Combined gas-wood boilers are, first of all, solid fuel boilers that have only a slightly modified design into which you can install a gas burner that burns natural or liquefied gas. Replacing the burner is done quite quickly, on your own, according to the manufacturer’s instructions, so combination boilers are multifunctional and, despite different opinions, retain the reliability and durability of simple solid fuel and gas models.

Despite all the advantages, we do not recommend considering combined models (with the exception of a few cases), since purchasing a separate gas boiler and a solid fuel boiler will cost much less, and the disadvantages of a dual-fuel design are often significant. Let's look at everything in order.

Features of combined boilers for solid fuel and gas

Universal heat generators are floor-standing units that do not differ in size from classic solid fuel models of similar power.

A feature of a dual-fuel boiler is the possibility of an additional installation for burning gas.

Scope of application

The use of universal settings is advisable under the following circumstances:

- due to the small area of the house, it is impossible to allocate enough space to install 2 single-fuel units;

- there is easy access to one of the types of solid fuel - waste from the woodworking industry, coal, firewood;

- gasification of the house is planned.

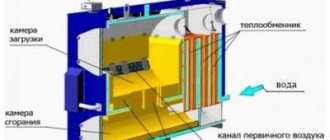

Boiler design

The combined device consists of the following components:

- Furnaces where fuel is burned - wood, coal, pellets. Some models use 2 separate working chambers. A gas burner is mounted in the lower one, and a grate is installed in the upper one.

- The housing is made of steel and covered with thermal insulation on the outside.

- Chimney for removal of combustion products.

- Heating circuit for heating the room.

- Automation systems that control the operation of the installation.

Combination boiler design.

How the device works

In the chamber of a mixed type boiler, solid fuel is burned. Water circulates between the walls of the firebox and enters the heating circuit. Firewood is loaded through the door in the unit housing. Gaseous combustion products are removed through the chimney. At the bottom there is a box for collecting ash.

To enable the device to operate on gas, a separate burner is mounted inside. It turns on when the chamber runs out of solid fuel. This makes it possible not to waste more expensive natural gas.

Modes are switched automatically or manually, depending on the functionality of the boiler model.

The design features of the device, such as a volumetric combustion chamber for solid fuel, reduce the energy efficiency of the installation. The efficiency of mixed type boilers is in the range of 75-85%. The best result is obtained by using 2 separate fireboxes for wood and gas. However, such models are much more expensive than classic boilers.

Varieties

Wood-burning solid fuel boilers for heating a private home are in most cases represented by classic convection units. In them, wood burns directly, forming a powerful flame, the heat from which is immediately collected by a heat exchanger. Disadvantages of this scheme:

- Lack of ability to smoothly regulate temperature;

- Not the highest efficiency;

- Virtually no automation.

Using traditional wood-burning boilers, it is difficult to maintain a certain temperature; if the combustion intensity is regulated, it is within extremely small limits.

Pyrolysis heating wood boilers are an alternative to convection devices. They are built according to a gas generator scheme. Firewood here burns in an oxygen-poor atmosphere. In fact, they do not burn, but simply smolder. Due to the high temperature, they begin to release pyrolysis products that are flammable. Combustible gases are burned in a separate chamber (called an afterburner), into which secondary air is supplied. And in order to be able to regulate the intensity of combustion, the equipment is equipped with blower fans.

Boilers built using the pyrolysis type are more complex than their convection counterparts. Here we see two chambers - in one, firewood smolders, releasing pyrolysis gases, and in the second, these gases burn at a very high temperature, reaching +800-1000 degrees. The generated heat is absorbed by the same fire-tube heat exchanger and partially by a protective water jacket (if any).

Pyrolysis wood boilers are equipped with automation systems that control blower fans. As soon as the temperature in the heating system with batteries reaches a predetermined limit, the fan stops and the flame in the afterburner goes out. This happens until the temperature in the heating drops - then the blower fan starts, and a humming flame appears in the afterburner chamber again.

Pyrolysis gas-generating wood boilers require dry wood. Using raw logs will make pyrolysis difficult or impossible. The efficiency of this equipment reaches 90%, as the calorific value of solid fuel increases.

When the boiler switches from wood to gas

The main type of fuel for a combined boiler is solid fuel. The device can work up to 4-5 hours on one load. Pyrolysis boilers are capable of heating a room for 8-10 hours. The gas burner comes into operation only when the firewood runs out. It maintains the set water temperature in the heating circuit. To avoid unnecessary gas costs, it is recommended to immediately add wood to the stove without waiting for the fire to completely go out.

Solid fuel is the main type of fuel for a combination boiler.

Criteria for choosing a combi boiler

When choosing equipment, several criteria should be taken into account simultaneously. In addition to the performance of the device, it is important to pay attention to the dimensions, design features of the model, and the possibility of expanding functionality by installing additional blocks and components.

Power

The main parameter of any heat generator is power. The size of the room the boiler can heat depends on this criterion. As power increases, equipment costs and fuel consumption increase. Therefore, choosing installations of maximum productivity is not always economically justified.

Power is the main parameter of the boiler.

Manufacturing materials

The most common materials for the manufacture of domestic heating systems are cast iron and steel. They have good thermal conductivity and strength. Cast iron heat exchangers are less susceptible to corrosion, but have more weight. The material is used in more expensive models. The service life of cast iron heat exchangers is up to 25-30 years. Another disadvantage of the material is fragility. Strong impacts can cause cast iron to crack.

Steel heat exchangers have less weight. They are resistant to temperature changes and mechanical damage. Such devices are inexpensive.

The disadvantage of metal is less resistance to corrosion. The service life of steel heat exchangers is 12-15 years.

Possibility of installing a water circuit

On sale there are heating boilers equipped with both 1 and 2 working circuits. In the latter case, the devices can be used not only for heating the room, but also for preparing hot water. Some boilers provide the possibility of additionally installing a water circuit. Another option is to use an external indirect heating boiler.

Some boilers have the option of installing a water circuit.

Dimensions and weight

Weight and size parameters are selected depending on the installation location of the unit. Cast iron models are heavier. Weight and dimensions increase in direct proportion to the increase in plant power.

Efficiency

The energy efficiency of solid fuel devices directly depends on the design of the unit and the characteristics of the fuel - humidity, type of wood, ash content. Pellets are considered the best fuel. For household use, it is recommended to choose models with an efficiency of at least 80%.

How to calculate the power of a boiler for TT and gas

To calculate the performance of heating equipment, several parameters should be taken into account:

- room volume;

- area of windows and doors;

- quality of thermal insulation of the building;

- climatic conditions of the area.

To calculate the boiler performance, the volume of the room is taken into account.

So, for an uninsulated house located in central Russia, with a height of 2.5-3 m per 10 sq. m area should be at least 1 kW. It is also advisable to provide a reserve of 20-30%. The resulting value is rounded up. If you plan to install a double-circuit boiler, it is recommended to add another 10-15% of power, because the heating circuit stops working when the appliance switches to hot water heating mode.

Approximate Cost: Factors Affecting Price

The number of energy sources used in the boiler is an important selection criterion. It affects the operating principle and functions of heating equipment. This parameter also determines pricing. It takes a lot of effort to make a multi-tank technique. The dimensions of the units are also becoming larger.

In addition, the cost of the boiler is determined by its power, set of functions and the presence of automation.

The average price of a combined installation is 40-70 thousand rubles. More advanced units with modern electronics and a power of over 30 kW will cost 100-160 thousand rubles.

Combination boiler installation

The heating device should be installed in an insulated room. Requirements for communication wiring and installation location are specified in the accompanying documentation for the product. It is necessary to ensure a flow of fresh air into the room, because... When fuel is burned, the oxygen concentration decreases. A chimney is provided for the removal of gaseous products. You should first check the traction level.

The unit is mounted on a flat surface. If the floor in the room is made of wood, to ensure fire safety, a concrete block is laid on the floor, and a sheet of heat-resistant steel with a thickness of at least 8 mm is placed on top. Fireproof boards are also used. The floor surface must be level. A building level is used for control. Ceramic tiles can be laid on top of the blocks.

It is recommended to protect the section of walls next to which the equipment is installed with a metal sheet or asbestos.

There needs to be a flow of fresh air in the room.

When connecting the device to a heating circuit, it is necessary to install shut-off valves at the inlet and outlet.

This will make it possible to repair and maintain the boiler without draining the water from the system.

If installation and wiring were carried out on your own, before putting the installation into operation it is better to invite a specialist who can check the correct installation and connection of the unit.

How to organize smoke removal

SNiP prohibits connecting several boilers operating on different types of fuel to a common chimney. If a scheme is chosen that excludes simultaneous operation of the units, the fire department and gas workers can give permission for such a connection. But it is better to install a 2-pass pipe with its own channel for each heater.

Several boilers cannot be connected to a common chimney.

When connecting 2 devices to a common pipe, adhere to the following rules:

- The insertion points are spaced at a distance of 1 m or more.

- A damper is installed on each branch so that when the boiler is idle, smoke from another unit does not enter the room.

- The cross-section of the main chimney is selected according to the total power of both devices.

Due to the large diameter of the pipe, when 1 heater is operating, a joint connection has the following disadvantages:

- the volume of condensate increases (the channel warms up worse);

- At low power, traction deteriorates.

Features of operation of a combination boiler

The use of universal type installations has a number of nuances:

- If the main fuel is solid fuel, it is necessary to ensure a sufficient supply of firewood or coal. This will make it possible to avoid unnecessary expenses on gas bills.

- Before putting the heating boiler into operation, the system is filled with water or antifreeze. The process should be carried out slowly to avoid the formation of air pockets in pipelines and radiators.

- During operation of a solid fuel unit, soot and fumes are formed, which settle on the heat exchanger and the internal surfaces of the chimney. This may lead to a decrease in unit performance. It is necessary to regularly clean the communications and internal parts of the firebox.

- To increase the efficiency of the device, you should use high-quality fuel. Firewood or coal with a high moisture content will need to be dried first.

- The operation of models capable of using pellets as fuel can be optimized. To do this, special capacious bunkers are installed, from where fuel is automatically supplied to the firebox.

The best models and manufacturers

When choosing a boiler, it is recommended first of all to pay attention to the products of leading companies that develop heating devices.

Teplodar Kupper OK 15

The domestic manufacturer’s installation has a power of 15 kW and is capable of heating a room with a total area of up to 150 square meters. m. The model uses an open combustion chamber. The Kupper OK 15 boiler is a non-volatile device, so it can operate without being connected to the electrical network.

Teplodar Kupper OK 15 heats a room up to 150 sq. m.

The use of coal, firewood and pellets is allowed as fuel. With the additional installation of a special burner, the device can operate on natural gas. An internal heating element with a power of 6 kW is provided. The heat exchanger is made of furnace steel. The efficiency of the installation is 78%. Mechanical control. The disadvantages of the model are high soot formation, a small loading hole and a small firebox, which can accommodate firewood no more than 35 cm long.

Hephaestus VPR KSTGV-20

A gas and solid fuel boiler in one system with a power of 20 kW is designed for floor mounting. The primary heat exchanger of the heating circuit is made of steel. Thanks to its design features, the device has good efficiency - up to 80%. The Hephaestus VPR KSTGV-20 model uses an open combustion chamber. The control is mechanical, the device is capable of operating in autonomous mode.

The boiler runs on coal and wood. The heat exchanger for preparing hot water is made of copper. The device is equipped with a burner capable of operating at reduced gas pressure. The operation of the installation is controlled by automation from the Italian company SIT. There is a gas control function that turns off the burner when the flame breaks off. Additional installation of heating elements is possible.

Zota Master-20

The heat generator of the Russian manufacturer has a power of 20 kW and an efficiency of 75%. The Zota Master-20 model is suitable for heating a room with a total area of up to 200 square meters. m. All solid fuels can be used as fuel - wood, coal, peat. The body of the device and the primary heat exchanger are made of boiler steel. The spacious working chamber allows you to load a large volume of fuel. Installation of an additional gas burner is possible. To prepare hot water, it is possible to install a DHW circuit. The model uses mechanical control.

Zota Master-20 has a power of 20 kW.

For easy cleaning of the firebox, a movable grate is used. The ash pan is installed on a water-cooled surface, which has a positive effect on the efficiency of the device. Additionally, it is possible to install a draft regulator. A thermomanometer is provided to monitor operating parameters.

Viadrus hercules U22 D

The model of the Czech manufacturer with a power of 22 kW is equipped with an open chamber and has a convenient ergonomic design. The efficiency of the device is 80%. The heat exchanger is made of cast iron. The boiler can operate on wood, coal, peat, pellets. Additional installation of a gas burner is possible.

The spacious firebox allows the use of logs up to 45 cm long. An additional circuit can be installed to prepare hot water.

Due to the cast iron heat exchanger, the total weight of the structure is 250 kg. The surface for mounting the unit must be well leveled and have high strength. Many owners note that when the draft gate is closed, increased soot formation is observed. The main disadvantage of Viadrus hercules U22 D is its high cost.

Mimax KSTGV-12.5

The 12.5 kW device is designed for heating a cottage or summer house with a total area of up to 125 sq. m. m. The unit has a high efficiency of 87%. Heat-resistant steel is used to manufacture the primary heat exchanger. The stove can be heated with wood, peat, or coal. Installation of a gas burner is allowed. A double-circuit solid fuel boiler is designed both for heating a house and for preparing hot water for domestic needs. There is a gas control option.

Mimax KSTGV-12.5 has a power of 12.5 kW.

Karakan 20 TEGV

The domestically produced device is equipped with 2 circuits. The power of the unit is 20 kW. The heating boiler is suitable for a private house with an area of up to 200 square meters. m. The model is distinguished by its simplicity of design and reliable mechanical control. Karakan 20 TEGV is able to work without connecting to the mains. It has a spacious firebox and a large loading opening. The device can operate on wood, coal, and waste from the woodworking industry. Equipped with a built-in heating element. The efficiency of Karakan 20 TEGV is 75%.

Roda Brenner Classic BCR 04

The gas-wood boiler from a Czech manufacturer is distinguished by its convenient design and reliability. Durable materials with high mechanical and corrosion resistance are used for manufacturing. The power of the Roda Brenner Classic BCR 04 is 23 kW. The combi boiler is designed to operate on wood, coal and natural gas.

The heat exchanger is made of cast iron, the body is covered with reliable thermal insulation. The unit has a large mass, so the unit can be mounted on a flat, solid surface. The efficiency of the model is 80%. The main disadvantage is the high cost of the product.

Reviews of universal boilers from owners

Ivan, 59 years old, Smolensk:

“I installed a long-burning Roda Brenner boiler in a country house six months ago. I burn with wood. The workmanship is excellent. Thick walls, good thermal insulation. Quickly warms up the room after startup. There is only one drawback so far – the high price.”

Alevtina, 37 years old, Saratov:

“I have been the owner of the Zota master 20 boiler for more than 2 years. My husband did the installation and did everything himself. We chose the model for its versatility and large firebox volume. No critical problems were found during operation.”

Yuri, 48 years old, Bryansk:

“I use an apparatus from the domestic manufacturer Teplodar, model Kupper approx 15, to heat the dacha. At first, when igniting, smoke often entered the room, then this problem disappeared. Among the disadvantages, I can note the shallow firebox - you can only use short logs. The walls of the device are thin, it is unknown how long it will last.”

Safety precautions during work

Observe the following rules:

- In a room with a gas boiler, install a gas analyzer connected to the solenoid valve on the fuel supply line.

- To avoid sparks, ground the metal parts of the unit.

- Supply gas through the dielectric insert.

- Do not store flammable materials in the same room as heaters.

- Regularly clean the chimney of a solid fuel boiler from soot.

When installing the boiler, follow the safety rules.

If you smell gas, do the following:

- close the valve on the fuel supply line;

- open doors and windows to ventilate the room;

- call a specialist.