Owners of country houses are sometimes faced with the need to purchase equipment to organize heating for their homes. When choosing a high-quality, economical and reliable unit, many people prefer gas boilers. And here they have to choose whether to buy equipment with a bithermic heat exchanger or two separate devices.

Sectional view of bithermic heat exchanger Source youtube.com

Distinctive features

A bithermal or combined heat exchanger is radiator-type equipment. Its peculiarity is that under the body there are heating chambers, as well as containers in which household liquid is prepared. The device is capable of simultaneously performing 2 tasks:

- heat the room;

- supply hot water to the consumer.

The main pipe, made of a heat-conducting metal (usually copper), includes an additional pipe (usually made of aluminum), which is bent into a diamond shape and soldered at several points along the entire length of the structure. This can be seen by examining a cross-section of a bithermic heat exchanger. So you can see that the inside of the structure is designed to heat water. Heat storage plates are attached to the top. The water heating the room is heated and circulates in the gap between these two pipes.

Bithermic heat exchanger for a gas boiler Source kotel.kr.ua

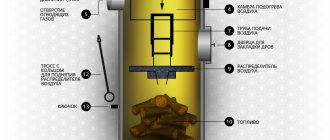

The operating principle of a bithermal heat exchanger is as follows:

- Heating plates accumulate heat, which is used to heat the inner pipe with circulating coolant.

- Until the tap is opened to supply hot water to the consumer, only one coolant circulates, which is responsible for heating the room. After opening the tap, this heating temporarily stops.

Thus, the bithermic heat exchanger of a double-circuit gas boiler has an alternating operating mode. Thanks to this principle, the heat emitted by the burner is consumed economically.

The service life of the device is affected by the thickness of the walls and the chemical composition of the water circulating in the system. The disadvantage of such devices is that scale can accumulate on the walls, causing them to fail.

Types of heat exchangers for gas boilers Source yvision.kz

Purpose

A biothermal heat exchanger (hereinafter referred to as BT) is a radiator equipment in which, under one housing, there are both heating chambers and containers for preparing household clean liquid. The separation of different temperature environments for their exchange is inherent in the internal system of chambers; it is not visible under the common body. It is represented by a heating chamber, which has two heating functions:

- For heating system.

- For supplying hot water supply (DHW).

This does not mean that liquid flows from one chamber further in different directions and of different quality. The operating principle is based on primary and secondary heating.

Operating principle of the equipment

The operation of a bithermic heat exchanger looks like this:

- First, the plate heats up, transferring heat to the outer tube with gradual heating of the water in the compartment, which is intended for heating. While the hot water supply tap is not turned on, the second circuit is closed, the heated liquid circulates inside the first circuit.

- If you turn on the hot water supply, the heating circuit is automatically shut off, and the second one is started accordingly. All the heat passes to the second circuit, and the heating water begins to circulate in the internal compartment. When the hot water grana is closed, the flow of water in the outer cavity is resumed.

Replacing a heat exchanger in a gas boiler Source theguardian.com

Operating principle

The principle of operation of bithermal equipment lies in its different modes. They can only be turned on individually and not simultaneously.

Operating mode for heating:

- The coolant is exposed to direct heating.

- Under pressure it is transferred to the receiving pipes.

- Then, circulating through the system, it returns to the exchange office.

DHW formation mode (secondary method):

- The coolant is heated in the chamber.

- From it, thermal energy is supplied to sections with domestic water.

- The heated coolant in the chamber does not enter the heating system, but is retained in its section.

Advantages and disadvantages

The main positive qualities of a gas boiler equipped with a bithermal heat exchanger include:

- Affordable price. Bithermal is much cheaper. But as far as its performance is concerned, it is practically not inferior to it. When the circuit is combined, the speed of the water heating process does not change. The consumption of hot water remains almost identical.

- Method of heating water. Thanks to the point fastening of the two tubes, the contact area becomes larger. Therefore, the heat emanating from the heating plate can partially transfer into the structure. Accordingly, the heating process is accelerated. If heating is used, the water supply circuit can also heat up to the same temperature. This happens until the water supply tap is opened. If you open the tap, there will already be heated water in the pipe.

- Ease of use in summer. The heat source for heating water is burning fuel. In order for the outlet water to be hot, you do not need to heat the entire circuit.

As for the disadvantages of bithermic heat exchangers, they are as follows:

- Due to the fact that the tube has a complex shape, the rate of formation of salt deposits inside it increases. This process occurs especially quickly if the liquid inside is very hot (up to 95 degrees). However, it is worth noting that this process depends less on temperature and more on the quality of the water. It is recommended to initially fill the coolant with prepared water that does not contain large amounts of iron, salts and other compounds. Alternatively, special antifreeze additives must be added to the liquid, the purpose of which is to prevent the formation of scale. The water inside the system moves in a circle, salts are gradually removed from it. As for the hot water supply circuit, everything depends on the presence of a filter at the entrance to the system and the adequacy of using a bithermal heat exchanger. If the hardness of tap water is high, then the risk of rapid formation of deposits increases, interfering with the normal operation of the system.

- Another disadvantage is that if the boiler operating parameters are incorrectly set, too hot water may flow from the tap during operation.

- Difficult to maintain. If the coolant pipes become clogged, not every specialist will be able to cope with the problem. And without special cleaning of the system, the operating efficiency of the gas boiler will be minimal.

Clogged bithermic heat exchanger of a gas boiler Source cosmo-frost.ru

How to clean a gas boiler from scale Procedure

To disassemble a heating unit at home, you do not need any special tools. A DIY kit with pliers, screwdrivers and keys is quite enough.

The algorithm of actions to effectively clean the heat exchanger of a gas boiler is as follows:

- Disconnect all wires from the gas valve.

- Remove the thermocouple from the combustion chamber. It is connected to the gas valve using a capillary tube.

- Disconnect the gas fuel supply pipe.

- Unscrew the four nuts that hold the stove with the burner.

- Now it’s the turn of the heat exchanger. To gain access to it, remove the top cover of the boiler, disconnect the chimney pipe and the draft sensor.

- After this, carefully remove the insulation, and then unscrew the screws securing the casing and remove it.

- A heat exchanger is located under the casing. Remove the turbulators from it.

- You can clean steel turbulators using a wire brush. And the heat exchanger itself can be cleaned using simple tools that you make yourself, in accordance with the size of the smoke pipes.

- After cleaning is completed, sweep the surfaces of the heat exchanger using a brush that is screwed to the handle.

- The last stage of cleaning is to clear the bottom of soot that has fallen off during the cleaning of the smoke pipe.

Equipment with two heat exchangers

To understand which is better, a bithermal heat exchanger or 2 different ones, it is necessary to consider the advantages and disadvantages of the latter option. The operation of a standard boiler consists of the constant movement of a circulation pump through the first heat exchanger, heated by a gas burner. This allows hot water to move from the boiler to the radiators and back.

When the hot water supply tap is opened, a special sensor transmits a signal that causes the three-way tap to redirect it from the first to the second heat exchanger. Consequently, here the liquid will be heated from an already hot coolant, and not from a gas burner. Thus, fuel will be consumed more economically, which will reduce the bill.

Construction of a gas boiler with two different heat exchangers Source serviceco.ru

The main advantages of such boilers include:

- Heating the temperature to no more than 60 degrees. This is enough to heat the room and reduces the risk of burns to zero.

- Due to the fact that the second heat exchanger is not used often, its service life increases significantly.

- The design is simple, so if it breaks, it can be easily repaired. But, doing this yourself is not recommended.

- The likelihood of clogging here is minimal. Thus, maintenance of such a boiler will have to be carried out much less frequently.

The disadvantages of a boiler with two different heat exchangers include:

- A bulky design that will require more free space in the room.

- The need to install a three-way valve to redirect water to the second heat exchanger. Such a faucet can break, which requires frequent replacement.

- Since the number of components in such a boiler is greater, the price of the unit increases.

Just like a bithermal heat exchanger, this option has certain positive and negative sides.

Comparison of bithermic and double-circuit boilers Source strojdvor.ru

Construction device

Such equipment is also called “pipe in pipe”, “section in section”. There are two main segments in the device where liquids do not mix with each other:

- water circulation for hot water supply;

- circulation of water for heating.

Copper fins-plates are attached to the pipes, increasing the efficiency coefficients. If the boiler is gas, then it will definitely have an ignition device - a burner. Such structures will also be additionally equipped with protective layers. In addition, all such heat exchangers, no matter what modification they may be, provide highly functional insulation and protection against electric short circuits, and mandatory grounding.

Which option is better?

It is impossible to answer this question unambiguously. If high-quality equipment is chosen, and the water inside the system is of good quality (without foreign impurities), then both boilers will do their job perfectly. There is a slight difference in their operating modes, but they are practically invisible to the consumer.

The main advantage of a bithermal heat exchanger is its cost. It is this criterion that buyers most often pay attention to. But, at the same time, we should not forget that due to the combination of contours, the width of the channels in them is smaller, which leads to their rapid clogging.

But it is worth noting that double-circuit boilers are also susceptible to scale deposits on the walls. Therefore, it will not be possible to avoid repairs by choosing such equipment. The cleaning principle is the same for both devices.

Advantages of bithermic units

The advantages of heat exchangers with a single block extend to both heating efficiency as such and ease of control, not to mention the higher reliability of the units. As for efficiency, bithermic radiators operate with a lower heat loss coefficient. If a system divided into two blocks requires heating of two blocks, then in this case the filling of one housing is serviced - accordingly, the volume of heat generated increases. In terms of control, a bithermal heat exchanger is more profitable for the same reason. Thermostats are guided by the indicators of one solid block, which affects the accuracy of the data obtained. Reliability, in turn, is achieved by minimizing the connecting infrastructure - in fact, only a connection between the heat exchanger and supply channels is required.

Preventing clogging

There are ways to extend the service life of bithermal heat exchangers:

- Self-cleaning of units. To do this, the owner will need a booster pump and a special substance. Since there is no need to disassemble the boiler, the operating time is about 15-20 minutes. The disadvantage of this method is the use of aggressive substances, which, if handled carelessly, can cause harm and break the tightness of the equipment, which is very difficult to restore. Using “folk” remedies such as citric acid for cleaning will be ineffective.

- Carrying out washing of units at the service center. This option is preferable, as it is carried out by specialists. The procedure restores the operation of the heating device and ensures the prevention of unforeseen situations or equipment breakdown. To do this, they use effective but gentle means.

Maintenance of gas boilers Source lscomplex-bud.pl

You need to resort to cleaning in the following cases:

- Prevention. It is carried out on average once every few years. Experts advise doing it annually if possible.

- On-demand cleaning. It is recommended to carry it out if there is a decrease in the efficiency of the boiler.

- Heat generator failure. In such a situation, it is recommended to combine repairs with cleaning of components.

Installing a bithermic heat exchanger on a gas boiler Source greentravaux.fr

Types of gas boilers

According to the principle of operation, gas boilers are divided into two groups:

- convection;

- condensation

The first group of boilers is considered traditional equipment that produces heating by burning gas, while part of the heat is lost along with smoke waste. The operating principle of such a boiler is simple, understandable, and the price is relatively low.

The second type of boilers was developed using new technologies that make it possible to more fully utilize the combustion heat of gas. This allows you to obtain an efficiency that is approximately 15-20 percent higher than that of the convection model. This means corresponding fuel savings and cheaper heat. However, it is significantly higher than that of convection.

Many European and world-class companies are engaged in the development and production of gas boilers. Almost all modern models are equipped with a reliable automated protective system that does not require manual control, which is responsible for supplying fuel and maintaining the temperature in a given mode. Models equipped with a gas pressure controller are guaranteed against overheating, fire and other similar breakdowns, since it will immediately stop the gas supply in the event of a decrease in pressure, fuel leakage or flame failure.

2013-01-23 10 529

In many European gas boilers, a bithermal heat exchanger is installed. Judging by the assurances of manufacturers, this reduces production costs and practically does not affect the heat transfer and efficiency of heating equipment.

On the contrary, you can find many articles on the Internet warning against purchasing boilers with a bithermic heat exchanger. To understand where the truth is, you need to learn about the design and operation features of the device.

Possible faults

Steel products are subject to corrosion and must be replaced.

Most problems require the intervention of specialists. Some can be eliminated by the user:

- Reduced pressure - if caused by contamination, it is enough to clean the heat exchanger. If the connection to the network is incorrect, you need to check the connection with the drawing in the instructions.

- Reduced efficiency - in case of mechanical contamination, the device is washed. If the reason is the accumulation of oil or substandard gases, additional devices are installed to remove them.

- Leakage - most often caused by decomposition of seals. They are being replaced.

- Mixing of working media - occurs when plates or tubes corrode. The plates can be partially replaced, but a new shell-and-tube heat exchanger will have to be installed.

While the warranty is valid, it is prohibited to open the heat exchanger yourself and carry out any repairs.

Correct operation

The heat exchanger is washed depending on the water hardness.

Transportation, installation and operation of the heat exchanger device are described in detail in the instructions:

- The heat exchanger is placed in the apparatus so that it has easy access for inspection and repair.

- Start-up is performed at stable pressure and temperature. Do not increase the temperature faster than 10 degrees per minute or increase the pressure more than 10 bar per hour.

- When filled with water, the air valves and valves behind the heat exchanger remain open. After the pump starts, they are closed. In this way, stable pressure is achieved.

- You need to change the heating parameters smoothly. The slower this happens, the longer the seals and the heat exchanger itself will last.

- The device needs to be cleaned periodically. The plate is cleaned directly in the frame, then the plates are removed and washed. Another method is possible: first removing and then cleaning the plates. It is not recommended to clean shell-and-tube machines. In case of complex blockages, the technician installs a plug.

- Before restarting, check the condition of all gaskets. Pressure and temperature are set as at 1st start.

To avoid salt deposits, a filter is placed on the water pipe in front of the boiler entrance.