The use of even relatively clean water as a heating fluid leads to clogging over time, not to mention untreated, contaminated coolant. The boiler heat exchanger is the first to suffer from clogging and scale. Precipitation on its walls narrows the cross-section of the pipe and the thermal conductivity of the metal, which affects not only the heating system, but also the operation of the boiler, which has to operate at increased power levels.

In the article we will look at how internal and external cleaning of the heat exchanger of a gas boiler is carried out. The process is not particularly difficult and can be done independently, without the involvement of specialists.

Read in the article

Citric acid in cleaning the heat exchanger of a gas boiler: flushing and cleaning

Hello, friends. How is the heat exchanger of a gas boiler washed with citric acid? Do I need to remove the heat exchanger? What are the stages of this work? The answers to these questions follow.

This article tells how to wash the heat exchanger with a well-known folk remedy - citric acid. What are the advantages of this method? Two cleaning methods are considered.

Useful tips

Of course, using and cleaning gas boilers is a little easier than solid fuel units, which often have to be cleaned of tar or tar. However, gas models still require careful handling and timely flushing.

Experts do not advise taking on this task if you are not confident in your abilities, because mistakes cannot be made in this case.

Pay attention to your kettle, in which you usually boil water. If there is a noticeable coating on it, which reappears after each new cleaning, this means that the heat exchanger in your boiler needs to be cleaned at least once every 2 years

If there are no deposits on the kettle, then you can get by with one cleaning every 3 years. When cleaning the boiler, never rub the plates with pressure or unnecessary force. Do not use rags, brushes or sponges. This is explained by the softness of the records - they can be easily damaged.

- Experts and users more experienced in these matters advise beginners to film the entire process of disassembly (if you are disassembling the unit) and cleaning on video or take photos. Based on the footage, it will be easier for you to put the equipment back together, and most likely there will be no extra parts left.

- When cleaning the heat exchanger, it is not recommended to use tools that have sharp edges. Such objects can damage important parts of the heating unit.

- When working with acids that clean the heat exchanger of deposits, it is recommended to wear rubber gloves and a mask. Follow safety precautions. Make sure that chemicals do not come into contact with the skin or mucous membranes.

- If you decide to hydrostatically clean the heat exchanger, then you should keep in mind that under no circumstances should the critical pressure level be exceeded. Otherwise, pipes may burst.

- Do not try to make the burner hole wider by using a thick needle. Of course, after this it will be easier to clean this element, but the performance of the equipment itself may deteriorate.

- The brush is perfect for cleaning internal surfaces of any shape. It is recommended to use a tool with a longer handle - with such a device it will be much easier to reach all contaminated areas.

When assembling the pilot burner, it is important to remember one important rule: the tip of the thermal paste should be located opposite the area where the flame ignites. If you decide to clean the heat exchanger chemically, then you should consider that high-quality reagents usually have a high cost. If a turbocharged boiler is installed in your home, then at the bottom you will see debris drawn into the inside of the air duct. It also needs to be removed

To do this, just use a vacuum cleaner. Some experts argue that regularly using hydrochloric acid to clean the exchanger can cause brittleness and severe wear on the metal. This must be taken into account when choosing the appropriate washing method.

- A common signal for cleaning the heat exchanger is a decrease in water pressure. If you notice this change, you should start cleaning the equipment as soon as possible.

- It is also necessary to start cleaning the equipment if the circulation pump begins to operate too noisily. This will indicate that this part is working under heavy load.

- You can use the non-dismountable method of washing only if your heating equipment does not have too serious and old contaminants. In addition, this method is not suitable for removing dirt caused by corrosion.

- After washing the unit, which you have not previously disassembled, you should neutralize and dispose of the cleaning solution immediately after carrying out all the necessary procedures.

If water flows freely, this will indicate that the inside of the pipe is free of debris. Once you have finished cleaning the necessary parts, reassemble everything in reverse order. Be sure to remove any contaminants from the inside of the boiler. Then run the equipment at full power - this must be done to make sure there are no leaks and the equipment is working properly.

To learn how to flush the heat exchanger of a gas boiler, see the following video.

Definition

A heat exchanger is a mechanism that directs heat from one coolant (water) to a second (air).

It contains special components and cavities.

If it is exposed to hard water for a long time, then scale, rust and other contaminants form in it. They need to be eliminated promptly.

The regularity of cleaning is determined by the quality of the water and the parameters of the boiler itself, as well as the degree of load on it.

Whatever washing method is chosen, first of all, deposits are removed using mixtures of different acids or special reagents. This is followed by rinsing with water.

If you do not carry out these operations, then:

- The heat exchanger will overheat.

- The efficiency of the boiler will decrease.

- The boiler may break down. In an advanced case, an explosion is not ruled out.

How to quickly remove scale from a kettle

To clean the kettle with citric acid quickly and effectively, you should use the following algorithm:

- Determine how much substance is needed to remove scale. The thicker the plaque, the more acid is needed. Required proportion: 2 teaspoons of citric acid per 1 liter of water;

- Pour clean water into the kettle, filling 2/3 of its volume;

- Add the powder to the water and stir until it is completely dissolved;

- If the scale has recently formed and its layer is quite thin, then there is no need to boil it; just leave the acid solution in the kettle for 2-3 hours. Then you need to thoroughly wash the container, freeing it from any flakes and grains that have formed. If the plaque is more old, you need to boil an aqueous solution of lemon juice in a kettle for a quarter of an hour. After this, let it cool and wash the dishes with clean water. If necessary, the procedure can be repeated more than once.

Frequency of cleansing

Typically, maintenance periods are reflected in the passport of each model. However, these are indicative values. And they mean that the device will work in comfortable conditions. In practice, the heat exchanger needs to be washed more often.

The need for these operations arises when:

- There is a big difference in the calculated parameters of the unit from the values in its passport. Efficiency decreases and thermal energy consumption increases.

- According to the plan, the rubber seals of the heat exchanger are being changed.

- Very dense deposits appeared on its plates.

How to determine when it's time to descale

You can try to determine the presence of scale on the heating element yourself. To do this, you don’t need to disassemble the car, you just need to arm yourself with a bright flashlight. Direct the light beam to the bottom of the drum - it is under it that the heating element is usually located. Carefully rotate the drum and look closely at its holes. With a little patience, you will be able to see the outline of the heating element. Some models of washing machines are equipped with special doors, by opening which you can inspect the heating element and assess its condition. If you notice the slightest traces of scale formation, arm yourself with our advice and hurry to help your washing machine.

The service technician will help you find out if it’s time to descale your washing machine.

About price tags

The price of flushing a gas boiler heat exchanger depends on the method chosen. The cheapest is mechanical. You can do it yourself. But you need to act extremely carefully. A stiff metal brush is used.

The second method is hydrodynamic. It uses jets of powerful pressure water. Special settings apply. They develop line pressure up to 1500 bar.

The effectiveness of the method is very high. But the price tag too -...

The third method is chemical. A booster is used - a special device. With its help, a composition for acid cleansing is introduced. This composition circulates in the heat exchanger for several hours and effectively cleanses it. Even carbonate scale is removed.

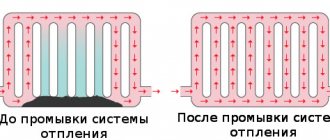

Example of a device before and after surgery.

Disadvantages of this method:

- high price tag of the reagent,

- metal wear,

- a lot of toxins are formed.

Citric acid is safer. It removes many deposits along with reagents such as Xanax and Silit. And it costs only...

Special cleaning equipment

A booster (installation for washing heat exchangers) is a rather rare and expensive equipment (40-90 thousand rubles), which is simply unprofitable to buy for personal purposes, no matter how often you clean it. It is a container with a built-in circulation pump that supports a change in flow direction - reverse, which increases the efficiency of washing. The devices are resistant to any reagents used.

PIPAL PUMP ELIMINATE 20 V4V

One of the best Italian-made units. It has compact dimensions and optimal performance - 2600 l/hour (44 l/min). Tank volume – 18 l, permissible pressure – 1 bar. Known for its simplicity and reliability.

Cost : 38,000 rub.

BWT Cillit SEK 28

An equally well-known, proven German-made installation. Capacity – 2400 l/hour, the operating principle is no different from the previous installation, designed for higher temperatures – up to 60°C. It has even more compact dimensions and a convenient handle for transportation.

Cost : 57,000 rub.

How to choose a water softener for a gas boiler and extend the life of the heat exchanger

Cleansing. Method 1

Cleaning the heat exchanger of a gas boiler with citric acid is profitable and safer. The first method of this operation involves removing the heat exchanger.

In addition to the acid itself, you will need:

- The valves supplying gas to the heating are blocked.

- The water is drained.

- The heat exchanger is removed. The bolts and water pipes are carefully unscrewed. The overheat indicator is removed from the case.

- A cleaning composition is being prepared. Per liter of water – 20 grams of acid.

- The heat exchanger is placed in the basin. This composition is poured into it. The device is completely immersed in it.

- The composition heats up for 5-10 minutes.

- The composition merges.

- The heat exchanger is thoroughly washed. Running water is used.

- The device is placed in its position. All fasteners and tubes are screwed in. The overheating indicator is strengthened.

Disassembly and soot removal

For efficient operation of the equipment, it is necessary to clean the gas water heater. The deposits formed on the walls can disrupt the uninterrupted operation of the device, so there is no need to wait for the equipment to completely fail; preventive cleaning should be carried out periodically.

Before dismantling, it is necessary to block access to gas and water. Do-it-yourself cleaning of a gas water heater begins with removing the boiler doors and disconnecting the auto-ignition wire. Then the thermocouple, piezoelectric element and burner tube are removed

Carefully remove the nozzle and the burner itself

The thermometer sleeve, boiler lid, and flue are removed. Cleaning the geyser is done using a brush and brushes, which clean all internal and external elements. The nozzle hole is cleaned with a needle with a smaller diameter to avoid enlarging the hole and disrupting the combustion mode. The internal channels of the heat exchanger are blown out with a vacuum cleaner and wiped with a damp cloth.

At the same time, you can carry out minor repairs to the heat exchanger yourself: replace the gasket under the pilot burner, check the thermocouple, which is prone to breakdowns due to the specifics of its operation, and so on. Such work does not require large investments, but maintains the boiler’s performance at a high level, and the thermocouple device is quite simple, and replacing the element will not be difficult.

Structure of a gas boiler

Assembly is carried out in reverse order. When connecting the piezoelectric element, it is recommended not to use a tool to avoid damaging the ceramic base; it is better to tighten it by hand.

When installing, you need to check the thermocouple on the gas boiler; you need to know that the end of the conductors must be at the level of the place where the flame appears.

Cleansing. Method 2

In this method, you need to use a special washing complex. It includes:

- Tank for cleaning composition.

- Pump.

- Connecting hoses.

- Boiler shutdown.

- Draining.

- Removing the circulation pump. A washing unit is placed in its position. It is connected with special hoses.

- Preparation of the composition in the tank of the designated complex. The proportions are the same as in the first method.

- Turn on the pump. The composition circulates. It is necessary to control the pressure in this complex. It shouldn't go off scale.

- Draining the composition.

- Rinsing the device with water.

- Dismantling of the washing complex.

- Return to the pump location.

Folk remedies for cleaning irons

In addition to acid, mineral water helps a lot. How to descale a tank:

- Pour in water to the maximum level.

- Turn on the iron to maximum temperature and let it warm up.

- After automatic shutdown, the device is placed over the bathtub and the steam button is pressed.

- Water with pieces of sediment and dirt will drain from the reservoir and openings.

If necessary, repeat the procedure. Finally, wash the tank with clean water and wipe dry.

Antiscale is a cheap and folk remedy. It is used in many areas when cleaning various materials. The drug is sold in hardware stores. The powder is diluted in water according to the instructions and poured into the compartment. Turn on the iron and press the steam button several times.

Important! Regular lemon removes scale and stuck fabrics from the iron perfectly. Rub the sole with a slice and clean the tank with juice.

If the boiler has two circuits

Washing the heat exchanger of a double-circuit gas boiler with citric acid is carried out using one of these methods:

- Bithermic: the coolant and water for hot water are heated.

- Work with a secondary heater made of stainless steel.

A booster is used for the operation. After all, it is very difficult to remove such a mechanism. Hoses from the tank are installed instead of water outlets.

Then the pump and boiler are turned on. The heating temperature should not exceed 50-55 degrees

Many modern boilers have a secondary heat exchanger, for example “Vailant A, Ferroli Divatech H C24.

The principle of their purification is largely similar. For example, cleaning the heat exchanger of a Vaillant AtmoTec gas boiler is shown:

- The secondary heater is removed. The front panel comes off. The control unit is unscrewed.

- The bolts of this heater are unscrewed.

- He is immersed in a container of water. Citric acid is pre-added to the water.

- Boil over medium heat for 10-15 minutes.

- The water is drained.

- The heater is washed with water and then returned to the boiler.

When to do cleaning

There are 3 options for the development of events:

- Preventative cleaning of the boiler is done by the homeowner himself once every 2 years at the lowest cost.

- The procedure is carried out as the heat exchangers become contaminated with soot and scale, which reduces the efficiency of heating and water heating for domestic hot water needs. In this situation, you can still clean the boiler yourself, although calling a specialist is also possible.

- The heat generator stopped due to a breakdown, which often happens during the heating season. The fault is fixed by a called specialist, who also cleans the heat exchanger of soot.

The last 2 scenarios are clearly unattractive for home owners, as they are associated with inconvenience and financial costs. You cannot do without a specialist even if a condensing boiler with a burner and a heat exchanger of a special design is used for heating. It is not recommended to climb there yourself, unless you are well versed in heating equipment of this kind.

Conclusion: Preventative cleaning and flushing of the heat exchanger of a double-circuit gas boiler is performed quite quickly and does not require any expense, which is why it is the optimal solution.

Flushing heating pipes with improvised means

I began to suspect that it was necessary to flush the heating system in a private home. The system is without a pump, passive, and without radiators, only pipes. Over the past few years, the pipes have begun to heat up less and heat the room less well. The pipes are steel, at least they are magnetic. I have no idea what’s inside, and I don’t know how to look, but I know for sure that no one has touched them in terms of cleaning and maintenance for 20 years.

In general, the question is: how can you clean pipes from possible scale and other water deposits with your own hands and improvised means? (water, of course, was always poured from the tap, there were no additives or anything else).

I’ve already read and googled about all sorts of terms like hydropneumatic flushing, but the city is very small and no one provides such services here. Tricky chemicals like Trilon-B can’t be bought anywhere from us either and can’t be ordered for delivery. It is necessary to rinse with available means at hand. But another nuance is that no one knows what condition the pipes are in, so you need something that won’t corrode them to hell if something happens. Crystal clear is not required, but something is needed that will remove the underlying deposits. Please help me out.

Plumbers hide it...

into the sciatic nerve.

The first thing that came to mind was to take a 100-200 liter barrel. Place a more powerful drainage pump there, a hose from the pump to the inlet, and a hose from the outlet back to the barrel. Pour water with some acid (weak solution) or salt (to soften the water) and let it run in a circle. In the first hour it will become clear whether it is effective or not. And it's not that expensive. If they go to shit, then leave them at work for a couple of days.

I myself encountered a similar problem just a couple of weeks ago. I also saw a lot and read a lot on the Internet and came to the conclusion that without special liquids and devices it will be problematic to achieve a positive result. As a result, I called the management company and told them about my sadness and misfortune. They immediately told me that the problem could be solved and gave me the phone number of a specialist to contact him directly and agree on a time. The master arrived at the appointed time, connected his shaitan unit, poured in the solution and began to rinse. While the system was being flushed, the technician answered several questions that arose along with the problem. The flushing time depends on the degree of pipe clogging and the solution. In my case, he immediately said that he poured fresh solution and the process would take less time. In fact, it was clearly visible through the tubes that at first there was a very foamy brown-yellow liquid coming out. The master said that the foam is obtained as a result of the reaction of scale with the solution, and the color is precisely the scale being washed off. After about 10 minutes, the foam disappeared from the outlet and the solution became transparent. The master explained that this is an indicator that the scale has been removed and the solution cannot be driven longer, so as not to damage the pipes, since the liquid being poured is really very aggressive. The entire service cost me 5k rubles, and the master said that the price was due to the high cost of the liquid, and the unit itself was not cheap. The master also said that he has been cleaning heating systems for several years, and every year the situation repeats: in the summer there are very few orders, but with the arrival of cold weather, everyone remembers problems with heating and orders have to be accepted several days in advance. I came to the conclusion for myself that if you don’t do this kind of money yourself, then there is no point in buying an expensive unit, and assembling it yourself is also a waste of time and money. Using alternative solutions such as citric acid, vinegar or anti-scale for heating systems does not work.

Cleaning the heat exchanger mechanically

Having removed the heat exchanger, you can begin cleaning it mechanically. Of course, you can choose the second option (using chemically active substances), but it will be described below.

Having gone through the removal process step by step and taking the heat exchanger out, users are presented with an unattractive picture: a large amount of deposits and soot both inside the pipes and between the cooling plates. The mechanical cleaning method involves the use of a metal cable with a brush at the end, as well as various scrapers and blades. Using this tool, harmful deposits are removed from both internal and external surfaces.

The outer surface of the heat exchanger can be cleaned using a hard bristle toothbrush.

To make the process of removing dirt faster, you can “soak” the device in water with the addition of detergents. Then plaque or scale will be removed much easier and without effort. When using a cable, it must be slowly pushed into the device, while turning it clockwise.

Using a metal brush on a rod when cleaning a floor-standing boiler

Steel brush with a diameter of 40 mm and a working surface length of 100 mm

After the inside is cleaned, you need to rinse the heat exchanger using a hose that can be connected to a centralized water supply. It doesn’t require a lot of pressure; even an ordinary stream of water is enough to wash away dirt, plaque and other deposits.

Contamination from the outer surface, especially between the blades, should be removed carefully, as this can lead to damage to the heat exchanger and disruption of its operation.

Flushing the heating system with citric acid

- Page 1 of 1

- 1

How much citric acid is needed to flush the heating system?

The article is devoted to an important problem that millions of boiler owners face every day. Find out how to wash the heat exchanger of a gas boiler with your own hands in a matter of minutes and completely free of charge. But remember, if you are not sure, do not take it, a gas boiler is not a test field, there is a danger of explosion.

A solution of citric acid at a temperature of 60°C perfectly removes scale and oxidation without affecting the metal of the heat exchanger. This product is perfect for cleaning copper, brass and stainless steel devices. Depending on the degree of contamination, the recommended concentration is from 0.5 to 1.5%.

Liquid for flushing heat exchangers of gas boilers

An aqueous solution of hydrochloric acid with a concentration of 2-5% is successfully used to clean heat exchangers made of copper or stainless steel. Special additives – inhibitors – help protect the metal without interfering with the dissolution of oxides and carbonates. Washing with hydrochloric acid is the job of professionals who are aware of their actions when working with this aggressive reagent. It is highly not recommended to clean the heat exchanger of a gas boiler with this product on your own, at home, without a clear understanding of the processes taking place.

The “Detex” cleaning agent is used to remove scale, oxides, salts and various biological deposits from the walls of cast iron, steel and copper heat exchangers. Due to the content of surfactants and corrosion inhibitor additives, it protects the metal, thereby increasing the service life of heating equipment. Depending on the degree of contamination, con is diluted with water in a ratio of 1/6 - 1/10 and poured into a washing machine.

Detex flushing liquid The process of circulating flushing liquid through the heat exchanger of a gas boiler is accompanied by gas release, the stop of which indicates the end of the reagent’s action. If the required quality of washing is not achieved, you should increase the pressure until the gas formation process resumes and continue the cleaning procedure. At the final stage, it is necessary to rinse the heat exchanger with a neutralizing liquid, and then with water.

Flushing with orthophosphoric acid is effective for heat exchangers of gas boilers of all types. This cleaning product not only perfectly removes scale and dirt, but also does not cause any harm to the metal and even creates a protective film. To obtain an effective reagent, it is necessary to dilute orthophosphoric acid in water to obtain a 13% solution.

How to rinse and clean the heat exchanger of a double-circuit boiler video In the video, the master explains in detail the progress of cleaning a double-circuit boiler with his own hands.

Chemical flushing of a gas boiler

Chemical (hydrochemical) flushing can be performed without dismantling the heat exchanger from the gas boiler. To remove rust, scale and other deposits, the heater is connected to a special device called a booster. This special device, equipped with a pump, pumps a chemical reagent through a heat exchanger in various directions for several hours. During this time, the chemistry included in the washing liquid completely removes the most complex contaminants without damaging the metal.

Pouring liquid into the booster (This is a special system for cleaning the boiler, the simplest and most effective way to rid the system of dirt, it can be purchased in specialized stores) Connecting the booster to the heating system, Open the lid of the booster and do not forget to plug it in, the cleaning process begins and the liquid is pumped into the system. Until the dirt comes out, do not stop cleaning. After cleaning, disconnect the booster from the system and let the water flow spontaneously. The final step is to flush the entire system with plain water.

Mechanical flushing of a gas boiler

The algorithm of actions should be as follows.

Step one. The upper part of the housing is removed. To do this, you must turn off the electrical power and gas supply (if all this is provided for by the boiler design). Step two. The exchanger is disconnected from the heating main. Step three. The fixtures of the device are removed.

After this, you can remove the heat exchanger from the heat generator and proceed directly to the washing procedure. What can you see after dismantling? As a rule, all internal cavities are clogged with scale - metal salts, calcium or sodium, as well as trivalent ferum. For cleaning you will have to use metal tools - pins, scrapers, and so on. During work, special care should be taken to avoid damaging the surfaces of the structure.

In some cases, the device is wetted in a container filled with a weak solution of hydrochloric acid. And as soon as the scale softens, you can begin to remove it. At the end of the procedure, all internal voids are washed with water under low pressure. For these purposes, you can attach a hose connected to the water supply system.

You can see for yourself how much dirt will spill out. You need to wait until clean water starts flowing. Additionally, you can tap the surfaces of the device with a mallet (this is a special hammer made of wood or rubber).

During operation of gas burners, carbon deposits gradually form, which accumulates and can interfere with the proper operation of the unit. Cleaning the element involves mechanical removal of contaminants. This can be done in various ways - remove carbon deposits with special brushes or use chemical solvents. Everything here will depend on the degree of pollution.

Where is it located and how to remove it

Basic methods involve completely removing the heat exchanger from the boiler. Cleaning without disassembly and removal is possible only when using the hydrodynamic flushing method, carried out exclusively by specialists. However, the extraction process does not require special skills or special equipment, and the design of all models of gas boilers is not fundamentally different.

The location of the heat exchanger using the example of a wall-mounted Baxi LUNA-3 Comfort 240 Fi.

- The first step is always to remove the front cover; simply unscrew the bolts and carefully remove it.

- We drain the water from the boiler through the appropriate outlet valve (usually located inside the boiler), be sure to release the pressure if there is any.

- Next, you need to remove the front combustion chamber cover. In simple models it is immediately visible; in more complex models, the combustion chamber can be insulated with fire-resistant, heat- or sound-insulating material, or rubber seals. It may also be necessary to remove the top of the combustion chamber.

- Typically, temperature or water flow sensors are installed on the pipes of the heat exchanger, which must be turned off.

- All that remains is to remove the fastening mechanisms, clamps, disconnect the pipes and remove the heat exchanger. Be careful, as when disconnecting the heat exchanger, residual water may flow out of the heat exchanger; cover the electronic components and wiring under the combustion chamber.

In floor-standing gas boilers with an open combustion chamber, the process is even simpler, since the heat exchanger is accessible immediately after removing the housing cover. In general, you can study the structure of your boiler model using the images of the operating instructions; for many models there are visual examples of disassembly analysis on YouTube.

Flushing heating pipes with improvised means

I began to suspect that it was necessary to flush the heating system in a private home. The system is without a pump, passive, and without radiators, only pipes. Over the past few years, the pipes have begun to heat up less and heat the room less well. The pipes are steel, at least they are magnetic. I have no idea what’s inside, and I don’t know how to look, but I know for sure that no one has touched them in terms of cleaning and maintenance for 20 years.

In general, the question is: how can you clean pipes from possible scale and other water deposits with your own hands and improvised means? (water, of course, was always poured from the tap, there were no additives or anything else).

I’ve already read and googled about all sorts of terms like hydropneumatic flushing, but the city is very small and no one provides such services here. Tricky chemicals like Trilon-B can’t be bought anywhere from us either and can’t be ordered for delivery. It is necessary to rinse with available means at hand. But another nuance is that no one knows what condition the pipes are in, so you need something that won’t corrode them to hell if something happens. Crystal clear is not required, but something is needed that will remove the underlying deposits. Please help me out.

Plumbers hide it...

into the sciatic nerve.

The first thing that came to mind was to take a 100-200 liter barrel. Place a more powerful drainage pump there, a hose from the pump to the inlet, and a hose from the outlet back to the barrel. Pour water with some acid (weak solution) or salt (to soften the water) and let it run in a circle. In the first hour it will become clear whether it is effective or not. And it's not that expensive. If they go to shit, then leave them at work for a couple of days.

I myself encountered a similar problem just a couple of weeks ago. I also saw a lot and read a lot on the Internet and came to the conclusion that without special liquids and devices it will be problematic to achieve a positive result. As a result, I called the management company and told them about my sadness and misfortune. They immediately told me that the problem could be solved and gave me the phone number of a specialist to contact him directly and agree on a time. The master arrived at the appointed time, connected his shaitan unit, poured in the solution and began to rinse. While the system was being flushed, the technician answered several questions that arose along with the problem. The flushing time depends on the degree of pipe clogging and the solution. In my case, he immediately said that he poured fresh solution and the process would take less time. In fact, it was clearly visible through the tubes that at first there was a very foamy brown-yellow liquid coming out. The master said that the foam is obtained as a result of the reaction of scale with the solution, and the color is precisely the scale being washed off. After about 10 minutes, the foam disappeared from the outlet and the solution became transparent. The master explained that this is an indicator that the scale has been removed and the solution cannot be driven longer, so as not to damage the pipes, since the liquid being poured is really very aggressive. The entire service cost me 5k rubles, and the master said that the price was due to the high cost of the liquid, and the unit itself was not cheap. The master also said that he has been cleaning heating systems for several years, and every year the situation repeats: in the summer there are very few orders, but with the arrival of cold weather, everyone remembers problems with heating and orders have to be accepted several days in advance. I came to the conclusion for myself that if you don’t do this kind of money yourself, then there is no point in buying an expensive unit, and assembling it yourself is also a waste of time and money. Using alternative solutions such as citric acid, vinegar or anti-scale for heating systems does not work.

To summarize: the problem is relevant for everyone who uses water heating, but the equipment and chemicals for flushing are very expensive. Contact the management company (your own or any other) or any heating company, and they will probably have such a specialist.

The manager shouldn’t do this for her (i.e. our) money?

if the house is private (not multi-apartment) - no.

You can argue with them for a long time, but you need warmth “yesterday.”

You can go to the courts with the Criminal Code and even get a decision that will oblige them to fix the problem, but how much time and nerves?!

According to the law of meanness, my boiler stopped turning on on Friday. The management company said that the master does not work on weekends and only on Monday it will be possible to coordinate everything. A weekend with a bucket on the stove was enough for me, so I didn’t argue when they said I’d have to pay.

Pay and then collect through court

What to charge for? If the house is private, you are your own management company, so you will compensate yourself.

Precautionary measures

Before using citric acid, take safety precautions:

- Do not use too much of the product - high concentrations of acid are dangerous for plastic and rubber parts.

- Cleaning should only be done with an empty drum. Under no circumstances combine the descaling procedure with washing the laundry, otherwise the items will be damaged.

- Do not use citric acid too often, as this may damage the washing machine parts.

The heating element of the washing machine before and after cleaning with citric acid

. Following the simple measures described in this article will help extend the life of the washing machine. But you shouldn’t rely only on citric acid; don’t forget about other rules for careful operation of the unit. If your laundry is heavily soiled, rinse it before washing in the machine to prevent dirt particles from settling on the mechanisms. We do not recommend leaving wet laundry in the tub for a long time; hang things up immediately after washing. Keep the tank clean, don’t forget to wash the filter, try to wash as little as possible at temperatures above +60 ℃. Be careful, and your washing machine will thank you with long and trouble-free operation!

How to flush the heating system in a private house with your own hands: instructions

Over time, private home owners inevitably notice that a well-functioning heating system begins to work less efficiently.

In most cases, the cause of poor heating of radiators is their clogging.

At the same time, energy costs are not reduced at all. The only way to solve this problem is to periodically flush the heating system.

Contact a professional or do it yourself

Professional cleaning of heating boilers is an expensive proposition. Depending on the condition of the equipment and the specifics of its operation, amounts can range from several tens to hundreds of dollars. In addition, the masters rarely arrive within the next few hours; sometimes you have to wait for them for several days. It is not comfortable.

The cost of professional cleaning using a special station for washing heat exchangers pays off: the parts are washed from the inside to a shine, and the equipment works much better. But if you want, you can always save money and do the same thing yourself. The result will be no worse, and you will only have to invest your own time and effort.

Professional device for washing heat exchangers

Causes of clogged heating system

The main source of contaminants that disrupt the operation of thermal circuits is the coolant. This is most often tap water. When filling the system, small debris from the water supply can easily get in with it. As the water circulates, this debris is transferred to the radiators, where it accumulates.

Another source of contamination is scale. It is formed in the boiler, where water comes into contact with the hot walls of the heat exchanger. Gradually, the inside of the boiler becomes covered with a layer of scale, which has relatively low thermal conductivity. A heat exchanger coated with scale transfers energy to the coolant much worse. With a thickness of salt deposits of several millimeters, the efficiency of the boiler can decrease by almost a third. During the process of cyclic heating and cooling, the scale crust is destroyed. The exfoliated particles enter the pipeline and are deposited both on the inner walls of the pipes and in the radiators. Accordingly, their heat transfer decreases and there is reason to think about how to flush the heating system in a private house with your own hands.

In addition, due to the oxygen contained in the water, rust gradually forms in the metal elements of the system. Like scale, rust increases the hydraulic resistance of pipes and is an additional source of contamination.

Why does scale form?

The main reason for the appearance of scale on the walls of heat exchangers of gas boilers is the use of hard lime water. As a rule, the water supplied to the heating system is not well purified and contains calcium and magnesium salts, as well as ferric iron, in dissolved form. When exposed to high temperatures, these impurities crystallize on the walls of the heat exchanger, forming a layer of deposits and rust.

Photo 1: Deposits inside bithermic copper heat exchanger

If the coolant used in the heating system undergoes at least some filtration, then water sometimes enters the DHW circuits of double-circuit boilers and bithermic heat exchangers without any purification. That is why these elements are especially susceptible to scale formation.

Why is scale on the walls of the heat exchanger dangerous? Several factors can be identified in the detrimental effect of deposits on the operation of the heating system as a whole and its individual devices in particular:

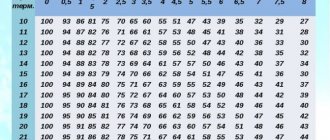

Increased gas consumption

The mineral deposits that make up the scale have much lower thermal conductivity compared to the metal from which the heat exchanger is made. Based on this, it will take more energy to warm up the coolant, and therefore the volume of gas burned will increase. Just 1 mm of deposits increases heating costs by 10%.

Heat exchanger overheating

The principle of operation of a gas boiler is that the coolant coming from the return line cools the heat exchanger, removing heat into the heating system. Scale interferes with normal heat exchange and the boiler automation commands to heat more strongly in order to achieve the required temperature in the supply line. Working for a long time at extreme temperatures, the heat exchanger quickly wears out and fails.

Additional load on heating equipment

The formation of scale on the walls of the heat exchanger reduces the effective diameter of the channels and interferes with the normal circulation of the coolant. As a result, the load on the circulation pump increases, which leads to its premature wear and failure.

Photo 2: Scale and rust on the walls of the heating system pipes

The problem of scale formation in gas boilers is quite serious and can hurt the owner’s pocket if it is not eliminated in time.

Signs of scale on the inner surface of pipes

The main reason to think that heating radiators need to be flushed is the appearance of the following signs:

- increasing energy consumption to achieve the usual indoor temperature;

- noticeable to the touch difference in temperature of radiators and pipes suitable for them;

- uneven heating of radiators, when their upper part becomes much hotter than the lower;

- when the heating boiler is operating, extraneous noise or crackling appears;

- increased heating time for the heating system.

How often should the heat exchanger be cleaned?

When visiting thematic sites, you come across very conflicting information regarding how often the heat exchanger, and all other elements of the heating device, should be cleaned. As a rule, information about service intervals is indicated in the manufacturer's instructions for a specific model. But it should be remembered that the information provided is approximate and implies the fact that operation will be carried out under the most favorable conditions. In fact, flushing the heat exchanger of a gas boiler is often required more often.

There are indirect signs by which it is possible to determine the degree of clogging of the heat exchanger. They are the ones that accompany the operation of the heating device.

- Fuel consumption has increased noticeably. According to statistics, in the case of internal scale on the surfaces of heating elements, fuel consumption can increase even up to 15 percent.

- The load on the circulation pump increases, it produces extraneous noise, and interruptions in operation are observed. All this indicates that flushing is required.

- The heating system's performance has dropped. The heating radiators take longer to warm up, the temperature of the working fluid in the return pipe is low, and the burner is on all the time. All these signs also clearly indicate that it is time to start flushing.

- Weak pressure in the tap and “barely alive” liquid in the hot water supply system also indicate that there are definitely problems in the heat exchanger.

Note! Modern gas boilers are manufactured with long-term operation in mind, and spare parts for them are quite expensive. For this reason, cleaning must begin immediately upon detection of the signs described above, otherwise the cost of servicing the device will increase significantly.

Correct operation of the heat exchanger: what to do to make the device last as long as possible?

- First of all, the make-up valve must be positioned correctly. During repair work, fluid may drain from the system. Often, replenishment is carried out through a special tap. If this happened once, then it’s okay, but if this tap is located at the entrance to the heating device and is supplied with cold water, then as a result the cast iron can experience the so-called “thermal shock” and simply crack. This happens due to the fact that cold liquid is supplied to the heated heat generator and the temperature jumps on a local scale, and cast iron, as you know, does not like this.

- You should not pour antifreeze into the system; as a last resort, use only a branded product. By the way, this costs about 600 rubles per liter. And if the area of the house is, for example, 250 square meters, then you will need about 200 liters of antifreeze. Of course, if desired, it can be diluted with water, but subject to strict adherence to proportions. For example, to obtain a liquid that will freeze at minus 25 degrees, the proportions are 1:1. Simply put, for the mentioned area you will need about 100 liters (read: 6 thousand rubles). Expensive - of course, but with such a coolant you will be able to protect yourself from possible problems for several years.

- Fill the system with softened water. As we have already found out, water hardness plays a key role in this matter. If the coolant is hard, then it will contain metal salts that can accumulate on the walls of overheated heat exchangers. This is almost the same as the scale that forms in a kettle.

Summing up a little

So, we found out that flushing the heat exchanger of a gas boiler (regardless of the chosen method) takes several hours and requires certain skills and knowledge. You can do this yourself, or you can entrust it to specialized companies. And you can check how well the cleaning was carried out both by indirect signs (increased productivity, absence of extraneous noise and overheating) and by means of a video probe inserted into the boiler body after washing. This will allow you to clearly see the quality of the result. The mentioned companies, by the way, provide such a service.

Methods for washing and cleaning pipes

There are two main technologies for flushing the heating system. How to flush the heat exchanger of a gas boiler must be decided on a case-by-case basis, based on the degree of contamination, financial capabilities and the configuration features of the heating system.

- Chemical cleaning. The principle of its operation is based on the dissolution of scale with special chemicals added to the coolant. These can be acids and alkalis. Biological treatment works in a similar way.

- Mechanical flushing. This is the oldest, but quite effective method. It consists of either supplying water under pressure into the main line, or, more effectively, disassembling the system and manually removing a layer of scale and other deposits.

These technologies for washing boilers, pipes and radiators can be applied in practice in several ways:

- cleaning with a water pulsating mixture. This method is based on the use of special equipment that pumps an air-water mixture into the heating system. In this case, the mixture is fed in a pulsating flow, washing away contaminants. This method is convenient because it is fast and efficient, but requires the use of expensive equipment;

- use of biological products . In this case, biologically active preparations are added to the coolant, interacting with many types of contaminants and gradually dissolving them. The use of such drugs is convenient because there is no risk of poisoning and no need to disassemble the system;

For example, an SP-V inhibitor can be used as an additive to the coolant. But before this, it is recommended to completely flush the system. For indiscriminate washing, you can use the chemical cleaning method using SP-OM liquid; it has successfully proven itself on an industrial scale. SP-OM perfectly cleans pipes made of any material and is safe for rubber seals and other non-metallic elements of the system. More details can be found on the manufacturer’s website https://spomcom.ru

- use of pneumatic-hydraulic shock. As in the case of a water pulsating mixture, hydropneumatic flushing requires the use of additional equipment that allows water to be cyclically pumped under high pressure into the system to create a controlled water hammer.

- cleaning the system with acid . By adding acid to the coolant, scale can be dissolved. Flushing the heat exchanger of a gas boiler with citric acid is very effective and easy to implement. However, it is necessary to understand that the acid will affect both the seals and the elements of the pipeline itself. Accordingly, there is a risk of leaks.

Popular means

Any method of removing contaminants will require a cleaning reagent. Liquids for flushing heat exchangers of gas boilers must be selected carefully, because... some types can corrode the material and cause equipment failure.

The following acids will help get rid of scale and deposits

- salt;

- sulfamic;

- orthophosphoric;

- lemon;

- Detex flushing fluid.

Hydrochloric acid, diluted in a concentration of 2−5%, is used to clean stainless steel and copper devices. Inhibitors as additives will protect the material from destruction. The substance is extremely aggressive, so it is better to entrust work with hydrochloric acid to professionals if the principle of its action is not fully understood.

Metal oxides are easily removed using a sulfamine solution. It does not harm the structure and is safe for home use. The composition contains an acid concentrate of 2−3% and anti-corrosion additives.

Heat exchangers of all types of gas boilers can be cleaned with phosphoric acid. The product fights dirt well, forms a protective coating on the surface and does not corrode the material. A solution with 13% reagent is sufficient for effective washing.

Citric acid qualitatively eliminates oxidation and scale when heated to +60°C, without affecting the metal of the structure. It is suitable for processing units made of brass, copper and stainless steel. The concentration may vary depending on the degree of contamination and range from 0.5−1.5%.

Steel, cast iron and copper devices are cleaned using a special Detex product that removes salts, scale, deposits and oxides. Active components and inhibitor additives protect the surface and extend the life of the device. The composition is diluted with water in a ratio of 1:6 - 1:10. As the reagent moves through the heat exchanger, gas is released. If its output stops, then the effect of the cleaning liquid has ended. To achieve the maximum flushing effect, you can increase the concentration of the Detex reagent, achieving the resumption of gas formation. After cleaning, the system is washed with a neutralizing solution and rinsed with water.

Do-it-yourself heating flushing

For self-flushing radiators, mechanical cleaning technology is most applicable. In this case, you will not have to use any special equipment or specific chemicals. Before you wash the heat exchanger of a gas boiler with your own hands, you should prepare the necessary materials:

- rags or old thick clothes. With their help, it will be possible to protect the bathtub from damage during the process of flushing the radiators in it;

- fum tape or plumbing linen with a tube of sealing paste;

- a pipe that allows you to connect a hose to threaded connections.

The equipment you will need is the following:

- two hoses;

- a set of keys;

- brush;

- steel wire brush;

- buckets, basin and rags.

The actual cleaning of the heat exchanger and lines consists of several stages.

- A hose of the appropriate diameter is connected to the drain pipe of the heating system. The other end of the hose is discharged into the sewer.

- A second hose is connected to the highest point of the system. As a rule, such a point is either a branch to the expansion tank or a safety group. The tank or safety group is unscrewed and a pipe is screwed into its place, onto which a hose is put. The second end of the hose is connected to the water supply.

- When everything is ready, water is supplied to the system. This makes it possible to get rid of scale and contaminants deposited in the system lines.

- Start draining the coolant. To do this, remove the hose through which tap water was supplied. The connection point to the system is not blocked. Under the influence of gravity, water begins to drain through the drain pipe at the lowest point of the line.

- Radiators are removed from the dehydrated system. Care must be taken when doing this. It is likely that the threaded connections on them are coked and you will have to make some efforts, trying not to damage the threads.

- The removed radiators are transferred to a bathtub, previously covered with rags or thick fabric. Here they are washed with running water, treated with a brush and a steel wire brush. After flushing the radiator, it is carefully inspected again for any remaining contaminants.

- The radiators are installed in place.

- The lines are filled with fresh water through the drain pipe. At the same time, monitor the formation of air pockets in the pipes and radiators. You can get rid of air bubbles by slightly opening the Mayevsky valves on the radiators. As soon as the air stops hissing and water begins to ooze from the tap, close it. As the lines fill, it is advisable to repeat this procedure several times.

- After the actual washing of the gas boiler heat exchanger is completed with your own hands, the heating system is put into operation.

- As the coolant begins to circulate, air pockets in the radiators may re-form. To eliminate them, the Mayevsky cranes are manipulated again. Some of the air will be removed independently through the air vent.

- As the pipelines and radiators are freed from air, the coolant pressure will drop. To level it, it is necessary to additionally pump water from the water supply. In addition, you should check the pressure in the expansion tank.

For an overview of connection diagrams for heating radiators in a private house, see here.

Liquids for flushing heat exchangers

In conclusion, we will consider the question of how to flush the heat exchanger of a gas boiler

Despite the abundance of recommendations in various sources, some caution must be exercised in choosing a cleaning product.

Many experts recommend using hydrochloric acid for washing. It removes scale really well, but is a rather aggressive compound that can damage the protective coating on the inner surface of the heat exchanger.

In addition, there is evidence that washing with hydrochloric acid can cause metal brittleness.

Citric acid is less dangerous for the heat exchanger material. It copes well with all types of deposits, as well as special reagents: DETEX, Cillit, Sanax and others.

Timely and proper care of the elements of the heating system will increase its service life and reduce the cost of maintaining operability. Cleaning the heat exchanger, as one of the most important operations performed during boiler maintenance, will make the most significant contribution to this process.

You might be interested to know

How to wash radiators

Natalia, depending on the design of the boiler, the following operations must be performed: 1. Using a long screwdriver, remove the front cover of the unit, the protective casing and the combustion chamber reflectors. 2. Disconnect the interfering wires of the flow sensors, temperature sensors, etc., as well as the pressure pipelines (in order not to forget how they are connected, you can photograph the internal filling of the unit). 3. Remove the fan and exhaust gas deflector. 4. The plate heat exchanger itself is similar to the radiator of a car heater and is attached with latches. 5. When removing the device, avoid sudden movements and mechanical impact - it is very easy to damage the heat exchanger. 6. When disconnecting copper pipes from the radiator, be sure to hold the nuts located at the base of the device with a second wrench, otherwise you may damage the outlet pipes of the device. After cleaning the heat exchanger, install it in the reverse order.

11 December 2015

Cleaning is necessary in the following cases: 1. The calculated parameters of the device differ significantly from those stated in the passport - the heat exchanger consumes more heat energy, but at the same time operates with less efficiency. 2. The time has come for the scheduled replacement of the rubber seals of the heat exchanger. 3. Such a dense build-up of dirt, scale, and scale has formed on the heat exchanger plates that it can only be removed mechanically.

11 December 2015

Based on my own experience, I can say: before choosing a method for washing a heat exchanger, it is necessary to take into account all its technical characteristics, analyze the degree of contamination, the intensity of work in order to settle on an option that will allow you to put the heat exchanger in order as carefully as possible, without causing damage to either the plates or seals by chemical reagents .

More information on the topic: https://all-for-teplo.ru

Price issue

From a financial point of view, the least burdensome way to clean your heating system is to do all the work yourself. In this case, the total costs will not exceed several hundred rubles. You will have to purchase consumables and tools:

- brush,

- brush,

- sealing tape or linen.

If you order cleaning from a specialized company, the cost of the work will depend on the technology chosen.

Washing one heating battery - from 800 rubles. This cost will include both the work itself and the solution of organizational issues: how to flush the heat exchanger at home, what technology will be used, etc.

What to do if scale remains

For owners who are not the most careful, who do not like to monitor the condition of their kitchen utensils, this is quite possible - all the scale will not be removed the first time, because the coating is too dense and thick. What to do in this case? You can repeat the procedure; the second time it will probably be more successful.

You can also try to enhance the effectiveness of citric acid with baking soda. In this case, pour one spoonful of acid and soda into the kettle, and then proceed as indicated above. After the water has cooled, it is drained and, if necessary, the walls of the kettle are mechanically cleaned of scale residues using a hard sponge.

Adblock detector

Tips for using heating pipes

To ensure that heating performance does not decrease below a critical state, you must adhere to several rules:

- Clean at least once a year

- If possible, avoid using untreated water as a coolant . In the simplest case, preparation consists of boiling, during which the content of dissolved salts is significantly reduced. Accordingly, the intensity of scale formation decreases. However, it is more effective to use special inhibitors that reduce the intensity of corrosion and scale deposits. When using inhibitors, make sure they are compatible with the material of the existing pipes and radiators.

- Coarse filters must be present on heating lines . They should be installed so that the pipe faces down. This will make cleaning easier and more effective, since all contaminants will be drained along with the water.

- to clean the wash filters at least once a year.

If the cleaning is carried out by specialists, when choosing a performing company, it makes sense to pay attention to those organizations that provide a guarantee for the work performed. Flushing the heating system is not the most time-consuming or complex undertaking. Even without assistants, it is quite possible to complete the task in one working day. Therefore, you should not neglect this procedure. The result will be not only trouble-free maintenance of a comfortable temperature in the house, but also significant savings on energy resources.

What is the best way to wash the device?

Now let's figure out what is best to use for washing

Despite the fact that there are quite a lot of recommendations and instructions, the choice of a specific liquid should be treated with extreme caution. Most experts advise using saline solution for this purpose.

This solution really effectively removes growths, but by its nature it is quite aggressive. Consequently, there may be a risk of destruction of the internal surfaces of the structure.

Note! In addition, there is information that the use of hydrochloric acid can lead to brittleness of the metal. But citric acid, as it turns out, is not so dangerous for heating equipment

It copes well with various types of scale – no less effectively than today’s popular reagents, including “Sanax”, “Sillit”, “Detex” and others

And if you promptly and, more importantly, competently care for all elements of the heating system, you can not only increase its performance, but also significantly extend its service life. Cleaning the heat exchanger - one of the most important operations, as we have already found out - will be a significant contribution to this process

But citric acid, as it turns out, is not so dangerous for heating equipment. It copes well with various types of scale – no less effectively than today’s popular reagents, including “Sanax”, “Sillit”, “Detex” and others

And if you promptly and, more importantly, competently care for all elements of the heating system, you can not only increase its performance, but also significantly extend its service life. Cleaning the heat exchanger - one of the most important operations, as we have already found out - will be a significant contribution to this process

Prevention measures

To prevent the appearance of scale and rust, it will not be superfluous to observe several points.

- After use, leave the kettles dry, pouring out all the water. Its remains produce calcium. It turns into scale and affects the walls of the products.

- Clean kettles at least monthly. The more often the procedure is performed, the less effort will have to be expended in the future. In addition, this will help maintain the functionality of the product for a long time.

- Boil only distilled water or purified water using a filter in a kettle.

- Rinse the kettle with a sponge after each use. This way you can remove scale at its initial stage.

The longer the kettle accumulates scale, the more time it will take to wash it. In any case, it is better to use proven methods, otherwise the risk of damaging the device increases.

Descaling methods

Washing the heat exchanger can be carried out using the in-place or disassembling method. The latter involves removing the unit from the gas boiler and subsequent cleaning. In the in-place option, plaque is removed with special devices.

Manual flushing

To wash it manually, you will need to remove the device. Using a metal brush, dirt from the outside is removed. The unit is soaked in a washing liquid or acidic composition for several hours.

This cleaning method prevents substances from circulating through the system and destroys seals. After flushing procedures, it is necessary to ensure that the connections remain insulated and do not leak when pressure increases.

You can manually wash the heat exchanger

Use of chemicals

Flushing with this method does not imply dismantling the heat exchanger. The unit must be connected to a booster to remove deposits, rust and scale. The device is equipped with a pump that will circulate the chemical through the heat exchanger parts for several hours. The cleaning composition is able to remove even the most serious deposits without corroding metal structures.

Hydrodynamic method

Another in-place cleaning option is hydrodynamic cleaning. Special equipment (booster) passes water under high pressure through the heat exchanger. To improve cleaning efficiency, a filler with abrasive components is added to the liquid. The high speed of water movement allows you to eliminate scale on the walls of the device.

It is better to invite a specialist to wash using this method. Incorrect pressure settings can cause damage and rupture of heating elements.