Where to start choosing a design

Fireplace stoves are combined devices and perform several functions. Sometimes additional features are provided, for example, a built-in tank for heating water, a niche for drying fruit or laundry. Multifunctional fireplaces are distinguished by their design.

When you decide to make a fireplace stove for a country house with your own hands, you need to clearly understand what requirements the future structure must meet.

To choose the right design, you need to consider the following parameters:

- dimensions of the future home;

- configuration that depends on location;

- thermal power level;

- additional features.

The design of a fireplace stove depends on many factors, but primarily on what functions it will perform.

What types of stoves and fireplaces are there?

When deciding how to build a fireplace stove, they proceed from their capabilities and preferences.

According to their stove design, fireplaces can be divided into two types:

- Stove fireplace with two fireboxes. This design is chosen if the area allows. Many problems associated with heating, providing a country house with hot water and cooking will be solved by a powerful multifunctional brick stove and fireplace. It can provide not only a hob, an oven and a water boiler, but also the ability to connect to a water circuit. The fireplace can become an attachment to the heating and cooking stove, combining with it a common chimney. Thus, the structure will have two fireboxes, and it will be possible to heat the fireplace and stove at the same time, or separately.

- A fireplace stove with a single firebox. Suitable for a small country house. This heating device is also called a modernized “Swedish” or “Dutch”. It is a modern version of a compact heating stove with an enlarged combustion chamber and a door made of heat-resistant glass.

The spatial layout of the structure is of great importance. The layout of a stove with a fireplace largely depends on the layout of the premises.

Among all the constructive diversity, several different types can be listed:

- one-sided (fireplace and stove inserts on the same line)

- double-sided (fireplace and stove inserts on different sides);

- corner;

- T-shaped in shape.

If we are talking about a small structure, you can limit yourself to a fireproof glass door in a single firebox.

Key points when building a fireplace stove with your own hands

The fireplace insert should perform two functions well: heat the room and serve as decoration for the home. It is difficult to find a person who would not like to sit in the warmth and watch the flames of the fire.

The combustion chamber can be laid out from special fire-resistant bricks, or a ready-made factory firebox made of metal can be placed in the brickwork. If an open firebox without a door is installed in the fireplace, the fuel burns out faster even when the smoke channel is adjusted. The door helps slow down the combustion process, thereby leaving more heat in the room. The second advantage of the combustion door is that less oxygen “burns”.

The advantages of a firebox made of refractory bricks (and stone external cladding) are that this material accumulates heat well. This means that after the fuel burns out, the walls of the stove will continue to heat the room for a long time.

Important! When choosing a fireplace stove design for a summer house with your own hands, take into account that brick cladding also plays a role in saving and distributing heat.

In brick versions, hot flue gases have to pass through a labyrinth of smoke channels. In this case, heat is transferred to the brickwork.

There are two types of smoke duct locations:

- above the combustion chamber;

- on the floor line.

The latter have special requirements for traction, but maximum comfort.

Details

Types

Open fireplace design

Is it possible to make a fireplace out of a stove? Without a doubt. These types of fireplaces are classified as traditional. They are usually used to decorate interiors that do not have the ability to heat. A fireplace of this type can only warm those people who are sitting nearby. In this design, the firebox is located either directly in the wall, or in a special extension to the ceiling. It is a small depression. As a rule, such fireplaces are decorated with grates or low glass, which is why they require close and constant attention in order to avoid a situation with a fire threat. In addition, wood burns out quite quickly in such fireboxes.

Closed type fireplace

Unlike open designs, such fireplaces have heat-resistant glass that completely covers the firebox to prevent the spread of sparks. One of the advantages of such a device is that it can heat rooms efficiently, as it has a high efficiency factor. Installation of this type of fireplace will cost much more, which is due to more stringent requirements for the chimney, the required insulation, and other factors that affect the complexity of the design. But such objects soon justify the money spent on it.

Features in terms of rework

When you start converting the stove into a beautiful fireplace design, the first thing you should do is assess the condition of the chimney - this will be the key to safety. It should be noted that such a unit is built according to a strictly drawn up individual plan-project. For this reason, the next step is to draw up a project. It is also important to assess the condition of the foundation, as well as the furnace. If everything is in order, you can start the next stage. How to make a fireplace from a stove? The simplest remodeling option would be to transform an old stove into a real decorative fireplace. It won't take a lot of your time and effort. List of necessary tools and building materials:

- Building level.

- Lots of clay

- A couple of bags of cement.

- Master OK.

- Putty knife.

- Masonry mortar.

- Bricks.

- New smoke exhaust pipe.

- Finishing material (for example, heat-resistant tiles).

- If desired, you can buy a glass door.

One of the most important requirements for a fireplace is to create a gap between the foundation and the base of the house, and the former must be covered with ordinary sand. When remodeling, the conditions that apply to fireplaces must be observed. Be sure to check the chimney pipe:

- The depth of the firebox should be approximately 0.5 meters, but in no case less.

- The cross section is more than 0.25*0.13 meters.

- Its height should be at least 7 meters (ideally more).

The inside of the firebox must be lined with refractory bricks. To prevent soot from settling on the door all the time, it is necessary to mark specialized channels. They are required to circulate air along the doors so that dirt does not settle and stain the door. When all stages are completed, the finishing stage will begin. Everything here is individual. The choice of building and finishing materials will depend on the personal preferences and tastes of the owners, as well as on the style direction in which the interior is designed. The main and popular materials that are usually used for finishing are tiles, tiles and stone. Naturally, a fireplace structure trimmed with stone will look chic and impressive.

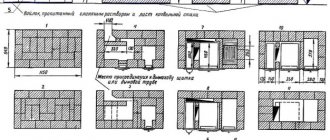

Location of brick fireplace stove

To decide where it is best to install a fireplace stove, you need to know the layout and dimensions of the house.

Optimal solutions for the location of the fireplace stove:

- in the middle of a large common room;

- in the center of the building at the junction of interior partitions;

- in the wall between the common room and the kitchen area;

- between the hallway and the bedroom.

If you place the fireplace stove in the center of the room near (against) one of the internal walls, several rooms are heated at once. It is convenient if the heating stove, which serves as a fireplace and cooking apparatus, is located between the common room and the kitchen. The fireplace side will be in the family room and the cooktop will be in the kitchen area.

The heat shield plays the role of a warm partition if the stove is built between the living room and bedroom.

Important! During operation, the fireplace “eats” a lot of oxygen. Therefore, the area of the room where it is installed should not be less than 15 square meters. m.

The greater the power characteristics of the combustion chamber, the more spacious the area of the fireplace room should be.

To improve the microclimate inside the building and ensure normal combustion, additional air supply is provided. This can be done in different ways. Regular window vents or special channels for air flow from the street will do. Their diameter depends on the type of combustion chamber. For a closed firebox, the channel is made at least 10 cm, for open fireboxes - at least 20 cm.

Selection of materials

There are no special requirements for choosing the material for constructing a fireplace stove in the country with your own hands. The materials are the same as for the construction of a conventional furnace. Their number will be selected for a specific project.

High-quality solid brick is ideal. Do-it-yourself lining of the internal surfaces of the fireplace stove is made from fireclay bricks. If desired, you can lay out the entire structure with this brick. But it’s better to decorate with more expensive building materials intended for cladding.

Important! The outer part of the chimney is laid out of bricks that have high frost resistance, using cement-sand mortar.

Fireclay brick protects the structure from burning out. The firebox door is fixed using a stainless steel frame.

The solution, which is used for laying stoves and fireplaces with your own hands, is mixed with clay and sand. Approximately 40 kg of clay is used for 100 bricks.

The optimal consistency of the solution, that is, the proportions of its components: clay, sand and water, is determined experimentally. A more convenient option is to use a ready-made factory mixture. The seams should normally be 3-4 mm.

Important! The main task when constructing a fireplace stove is to achieve a small thickness of the seams. This is the peculiarity of the stove masonry.

The nuances of drying a lined stove

The laid oven should dry well.

There are several nuances:

drying is necessary even before the construction of the chimney; You cannot fully heat the stove right away - there is a risk of loss of tightness and the appearance of streaks; drying should be natural for at least 10 days, with doors and valves open; The first times you need to heat it carefully - use little wood, open the smoke valves and close the fireboxes; For 1-1.5 weeks, the stove is heated every day, starting with 3-4 kg of firewood and increasing their amount daily by 1-1.5 kg; a full-fledged firebox is permitted when, after 2 hours from the start of the firebox, there is no condensation at all on the metal elements.

To make a fireplace stove with your own hands, you need to purchase a grate and cast iron doors for the ash pan and firebox. If the fireplace insert is closed, use a door with fireproof glass. Most often it is mounted using a stainless steel box. The fireplace insert is assembled onto a wedge and additionally reinforced with a steel corner or a profile rectangular pipe. These rules apply to both all-brick structures and those with cast-iron fireboxes.

From time to time, the chimney will need to be cleaned of the soot accumulated inside. To have access to it, special cleaning doors are built in (sometimes so-called “knockout” bricks are installed in these places).

These doors for cleaning smoke ducts are located both on the front side of the stove and on the back.

To control flue gases, several valves are installed. For example, in a heating and cooking stove with a fireplace, one valve is placed above the firebox, the other above the heating ducts of the stove. Another valve is provided in the “summer” chimney.

Important! To avoid staining or damaging the metal elements of the stove, you can wrap them with masking tape during laying.

Security measures

Do not forget that a fireplace is, first of all, a source of increased danger if you do not look after it. Any spark that accidentally jumps out of it can cause a fire.

Therefore, there are certain safety precautions that must be observed:

- The walls of the fireplace get very hot, so it is contraindicated to place it in children's rooms. That is why there are requirements for insulating walls and floors;

- The chimney, through which combustion products must escape, is made with an outlet through the roof to the street. That is why it is important to choose the right place so that there are no problems with the removal of parts.

Required thermal insulation materials

Stone wool 50 mm thick serves as a fire shield between the chimney and other building elements. It is necessary to take this moment responsibly, especially when it comes to transition nodes in the areas of interfloor and attic floors.

The fireclay core and facing parts are sometimes separated by basalt cardboard, which has low thermal conductivity. Thanks to this thermal insulation layer, the temperature of the working core is maintained and the outer part of the fireplace does not overheat.

The tightness of the junction of metal elements to the brickwork is ensured using sealants that can withstand high temperatures. If this is not done, there will not be good draft in the chimney, which means the performance of the heating structure will decrease.

Features of chimney installation

The inner surface of the chimney pipe is a straight channel, but its outer part has design features.

Design features keep you warm

At the intersection of the floor beam, the chimney has an expansion. This design element is important because it reduces the temperature of the outlet streams. As a result, there is no need to make additional thermal insulation in this place.

At the level of the intersection of the roof, the chimney has an extension. This feature protects the brickwork from the harmful effects of precipitation.

The smoke channel is also protected in the form of a metal cap. It is recommended to equip the chimney with a spark arrester.

How to build a foundation

The weight of an average static fireplace stove (with a chimney) reaches four tons. Therefore, it is imperative to build a solid foundation for it. One part cement goes to three parts sand. A fifth of the solution is crushed stone. Sometimes good quality natural stone is used to make the foundation. You cannot replace it with construction waste or broken bricks, as this will significantly weaken the concrete.

Important! A frame made of reinforcement must be laid inside a solid concrete foundation.

The structure of the frame, methods of tying reinforcement and thickness depend on the design and size of the furnace. The building and the fireplace have different shrinkage parameters, so their foundations cannot be connected together to avoid structural failure.

When building a fireplace stove with your own hands, you must comply with all building regulations. When performing foundation work, you need to correctly calculate the depth. It is important to know how to properly reinforce a structure and assemble formwork. After the foundation is poured, the required period of concrete maturation is maintained, and only then the laying begins.

It’s not enough to understand theoretically how to build a fireplace stove with your own hands. You need to listen to the advice of experienced craftsmen. After all, seemingly small defects and omissions can become critical during the operation of a heating structure. When it comes to a combined model, it is necessary to comply with building regulations at all stages of construction.