A fireplace in the classical view is perceived as a structure made of stone or brick, having a powerful base and actively participating in heating the house. Modern technologies have somewhat modified the fireplace, as models have appeared that can be installed in apartments; we are talking about electric options.

Any electric fireplace consists of a firebox and a frame; it is this frame that is often called a portal. Although we must pay tribute, the hearth of an electric fireplace can be built into a wall, furniture, or be a separate device, ready for use.

Beautiful natural stone finish

A portal is a housing that performs a load-bearing and insulating function. It may differ in appearance, depending on what type of fireplace is used according to the installation method. Wall models are framed in a portal in the form of a parallelepiped. Corner portals have the shape of a triangular or trapezoidal prism. In this article we will talk about how to independently build a portal for a fireplace from plasterboard.

Main stages of construction

In stores that sell fireplaces, any buyer will certainly be offered kits that already contain a firebox built into a ready-made portal. If you compare the price with the cost of one firebox, the difference will be simply colossal. That is why many are interested in the question of how to make a portal for a fireplace with your own hands from plasterboard?

Drywall as a material was not chosen by chance. This is the most optimal option for the material, since it is easy to process and cut, is resistant to moisture (of a certain type) and to temperature changes.

Not all fireplaces can be framed with plasterboard portals. Fireboxes for wood-burning and gas models are built into housings made of brick or metal. Those portals, which will be discussed below, are suitable only for electric fireplaces or biofireplaces. Therefore, when constructing with our own hands, we will not be burdened by safety restrictions.

The finish of the finished structure can vary greatly

All work should be divided into stages. By performing them consistently, you can get a high-quality portal, which in all respects is not inferior to an expensive factory product.

- Selecting a project. The project requires a drawing of the portal with all dimensions and a description of the materials used. The safety of fireplaces in operation will allow you to show your creativity and draw a diagram of the portal under the fireplace yourself in the form in which you see fit. But if there is no desire or time to create a diagram, then the finished drawing can be found in the archives of craftsmen who deal with this matter professionally.

- Construction of a frame from a profile. The metal profile ensures structural strength and allows convenient joining of drywall sheets. At this stage, the appearance of the fireplace portal is being formed, so once again carefully consider the installation location of the fireplace, its additional functions, and dimensions.

- Plasterboard cladding. Only by installing the sheets can you evaluate the general appearance of the design of the future masterpiece. There are certain requirements for fastening sheets, which we will discuss later. Otherwise, this type of work is the most favorite for beginners. This is because drywall is easy to handle.

- Finishing. At the final stage, the plasterboard frame for the fireplace should be finished with one of the proposed materials. It is this type of work that is responsible for the stylization of the entire fireplace as a whole.

Classic wall portal

What can you make a decorative fireplace from?

Craftsmen have come up with many design options for false fireplaces. We present to your attention an overview of the most popular of them.

Brick

This material allows you to bring the design of the decorative structure as close as possible to the appearance of a real fire. The false fireplace is laid out from decorative or facing bricks for jointing.

Anyone who has at least once encountered masonry work can handle this activity. However, you must first make sure that the existing floor can support the weight of the finished structure, especially if it has large dimensions.

Expert opinion:

Masalsky A.V.

Editor of the “construction” category on the Stroyday.ru portal. Specialist in engineering systems and drainage.

A beautifully laid out brick decorative portal does not require any additional finishing. To decorate it, it is best to use a massive wooden shelf - the combination is very successful and attractive.

laminated chipboard

Laminated boards and other similar materials are perfect for decorating false fireplaces.

In order for the structure to have a neat and attractive appearance, it is necessary to thoroughly prepare for the upcoming work. Preparation comes down to creating a drawing indicating all the dimensions of the future false fireplace. Based on this drawing, you can order cutting of the slabs from a specialized company, or you can do it yourself if you have the required skills.

If you want to save money, laminated boards can be replaced with a more budget-friendly analogue - chipboard. After assembling the structure, you can decorate it at your discretion.

Polyurethane

Products made from polyurethane are used mainly to decorate ready-made structures. However, if desired, all kinds of moldings, platbands and half-columns can be glued directly to the wall. Such a design will not look like a full-fledged fireplace, however, special decorative techniques will allow you to benefit from the portal, making it look like a real fireplace.

Expert opinion: Masalsky A.V.

Editor of the “construction” category on the Stroyday.ru portal. Specialist in engineering systems and drainage.

For example, you can attach a mirror to the back wall of the “firebox” of such a fireplace. Thanks to this technique, the depth of the “firebox” will increase. To enhance the effect, you can attach a wooden shelf, stylized as a fireplace, above the portal.

Drywall

This material is most often used to decorate false fireplaces. Drywall is characterized by extreme ease of assembly and goes well with a wide variety of finishes. From sheet material you can create spatial forms of almost any complexity. At the same time, the cost of drywall makes it accessible to a wide range of buyers.

Sheet construction requires mandatory finishing. But this is rather an advantage of the material, rather than its disadvantage - over time, the cladding can be changed without dismantling the decorative portal itself.

Let's start with the project

No type of work, even the most basic, should be carried out without a clearly defined purpose. When installing a portal, we set our goal in the form of a finished fireplace that will look great in a specific interior.

You must make a drawing at your own discretion. The only significant parameters of the product are the dimensions of the niche where the hearth is inserted. But it is impossible to know these dimensions in advance. Therefore, before buying a fireplace, you can only make a schematic sketch of the future model.

At the same time, start calculating the costs of the material. Write down all the results on a separate sheet, which you will have to go to the store to see. The following materials are subject to recalculation:

- drywall (number of sheets);

- guide profile;

- self-tapping screws;

- putty;

- decorative material for finishing.

The simplest drawing

In some projects, there is advice according to which the load-bearing structures should be made of a PN profile, and the box should be reinforced with a PS profile. To facilitate calculations, it is possible to allow the entire frame to be manufactured with one type of profile, since it can be easily processed using special scissors.

Good to know: How to make a fireplace from a stove, a couple of simple ways

We create a fireplace for an electric fireplace ourselves

How to make an electric fireplace with your own hands, step-by-step instructions for which include dividing into several blocks? Let's look into this issue. After the portal and logs have been created, you should think about making the heart of the electric fireplace - the hearth.

You can make a fireplace for an electric fireplace with your own hands, both ordinary and with the effect of a live fire. You can make ordinary hearths with your own hands from scrap materials. For example, candles, fabric, wire, tree branches.

We recommend that you study the material on how to decorate a fireplace for the New Year with your own hands and find answers to your questions.

Hearth of many candles

Lots of candles will create the illusion of a burning flame. Candles are located at different heights and distances from each other. The disadvantage of this imitation is that the candles smoke.

The hearth is located in the fireplace portal. Fire is simulated by many candles

An original hearth made of tree branches, fabric and LED bulbs

- You can buy an LED lamp socket that shimmers with red and yellow colors in a chaotic manner.

- Lay out the base from tree branches in the shape of a well and glue it with construction glue.

- Push the lampshade through from below and fix it on the top of the resulting well.

- Take a strong wire and cut it into 4 pieces, 25 centimeters each. Then fix some ends on the branches, and twist the other ends together at the top.

- Fasten a light fabric over the wire. For example, chiffon, organza.

About

Frame assembly

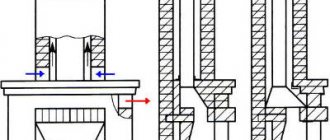

Installation of the frame begins with drawing out the contours on the wall and floor. Firstly, the assembly will be carried out according to established guidelines, and secondly, vertical and horizontal lines will be immediately marked off, which will guide the future edges of the portal. By the way, level verification is one of the most important stages. Any violations will lead to gaps forming during the cladding, especially if the finish is in the form of tiles.

You can start with a horizontal base or a vertical frame. The frame is assembled to size from four prepared profiles. The profiles are fastened together with self-tapping screws. Immediately the frame must be secured to the wall. The portal itself, after the firebox is installed in it, will turn out to be quite unstable. When fastening, a hammer drill is used. Dowels are inserted into the holes and the frame is screwed to the wall.

Next, horizontal posts at the corners are attached to the frame. Their length should be several centimeters greater than the depth of the firebox. And even though you haven’t chosen the firebox yet, you should evaluate all the dimensions and make racks with a certain margin. Another frame is installed on the racks. The frame in the form of a parallelepiped is ready.

Assembling a metal frame

The remaining work will only strengthen the resulting frame from the profile. Prepare horizontal spacers and secure them along the portal plane. It is important that these spacers cut off the space for installing the firebox. To attach these elements, you will have to work with scissors. At the ends of the profile, the side parts are cut off so that they do not interfere with the tight joining of the horizontal and vertical posts. The completed composition must be screwed to the floor. Note that such a portal, together with the fireplace, could theoretically be placed in another place, but the remaining perforations will need to be sealed.

We return to the place where the fireplace was installed. In the simplest version, it is only necessary to make vertical inserts between the horizontal struts. An opening is formed where the firebox will be inserted. The support for the firebox is made from the same profile. It is mounted horizontally in the form of slats that go deep into the fireplace and attached to the wall. If you decide to make a fireplace opening in the form of an arch, then our favorite profile is used as the ceiling. You can bend it by making notches with scissors. The completed arch already makes a change in the entire design process.

Good to know: Vacuum cleaner for cleaning fireplaces and stoves, the main differences from its household counterpart

What materials to use for the portal and mantelpiece

Traditionally, stone is used to build a fireplace portal and countertop, but even artificial agglomerate weighs a lot, and it will require certain work skills from the master. There are also more “friendly” materials on the market that can be easily improved with the help of properly selected cladding. For example, a classic tabletop can be made from a thick board, staining the wood and covering it with thin layers of varnish. A more budget-friendly option is plywood or MDF - after installation, they are covered with small ceramic tiles or laminated with decorative film.

Before choosing the material for making a portal with your own hands, it is worth deciding on the functionality of the decorative fireplace. If this is just an installation or a screen with the image of a living flame, there are no restrictions: drywall, foam plastic, chipboard or natural wood will do. The main thing is that after finishing work they become similar to natural materials.

Using polyurethane elements you can create a luxurious portal for a decorative fireplace

For decorative heating equipment that actually warms up the room, you will have to choose safer options (gypsum plasterboard, foam blocks) or protect the structure with heat-resistant cladding. It is not necessary to build a portal out of brick, but for finishing it is better to use non-flammable or low-flammable products and mixtures: tiles, mineral tiles, plaster.

Decorative brick cladding is not afraid of overheating

Table: Advantages and disadvantages of basic materials

| Indicators for comparison | Tree | Wood-based materials (chipboard, MDF) and plywood | Drywall |

| Weight, kg/m3 | 400–700 | 600–700 to 850 for MDF | 800–850 |

| Bending strength, kgf/cm2 | 1000 | 20–250 | 15–18 |

| Compressive strength, kgf/cm2 | 500 | 60–200 | 100 |

| Flammability group (taken into account only for heating devices) | G3-G4 (G2 after treatment) | G3-G4 | G1 |

| Environmental friendliness | ++ | — | ++ |

| Machinability (milling, drilling, cutting) | ++ | + | + |

It is easy to give solid wood the desired shape, and also to decorate it, if not with carving, then at least with elegant milling. But this will require special equipment, so workability is a very conditional advantage of wood. Its main disadvantage remains that over time it dries out, warps and becomes covered with cracks. When the humidity in the room changes, the array can indeed behave unpredictably. If it is not possible to maintain stable conditions in a room with a fireplace, but you definitely want to use natural wood, it is better to choose species that are not prone to serious deformation:

- pine;

- cedar;

- aspen.

According to their strength characteristics, pressed slabs made from veneer and wood processing waste are quite suitable for the manufacture of an electric fireplace portal. However, unprofessional cutting of sheets leads to loosening of the fibers at the ends, which somewhat complicates the covering of the frame with small elements. The disadvantages include the toxicity of phenolic and formaldehyde resins in their composition, but after finishing with airtight materials, the issue of harmful effects on humans is removed.

OSB can also be used in independent work

As for drywall, it is considered the best material for creating decorative interior elements with your own hands. The low load-bearing capacity of the slabs is fully compensated by a reliable metal frame. The variety of gypsum plaster boards will allow you to choose the appropriate design for any conditions: fire-resistant boards for heating fireplaces, waterproof boards for ceramic finishing.

Installing gypsum boards

There is no need to list all the advantages of drywall, but it should be emphasized that in different designs certain qualities can be most clearly highlighted. We are interested in heat-resistant drywall, since an electric fireplace has a heating function, which means that heat will certainly be transferred to the walls of the portal. Any drywall is already fire-resistant, the only difference is the paper.

The more jumpers you make on the frame, the easier it is to cover the frame with plasterboard. After all, you can cut the sheet into small pieces, but you shouldn’t get too carried away with this matter. It is desirable that the casing be solid. Solid sheets give the portal additional stability.

If experience does not allow you to cut the material so precisely, as an exception, it is allowed to divide it into parts, because all the joints will be sealed with high quality. The main thing is to make sure that the place where the sheet is attached is not empty, otherwise you will simply ruin the material.

Working with drywall

The drywall is attached to the profile using self-tapping screws. They need to be tightened with such force that the caps fit inside the sheet, but do not damage the cardboard layer. The joints of the sheets and the holes from the screw heads are puttied with a metal spatula.

Seam processing has a certain technology. Using a stationery knife, the joint is deepened and a chamfer is removed from the sheet. It turns out to be a kind of channel for putty. Thanks to this channel, the mastic will stick to the sheets better. Putty is also applied to the screw holes. After it dries, the excess should be removed with sandpaper. The resulting perfectly smooth surface is ready for finishing.

Let's make a mess

Now that the box is out, covering it with plasterboard sheets will be quite easy

Particular attention should be paid here to the portal, which must be sheathed very carefully, since it will be the “face” of your fireplace. You can make the correct plating of the portal according to the following scheme:

- First we sheathe the inner part with the material, and then the outer part;

- try to ensure that the sheets of drywall match in the corners. To make them even, use a special metal perforated corner;

- The sheet is fastened with self-tapping screws. The step for installing them can be chosen arbitrarily or stopped at 10-15 cm;

- avoid coinciding places for screwing in screws on adjacent sheets;

- The fastening elements are embedded by 1 mm. The heads of the screws must not be allowed to protrude above the surface of the sheet.

Portal skin

After this, all you have to do is putty the surface of the portal until it is even and smooth. Do not forget that before you finally decorate the fireplace, its entire structure should be primed. This increases adhesion between the surface and the finishing material.

Finishing

The appearance of the fireplace is dictated by the texture of the finishing material that you decide to use. You can familiarize yourself with the entire range and choose the material you like. Wooden lining, MDF panels, ceramic tiles and artificial stone tiles are especially popular when carrying out such work. All these materials are quite processable. The use of MDF is somewhat limited by the temperature and power of the fireplace, so they are trying to avoid this type of finishing.

Good to know: How to build an outdoor fireplace with your own hands, a short educational program

It is advisable to use fire-resistant adhesive for installing tiles. It's not that this zone experiences high temperatures. This glue, even when frozen, is elastic. It is needed to avoid destruction of tile surfaces due to thermal expansion. The technology of laying tiles is that each element in a row is glued and aligned with the previous one, which is why it was necessary to maintain the levels of the frame.

To imitate the presence of a real fireplace in the room, many construct a chimney from plasterboard. Its installation steps are the same as for the portal. This type of work is often performed by novice craftsmen and is considered the most accessible and easiest.

What is a portal for an electric fireplace and why is it needed?

In the design of real fireplaces, the portal performs an important function - it protects the adjacent walls from the high temperature of burning wood. In the case of an electrical appliance, the enclosing structure is only required to have an aesthetic appearance and make the dummy resemble a real fireplace. To do this, the portal must externally replicate traditional fire-resistant materials: brick, wild stone, marble. However, a wooden copy will also work for decorative purposes, but the credibility will be reduced.

An elegant portal makes the electric fireplace look like a real one

General design

We have already decided that the portal is a kind of frame that frames the electric fireplace and helps it “fit” into the surrounding interior. Also, a stable design with a massive shelf can serve as a stand for souvenirs, family photos and other accessories. The main thing is that it can support the weight of the built-in fireplace. Complex portals that are a continuation of furnishings look unusual: cabinets, shelving, niche systems made of plasterboard.

An unusual portal under the window can itself become a decoration of the room

Structurally, portals are divided into stationary and portable. The former are undemanding when it comes to manufacturing materials, but mobile models require special stability. Portable portals should be low and have sufficient depth and width. They are distinguished by a low center of gravity, which means they will not fall if moved carelessly.

This fireplace can be easily moved to another place if you want to refresh the interior

If you plan to place any equipment on the fireplace tabletop, it is better to make the shelf wider. And for greater reliability, it can be supported not only on the portal, but also on a corner screwed to the wall.

Interior design

The dimensions of the fireplace in the apartment must correspond to the overall space of the room in which it is located. Large fireplaces are suitable for a large room; small designs will look appropriate in a small room. A false fireplace is often installed in the hall, living room, kitchen, bedroom and even bathroom. It is sometimes used as a TV stand. The fireplace, depending on the interior of the room, can be decorated in a classic, modern, rustic, English, or hi-tech style.

6 photos

If you want the design to match the style of the apartment or house, pay special attention when designing the portal, chimney, or pre-furnace area. If the fireplace is made in a classic style, it is decorated with marble and natural wood

Shelves are a mandatory decorative element for such a design. With shelves, the fireplace looks beautiful and becomes functional. You can put figurines, candlesticks, vases on them.

6 photos

The fireplace portal made of plasterboard is decorated with glass and an electric fireplace. The portal with an aquarium looks original and stylish. It can also be placed on a wide shelf. An electric fireplace made in the wall looks unusual and completely merges with the surface. Designers advise decorating an empty portal with a forged lattice, firewood, candles, original vases, a painting, a mirror.

Gallery of ready-made solutions - for inspiration

The portal appears flat, while the hearth is built into a tall plasterboard box

Using additional elements, an elegant composition is created

Making such a portal will not take much time

An unusual solution for a corner fireplace

Sockets above the mantel can be easily hidden behind a clock or photo frame

Strict design and noble ivory color

Creating a portal for an electric fireplace yourself allows you to save part of the repair budget. Although it is easier to buy a ready-made kit, the cost of decorative structures from all manufacturers is comparable to the prices of electric fireboxes built into them. You won’t need any expensive materials for your work, so you can pay half as much for an island of comfort in your home. And this is a great incentive to work with your own hands.

Where can I buy

If you really want to, you can always build a portal for an electric fireplace yourself; this will require minimal construction skills. However, a simpler and more practical solution would be to buy a finished product in a store.

In construction and specialty stores there is a wide range of various devices and additional accessories for an electric fireplace. You can find here ready-made frames made of plaster, polyurethane, stone, marble, brick, wood, MDF, metal and even plastic. Choose a structure suitable in size for your built-in electrical appliance, evaluate its strength, stability and appearance.

Modern electric analogues of fireplaces look so believable that they take your breath away. In this case, the portal plays an important role in the design of the hearth. Therefore, try to choose a product that matches your interior and the general atmosphere in the house.

Plasterboard cladding, eliminating cracks

The portal is made of metal profile. Next, the work was done using drywall

Your own portal for an electric fireplace allows you to match the interior as clearly as possible. However, before achieving such an effect, it must be lined. To do this, sheets of drywall are taken, marked and cut into the necessary parts. After this, they are gradually screwed to the frame until it is completely covered, which will provide it with additional rigidity and stability. As a result, we will have a complete object that will still need to be processed, eliminating all the cracks and holes. The necessary actions are carried out using a spatula and putty, which fills all problem areas. For particularly large gaps, application is carried out in 2-3 stages, until the gap is completely closed and a monolithic surface is formed in its place.

As for the upper tier of the portal, which plays the role of a shelf, it should be reinforced with a wooden board. Otherwise, the plaster may not withstand the elements that will be installed on top of the fireplace and will fail.

A wooden base will eliminate this problem, making the shelf not only durable, but also capable of withstanding increased loads.