In recent years, Russian manufacturers of heating equipment have achieved considerable success.

One of the devices that has become popular is, without a doubt, the Conord gas boiler: reviews of this equipment in the vast expanses of the Runet are quite common.

What exactly users write and what types of boilers this manufacturer offers will be discussed in our article.

About company

The production facilities of the Russian brand Conord are located in Rostov-on-Don. Gas heaters have been produced here since the seventies of the twentieth century. Today it is a leading Russian manufacturer, the quality of its products is based on large-scale modernization of production. Instead of old machines, European lines were launched - Swiss and Italian. The cost of manufactured heaters is much lower than European ones - in the range of 15-50,000 rubles.

CONORD is not just a name consonant with the name of a large eagle, it is an abbreviation. It stands for: Heating boilers of non-standardized equipment Rostov-on-Don. The first heating boiler produced by the company is DON-16.

Device (automation)

The main element is the gas burner. It heats the heat exchanger in which the coolant is located.

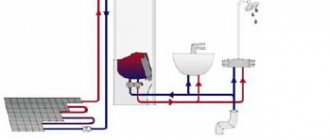

It is supplied by gravity or under the action of a circulation pump (purchased separately and connected as an external component of the system) into the heating circuit.

For double-circuit models, a coil is installed around the smoke pipe to heat the hot water of the DHW circuit.

Smoke is exhausted naturally, using the chimney draft, to which the boiler should be connected during installation.

The heating system must be installed taking into account the placement levels of radiators that ensure natural circulation of the coolant.

If this is not possible, you have to use a circulation pump, which stabilizes the liquid movement mode, but makes the boiler energy-dependent.

Advantages

After reading reviews about the products of the Rostov enterprise, it is easy to understand that they are in high demand. The Russian consumer is attracted to Conrod products by:

- Cost - prices for Russian products are much lower than for European ones. Sometimes the difference is 50%. The cheapest 8 kW models, used for heating a private home, cost only 15,000 rubles.

- Long warranty. The manufacturer guarantees uninterrupted operation for fifteen years.

- Does not depend on electricity. A blackout, especially in winter, due to lack of electricity, is almost a disaster. Therefore, for volatile equipment it is necessary to install backup power - a generator or battery. There are no such problems with Conord.

- Easy to use. The abundance of functions, electronics and automation from other brands often causes unnecessary trouble.

- Quiet operation.

- High quality build.

- Good technical characteristics: Rostov boilers are practically not inferior to foreign analogues in productivity, efficiency, and heating speed.

- High efficiency - about 90%.

Advantages and disadvantages

The positive features of gas appliances from Conord can be determined according to the reviews of those owners who actively use them:

- large model range;

- models have 3 types of automation;

- efficiency;

- high efficiency;

- in the event of a boiler breakdown, you can find spare parts quite quickly;

- good thermal insulation;

- guarantee of flawless operation for 3 years;

- uninterrupted operation for almost 15 years;

- steel heat exchangers help withstand thermal deformations;

- the use of water from the water supply system as a coolant;

- the ability to connect to a system with various types of circulation of the working environment;

- almost complete absence of wall-mounted appliances;

- energy independence of devices;

- use in certain series of automation parts made in Italy and Poland;

- simplified process of using the device.

Boilers from this manufacturer are created in accordance with the characteristics of the domestic climate and are designed to generate the required amount of heat to warm the home even in the most severe frosts.

The reliability of these popular devices is guaranteed by the increased level of durability of heating devices, and their independence from electricity will allow them to function without any failures or delays, especially in conditions where there is no electricity.

The low level of noise impact during operation, compact size and stylish design will allow you to place the device in the kitchen or any other room without harming the design of this room.

A gas unit with 2 circuits from Conord can heat the room as quickly as possible, and also provide home owners with heated water for personal needs.

The safe operation of the products is guaranteed by the arrangement of various protection components of the automation box, which will help turn off the product when the traction is lost. In addition, the boiler will be turned off in the event of any breakdown or any other type of failure. You will be able to automatically adjust the heating temperature of the device, and if the fuel pressure level is too low, the device will provide rapid forced air injection to maintain the functionality of the device.

Disadvantages of Conord products:

- not the highest build quality of some models;

- the steel thickness will be no more than 3 mm;

- ban on the use of antifreeze.

Design Features

- Convenient adjustment. Heating is adjusted by a mechanical rotary regulator, which allows you to change the strength of the fire.

- Simple ignition - no complex automation, which in imported analogues often makes you nervous.

- Thanks to its special design, the cold-rolled steel heat exchanger is resistant to overheating, which significantly increases its service life.

- The burner is capable of operating even at the lowest gas pressure.

- Low heat loss - the body is thermally insulated.

- Dimensions are modest. Floor-standing units are always larger than wall-mounted units, but Conord’s dimensions are quite acceptable for small rooms. Stylish design - easily combined with modern interiors.

- The body is lined with steel sheets (3 mm thick): thanks to the powder coating, they are characterized by increased heat resistance.

- The burner flame is modulated automatically - the device is economical and efficient.

- A transition to another fuel is provided.

- The security system protects the device from emergency situations.

Technical characteristics of Conord boilers

Among the common characteristics of all boilers of this brand:

- warranty period - 3 years;

- nominal service life is approximately 15 years;

- the service life of units equipped with cast iron heat exchangers can be up to 25 years;

- heat exchangers are made of cold-rolled metal, so they can easily cope with thermal deformations;

- The coolant in the system with the Conord boiler is water from the water supply;

- it is prohibited to use antifreeze;

- the ability to use equipment with or without a circular pump.

What are they?

If you are interested in the products of the Rostov manufacturer, you can choose a boiler from four series.

- With Italian automatic equipment SIT: KSts-G-S/ KSts-GV-S - single-circuit/double-circuit.

- With thermo-hydraulic automation: KSts-G-N/KSts-GV-N - single-circuit/double-circuit.

The manufacturer offers heating boilers with two types of heat exchangers: steel and cast iron. All gas heaters produced by the Rostov enterprise are only floor-standing. If you're interested in a wall-mounted unit (with a closed firebox), you'll have to look to a different brand.

Steel

Heaters with steel heat exchangers have the following advantages:

- Steel is more ductile compared to cast iron.

- Specific gravity is less.

- High heat dissipation.

There is one minus, but a very important one - low resistance to damage and corrosion. That is why consumers who know a lot about materials choose cast iron analogues. Manufacturers try to minimize this by using durable coatings, but they cannot provide 100% corrosion protection.

Cast iron

The main advantages of cast iron heat exchangers: high thermal conductivity and immunity to corrosion.

Minuses:

- Cast iron is less flexible and ductile than steel and is not as resistant to deformation.

- Inferior to steel in strength.

- Brittleness is the main disadvantage of cast iron. Particularly dangerous situations arise during transportation and installation, which is why installation should be entrusted to specialists. After delivering the device home, be sure to check the integrity of the cast iron heat exchanger. Even the presence of microcracks is a most dangerous situation for equipment. If they appear, the equipment will soon fail and the heat exchanger will need to be replaced.

Second group with a steel heat exchanger:

The Conord boiler with the design of a steel cylindrical heat exchanger made of cold-rolled metal is offered by the plant in single- and double-circuit versions. The service life is reduced compared to cast iron to 15 years. The designs use two automation options.

The first option: SIT automation from an Italian company known for its quality throughout the world. It is installed in the vast majority of all manufactured boilers in the European Union, such famous devices as: IMMERGAS, Fondital, Vaillant, Bosch and many others. The SIT valve allows you to guarantee a stable set temperature.

In addition, automation controls stable operation with a reduced gas pressure in the city pipeline. So the nominal value provides for operation with a pressure of 1.3 kPa, but a drop to 0.6 kPa is not a big problem and the Conord gas boiler continues to operate steadily, despite the fact that this is 46% less than required.

Single-circuit, with automatic SIT – heating only:

KSts-G-8S Heating capacity =8 kW KSts-G-10S Heating capacity =10 kW KSts-G-12S Heating capacity =12 kW KSts-G-16S Heating capacity =16 kW KSts-G-20S Heating capacity =20 kW KSts-G-25S Heating capacity =26 kW KSts-G-30S Heating capacity =30 kW KSts-G-40S Heating capacity =40 kW KSts-G-50S Heating capacity =50 kW

Single-circuit, with thermohydraulic automation

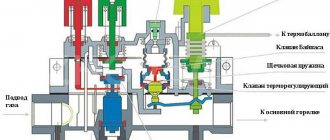

The second option is more budget-friendly, equipped with domestically developed AGU-T-M automatic equipment. AGU is an automatic gas burner device, consisting of nozzles and safety automation. The main manufacturers are Mimax and Tagonrog. ASU automation consists of:

- temperature sensor;

- igniter with thermo-bimetallic plate;

- adjusting screw with lever;

- gas valve;

- block crane;

- connecting parts.

Ignition order:

- We check the draft, move the damper, light the igniter.

- Press the gas valve and light the wick. We fix and do not release the button until the bimetallic plate heats up.

- While continuing to hold the button, follow the lever. It will creep onto the inscription “on the button”, we need to wait for the moment when it is fixed.

- Release the gas valve and set the required temperature using the control knob.

Domestic automation makes it possible to buy a Conord boiler a little cheaper. In contrast to European analogues, it has the simplest design. It is non-volatile - no power supply is required. The starting process is carried out manually by igniting with matches or a lighter. By the way, thermo-hydraulic automation type AGU-T-M is widely used in Russian gas boilers

According to customer reviews, such automation is completely unpretentious, and the Conord floor-standing boiler equipped with it is not “capricious.” In addition, it is not difficult to find spare parts on the market even far from city centers. The prices are also not satisfactory, for example, one of the frequently requested parts - a bimetallic plate - is found everywhere for no more than 100 rubles.

KSts-G-10N Heating capacity =10 kW KSts-G-12N Heating capacity =12 kW KSts-G-20N Heating capacity =20 kW KSts-G-25N Heating capacity =25 kW KSts-G-30N Heating capacity =30 kW

Double-circuit with DHW and SIT automatic control system

The Conord floor-standing gas boiler, when equipped with two circuits, copes with the task of heating buildings and at the same time is capable of preparing hot water used for household needs. The design uses the proven modulation function. Burner operation using modulation significantly increases the efficiency of hot water supply.

KSts-GV-8S Heating capacity =8 kW KSts-GV-10S Heating capacity =10 kW KSts-GV-12S Heating capacity =12 kW KSts-GV-16S Heating capacity =16 kW KSts-GV-20S Heating capacity =20 kW KSts-GV-25S Heating capacity =25 kW KSts-GV-30S Heating capacity =30 kW

Double-circuit with DHW, with thermo-hydraulic automation

KSts-GV-12N Heating capacity =12 kW KSts-GV-20N Heating capacity =20 kW KSts-GV-25N Heating capacity =25 kW KSts-GV-30N Heating capacity =30 kW

Boiler Conord decoding

- K – boiler

- C – steel material for the heat exchanger

- C – cast iron, heat exchanger material

- G – gas

- B – DHW circuit

- C – cylindrical.

Secrets of High Performance

Modifications with thermohydraulics are non-volatile. The operating principle is based on the use of a thermostat. When the temperature reaches the declared value, the gas supply to the burner stops. This maintains the necessary heating of the coolant.

The devices are ideally adapted for harsh winters: they can stably maintain the required heating, the main thing is to correctly calculate the power. Efficiency increases due to:

- modulating burner;

- obtaining the optimal composition of the gas-air mixture;

- leaving the bulk of the heat for heating the coolant.

Description and automation

The Conord boiler is made of 3 mm thick steel and has a high efficiency of 90%.

It became popular due to two serious advantages: budget cost and independence from electricity. Today, Conords are produced in two modifications - with and without the ability to prepare hot water. Moreover, any model can be equipped with thermo-hydraulic automatics or SIT automatics. This function makes it energy independent, and the fuel supply is controlled by a thermostat. This happens as follows: when the temperature reaches a certain parameter, the gas supply is shut off; This is how comfort mode is maintained.

This equipment is designed for moderately cold or very cold winters: the main thing is to correctly calculate the required power, and the unit itself will maintain the optimal temperature.

How to decipher the symbols

For example:

- KSts-GV-12

- KSts-G-10S

"K" is for boiler. "C" - made of steel. "C" - cylindrical firebox. "G" - gas. "GW" - heats the water. The number is the maximum power.

How to choose the right performance? For 10 sq.m you need 1000 W (ceiling height 2.5 m). This formula is suitable for rooms with average heat loss.

Single-circuit gas boiler ServiceGas Ochag Premium AOGV-11.6-Ewith SIT automatics

Gas boiler Ochag AOGV-11.6 Premium EuroSit ServiceGas is a single-circuit device, the main purpose of which is to heat private households, apartments in houses, as well as various types of buildings

When developing the Ochag AOGV device, the specifics of Russian gas pipelines were taken into account, namely the low pressure of the incoming gas. The Hearth boiler is completely energy-independent and operational in heating systems with normal (working) pressure up to 3 atm, both closed - forced type with a pump, and open type with natural coolant circulation

The marking of the “Ochag” units is quite simple; next to the abbreviation A-O-G-V (gas hot water heating unit) there is a number indicating the boiler power in kW, after which the letter indicates the boiler’s automation:

C – SABC (T or AT)

E or EM (EN) – Eurosit

Advantages of the heating device "Ochag" Premium with a power of 11.6 kW

- Moderate gas consumption. The manufacturer has included a stabilization device in the boiler design to equalize the fuel pressure. With the help of a stabilizer, gas consumption is reduced by 30%.

- Protection during operation of the device is provided by a safety system that will automatically turn off the boiler in the event of: insufficient or complete absence of draft in the chimney, the burner flame goes out, the gas line is cut off, and a coolant overheating control device will protect against premature wear of the heat exchanger.

- Non-volatile. The fireplace is an autonomous boiler and does not require any external sources of electricity to operate.

- A strict, but at the same time modern appearance that fits perfectly into the modern interiors of apartments and houses without standing out compared to other equipment in the house.

- Accurate temperature setting.

- The highest efficiency of 92% in its class by means of modernizing the fire-tube heat exchanger device, which is made of high-quality steel up to 3 mm thick and fully complies with Russian GOST.

- Works great in closed heating systems with operating pressure up to 3 atm.

- Equipped with automatic gas block 630 EUROSIT (EUROSIT).

- Equipped with a pressure indicator in the heating circuit and a thermometer showing the temperature of the coolant.

- The special connection of the smoke collector ensures simple and convenient installation and maintenance work for the chimney part of the device.

- Warming up of the chimney is ensured, this is especially true when starting the boiler in the off-season, thanks to the built-in damper - “TURBO mode”.

- There is also the possibility of operating the device on liquefied gas; when changing burner nozzles, this is possible and feasible as an option.

- The hearth is also convenient for the user as it has detachable turbulators, it is possible to lay a gas supply on both sides of the device, a reversible door with opening both to the right and to the left, a quick-removable top cover, and a condensate collector. The burner (burner unit) is mounted on an easily detachable mount.

- The burner itself is made of heat-resistant steel - stainless steel with very economical gas consumption.

- High quality build. Multi-level quality control.

- Service life 15 years, factory warranty 24 months.

The Ochag Premium AOGV boiler has the main parts:

- Gas apparatus housing

- Automatic control module

- Steel heat exchanger

- A security system consisting of several subsystems.

A firebox or combustion chamber is installed in the body of the apparatus on the lower side; sections of the heating jacket are located on the side and rear of the apparatus. A heat exchanger is located above the firebox. High efficiency of heat transfer and heat exchange between exhaust carbon monoxide and coolant is achieved due to the progressive convective part of the heat exchanger, which consists of flame tubes.

A smoke collector with a built-in draft stabilizer is installed on top of the heat exchanger. In the front part of the smoke collector there is a draft sensor, in the upper part of the smoke collector there is a boiler outlet pipe.

There is a partition on top of the smoke collector to ensure stable operation of the device regardless of weather conditions. The heat exchanger, complete with a smoke collector, ensures cost-effective operation of the boiler without the participation of the consumer, and does not require any manual adjustments. The draft stabilizer allows the boiler to operate stably even with unstable draft.

A gas burner device is installed in the combustion chamber of the apparatus, which consists of a front panel, burner pipes, safety sensors (flame sensor and draft sensor), and the EUROSIT control system. There is a lattice damper located under the pipes, which helps supply secondary air to the burner.

How they work

The firebox is made of 3 mm steel sheets. There is a water jacket, a gas burner unit and smoke pipes with turbulators, which increase the efficiency of the device. The gas burner unit operates automatically - the power is modulated. Basalt cardboard is used for thermal insulation. There is a thermometer to visually monitor the water temperature.

If the model is 2-circuit, then the chimneys are equipped with a coil for hot water supply. The input-output of the latter is located on the rear panel of the case. The diameter of the pipes is 2 inches / 5 cm. For hot water supply - 0.5 inches or 1.5 cm. Devices with a power of 8-12 kW have a chimney with a diameter of 11.5 cm. 16 kW - 15 cm. There are modifications with and without circulation pumps .

Important! The coolant of the system is plain water; the use of antifreeze is prohibited.

Gas water heating device

The use of Italian SIT automation ensures stability of the set temperature and operation at low gas pressure.

Possibility of installing a circulation pump and operating the AOGV in a closed heating system. The cylindrical heat exchanger is made of high quality steel and can withstand high pressure.

3 years warranty

Simple installation without reworking the heating system or replacing the design. Complete match of all connecting dimensions for this model

| Connecting thread of the gas supply fitting | ½» |

| Efficiency for exhaust gases on gas fuel | at least 85-90% |

| Operating water pressure in the apparatus | 100+20 kPa (1.0+0.2 kg/cm²) 0.12 (1.2) |

| Water temperature in the apparatus | 50—90 °C |

| Internal dimensions of the chimney | ø 112.6 mm |

| Nominal gas pressure | 1274 Pa (130 mm water column) |

| Exhaust gas composition: | - no more than 119 mg/m³ carbon monoxide CO - no more than 240 mg/m³ nitrogen oxide NO |

| Discharge behind the device | — minimum 5 Pa — maximum 25 Pa |

The power calculation does not include the power consumed by the hot water circuit. All parameters indicated in the table correspond to the operation of the device at rated heat output and established thermal equilibrium.

The prices presented on the website are not a public offer and may differ at points of sale.

How to maintain your warranty

In order not to be denied warranty obligations, you should not undertake installation and adjustment work. Connection, configuration, and first start-up are carried out by service center specialists. They also make a record of the work done in the device passport. Preventative maintenance should be carried out annually - this is also noted in the technical passport. Failure to maintain such records will void the warranty.

The instructions and connection diagram are provided for reference. Their presence in the package does not mean that the owner of the equipment can connect it himself.

The lineup

Conord gas floor-standing boilers go on sale in several series. Each of them has its own characteristics.

- Conord single-circuit boiler with SIT automation:

- power – from 9 to 27 kW;

- temperature adjustment ranges from 60 to 90 C;

- system pressure – from 0.3 to 1.8 BAR;

- approximate cost – 12,000 rubles.

- Conord single-circuit boiler with thermo-hydraulic automation:

- power – from 11 to 27 kW;

- cylindrical heat exchanger;

- system pressure up to 5 BAR;

- approximate cost – 13,000 rubles.

- A unit with two thermal circuits, that is, it can be mounted inside a boiler system:

- power – from 12 to 30 kW;

- both natural and forced types of coolant circulation are acceptable;

- the average price is from 15,000 rubles.

- Double-circuit heating plant with SIT automation:

- power ranges from 11 to 29 kW;

- both natural and forced types of coolant circulation are acceptable;

- this model has a specialized sensor that can both turn off the gas supply if there is no traction, and restart the fuel supply when the process resumes;

- average cost – from 15,000 rubles.

You might be interested >> Description of the double-circuit gas wall-mounted boiler Baxi

Installation nuances

Reviews from owners confirm that Conord may go out. Provoking factors:

- The burner is dirty. Before turning on the device, you should clean the nozzles with a brush or vacuum cleaner.

- There is not enough oxygen to start the burner. The air nozzles should be cleaned and the room ventilated.

- Thermostat contacts have oxidized. Cleaning needs to be done.

- Automation sensors are broken.

If the coolant cools down too much, you need to switch the thermostat to maximum or increase the flow of gas to the burner, if the instructions allow such an action.

Features of summer use

In summer it is necessary to turn off the heating circuit. To do this, turn off the tap at the coolant inlet. When one pilot burner is running, the water will heat up to 60 °C in 60 minutes. If water is not consumed, it will retain heat for about two hours - it can be used for domestic needs. When the device heats up and there is no active consumption of water, it is turned off so that the water does not boil.

Elements of safety and comfortable operation

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure safe operation, and devices that facilitate comfortable operation of the boiler.

The following parts are responsible for safe operation:

- thermostat;

- draft and flame control sensors;

- safety valve.

The flame control sensor consists of a thermocouple and an electromagnetic gas valve that shuts off or turns on the gas supply.

The flame temperature regulator (thermostat) maintains the required coolant temperature and also provides protection against overheating. This module turns the boiler on or off as soon as the coolant reaches a critical point (maximum or minimum).

The draft control module stops gas supply to the burner as soon as the location of the bimetallic plate changes due to increased temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

We examined temperature, draft, pressure and flame sensors in more detail in this article.

In a heating system, a safety valve is an integral component of pipeline fittings, which is important in controlling the volume of coolant involved in the circuit. The hole in the valve through which gaseous fuel moves is called the seat

To turn off the device, you need to block it with a disk or piston

The hole in the valve through which gaseous fuel moves is called the seat. To turn off the device, you need to close it with a disk or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as modeling:

- Single-stage devices have only two operating positions: on/off.

- The two-stage device is equipped with one input and two outputs, and the valve opens when it is turned to an intermediate position, due to which the switching occurs more smoothly.

- A three-stage device is equipped with boilers that have two power levels.

- Modulating valves are used to smoothly change the power rating of devices.

Automation, used for convenience, includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnosis, selection of the optimal operating mode, and others.

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will display a corresponding error).

It is recommended to rotate the shaft manually before starting.

To do this, you need to remove the front panel of the housing, unscrew the central bolt on the pump and use a straight-bladed screwdriver to turn the shaft in the direction indicated by the arrow.

An air vent is installed above the pump. You need to pull the bright lid up and let the air escape.

Floor-standing boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. Floor-mounted gas boilers for home heating – overview of design options and models.

Read about the installation features of combined heating boilers in the following material.

Conclusion

At first, the system may make gurgling sounds, all because during startup it is impossible to bleed air down to the last atom. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the operating range. Temperature adjustment and other boiler settings are described in the instructions for each model.

Types

Conord floor-standing gas boilers do not need to be connected to the power supply. This means that the use of fans or pumps is eliminated.

The combustion chamber of all units is of an open type (atmospheric), circulation of liquids occurs either naturally or using an external circulation pump.

The fundamental difference in design is only the functional features:

- Single-circuit boilers designed for heating.

- Double-circuit, capable of preparing hot water for household needs simultaneously with heating the coolant for the heating system.

IMPORTANT! Most single-circuit models can be connected to an external indirect heating boiler, which makes them capable of providing hot water to the home in larger volumes than double-circuit models.

In addition, there are differences in the design of the heat exchanger:

- Steel heat exchangers 3mm thick.

- Cast iron components with increased efficiency.

In addition, there are different types of control automation. These are mechanical gas supply and adjustment units.

Exist:

- Italian SIT nodes. In the boiler marking they are designated by the letter S.

- Thermohydraulic elements. They are designated by the letter N.

Recently, American-made components have been installed in some boiler models, which expands the range of boilers. In the marking they are designated by the letter M.

Advantages

Conord gas heating appliances have the following advantages:

- boilers are very reliable and durable. They are absolutely independent of electricity, so their operation proceeds without failures or malfunctions;

- manufactured units are safe. The package includes modern automation, which is responsible for stopping the operation of the boiler in the absence of draft and other negative aspects. In addition, automatic regulation of the set temperature level is carried out and the boiler’s operability is ensured at low gas pressure;

- The performance is very high, the efficiency reaches 90%, the unit is economical. And due to the use of heat-insulating materials in the device body, heat loss is reduced;

- during operation, the unit makes virtually no noise, it is small in size and has an attractive design;

- If we compare Conord equipment with devices of other brands, we can say that the price of the equipment is quite reasonable;

- gas consumption is much less. This is due to the fact that innovative technologies were used in the process of creating burners;

- Double-circuit boilers are used not only for heating, but also to provide the premises with hot water.

Of course, Conord heating boilers have many advantages. The key ones are low price and independence from electrical energy. That is why such heating boilers can be called economy-class products. At the same time, their quality is at a high level.

Types of burners

According to their design and functional differences, burner devices are divided into:

By purpose:

- for high power industrial equipment

- for household equipment.

By type of fuel used:

- devices for natural gas;

- devices for liquefied gas;

- universal devices.

By adjusting the flame:

- single-stage – capable of operating on/off;

- two-stage (as a variation - models with smooth modulation) - operate at full power, when the desired temperature is reached, the flame is reduced by half;

- modulating - boilers with a modulating burner are characterized by smooth adjustment of the flame power.

According to the principle of operation:

- injection/atmospheric. They operate by supplying air from the room. They are installed respectively in open combustion chambers. Also used for old-style boiler models.

- fan/supercharged. They work in isolated combustion chambers. Combustion air is supplied by a fan. According to their design features, they are divided into: - vortex (round-shaped nozzle holes) - direct-flow (shape of a narrow slot with a round/rectangular cross-section).

- diffuse-kenetic. Air enters two simultaneously: one is mixed with gas fuel, the second is added directly to the chamber during combustion.