will lose to brick stoves in terms of heat conservation. When heating a room with such models, warm air is retained in it for only a few hours, and in the morning there will be no more heat. However, this drawback can be solved if you purchase a stove made of metal with stable operation. After purchasing and installing it, you can forget about adding fuel for 8 hours.

Iron furnaces can last up to 20 years. According to statistical data, much earlier than this period, the metal in the combustion chamber burns out and requires replacement.

When purchasing a metal stove, it is worth considering who will use it and how. If installation is intended for residential premises, then it is necessary to take into account the presence of people with chronic diseases of the respiratory tract or cardiovascular system. In addition to the fact that such stoves generate powerful radiation, they create the effect of “air without water vapor.” This kind of problem can be solved if you cover the metal base of the stove with bricks (at the same time, calculate whether the floor will support the additional weight). This will greatly reduce the operating time of the stove and void the product warranty. The heating rate will become slower, but the heat capacity will increase.

Design

The design features of metal stoves are directly related to the type of fuel. However, there are always common elements:

- frame;

- firebox (or burner, fuel combustion chamber);

- chimney;

- heater;

- container for water.

There are stoves that do not require some structural elements. For example, electric stoves do not require chimneys and do not have a firebox (combustion chamber). Gas stoves are equipped with burners, but they do not have a firebox as such.

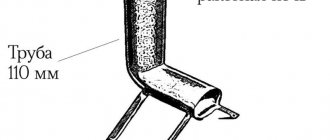

The most difficult design is for wood-burning stoves, which in addition to the firebox have an ash pit (a small compartment under the firebox where ash and soot accumulate). In addition, wood-burning stoves require a high-quality chimney and a passage through the ceiling (these are elements of the smoke removal system, which are purchased separately).

Chimneys are also used on gas and liquid fuel stoves, but the combustion products of these fuels are not as abundant and do not contain as much tar and water vapor.

At the same time, due to traditional preferences, wood-burning stoves are most often found in bathhouses. Users are attracted by the romantic component of the process - the crackling of firewood, a specific smell and other attributes.

All alternative designs, although more effective and convenient to use, have not become so widespread.

Types of metal stoves for a country house

Modern stoves, which run on wood and are made of metal, bear little resemblance to a “potbelly stove”. Metal stoves for the home are usually divided into two groups:

- Traditional ones, which operate using a direct combustion system.

- Heating devices intended for long burning.

One or the other system may be located in steel ovens, which are intended for cooking or heating. You can find a decent number of similar stoves on the market, among them the following should be noted:

- A bell-type stove is considered a heating stove; it uses the principle of convective movement of gases that move through channels and then exit into the chimney. Instead of a hob, an open oven is installed, which is located directly under the hood. This helps keep food hot for a long time. Firewood is loaded in a horizontal position; the combustion chamber door is made of heat-resistant glass.

A regular oven. Almost always these are small models, for example, Termofor or Cinderella. The design performs 2 functions at once - it heats the room and assists in cooking. The thermal power of such a “baby” is 4 kW or a little more, which makes it possible to heat a room up to 50 m2. There are models that are equipped with electricity generators, which increases the voltage production and power of the furnace. For example, the Indigirka cooking stove, which does not stop working on wood, not only heats the house, but is also suitable for charging devices.

Stoves for long-term burning of wood. They are great for dachas, because the designs are economical and have modest dimensions, and have a high level of efficiency, which can reach 80%. For long-term operation of this type of stove, you need to equip a chimney and burn it with high-quality firewood. Stoves for long-term burning of wood work due to the fact that firewood (or other fuel) is loaded into the firebox, ignited, and then the door is closed. Clean air flows through the telescopic pipe, which descends lower when the amount of firewood decreases. The air supply process is changed by a damper. The working life of the furnace is approximately three days. If stoves for long-term burning of wood have a water heating system mode, you can save on the use of firewood.

Types of steel furnaces

If before this time potbelly stoves were made in a handicraft way somewhere in a garage, today specialized companies are engaged in their production on an industrial scale. This makes it possible to be confident in their reliability and choose the appropriate option for each home.

Choice for small spaces

A small steel stove, for example, the “Gnome” type, is great for a cottage or garage. This option is miniature and can heat rooms up to 100 m². Consists of two chambers: combustion and blowing chambers. It has several variations, with removable burners or from a solid steel sheet. The body is covered with fire-resistant paint, which protects well from rust.

Another advantage of this device is its low weight, which makes it very easy to transport and quickly install it in almost any place, even in the attic. This type of heating device has a vertical chimney. This leads to the fact that all the heat immediately goes away, literally “down the drain.” Because of this, to maintain a stable temperature, the fire needs to burn all the time.

Heating device with hydraulic circuit

This option is more universal. Using such a unit, you can heat a house over a larger area. This is possible thanks to the built-in circuit in which the water is heated. It is supplied through a recirculating system to heating devices, which heat other rooms. Such a heating device can also be successfully used for the “underfloor heating” system.

In size, this version of the heating device is slightly larger than the previous one. A combustion chamber of this design makes it possible to make a large stack of firewood. An additional advantage of this option is that during heat supply, not only wood is burned, but also combustion products, and this helps to save fuel. Savings are also facilitated by the slow release of heat, because heating occurs not only directly from the iron walls, but also from water, which cools much very slowly.

The versatility of this model lies in the fact that it can be used as a heating device and as a fireplace.

Furnaces of this kind have a longer service life due to the interior finishing with specialized fireclay slabs, which protect the iron walls from burning out.

Long burning stoves

This option differs from the previous one in its larger size. Using a heating device you can heat a large house. An important advantage of such a stove is that wood is stored once every 8–12 hours. The design of the combustion chamber is designed so that the combustion of wood occurs in stages. At the first stage, wood is burned, and when the temperature is brought to the required level, gas-generating disintegration of the fuel occurs, during which the oxygen supply ends and smoldering occurs. This slows down combustion, but the heat transfer remains the same.

Ovens are available with doors made of heat-resistant glass. Many models are equipped with additional windows on panels located on the side, which makes it possible to monitor the combustion process.

Multifunctional option

For practical homeowners, there is an option for a metal stove for a wood-burning home with a heating and cooking function. Using such a model, you can both heat the house and prepare food. There are models with a hydraulic circuit, and others without it. The design of such a stove will fit perfectly into any kitchen. For very practical owners, there is an option with a built-in oven and a compartment for drying firewood. This model is ideal for a country house where there is no gas or power outages. In addition to solving many household problems, it will free you from dependence on housing and communal services.

You can debate for a long time about which oven is better. But sitting in the warmth and watching the crackling of the wood in the stove is considered a real pleasure and the optimal confirmation of comfort.

Classification

Metal furnaces are the collective name for a broad category of devices that can be combined into separate groups according to various characteristics.

Based on body material:

steel

cast iron

Steel stoves are cheaper, they are quite efficient and practical. However, their common disadvantage is their relatively small resource - the steel burns out sooner or later. If the furnace body is made of thick sheet metal (4-5 mm), the working life can be increased. In addition, you can make a steel stove yourself.

Cast iron stoves are more expensive, but they have a long service life. At the same time, it is impossible to make a cast iron stove with your own hands.

According to the type of fuel, metal stoves are divided into:

solid fuel (firewood, coal, pallets, etc.)

gas

electric

liquid fuel

There is an opinion among experts that the best option is an electric oven. It is safe, does not require the installation of a chimney, and does not produce soot or carbon monoxide. For a sauna, this type of heating is considered the most effective. However, the cost of electricity is quite high (even too high in some regions), which makes electric ovens not very popular.

Gas furnaces are very effective, but operating gas equipment in itself is a rather dangerous undertaking. Most users prefer wood stoves - they are closest to the tradition of the Russian bath.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Liquid fuel metal stoves are not popular, as they are fueled with gasoline, diesel fuel or other similar types of fuel. For a bathhouse, this type of heating is considered not the best solution, although, with the correct placement of the stove, you can get quite successful results.

By availability of additional functions:

heater

This is a traditional element of a sauna stove, used not only to supply steam, but also as a decorative design element (this is found in electric stoves, where stones simply cover the heating elements);

possibility of remote control

This option is found only on electric and gas models, since it is impossible to regulate the supply of firewood remotely;

water tank

Not found in all models of metal stoves, it is a convenient and practical addition;

heat exchanger

It is found mainly in gas furnaces;

steam generator

A device that replaces the traditional method of supplying steam (splashing a ladle of water onto the heater). Found in models with small stone backfill.

In addition, stoves with a built-in heater differ in their design:

with open heater

At the top there is a net or basket made of metal strips filled with stones;

with closed heater

There is a compartment in the body where the stones are located. To supply water, a door is used that gives access to the stone backfill.

It is believed that an open heater produces heavier and harsher steam, typical of a Russian bath. A closed heater allows you to get softer and drier steam, more suitable for saunas.

How to install a stove according to all the rules

- The primary point is the choice of installation location and area measurements. Everything must comply with safety regulations. The stove should be placed at a distance of at least 60 cm from the plaster and 80 cm from the wallpaper.

- The stove must be placed on a slab of concrete (at least 0.7 cm), asbestos or basalt cardboard.

- The furnace parts are assembled in accordance with the instructions, after which the tightness of the assembled structure must be checked.

- A protective element should be attached above the stove, on the surface of the ceiling.

- Installation of a chimney (it is better to choose a round option - rectangular ones have worse draft).

- If you want to paint a stove, then every paint will not be suitable for this. It is necessary to select specialized enamels (silicate or organic).

- Call a fire inspector who will check that the installation is impeccable.

- Test check of the entire system.

Step-by-step instruction

It is not difficult to assemble a heating stove with your own hands; just read the instructions.

Further sequence of actions:

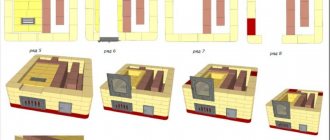

Two examples of brick oven laying

- After the third row has been laid, the blower door should be placed in the oven.

- To keep everything level, a level is used, and an asbestos cord is used to close the gap.

- Then they begin laying out the main part intended for heating. For this purpose, fireclay or stove bricks are used.

- Before laying a brick stove, the ceramic material is cleaned of dust and dirt and moistened with clean water.

- Fireclay bricks should not be wetted.

- Laying out the mortar can be done manually, since it is difficult to achieve a mortar thickness of 3 mm using a trowel.

- The furnace laying must be verified. Tapping and separate editing are not allowed.

- If you can’t do this the first time, you can repeat everything, having first cleared the brick from the mortar.

- After completing several rows of masonry, a grate is installed in the grooves of the fireclay bricks to separate the ash chamber.

- The working combustion door is installed in the furnace in the same way as the blower.

- The body of the furnace is laid out with brickwork.

- If the cast iron slab should be below the level of the bricks, then the last row of masonry should be moved outward.

Before carrying out work, you should consult a specialist.